Lignin/reduced graphene oxide carbon aerogel electromagnetic shielding material as well as preparation method and application thereof

An electromagnetic shielding material, carbon aerogel technology, applied in the fields of magnetic field/electric field shielding, graphene, carbon preparation/purification, etc., to improve the preparation efficiency and raw material utilization, weaken the volume shrinkage phenomenon, and improve the interface polarization effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

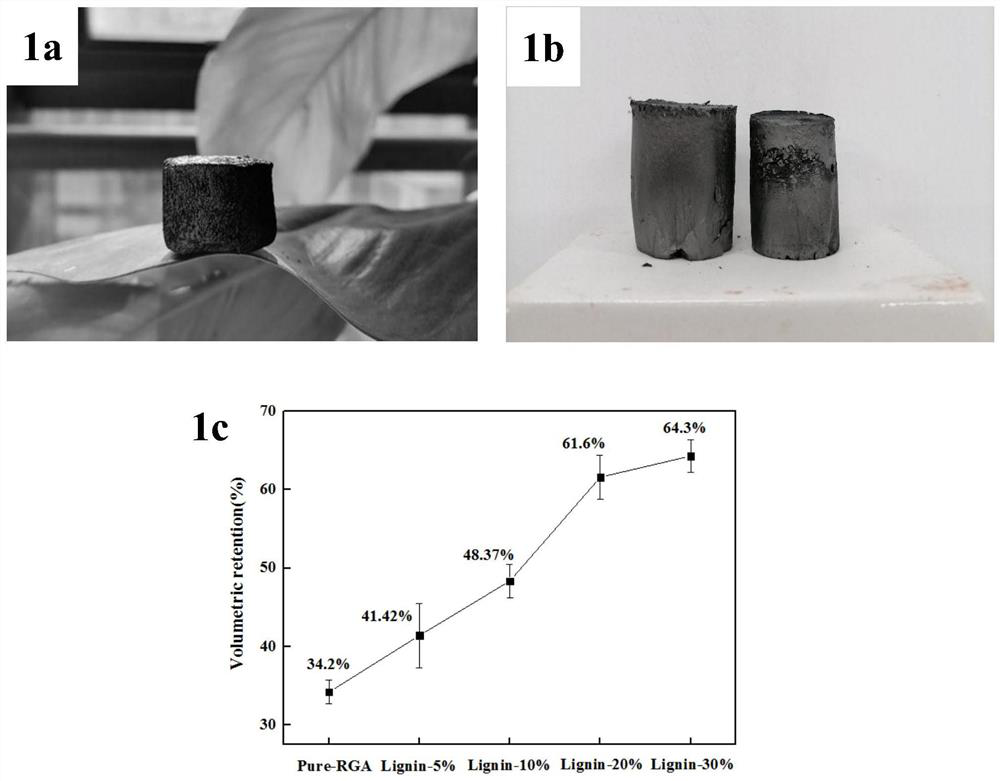

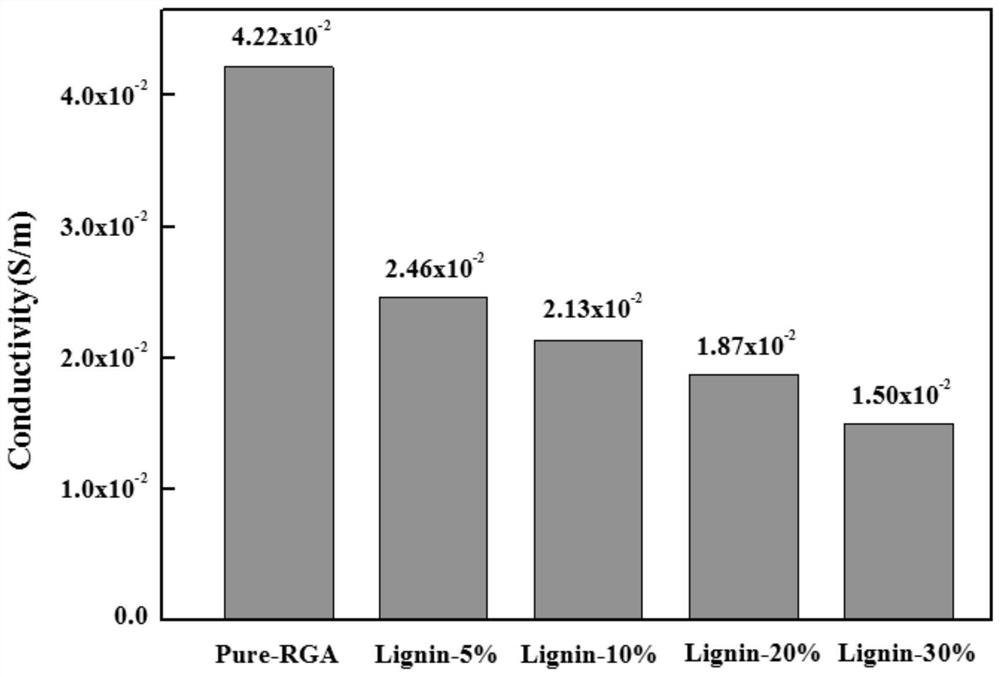

[0046] Take a certain amount of lignin to make 20wt% aqueous solution, dissolve it with sodium hydroxide, adjust the pH to about 11, stir for 24 hours to fully dissolve the lignin; centrifuge the solution for 10min with a centrifuge at a speed of 10000r / min, and take the supernatant The liquid is a lignin alkali solution; the solid content of the lignin solution is measured 3 times with a fast moisture evaporator, and the average value is the lignin mass fraction (16.94wt%) in the lignin solution. Take 0.12g each of graphene oxide and L-ascorbic acid, dissolve them in 20mL of deionized water, add 0.0745g of lignin alkali solution, mix well, and use an ultrasonic cell pulverizer to perform ultrasonic cavitation, cavitation time is 5 minutes, and the power is 200W , the cavitation interval is cavitation 3s stop 2s. Put the ultrasonically cavitated solution into an oven at 70°C to react and reduce graphene oxide for 3 hours. After taking it out, wash the hydrogel alternately with...

Embodiment 2

[0049] Take a certain amount of lignin to make 20wt% aqueous solution, dissolve it with sodium hydroxide, adjust the pH to about 11, stir for 24 hours to fully dissolve the lignin; centrifuge the solution for 10min with a centrifuge at a speed of 10000r / min, and take the supernatant The liquid is a lignin alkali solution; the solid content of the lignin solution is measured 3 times with a fast moisture evaporator, and the average value is the lignin mass fraction (16.94wt%) in the lignin solution. Take 0.12g each of graphene oxide and L-ascorbic acid, dissolve them in 20mL of deionized water, add 0.1574g of lignin alkali solution, mix well, and use an ultrasonic cell pulverizer to perform ultrasonic cavitation, cavitation time is 5 minutes, and the power is 200W , the cavitation interval is cavitation 3s stop 2s. Put the ultrasonically cavitated solution into an oven at 70°C to react and reduce graphene oxide for 3 hours. After taking it out, wash the hydrogel alternately with...

Embodiment 3

[0052] Take a certain amount of lignin to make 20wt% aqueous solution, dissolve it with sodium hydroxide, adjust the pH to about 11, stir for 24 hours to fully dissolve the lignin; centrifuge the solution for 10min with a centrifuge at a speed of 10000r / min, and take the supernatant The liquid is a lignin alkali solution; the solid content of the lignin solution is measured 3 times with a fast moisture evaporator, and the average value is the lignin mass fraction (16.94wt%) in the lignin solution. Take 0.12g each of graphene oxide and L-ascorbic acid, dissolve them in 20mL of deionized water, add 0.3549g of lignin alkali solution, mix well, and use an ultrasonic cell pulverizer for ultrasonic cavitation. The cavitation time is 5 minutes and the power is 200W. , the cavitation interval is cavitation 3s stop 2s. Put the ultrasonically cavitated solution into an oven at 70°C to react and reduce graphene oxide for 3 hours. After taking it out, wash the hydrogel alternately with de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com