A high-strength heat-shock resistant push plate and its preparation method

A heat-resistant and high-strength technology, applied in the field of high-strength thermal shock-resistant push plates and their preparation, can solve the problems of affecting the service life of the kiln, the contradiction between the thermal shock resistance and strength of the push plates, and the stuck channels of the push plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

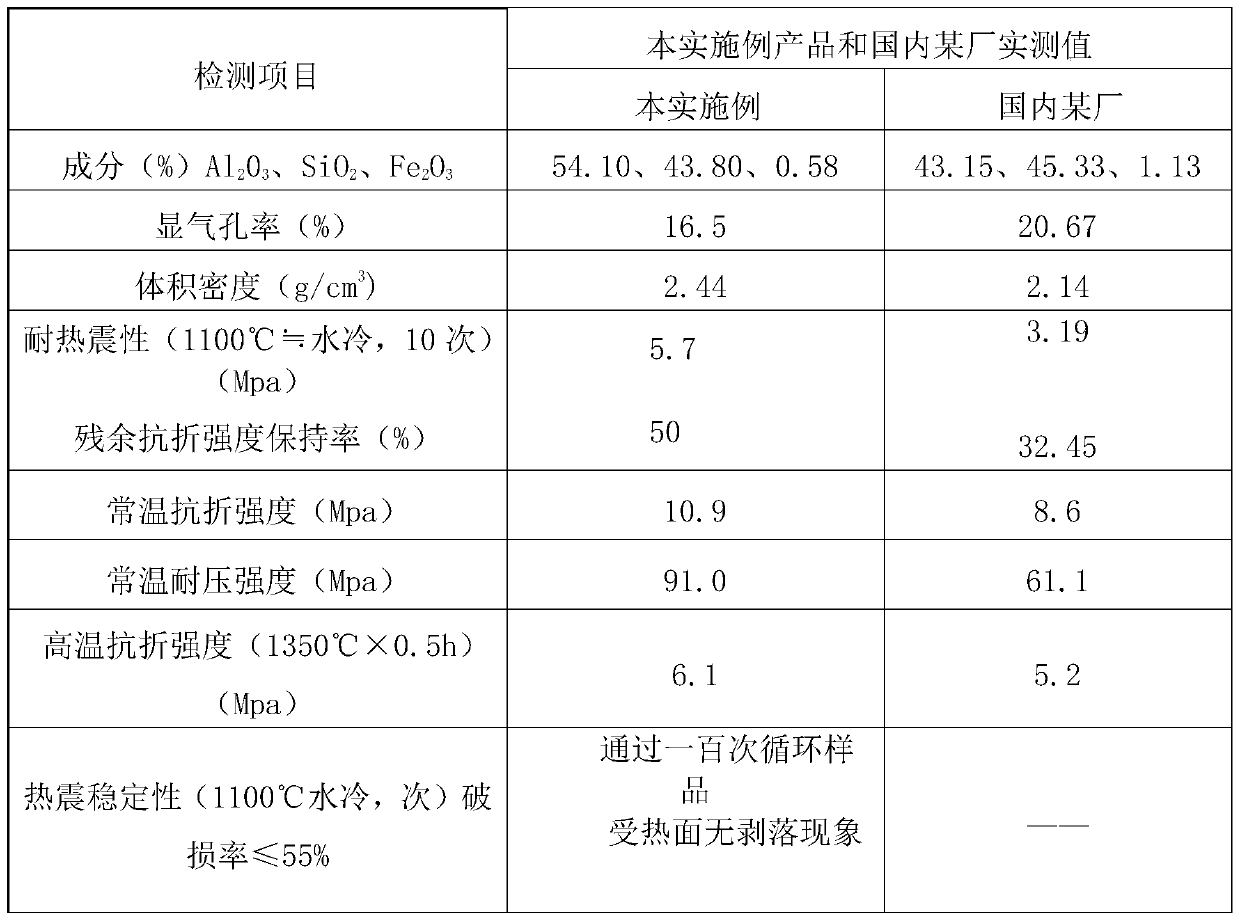

Embodiment 1

[0017] A high-strength heat-resistant shock-resisting push plate, the raw material of which includes the following components in parts by weight: 21 parts of 3-0.5mm mullite particles, 20 parts of 1-0.5mm corundum particles, 11 parts of 0.5-0.1mm quartz particles, 320 mesh 20 parts of andalusite fine powder, 25 parts of 220 mesh mullite fine powder, 12 parts of 2μm alumina fine powder, 5.2 parts of 320 mesh corundum powder, 15 parts of silica powder, 5 parts of zircon, 2 parts of cerium oxide, fluoride 2 parts of aluminum, 9.5 parts of aluminum, 10 parts of silicon, 10 parts of white clay, 3 parts of external binder.

Embodiment 2

[0019] A high-strength heat-resistant shock-resisting push plate, the raw materials of which include the following components in parts by weight: 30 parts of 3-0.5mm mullite particles, 16 parts of 1-0.5mm corundum particles, 15 parts of 0.5-0.1mm quartz particles, 320 mesh 15 parts of andalusite powder, 28 parts of 220 mesh mullite powder, 8 parts of 2μm alumina powder, 10 parts of 320 mesh corundum powder, 5 parts of silica powder, 10 parts of zircon, 0.5 part of cerium oxide, fluoride 9.2 parts of aluminum, 5 parts of aluminum, 14 parts of silicon, 15 parts of white clay, 1 part of external binder.

Embodiment 3

[0021] A high-strength heat-resistant shock push plate, the raw materials of which comprise the following components in parts by weight: 25.5 parts of 3-0.5mm mullite particles, 19 parts of 1-0.5mm tabular corundum particles, 12 parts of 0.5-0.1mm quartz particles, 320 mesh andalusite fine powder 18 parts, 220 mesh mullite fine powder 26.5 parts, 2μm alumina micro powder 12 parts, 320 mesh corundum fine powder 7 parts, silica micro powder 11 parts, zircon 7.6 parts, cerium oxide 1.56 parts, 5.6 parts of aluminum fluoride, 8.5 parts of aluminum, 11 parts of silicon, 12 parts of white clay, 2.4 parts of sodium carboxymethyl cellulose;

[0022] The silicon powder is ultrafine silicon powder, and the particle size of the ultrafine silicon powder is 0.5 microns;

[0023] The cerium oxide is nano cerium oxide, and the average particle size of the nano cerium oxide is 5 nm;

[0024] The mullite particles are a mixture of fused mullite particles and sintered mullite particles in a weight ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com