Lightweight waterproof high-strength foam concrete and preparation method thereof

A foam concrete, high-strength technology, applied in the field of concrete, can solve the problems of large drying shrinkage, different sizes of closed pores, uneven distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

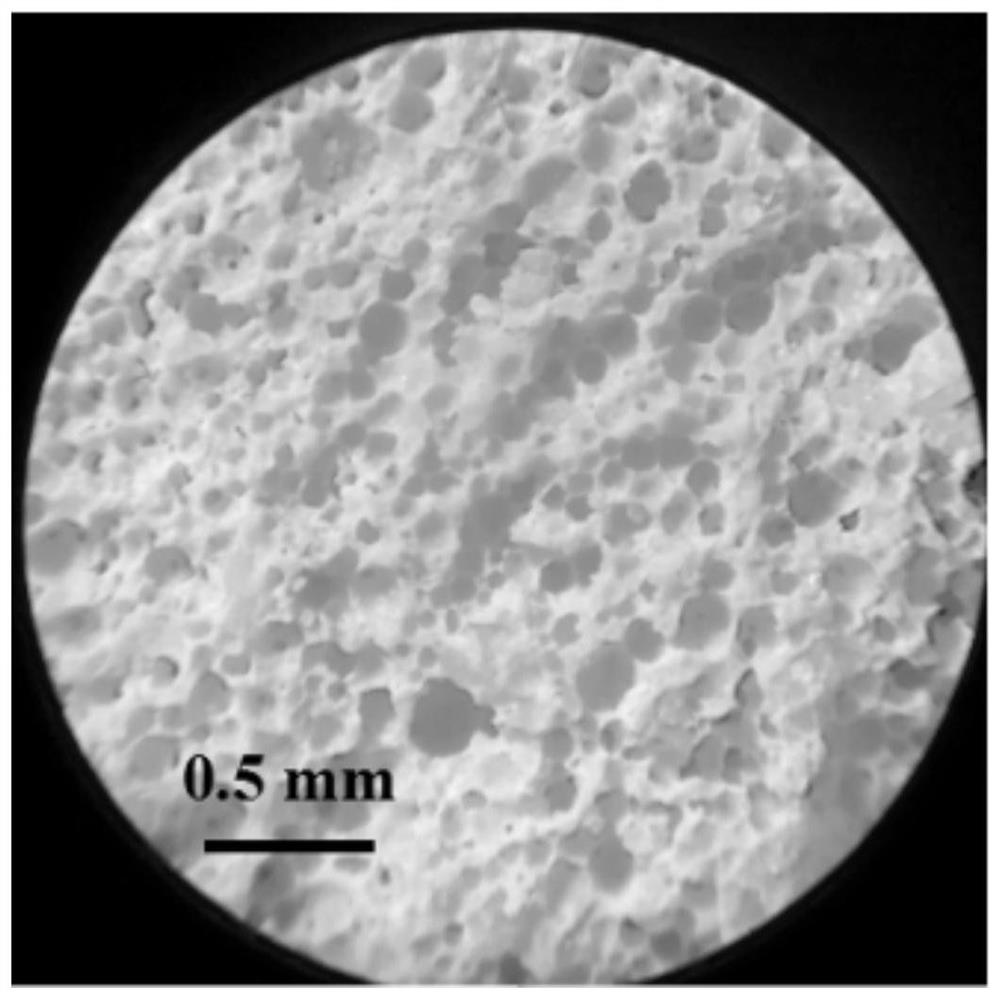

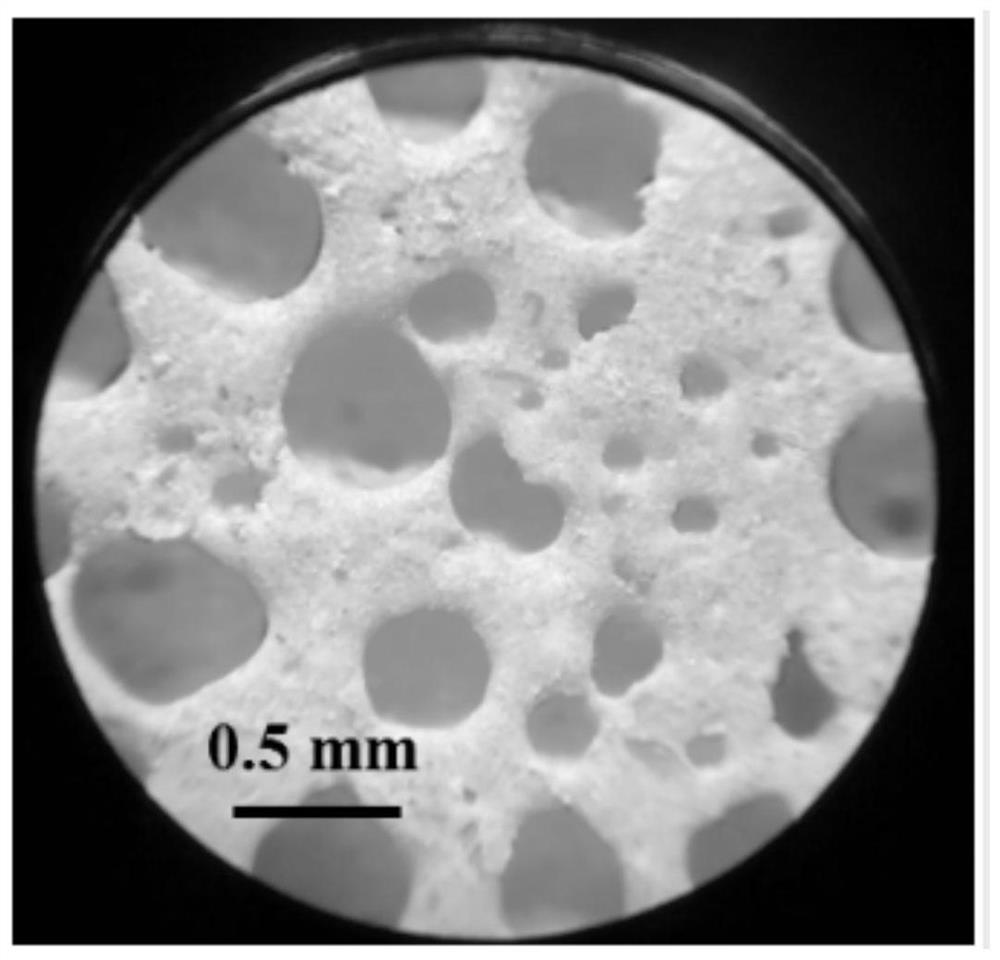

[0052] see figure 1 , figure 1 The pore distribution of the lightweight waterproof high-strength foam concrete section prepared for Example 1 of the present invention.

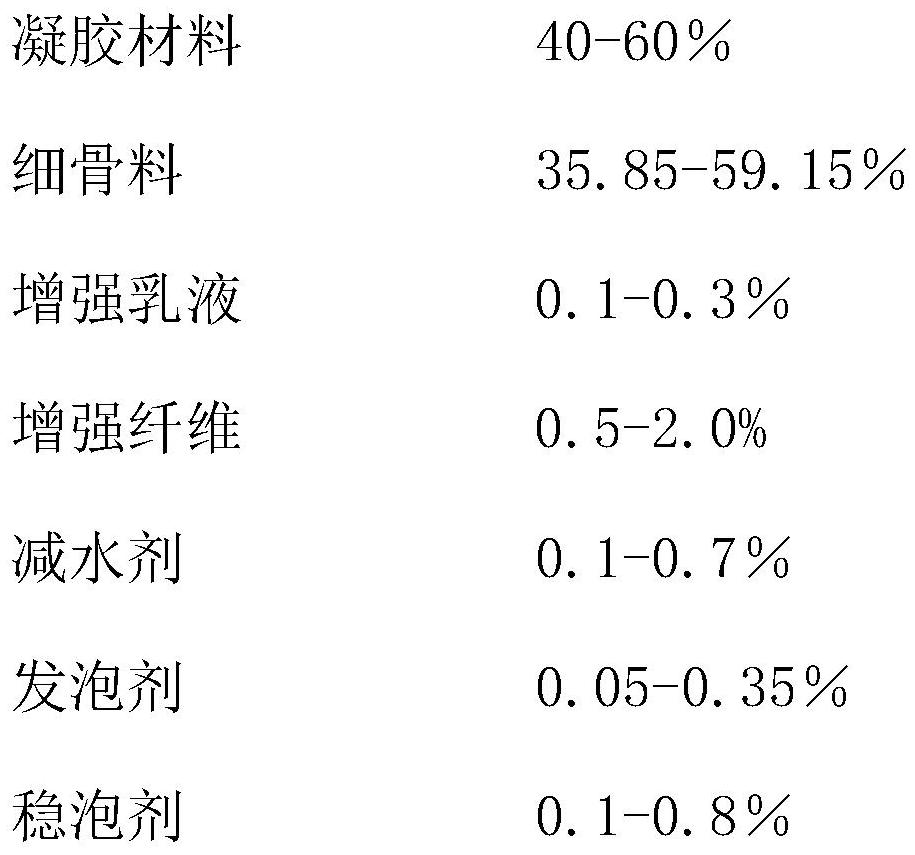

[0053] Table 1 Embodiment 1 batching list (weight ratio)

[0054]

[0055]

[0056] (1) Add the animal protein foaming agent and water into the foaming machine according to the volume ratio (1:30) to produce foam with a bulk density of 0.05g / cm 3 .

[0057] (2) Weigh the gel material, fine aggregate, cement waterproof emulsion, polypropylene fiber, and polycarboxylate superplasticizer into the mixer in proportion, add 80% water and stir for 3 minutes, and stir to form a slurry , the expansion degree is 180 mm, after adding the hydroxymethyl cellulose ether and stirring for 1 min, add the remaining 20% of water, and then stir for 2 min, the weight ratio of the total weight of the gel material to water is 5:1.

[0058] (3) Add the foam prepared in (1) into the mixer according to a certain amount and ...

Embodiment 2

[0064] Embodiment 2 compares with embodiment 1, and difference is: the kind of cement used is different, becomes sulfoaluminate cement by portland cement, and in total component, proportion rises, rises to 39% by 16%; The composition of the aggregate is different, from finely ground fly ash and volume stabilizer to mineral powder and volume stabilizer, the proportion in the total component decreases from 24% to 21%; the type of fine aggregate is different, from 40% -70 mesh quartz sand becomes 70-200 mesh quartz powder, and the proportion in the total component decreases from 59.15% to 35.85%; the proportion of cement waterproof emulsion in the total component increases from 0.1% to 0.3%; the type of reinforcing fiber Different, from polypropylene fiber to polyethanol fiber, the proportion of the total component increases from 0.5% to 2%; the proportion of the water reducing agent in the total component increases from 0.1% to 0.7%; the proportion of the foaming agent The types...

Embodiment 3

[0077] Embodiment 3 compares with embodiment 1, and difference is: the kind of cement used is different, becomes phosphate cement by Portland cement, and in total component, proportion rises, rises to 22.5% by 16%; Blending The material components are different, from pulverized fly ash and volume stabilizer to kaolin and volume stabilizer, and the proportion in the total component increases from 24% to 27.5%; the type of fine aggregate is different, from 40-70% Mesh quartz sand becomes a mixture of 40-70 mesh quartz sand and 70-200 mesh quartz powder, and the proportion in the total component decreases from 59.15% to 38.6%; the proportion of cement waterproof emulsion in the total component increases from 0.1% to 0.2%; the type of reinforcing fiber is different, from polypropylene fiber to polyethylene fiber, the proportion in the total component increases from 0.5% to 1.2%; the proportion of water reducing agent in the total component increases from 0.1% to 0.4%; the proporti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com