A smokeless scented candle and its manufacturing process

A manufacturing process and technology of smokeless incense, which is applied in the production of candles, candle ingredients, fatty acids, etc., can solve the problems of insufficient combustion of silicone-modified epoxy resins, increased flame retardancy of epoxy resins, and affecting aromatherapy effects. To achieve the effect of reducing combustion smoke production, reducing the loss of aromatic essential oils, and increasing the effect of aromatherapy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A smokeless scented candle,

[0051] The raw materials are: coconut wax 80kg, soybean wax 50kg, palm wax 10kg, rose essential oil 1kg, nanometer calcium carbonate 1kg, aluminum ethyl acetate complex 2kg, octanol 2kg;

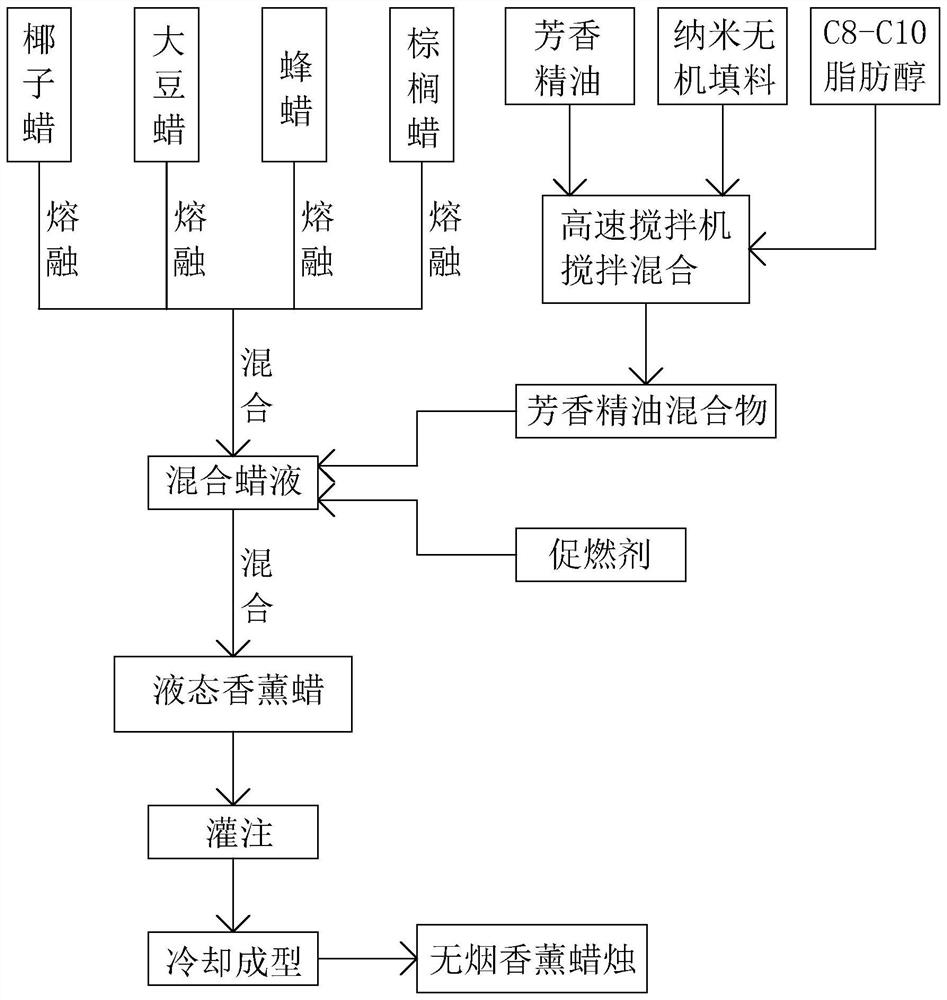

[0052] refer to figure 1 , its manufacturing method includes the following steps,

[0053] Mixed wax preparation: Put coconut wax, soybean wax and palm wax into wax melting tanks, heat until melted into a liquid state, and keep stirring during the heating process to obtain a mixed wax liquid;

[0054] Essential oil pretreatment: Put the weighed rose essential oil and nano-calcium carbonate into a high-speed mixer, and mix at a high speed of 3500rpm for 10 minutes; then put in the weighed octanol, and continue to mix at a high speed of 3500rpm for 20 minutes to obtain a rose essential oil mixture ;

[0055] Mixing: stop heating, when the temperature of the mixed wax liquid drops to 75°C, add aluminum ethyl acetate complex and rose essential oil mixture ...

Embodiment 2

[0059] A smokeless scented candle,

[0060] The raw materials are as follows: coconut wax 85kg, soybean wax 60kg, palm wax 15kg, rose essential oil 2kg, nano calcium carbonate 2kg, aluminum ethyl acetate complex 2kg, octanol 2kg;

[0061] refer to figure 1 , its manufacturing method includes the following steps,

[0062] Mixed wax preparation: Put coconut wax, soybean wax and palm wax into wax melting tanks, heat until melted into a liquid state, and keep stirring during the heating process to obtain a mixed wax liquid;

[0063] Essential oil pretreatment: Put the weighed rose essential oil and nano-calcium carbonate into a high-speed mixer, and mix at a high speed of 4000rpm for 10 minutes; then put in the weighed octanol, and continue to mix at a high speed of 4000rpm for 20 minutes to obtain a rose essential oil mixture ;

[0064] Mixing: stop heating, when the temperature of the mixed wax liquid drops to 75°C, add aluminum ethyl acetate complex and rose essential oil mi...

Embodiment 3

[0068] A smokeless scented candle,

[0069] The raw materials are: coconut wax 95kg, soybean wax 70kg, beeswax 15kg, rose essential oil 3kg, nano calcium carbonate 3kg, aluminum ethyl acetate complex 2kg, octanol 2kg;

[0070] refer to figure 1 , its manufacturing method includes the following steps,

[0071] Mixed wax preparation: Put coconut wax, soybean wax and beeswax into wax melting tanks, heat until melted into a liquid state, keep stirring during the heating process, and obtain a mixed wax liquid;

[0072] Essential oil pretreatment: Put the weighed rose essential oil and nano-calcium carbonate into a high-speed mixer, and mix at a high speed of 4500rpm for 10 minutes; then put in the weighed octanol, and continue to mix at a high speed of 4500rpm for 20 minutes to obtain a rose essential oil mixture ;

[0073] Mixing: stop heating, when the temperature of the mixed wax liquid drops to 75°C, add aluminum ethyl acetate complex and rose essential oil mixture in turn, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com