Material for preparing turbine rotor of pressurizer and method for preparing turbine rotor by material

A technology of turbine rotor and supercharger, applied in mechanical equipment, machine/engine, blade supporting element, etc., can solve the problems of unstable performance in service environment, unstable performance, low service life, etc., to shorten the response time, The effect of low density and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

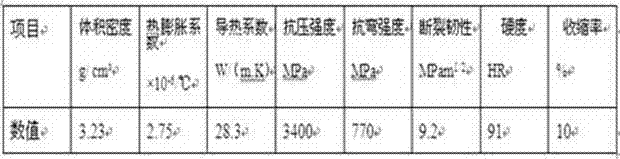

Embodiment 1

[0032] A material for preparing a supercharger ceramic turbine rotor, comprising the following components by weight: 85 parts of silicon nitride powder, nitrogen

[0033] 5 parts of boron nanotube powder, 2 parts of metal aluminum powder, 3 parts of silicon powder, and 5 parts of zirconia powder.

[0034] A method for preparing a turbine rotor from said material, comprising the steps of:

[0035] (1) Raw material preparation: Weigh 85 parts of silicon nitride powder, 5 parts of boron nitride nanotube powder, 2 parts of metal aluminum powder, 3 parts of silicon powder and 5 parts of zirconia powder in parts by weight to form the raw material.

[0036] (2) Paste preparation: Add the raw materials obtained in step (1) and silica sol in a ratio of 1:1.5 by weight to a liftable forced mixer for stirring and mixing. The stirring speed is 60 r / min. After stirring for 50 minutes, add Diyttrium trioxide sintering aid with 3% weight of raw material, and distilled water with 14% weight ...

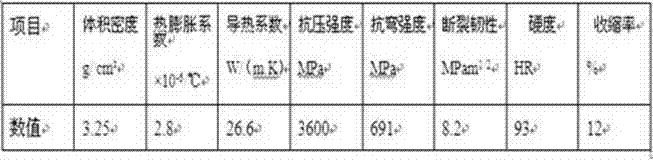

Embodiment 2

[0044] A material for preparing a supercharger ceramic turbine rotor, comprising the following components by weight: 87 parts of silicon nitride powder, nitrogen

[0045] 3 parts of boron nanotube powder, 3 parts of metal aluminum powder, 4 parts of silicon powder, and 3 parts of zirconia powder.

[0046] A method for preparing a turbine rotor from said material, comprising the steps of:

[0047] (1) Raw material preparation: Weigh 87 parts of silicon nitride powder, 3 parts of boron nitride nanotube powder, 3 parts of metal aluminum powder, 4 parts of silicon powder and 3 parts of zirconia powder in parts by weight to form the raw material.

[0048] (2) Paste preparation: Add the raw materials obtained in step (1) and silica sol in a ratio of 1:1.5 by weight to a liftable forced mixer for stirring and mixing. The stirring speed is 55r / min. After stirring for 60 minutes, add the raw materials 2% by weight of diyttrium trioxide sintering aid, at the same time add 13% by weight...

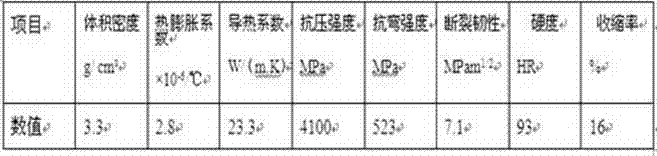

Embodiment 3

[0056] A material for preparing a supercharger ceramic turbine rotor, comprising the following components by weight: 90 parts of silicon nitride powder, nitrogen

[0057] 1 part of boron nanotube powder, 2 parts of metal aluminum powder, 2 parts of silicon powder, and 5 parts of zirconia powder.

[0058] A method for preparing a turbine rotor from said material, comprising the steps of:

[0059] (1) Raw material preparation: Weigh 90 parts of silicon nitride powder, 1 part of boron nitride nanotube powder, 2 parts of metallic aluminum powder, 2 parts of silicon powder and 5 parts of zirconia powder in parts by weight to form the raw material.

[0060] (2) Paste preparation: Add the raw materials obtained in step (1) and silica sol in a ratio of 1:1.5 by weight to a liftable forced mixer for stirring and mixing. The stirring speed is 65r / min. After stirring for 55 minutes, add the raw materials 4% by weight of diyttrium trioxide sintering aid, at the same time add 15% by weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com