Treatment method capable of improving mechanical performance of mongolian scotch pine wood

A treatment method and wood technology, which is applied in wood treatment, wood treatment details, radiation/wave wood treatment, etc., can solve the problems of dry shrinkage and wet expansion, deformation and cracking, oiliness of Pinus sylvestris pine wood, etc., to reduce shrinkage, The effect of improving the bending strength and enhancing the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

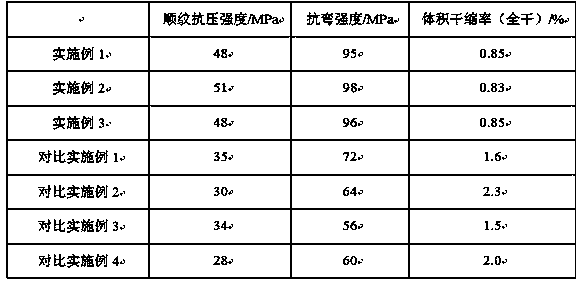

Examples

Embodiment 1

[0015] A treatment method for improving the mechanical properties of Pinus sylvestris sylvestris, comprising the following steps:

[0016] (1) Choose pine wood with a diameter of 20cm and a length of 1m, peel it, and set it aside;

[0017] (2) Water the sylvestris pine wood obtained in step (1), the water temperature is 60°C, and then water the wood with 1°C water after moisture penetration, then dry it at 50°C, and then use the treatment liquid Spray the obtained Pinus sylvestris wood, the spraying amount is 10% of the weight of the wood, transfer it into a closed container after spraying, pump out the air, and introduce carbon dioxide gas to a pressure of 0.5MPa, treat it at 120°C for 20min, let it out After the pressure is taken out, the treatment liquid is sprayed again-carbon dioxide high temperature and high pressure treatment. After 3 cycles, the pressure is released and taken out; the treatment liquid is made of the following raw materials in parts by weight: 10 parts ...

Embodiment 2

[0021] A treatment method for improving the mechanical properties of Pinus sylvestris sylvestris, comprising the following steps:

[0022] (1) Choose pine wood with a diameter of 25cm and a length of 1.2m, peel it, and set aside;

[0023] (2) Water the sylvestris pine wood obtained in step (1), the water temperature is 65°C, and then water the wood with 3°C water after moisture penetration, then dry it at 55°C, and then use the treatment liquid Spray the obtained Pinus sylvestris pine wood, the spraying amount is 11% of the weight of the wood, after spraying, transfer it into a closed container, extract the air, and introduce carbon dioxide gas to a pressure of 0.55MPa, treat it at 124°C for 25min, let it out After the pressure is taken out, the treatment liquid is sprayed again-carbon dioxide high-temperature and high-pressure treatment. After 4 cycles, the pressure is released and taken out; the treatment liquid is made of the following raw materials in parts by weight: 12 p...

Embodiment 3

[0027] A treatment method for improving the mechanical properties of Pinus sylvestris sylvestris, comprising the following steps:

[0028] (1) Select pine wood with a diameter of 30cm and a length of 1.5m, peel it, and set aside;

[0029] (2) Water the sylvestris pine wood obtained in step (1), the water temperature is 70°C, and then water the wood with 5°C water after moisture penetration, then dry it at 60°C, and then use the treatment liquid Spray the obtained Pinus sylvestris pine wood, the spraying amount is 12% of the weight of the wood, after spraying, transfer it into a closed container, extract the air, and introduce carbon dioxide gas to a pressure of 0.6MPa, treat it at 128°C for 30min, let it out After the pressure is taken out, the treatment liquid is sprayed again-carbon dioxide high temperature and high pressure treatment. After 5 cycles, the pressure is released and taken out; the treatment liquid is made of the following raw materials in parts by weight: 15 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com