Microwave-hot air coupled dried beef jerky production method

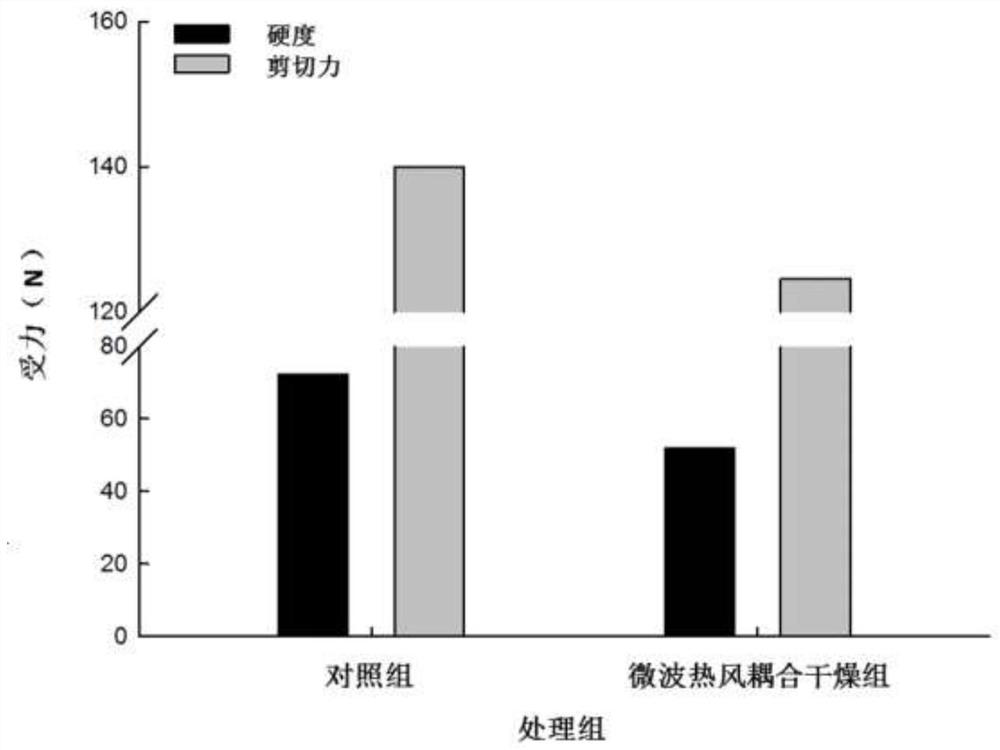

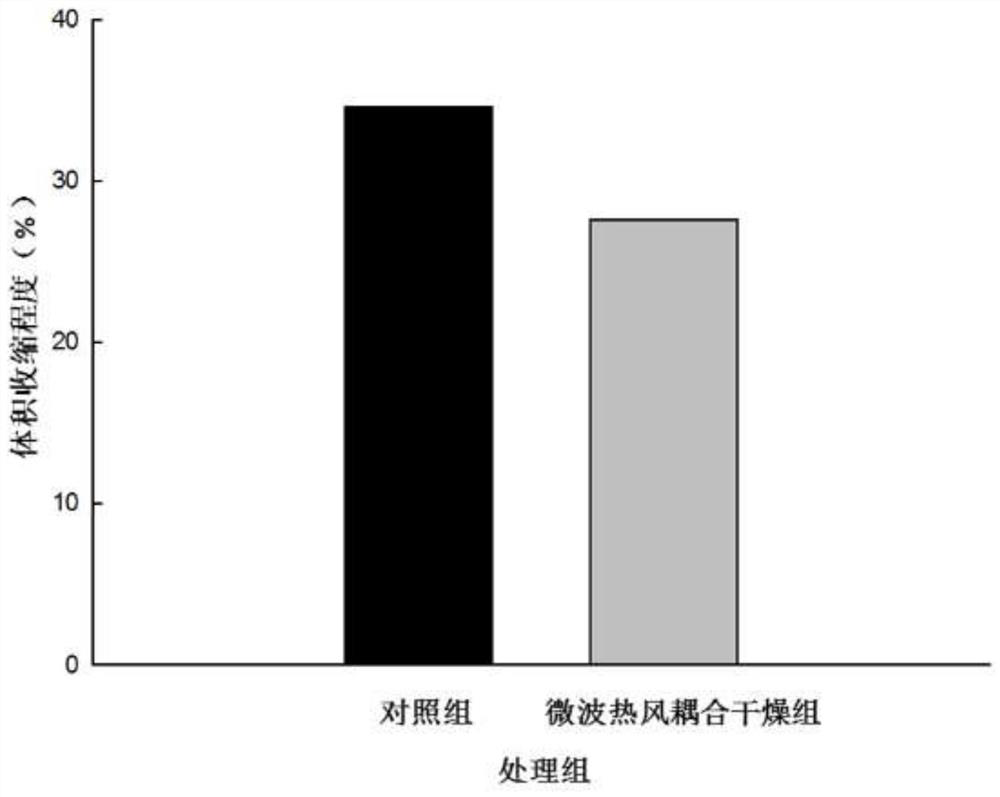

A beef jerky and drying technology, applied in the fields of food science, food preservation, application, etc., to achieve the effects of uniform moisture distribution, improved yield and uniform texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A microwave-hot air coupled dried beef, comprising the following components by weight: 500g of beef, 2g of salt, 5g of sugar, 3g of ginger, 30ml of light soy sauce, 10ml of dark soy sauce, 40ml of cooking wine, 30ml of mature vinegar, 2g of grass fruit, Star anise 1g, fragrant leaves 0.5g, cinnamon 3g, pepper 1g, pepper 1g.

[0026] A microwave-hot air coupling drying beef jerky production method comprises the following steps:

[0027] S1. Raw materials: fresh beef hindquarters, thawed at 4°C, divided, and removed visible fascia and fat;

[0028] S2. Ingredients: Take beef, salt, sugar, ginger, light soy sauce, dark soy sauce, cooking wine, mature vinegar, grass fruit, star anise, bay leaves, cinnamon bark, pepper, and pepper according to the above weight parts;

[0029] S3. Initial cooking: Add appropriate amount of water, add 2g of ginger, 20ml of cooking wine, put the cut meat samples into the initial cooking for 20 minutes, remove blood and foam, and cook at a powe...

Embodiment 2

[0038] A microwave-hot air coupled dried beef, comprising the following components by weight: 500g of beef, 2g of salt, 5g of sugar, 3g of ginger, 30ml of light soy sauce, 10ml of dark soy sauce, 40ml of cooking wine, 30ml of mature vinegar, 2g of grass fruit, Star anise 1g, fragrant leaves 0.5g, cinnamon 3g, pepper 1g, pepper 1g.

[0039] A microwave-hot air coupling drying beef jerky production method comprises the following steps:

[0040] S1. Raw materials: fresh beef hindquarters, thawed at 4°C, divided, and removed visible fascia and fat;

[0041] S2. Ingredients: Take beef, salt, sugar, ginger, light soy sauce, dark soy sauce, cooking wine, mature vinegar, grass fruit, star anise, bay leaves, cinnamon bark, pepper, and pepper according to the above weight parts;

[0042] S3. Initial cooking: Add appropriate amount of water, add 2g of ginger, 20ml of cooking wine, put the cut meat samples into the initial cooking for 20 minutes, remove blood and foam, and cook at a powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com