Patents

Literature

74results about How to "Robust processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monitoring physiological parameters based on variations in a photoplethysmographic signal

InactiveUS7001337B2Fast and robust and computationally efficientRobust processingEvaluation of blood vesselsCatheterNervous systemRR interval

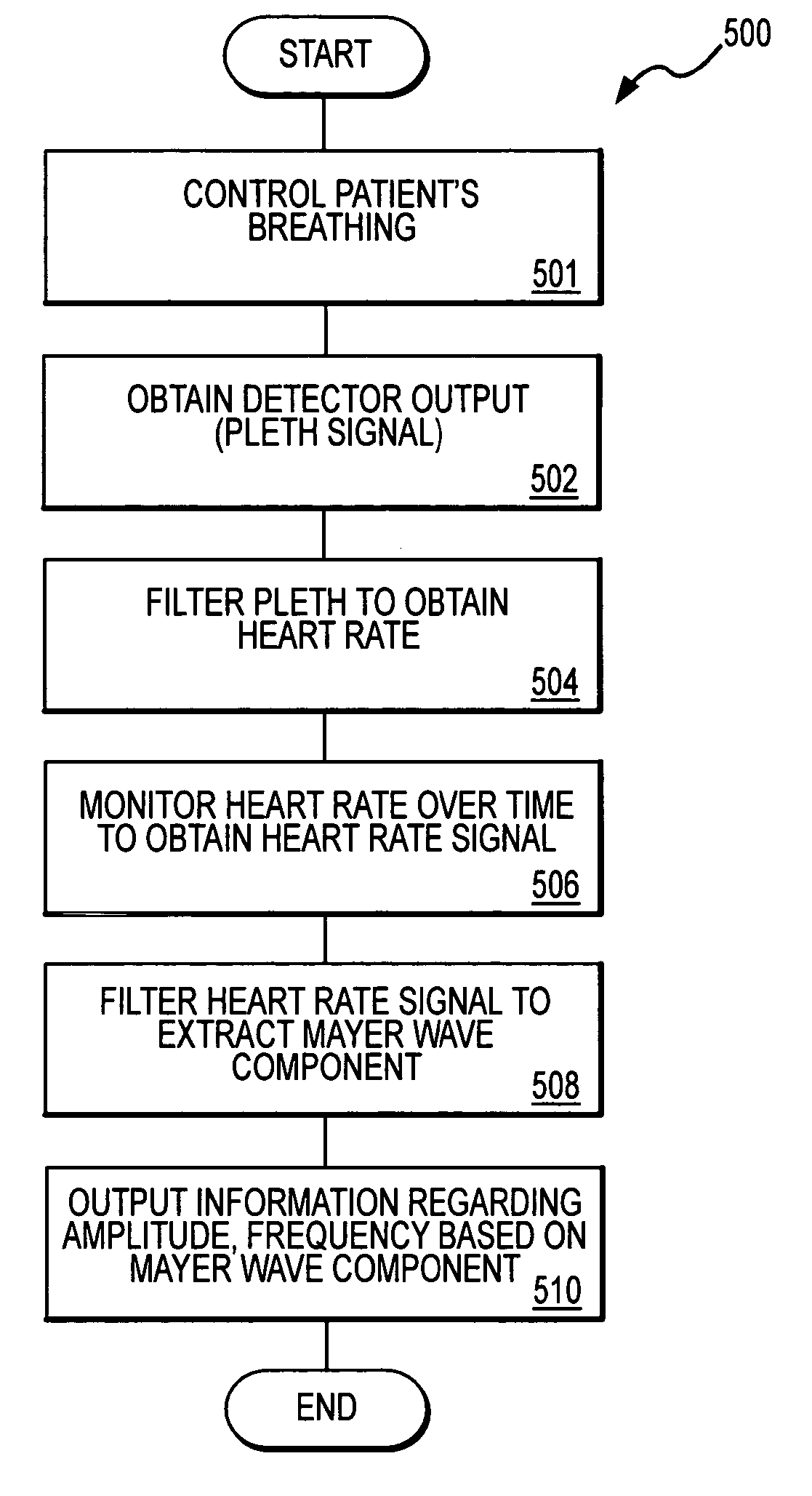

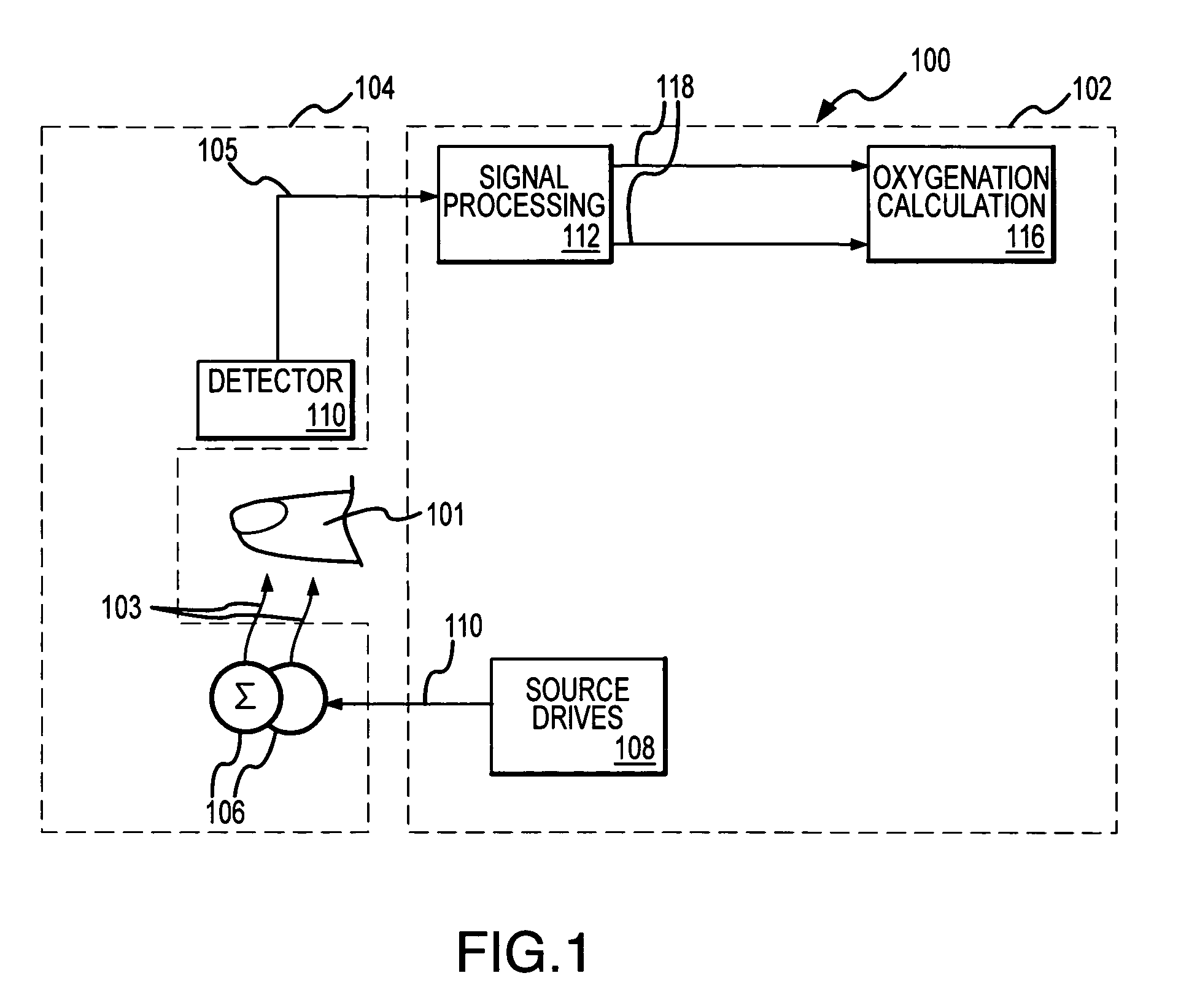

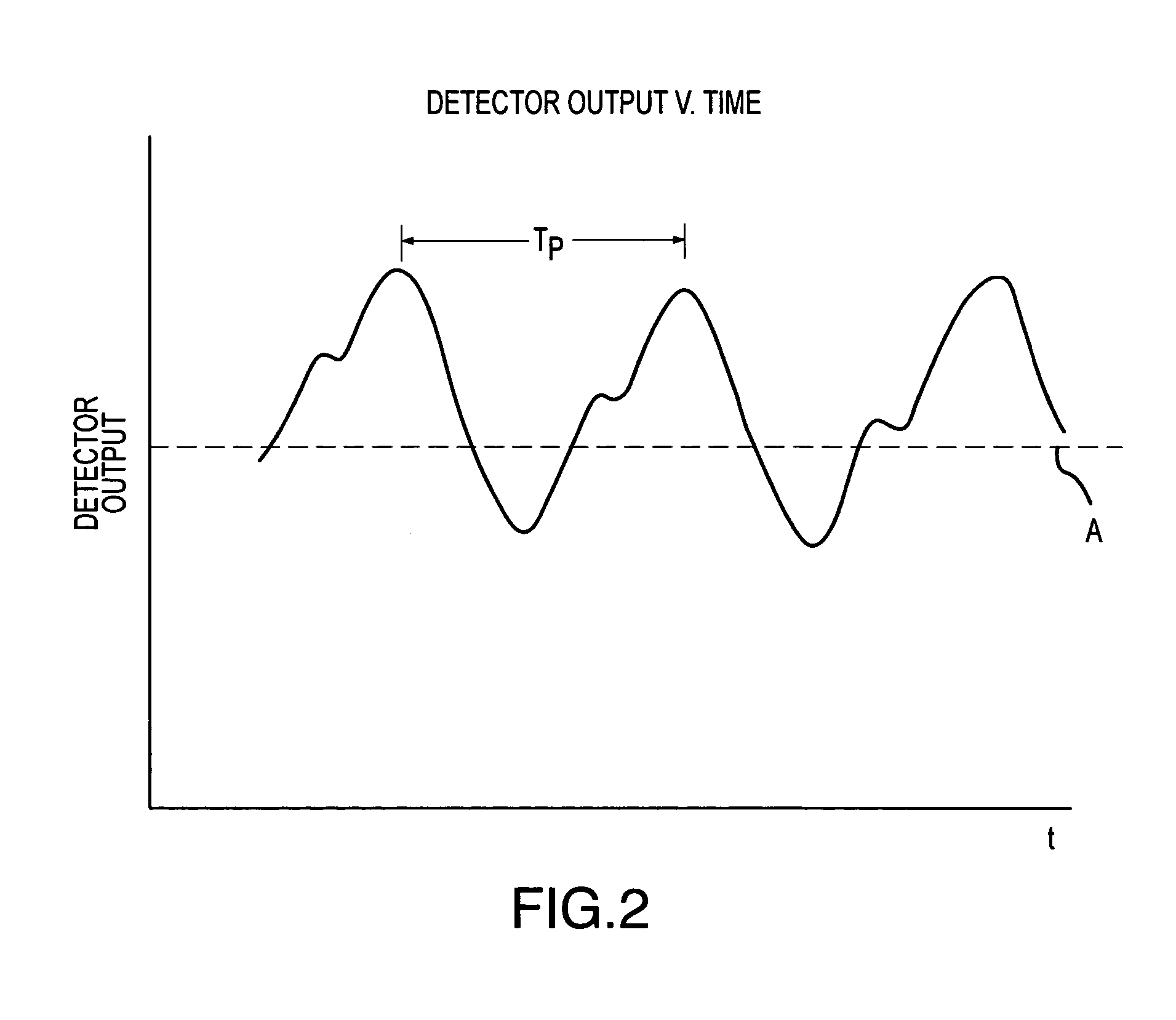

A method and apparatus are disclosed for using photoplethysmography to obtain physiological parameter information related to respiration rate, heart rate, heart rate variability, blood volume variability and / or the autonomic nervous system. In one implementation, the process involves obtaining (2502) a pleth, filtering (2504) the pleth to remove unwanted components, identifying (2506) a signal component of interest, monitoring (2508) blood pressure changes, monitoring (2510) heart rate, and performing (2512) an analysis of the blood pressure signal to the heart rate signal to identify a relationship associated with the component of interest. Based on this relationship, the component of interest may be identified (2514) as relating to the respiration or Mayer Wave. If it is related to the respiration wave (2516), a respiratory parameter such as breathing rate may be determined (2520). Otherwise, a Mayer Wave analysis (2518) may be performed to obtain parameter information related to the autonomic nervous system.

Owner:DATEX OHMEDA

Metal-containing composite materials

InactiveUS20060167147A1Robust processingStable materialPowder deliveryInorganic active ingredientsMetallic materialsMaterials science

The present invention relates to a process for the manufacture of metal-containing materials or composite materials, the process comprising the steps of encapsulating at least one metal-based compound in a polymeric shell, thereby producing a polymer-encapsulated metal-based compound and / or coating a polymeric particle with at least one metal-based compound; forming a sol from suitable hydrolytic or non-hydrolytic sol / gel forming components; combining the polymer-encapsulated metal-based compound and / or the coated polymeric particle with the sol, thereby producing a combination thereof; and converting the combination into a solid metal-containing material. The present invention further relates to metal-containing materials produced in accordance with the above process.

Owner:CINVENTION AG

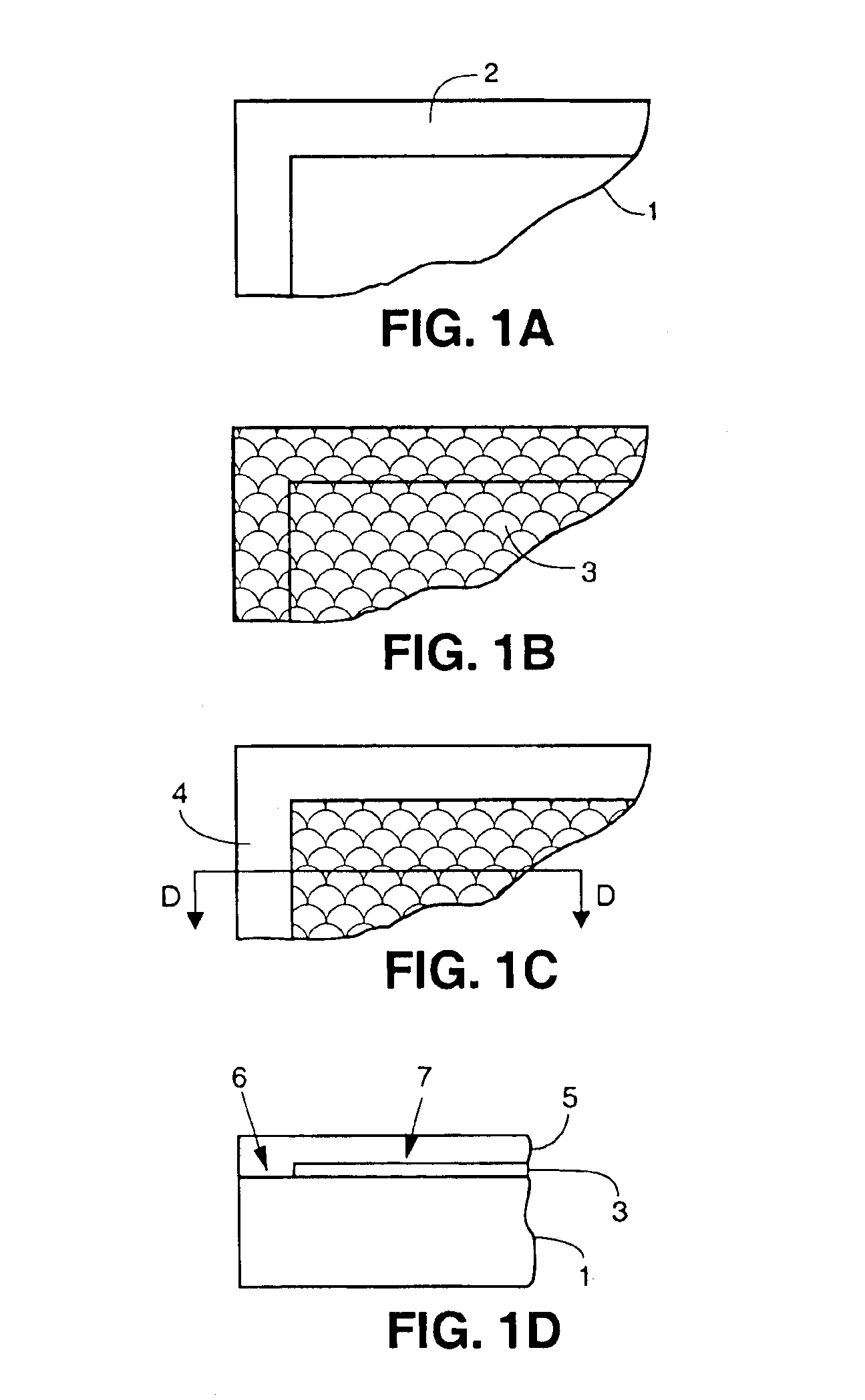

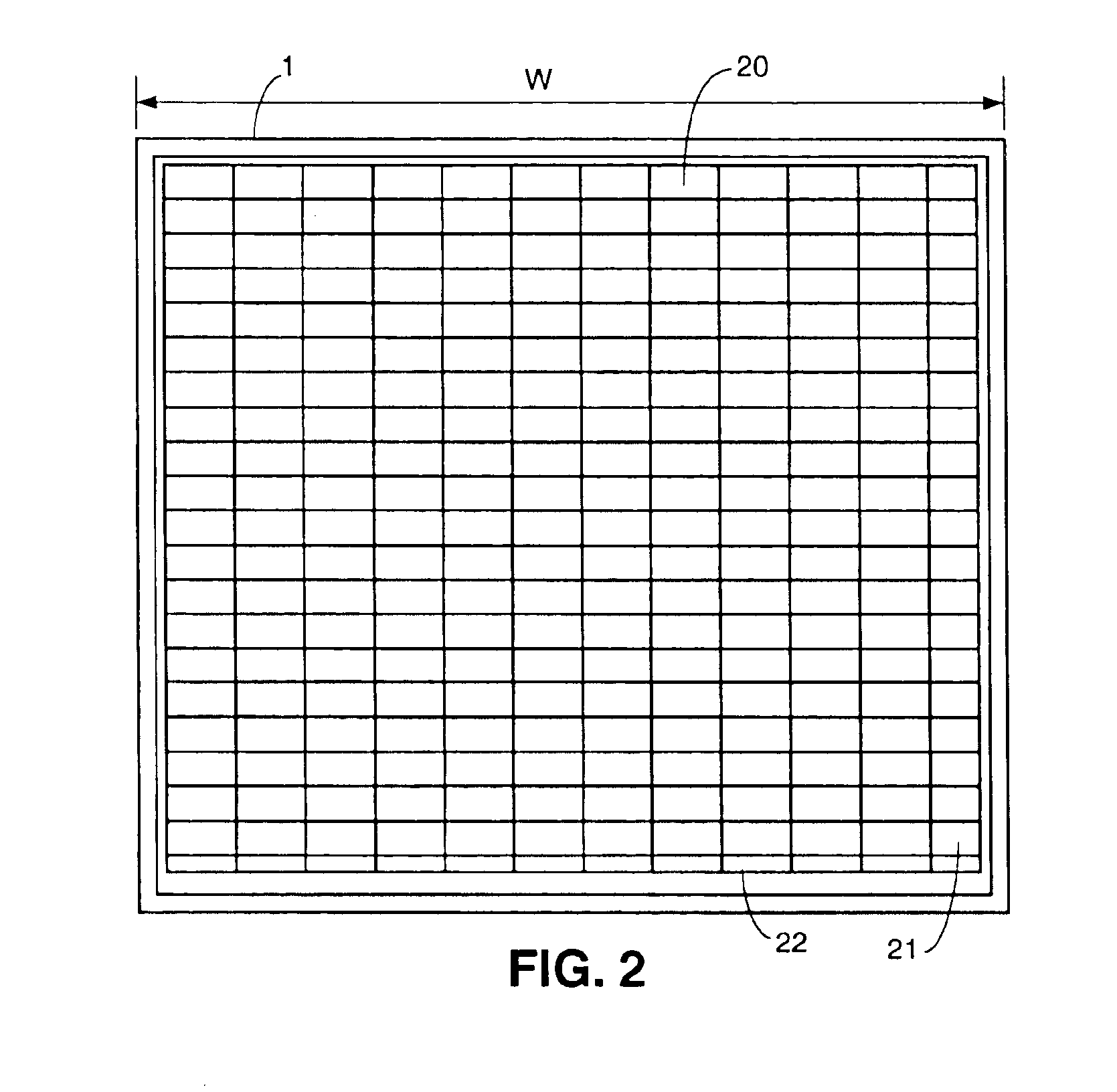

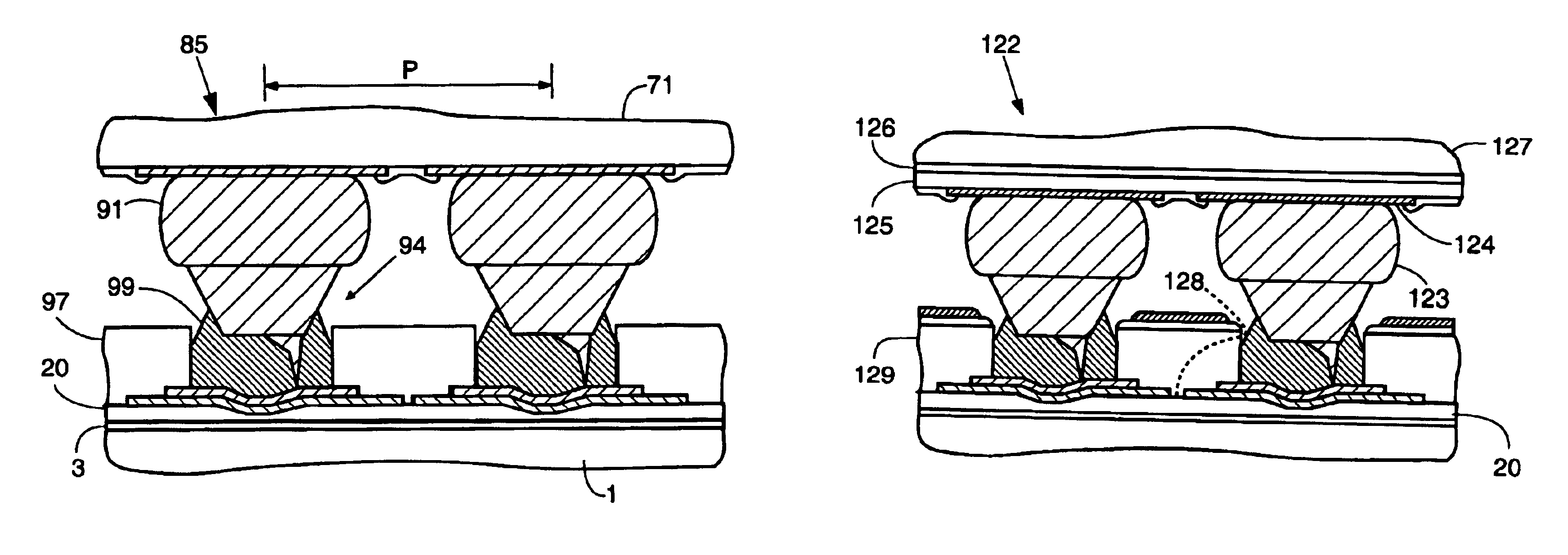

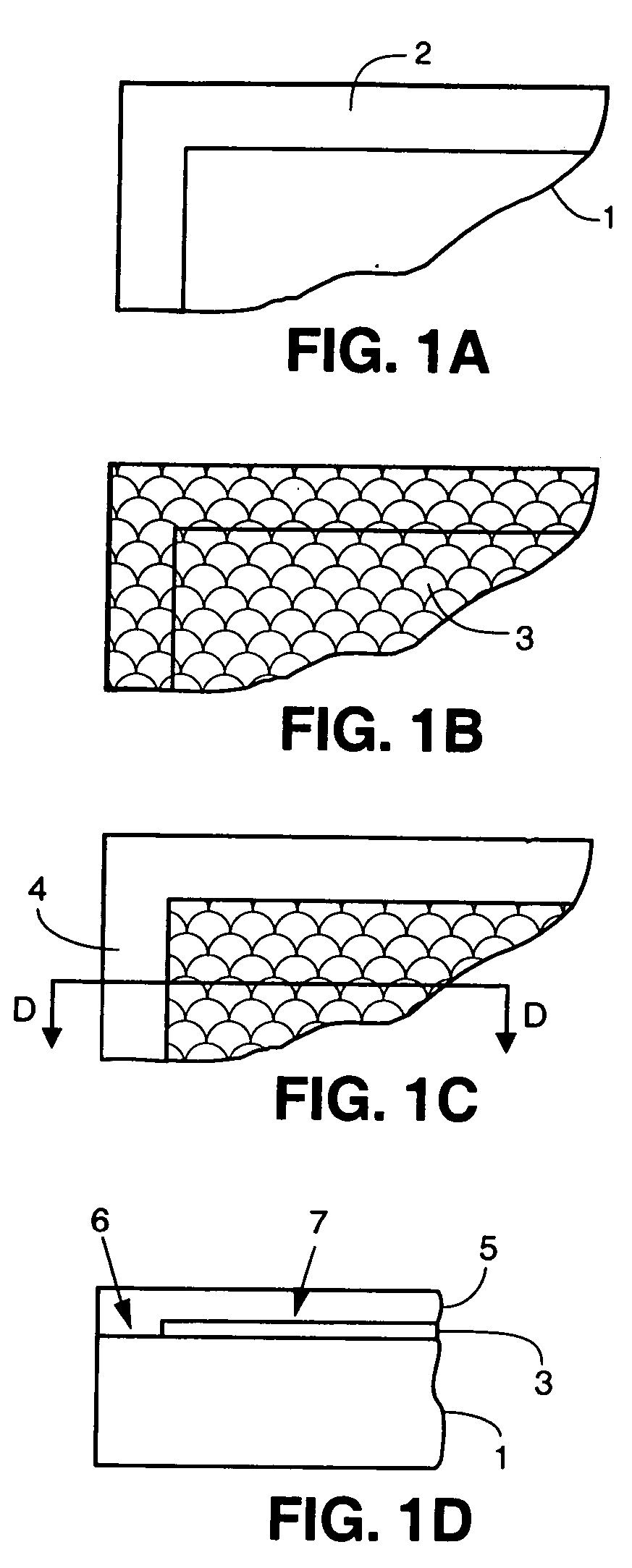

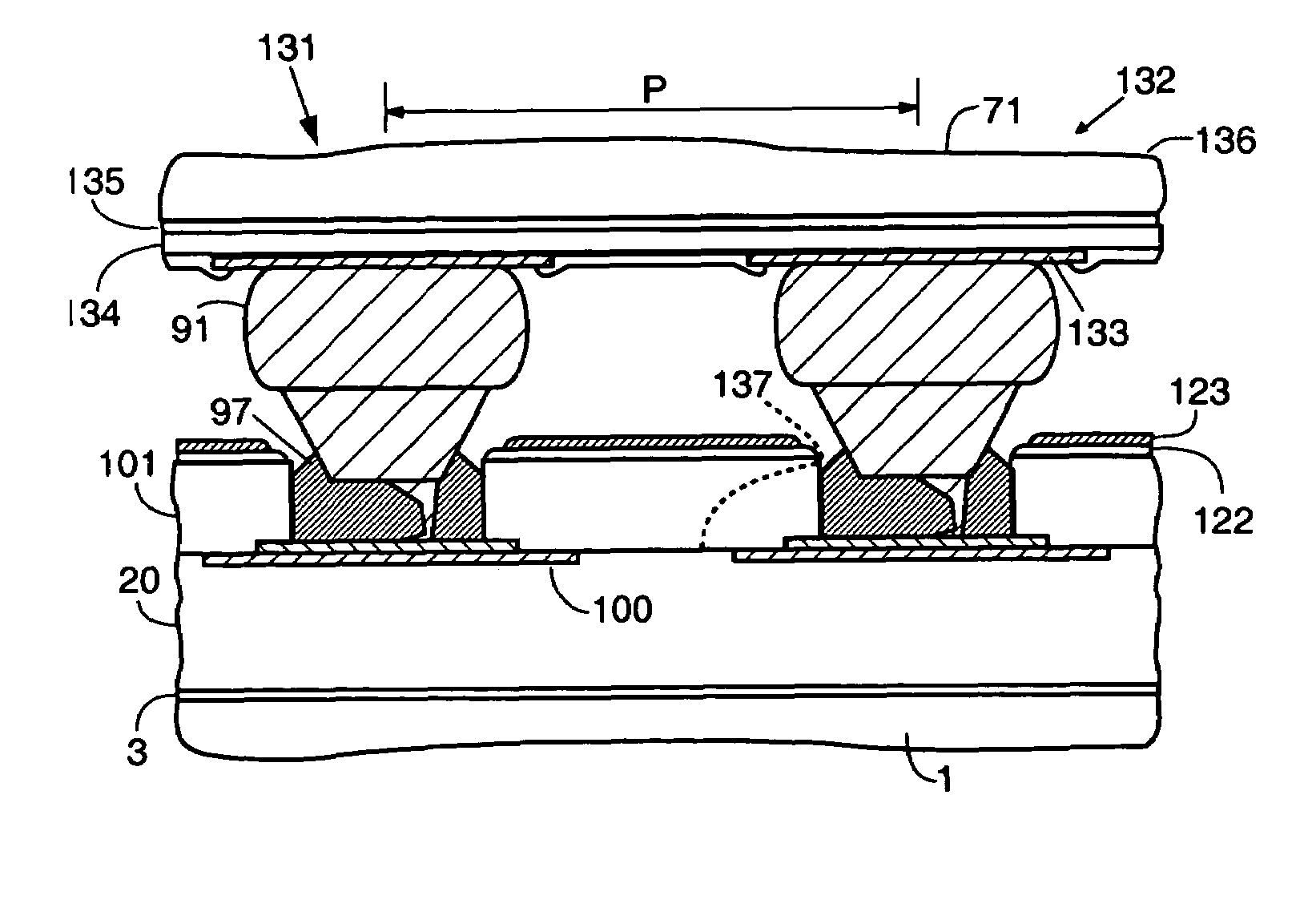

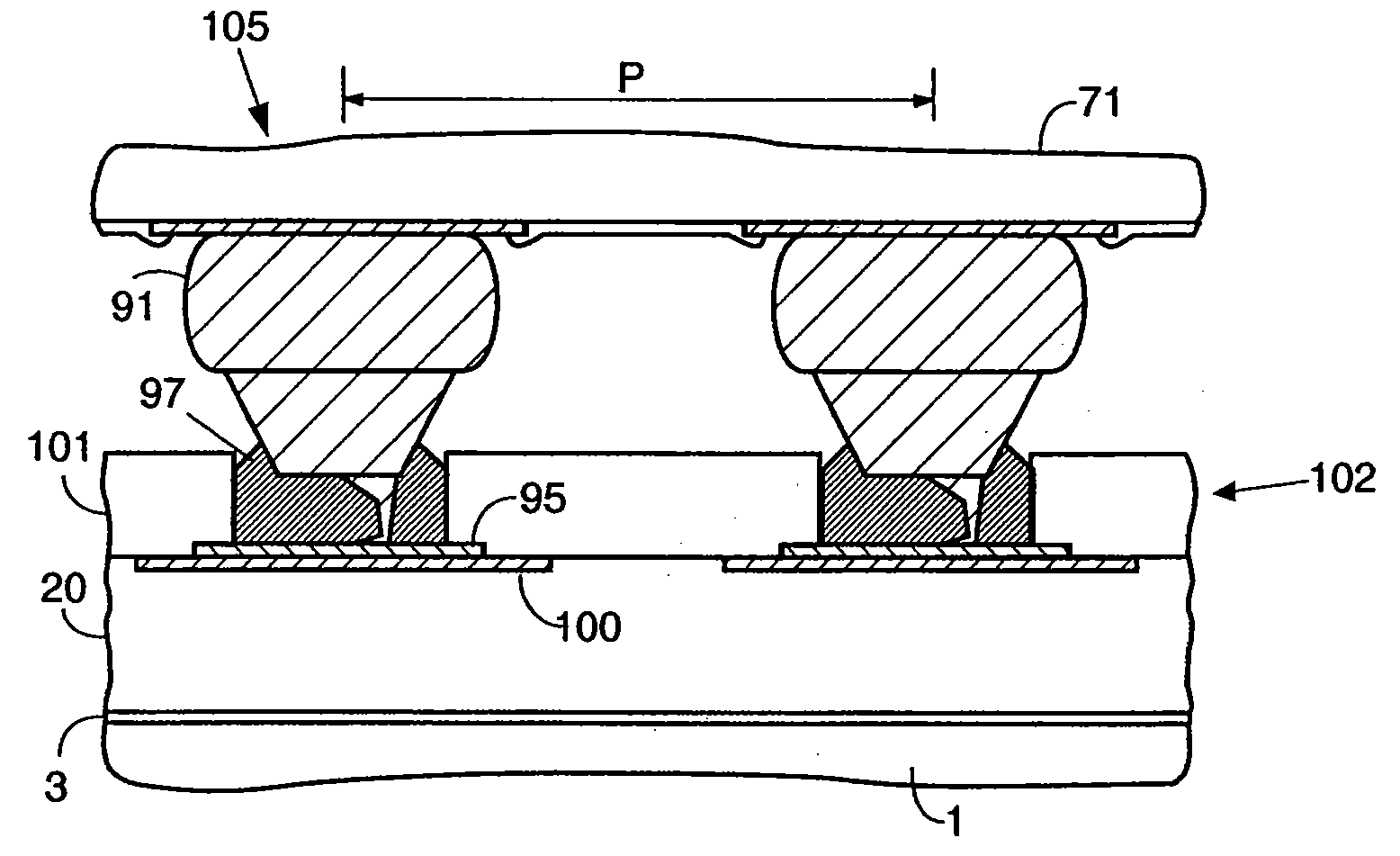

Component connections using bumps and wells

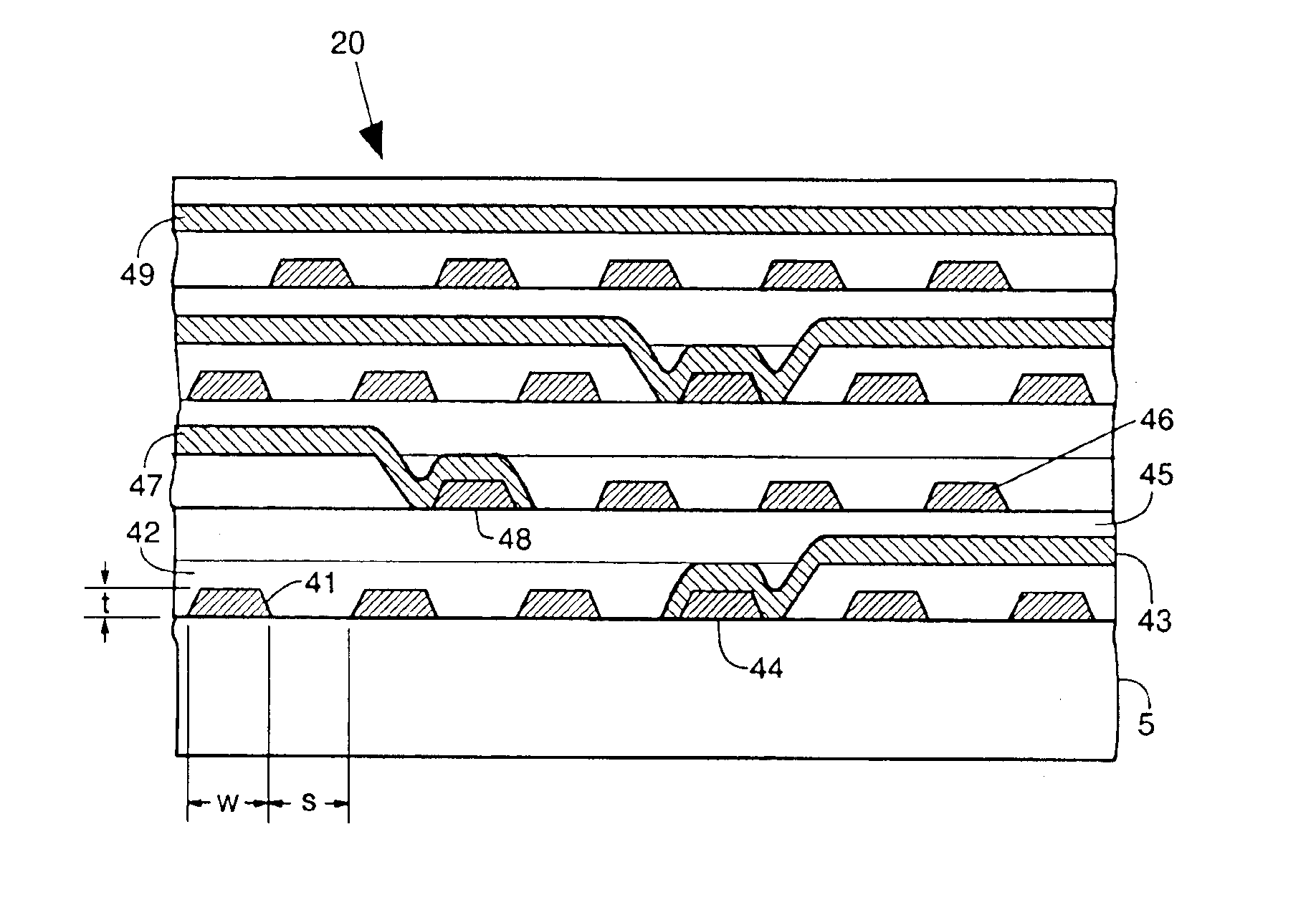

InactiveUS6881609B2Conveniently formedAccurate locationPrinted circuit assemblingFinal product manufactureHigh densityInterconnection

This specification describes techniques for fabricating connections between pairs of components. Each connection includes an array of bumps on a male component, and a matching array of wells filled with bonding material on a female component. The bump / well connections can be spaced with a pitch of less than 100 microns. One application of the invention is the attachment of electronic components to interconnection circuits or circuit assemblies to form electronic modules. The electronic components may be IC chips or high-density interconnect cables. Another application is alignment of optical components. The direct chip attachment techniques are described in the context of fabrication, assembly, test, rework, and cooling of electronic modules employing flip chip components. The preferred method is to fabricate the module on a glass carrier using a release layer so that the carrier can be removed after most of the processing is done.

Owner:SK HYNIX INC

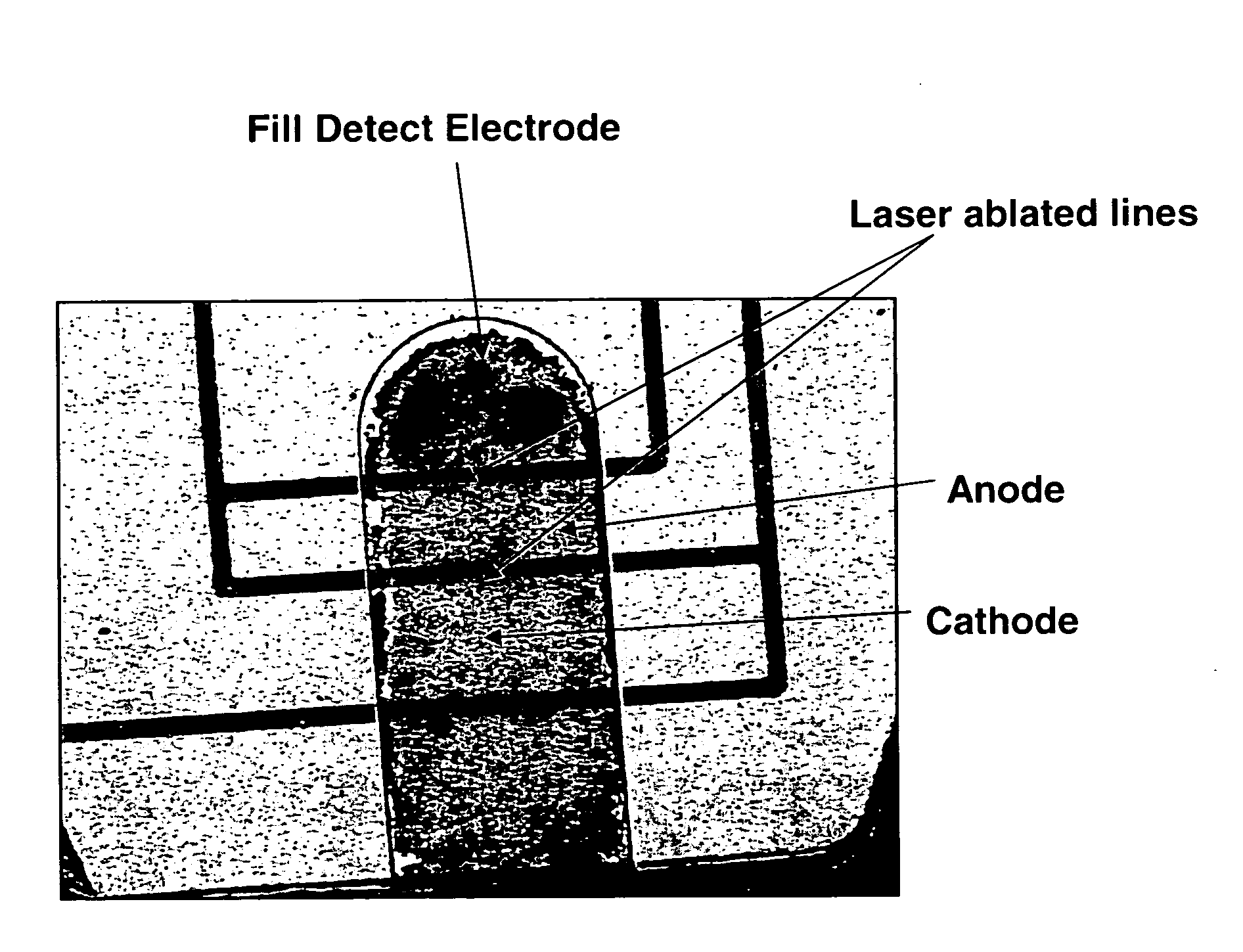

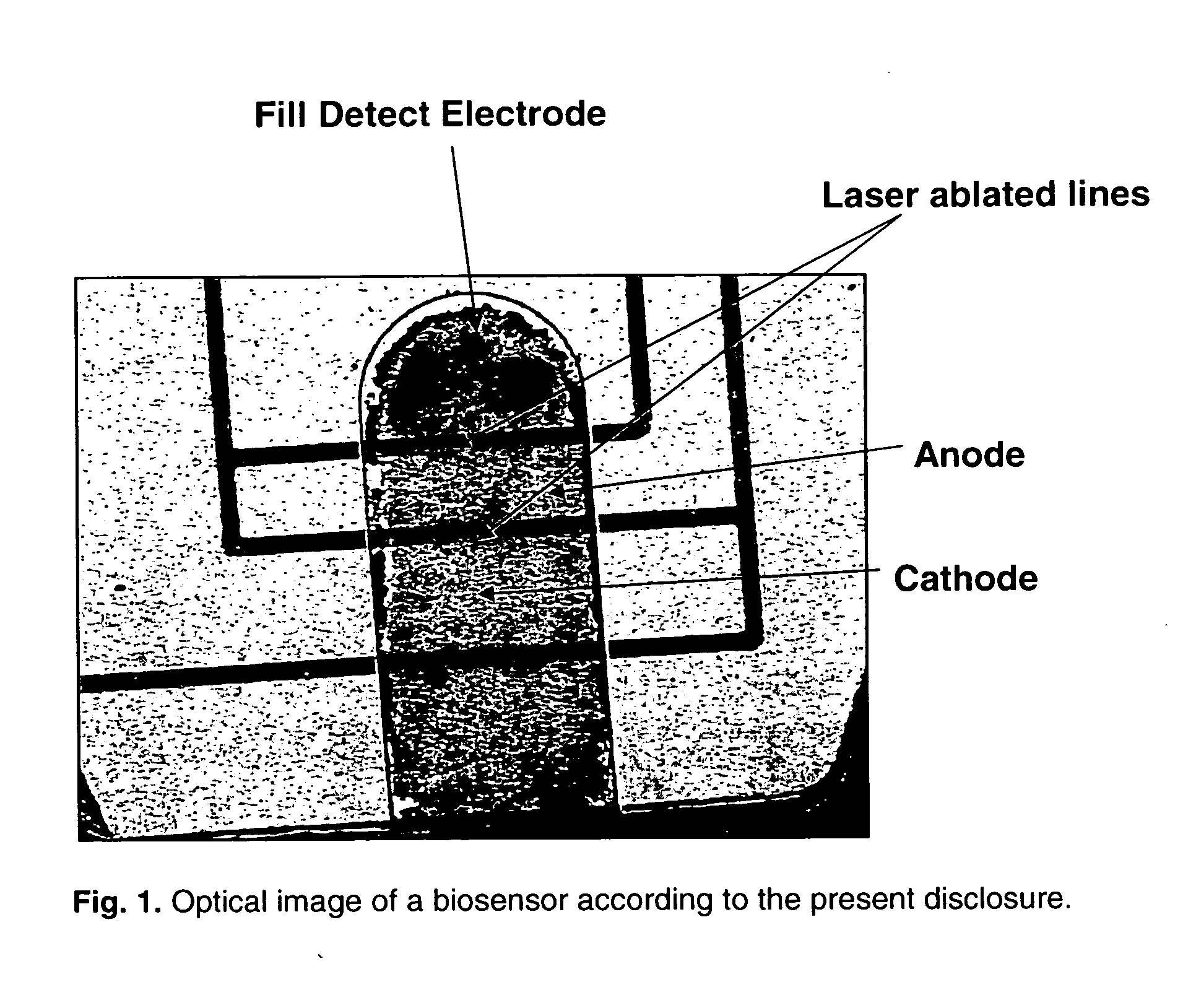

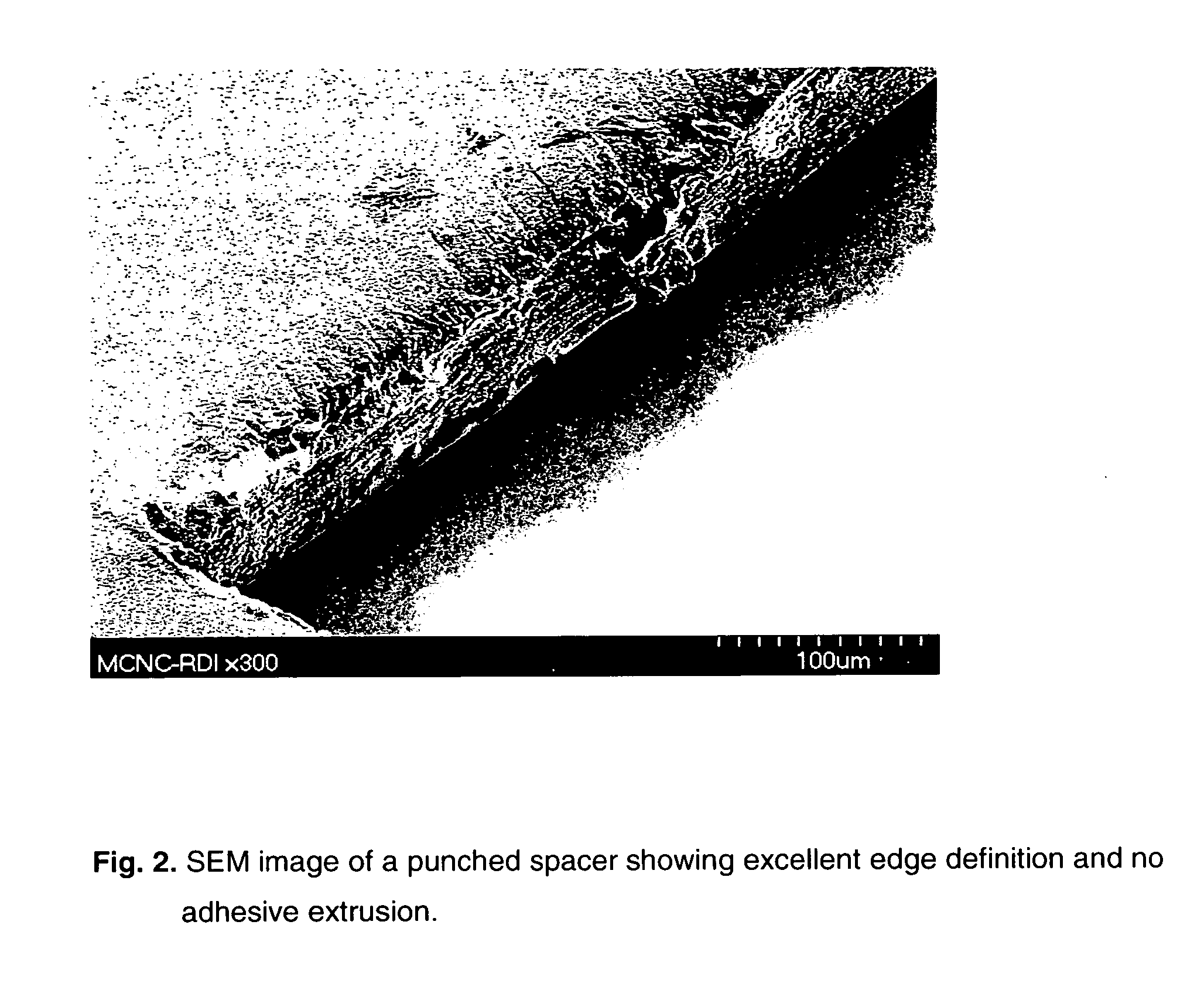

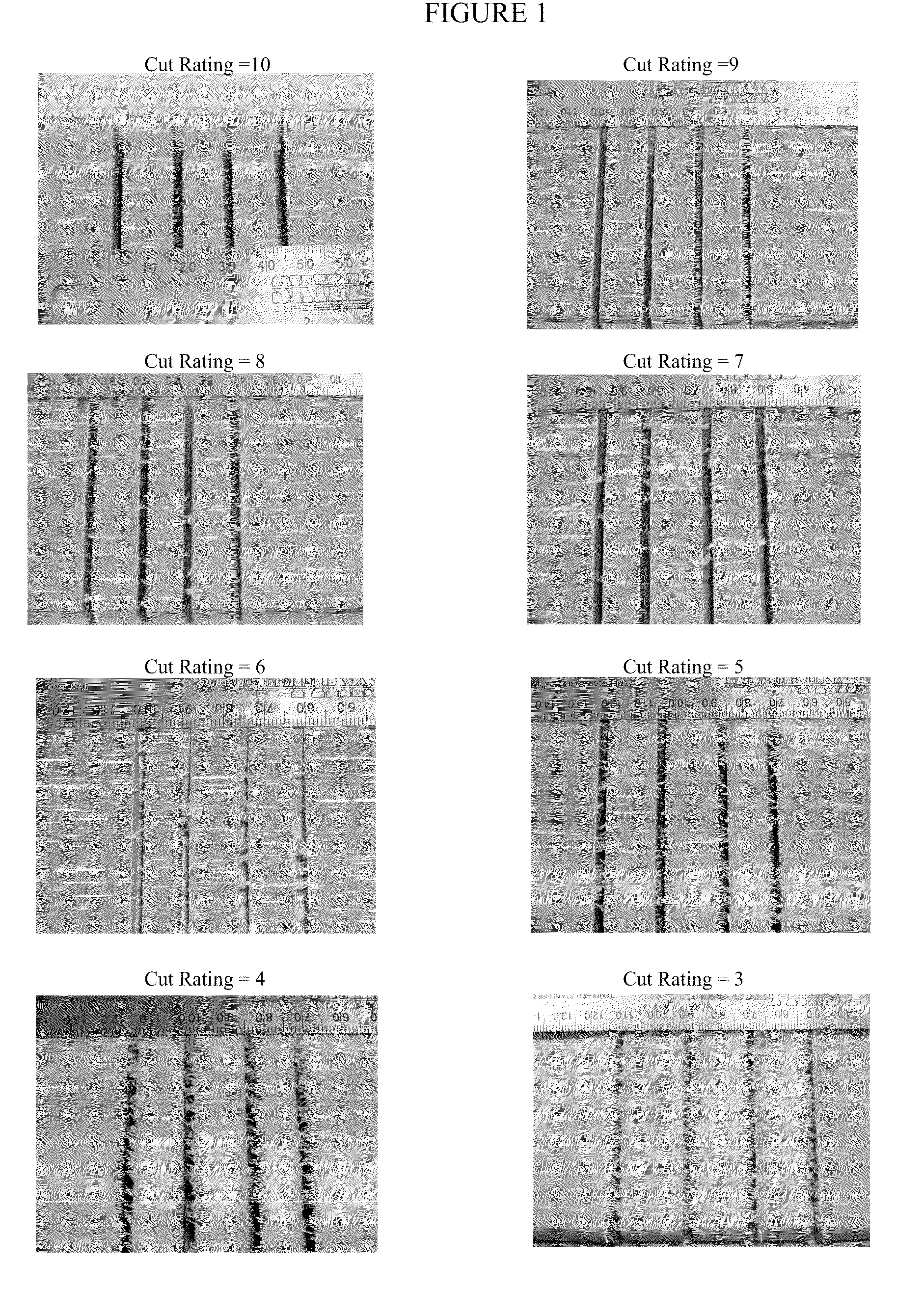

Biosensors comprising heat sealable spacer materials

InactiveUS20070240984A1Improve edge qualityLess-painful lancingImmobilised enzymesBioreactor/fermenter combinationsAnalyteOrganic layer

Disclosed herein is a biosensor for measuring analyte in a fluid that comprises a substrate layer having disposed thereon at least one each of an electrode, cathode, anode, and a novel spacer material. The spacer material according to the present disclosure comprises a heat sealable organic layer that covers at least a portion of the anode and defines at least one edge of the anode, wherein the spacer material has at least one hole punched through it and defines a cavity or well for accepting chemistry. Also disclosed is a method of making such biosensors.

Owner:NIPRO DIAGNOSTICS INC

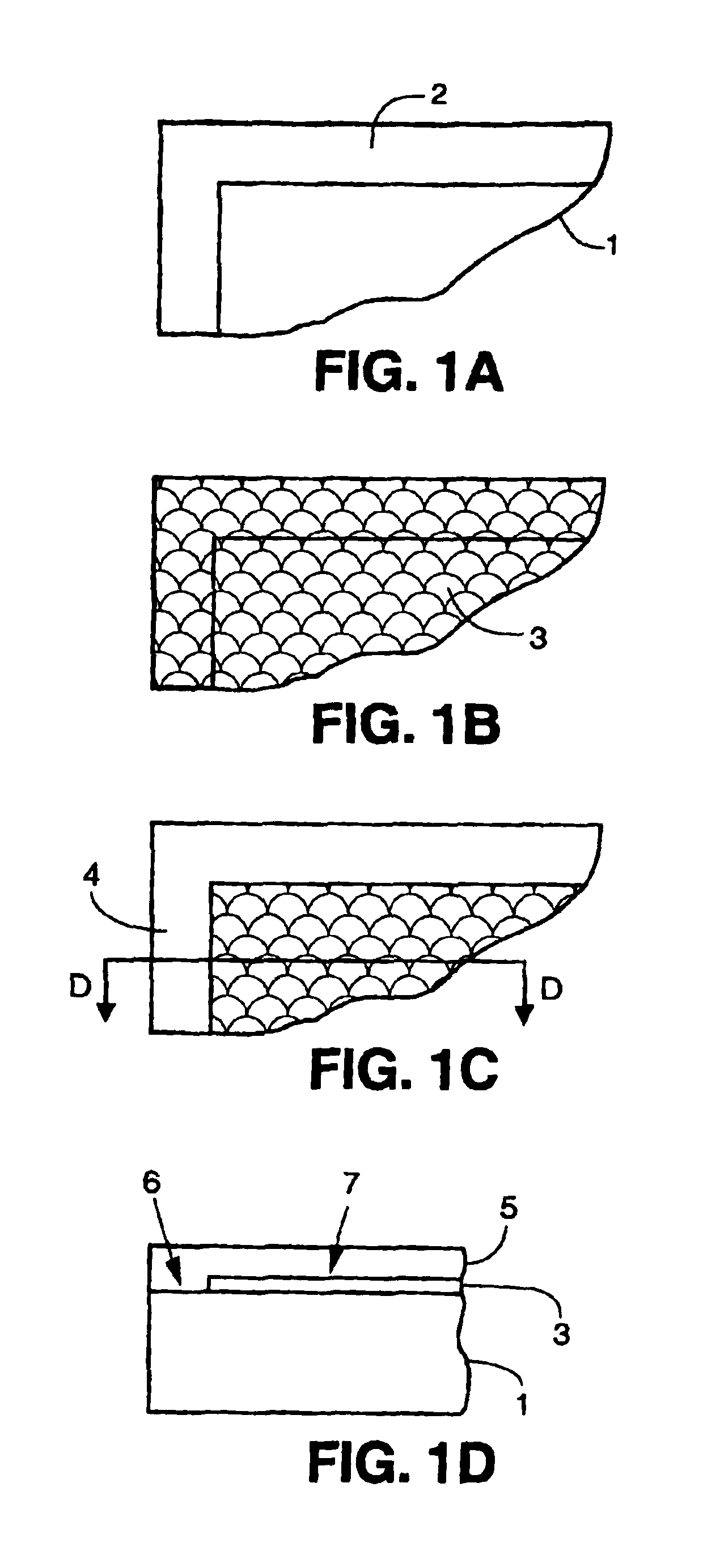

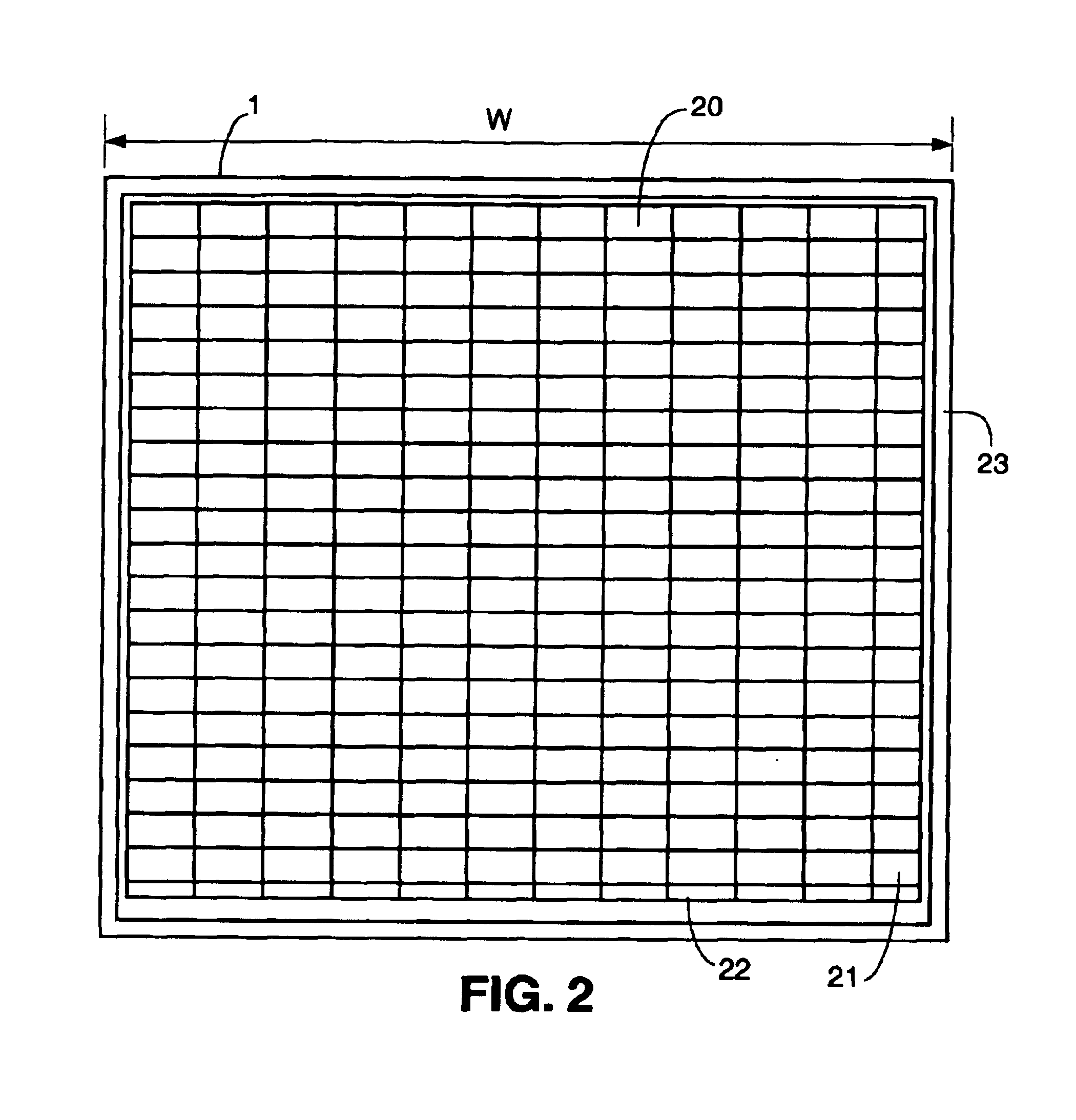

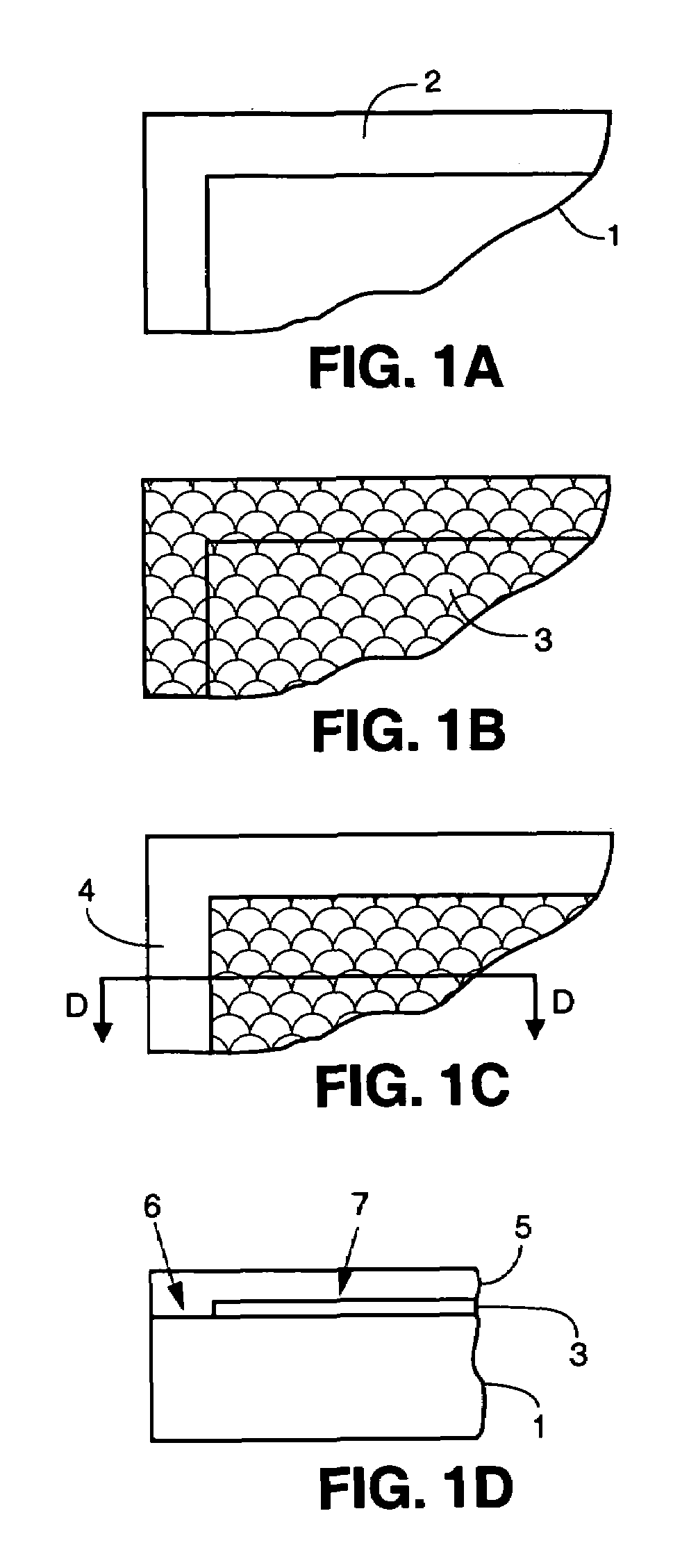

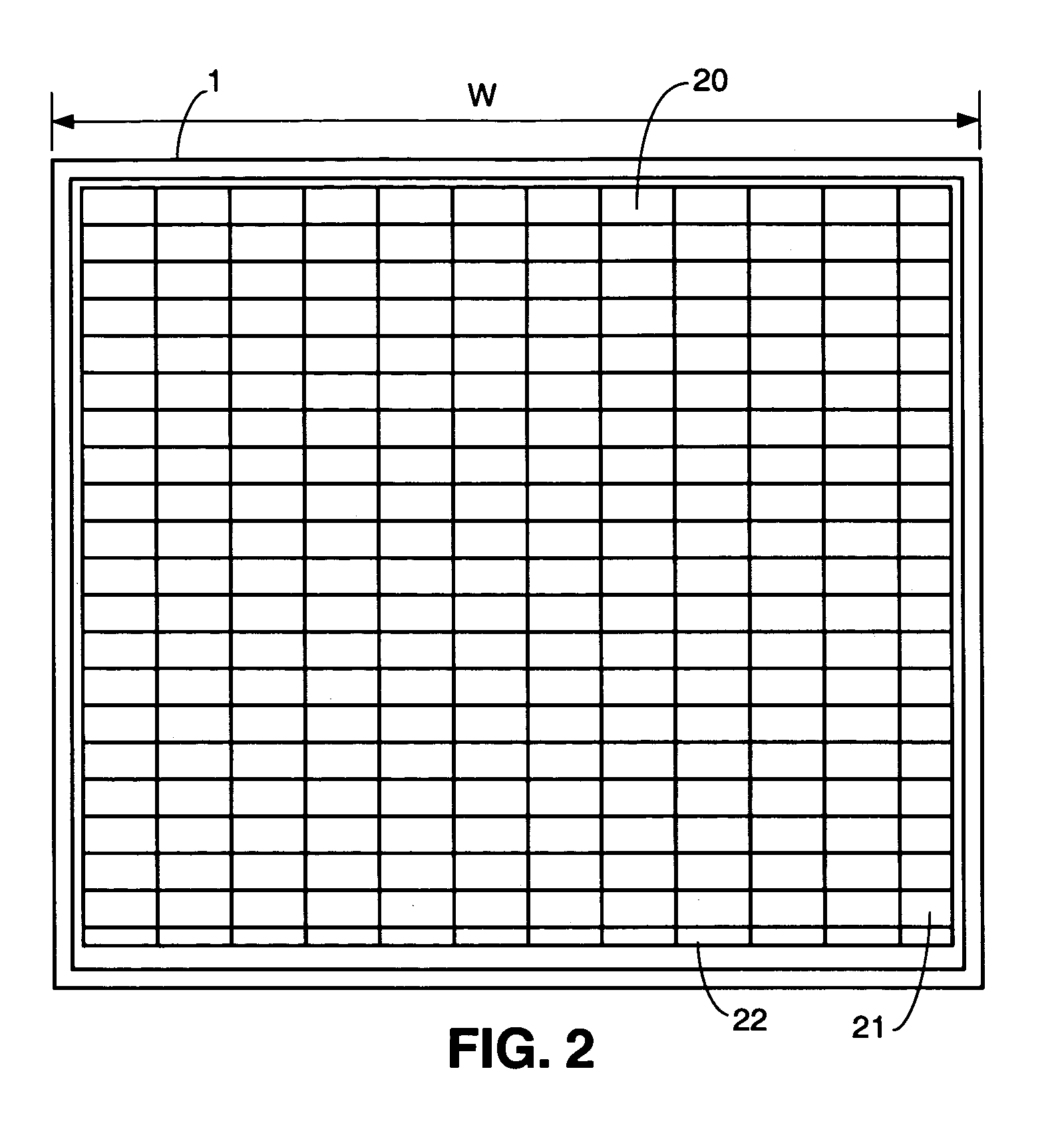

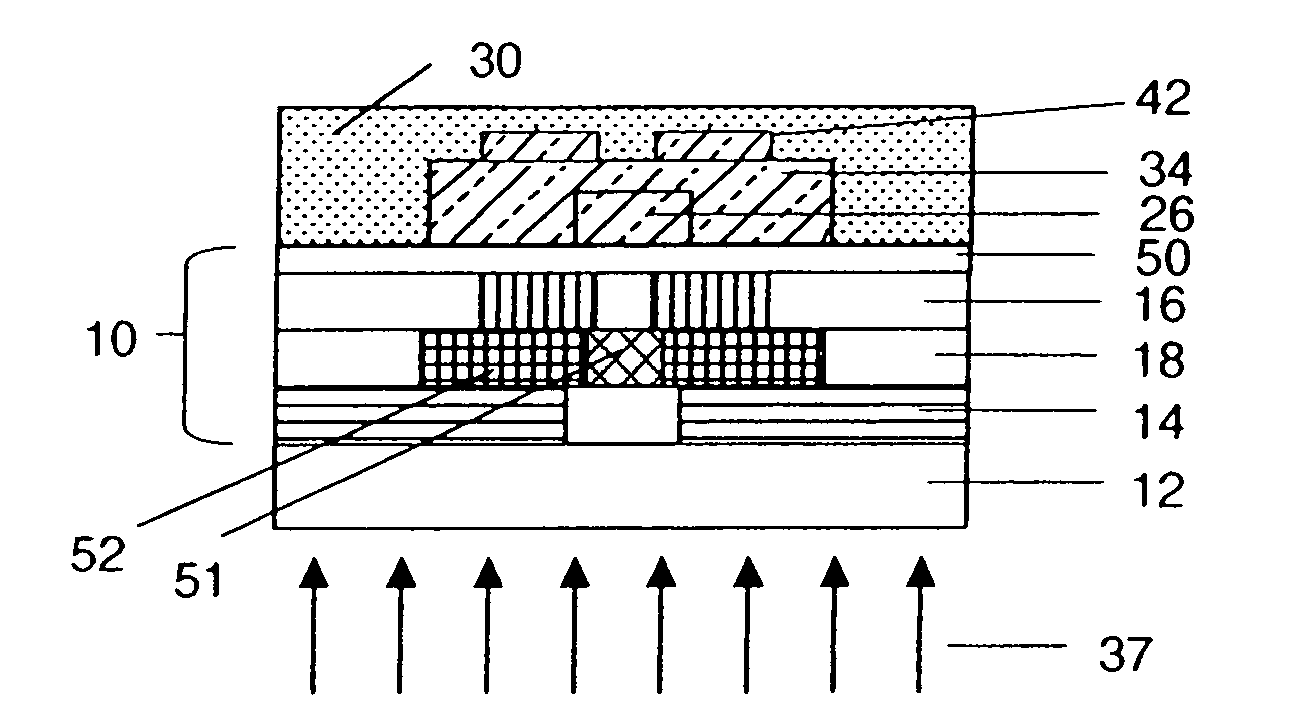

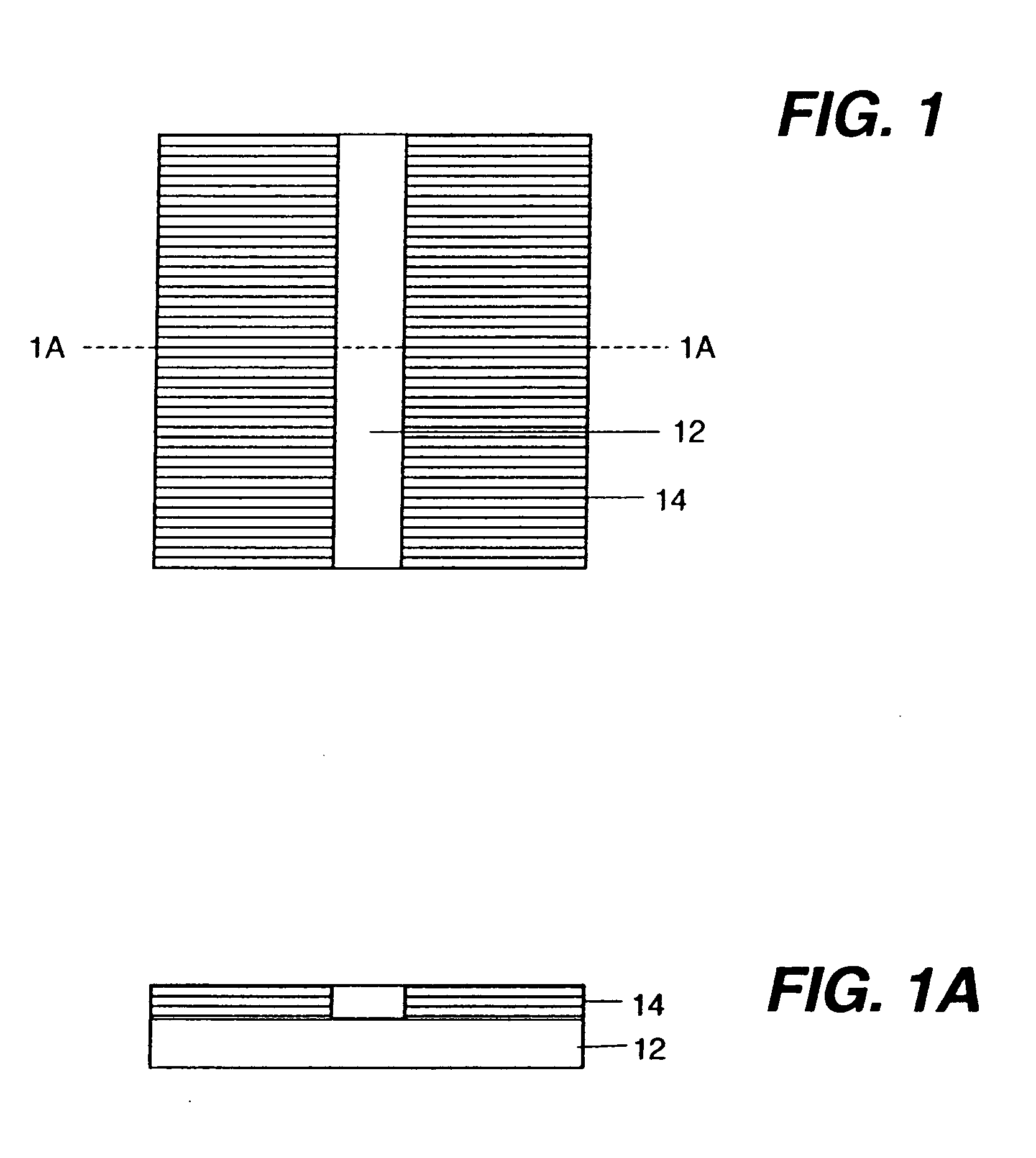

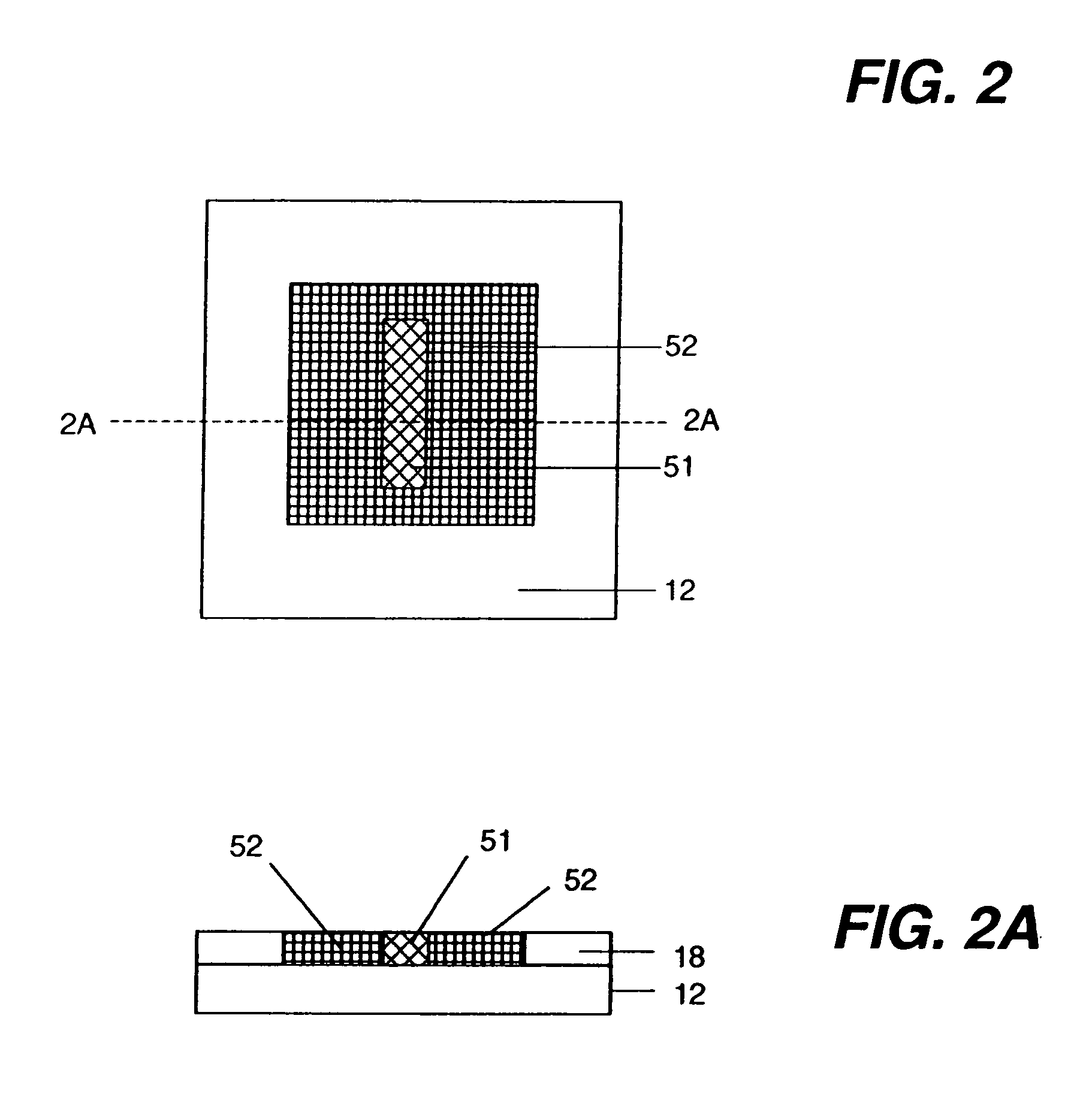

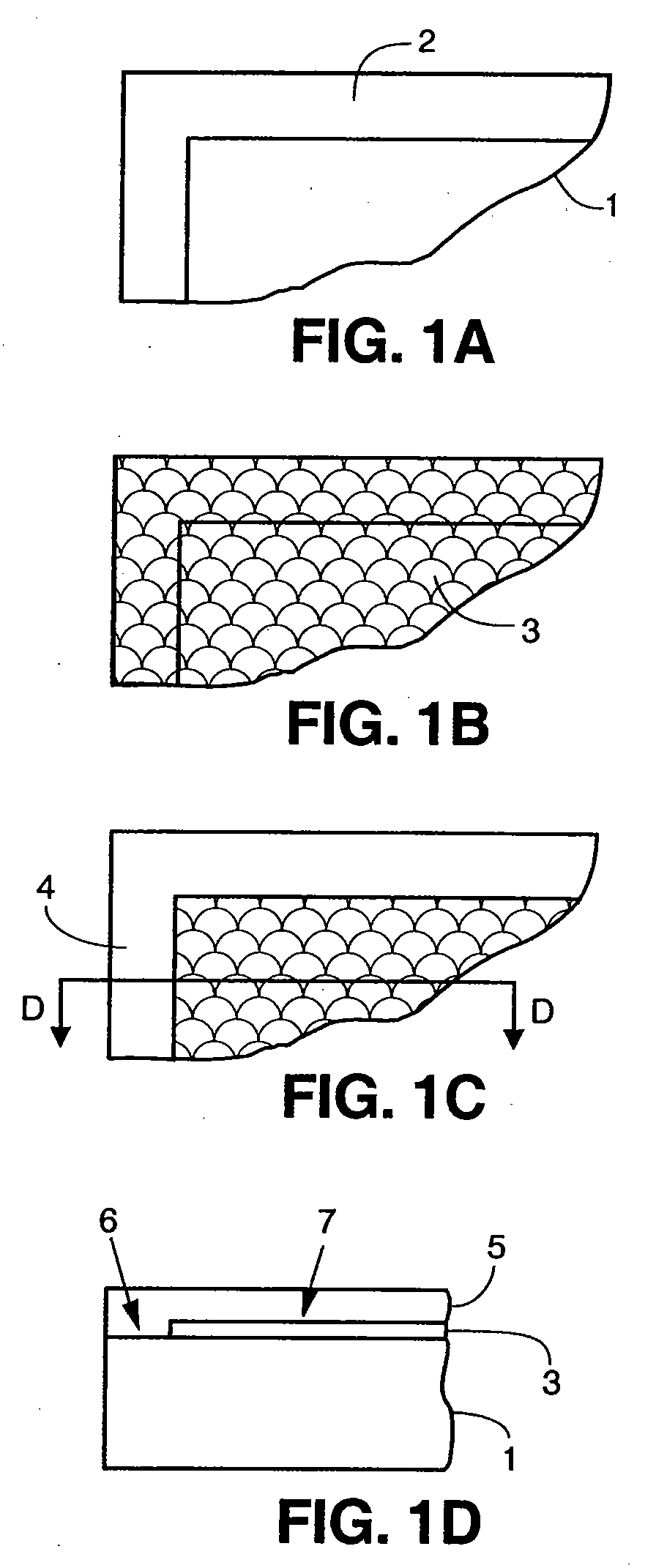

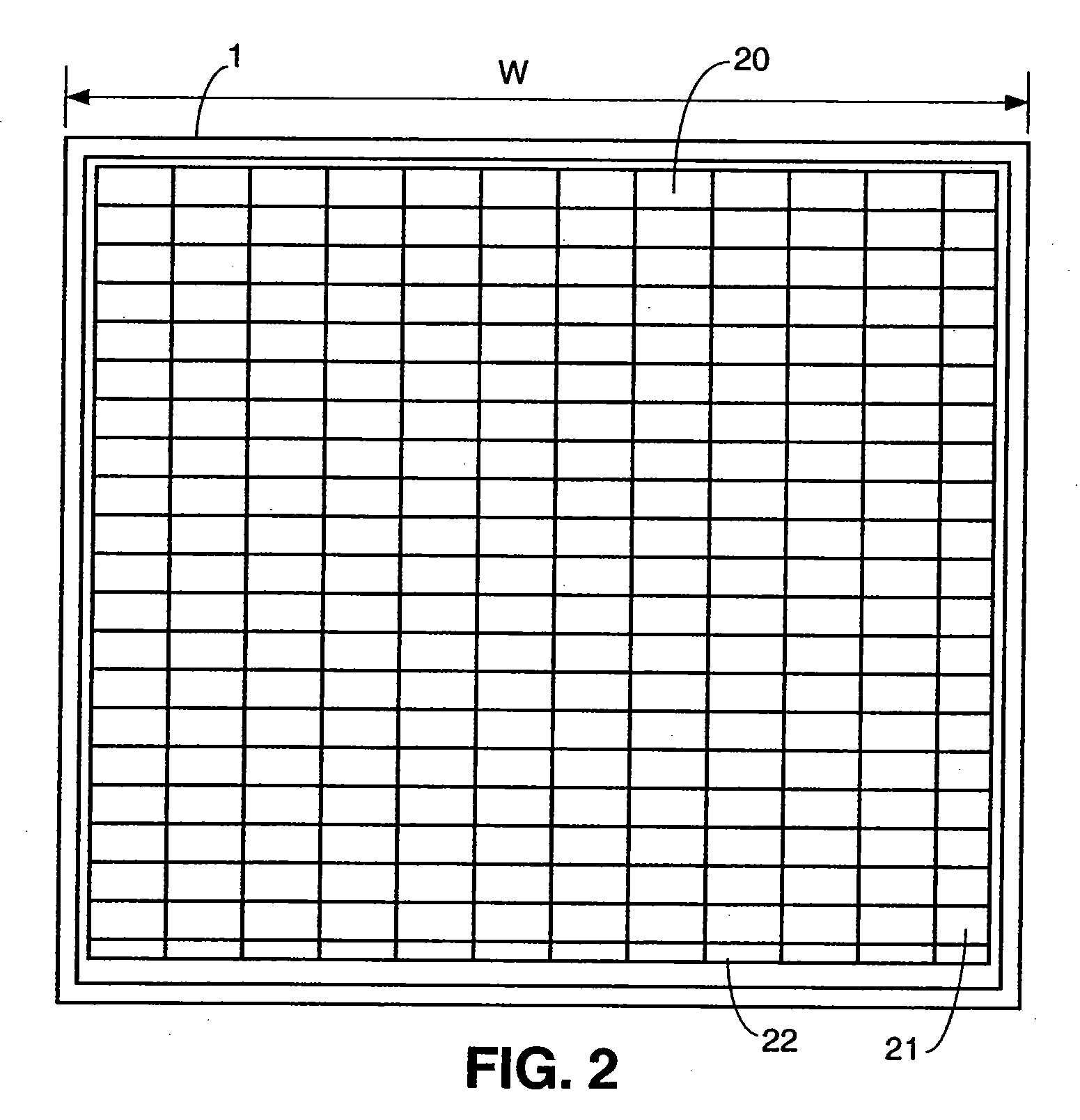

Electronic system modules and method of fabrication

InactiveUS6927471B2Good dimensional stabilityLow costPrinted circuit assemblingFinal product manufactureDielectricEngineering

This specification describes techniques for manufacturing an electronic system module. The module includes flexible multi-layer interconnection circuits with trace widths of 5 microns or less. A glass panel manufacturing facility, similar to those employed for making liquid crystal display, LCD, panels is used to fabricate the interconnection circuits. A polymer base layer is formed on a glass carrier with an intermediate release layer. Alternate layers of metal and dielectric are formed on the base layer, and patterned to create an array of multi-layer interconnection circuits on the glass panel. A thick layer of polymer is deposited on the interconnection circuit, and openings formed at input / output (I / O) pad locations. Solder paste is deposited in the openings to form wells filled with solder. After dicing the glass carrier to form separated interconnection circuits, IC chips are stud bumped and assembled using flip chip bonding, wherein the stud bumps on the components are inserted into corresponding wells on the interconnection circuits. The IC chips are tested and reworked to form tested circuit assemblies. Methods for connecting to testers and to other modules and electronic systems are described. Module packaging layers are provided for hermetic sealing and for electromagnetic shielding. A blade server embodiment is also described.

Owner:SK HYNIX INC

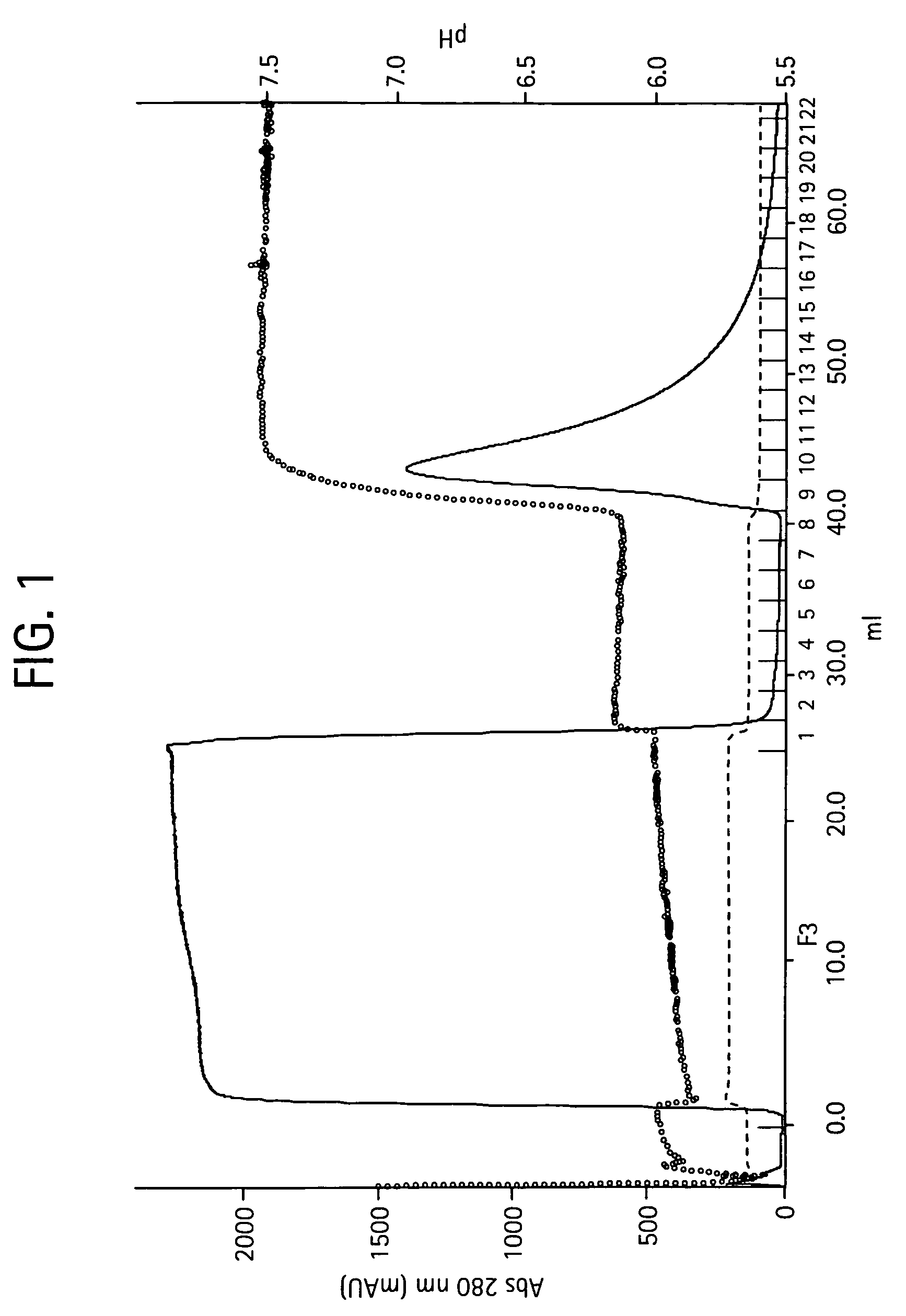

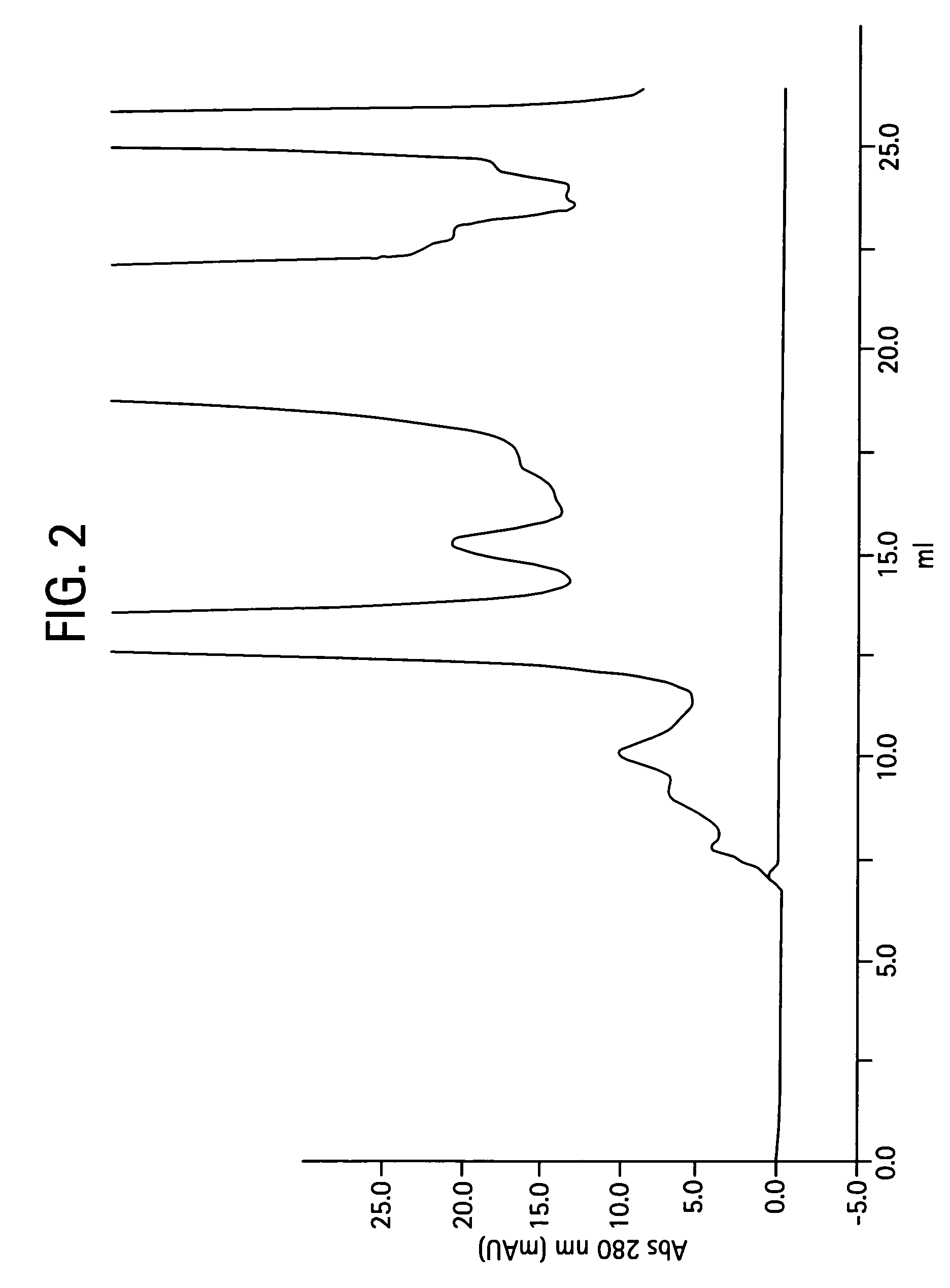

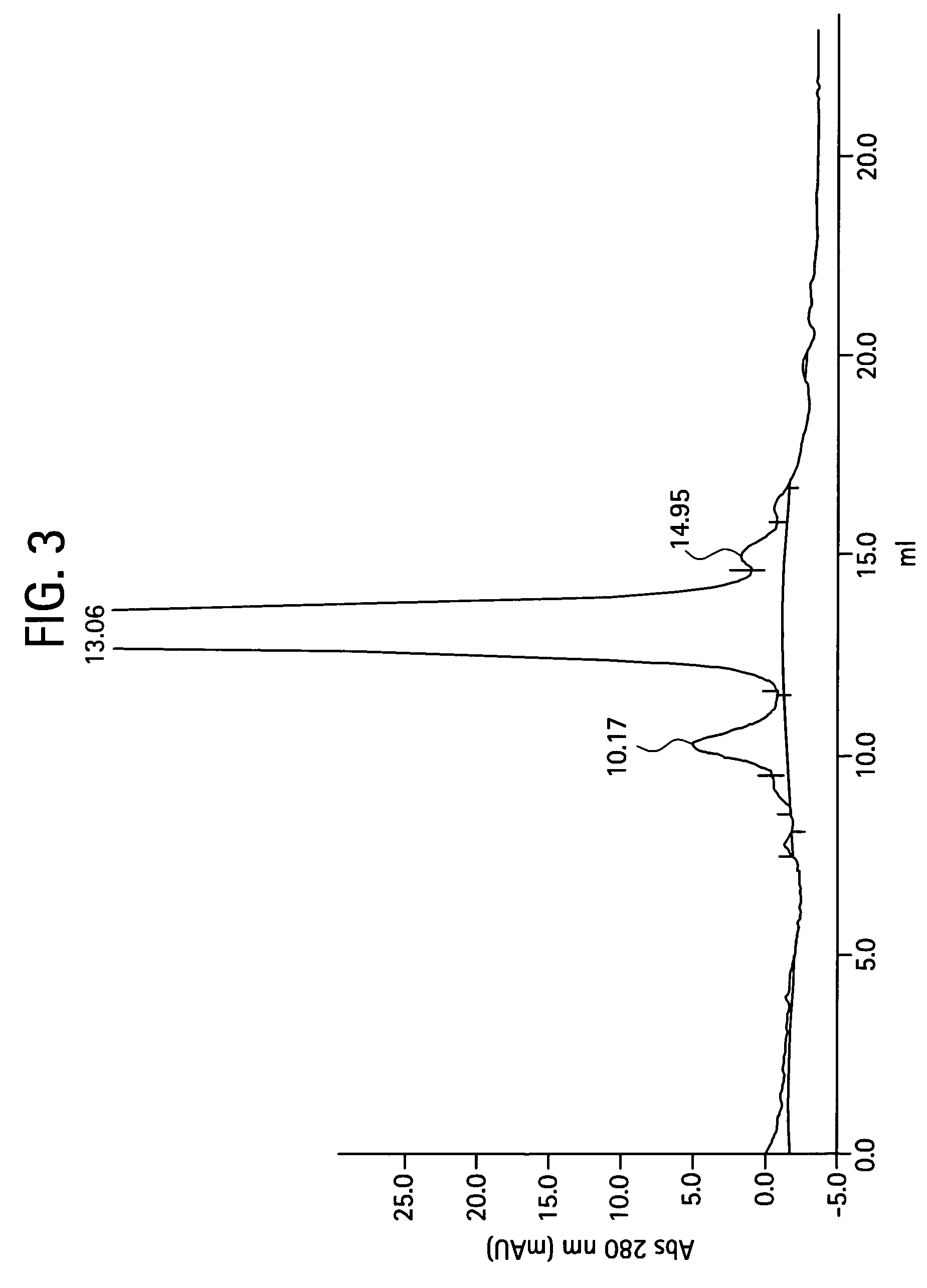

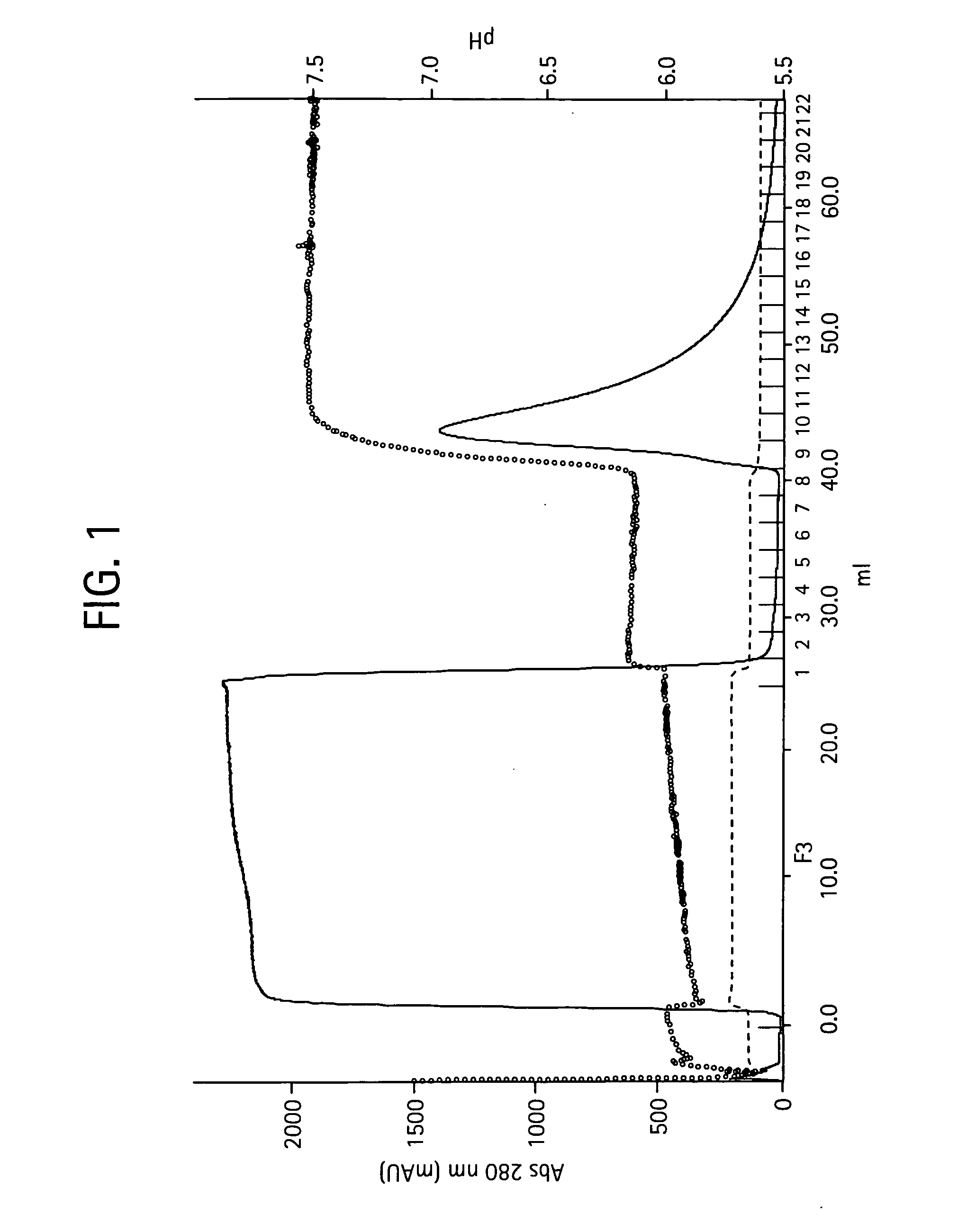

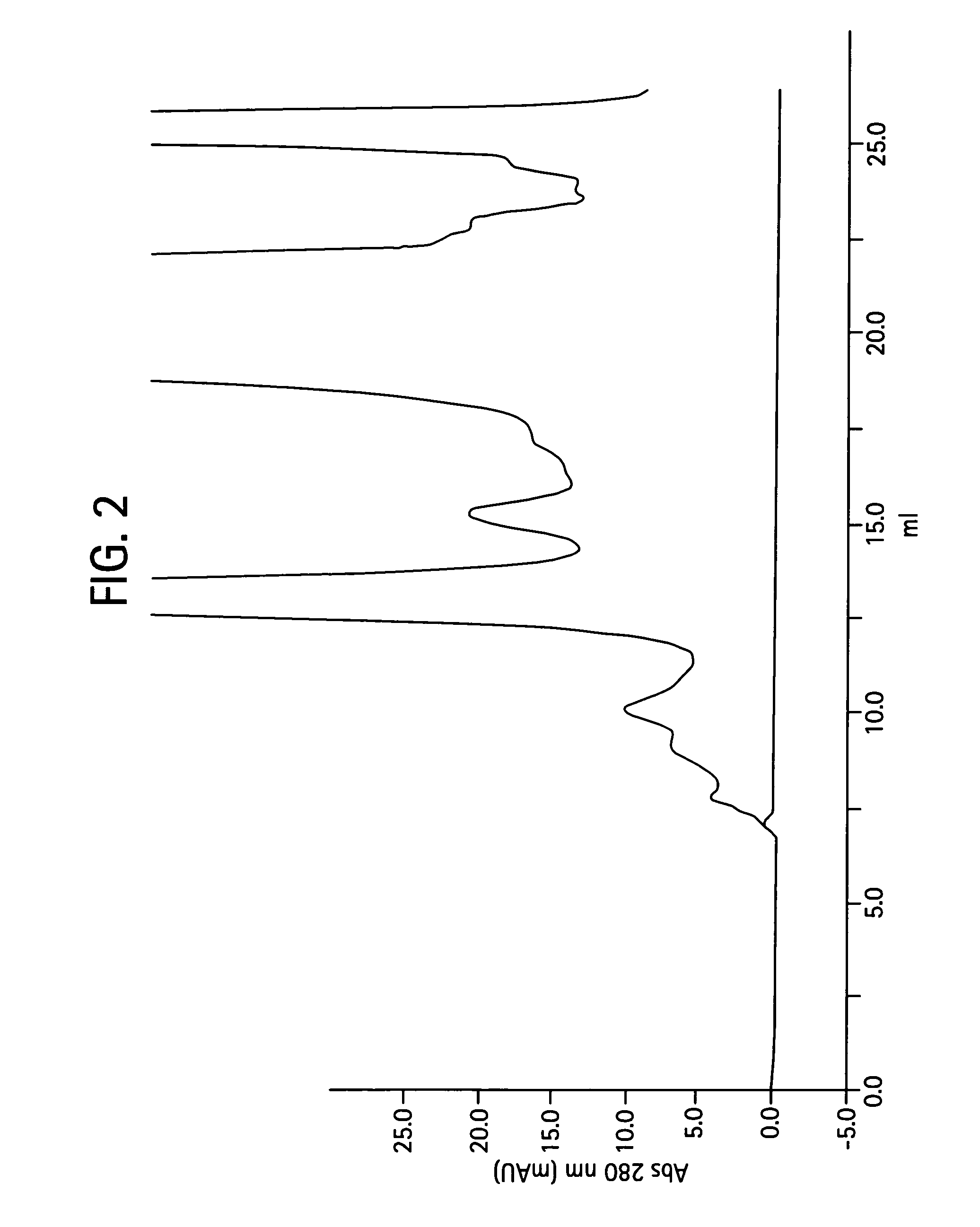

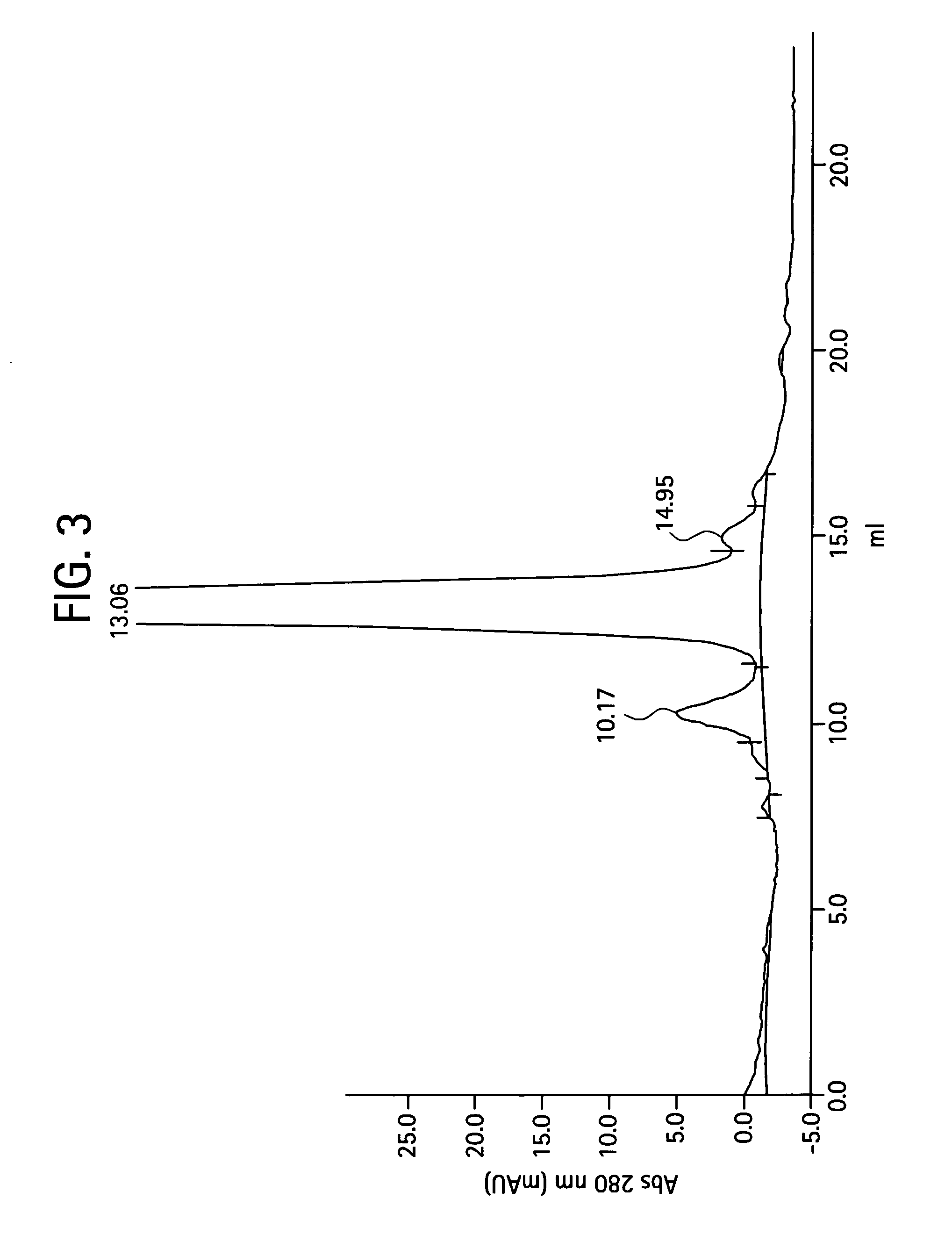

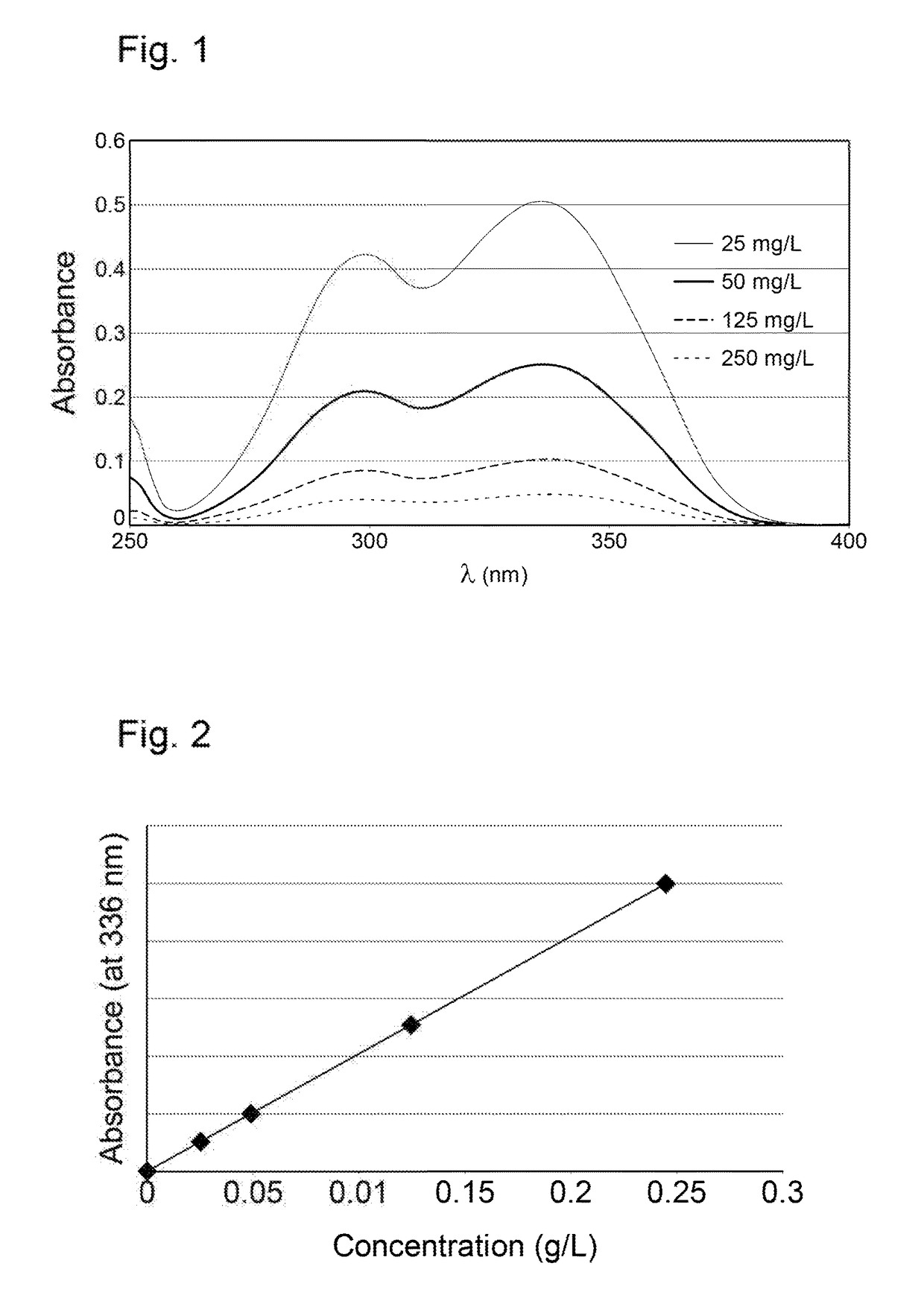

Process for the purification of antibodies

ActiveUS7750129B2Robust processingIon-exchange process apparatusIon-exchanger regenerationImpurityAntibody

The present invention relates to a process for the purification of antibodies from one or more impurities in a liquid, which process comprises contacting said liquid with a first chromatography resin comprised of a support to which multi-modal ligands have been immobilised to adsorb the antibodies to the resin, wherein each multi-modal ligand comprises at least one cation-exchanging group and at least one aromatic or heteroaromatic ring system; adding an eluent to release the antibodies from the resin; and contacting the eluate so obtained with a second chromatography resin. In one embodiment, the ring-forming atoms of the aromatic or heteroaromatic entity are selected from the group consisting of C, S and O, and the cation exchanging group is a weak cation exchanger.

Owner:CYTIVA BIOPROCESS R&D AB

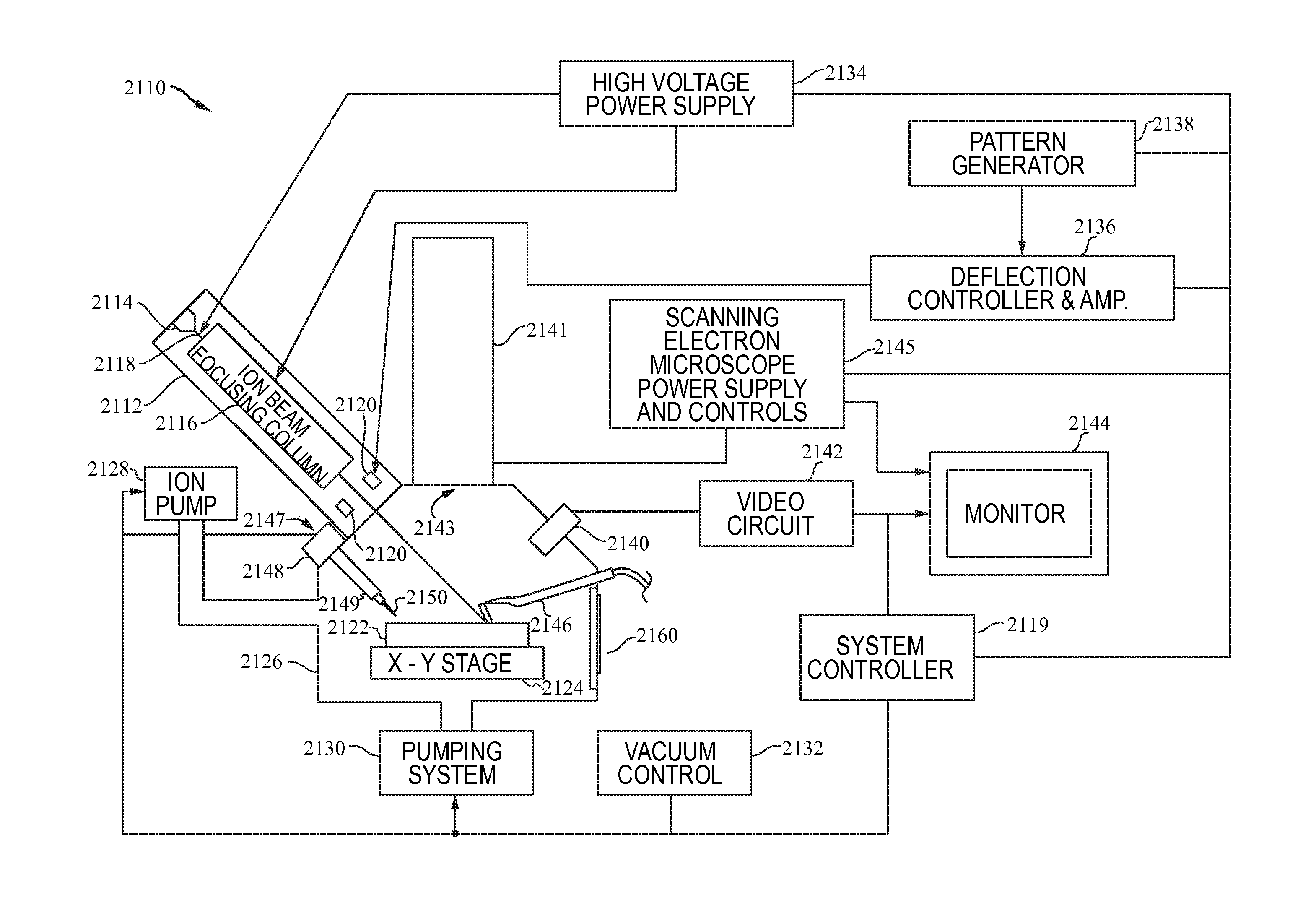

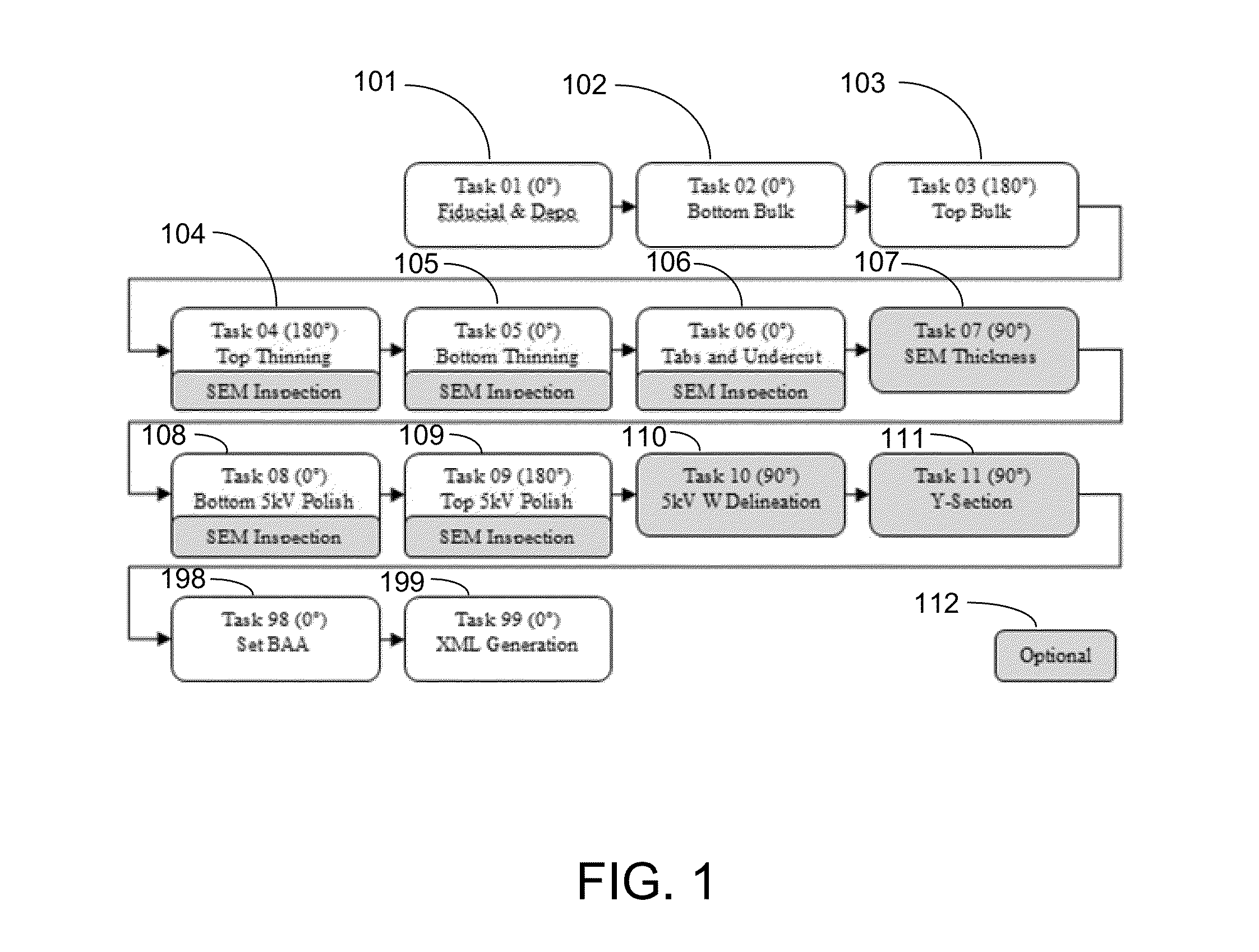

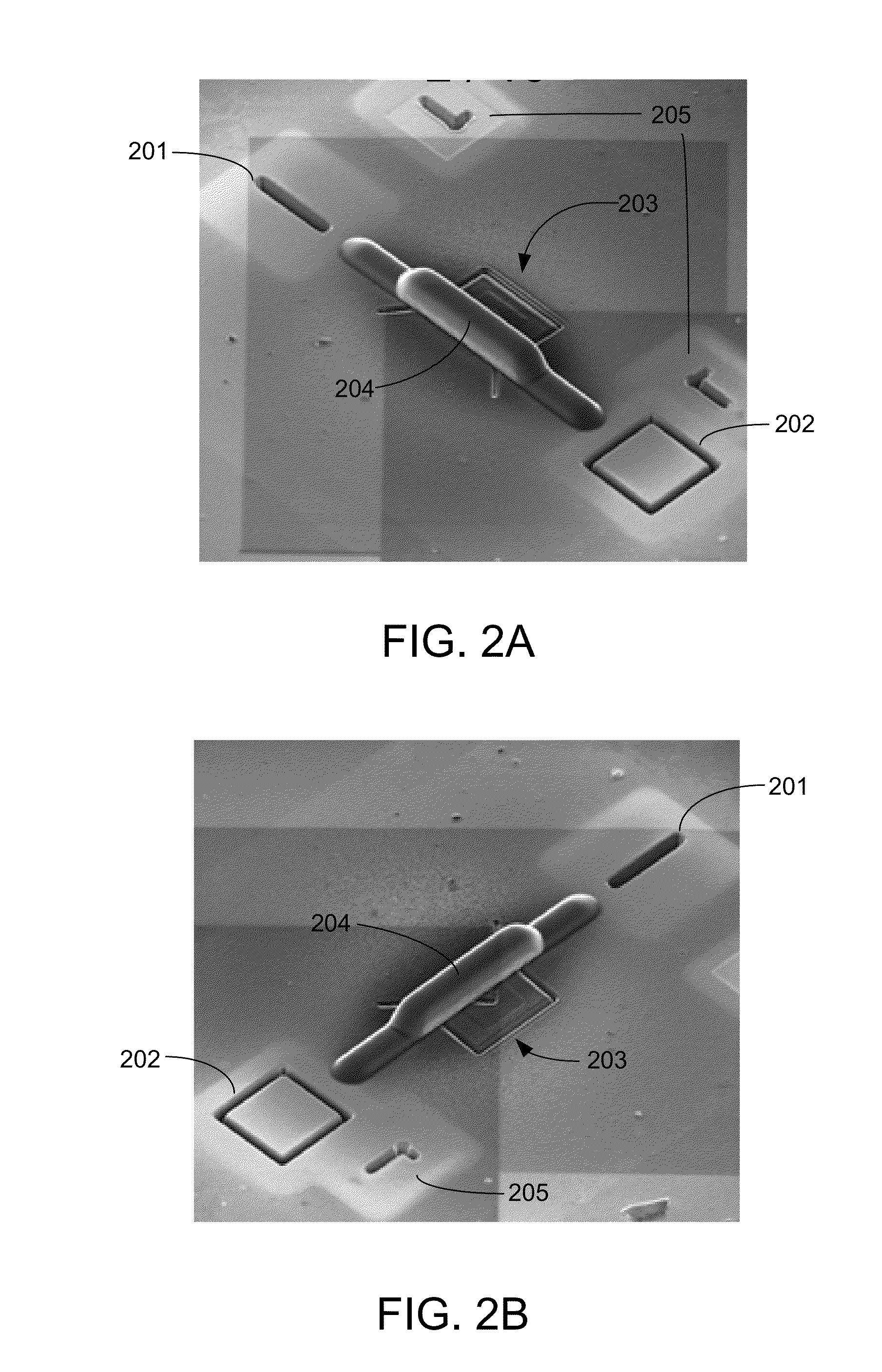

Preparation of lamellae for tem viewing

A method and apparatus for producing thin lamella for TEM observation. The steps of the method are robust and can be used to produce lamella in an automated process. In some embodiments, a protective coating have a sputtering rate matched to the sputtering rate of the work piece is deposited before forming the lamella. In some embodiments, the bottom of the lamella slopes away from the feature of interest, which keeps the lamella stable and reduces movement during thinning. In some embodiments, a fiducial is used to position the beam for the final thinning, instead of using an edge of the lamella. In some embodiments, the tabs are completed after high ion energy final thinning to keep the lamella more stable. In some embodiments, a defocused low ion energy and pattern refresh delay is used for the final cut to reduce deformation of the lamella.

Owner:FEI CO

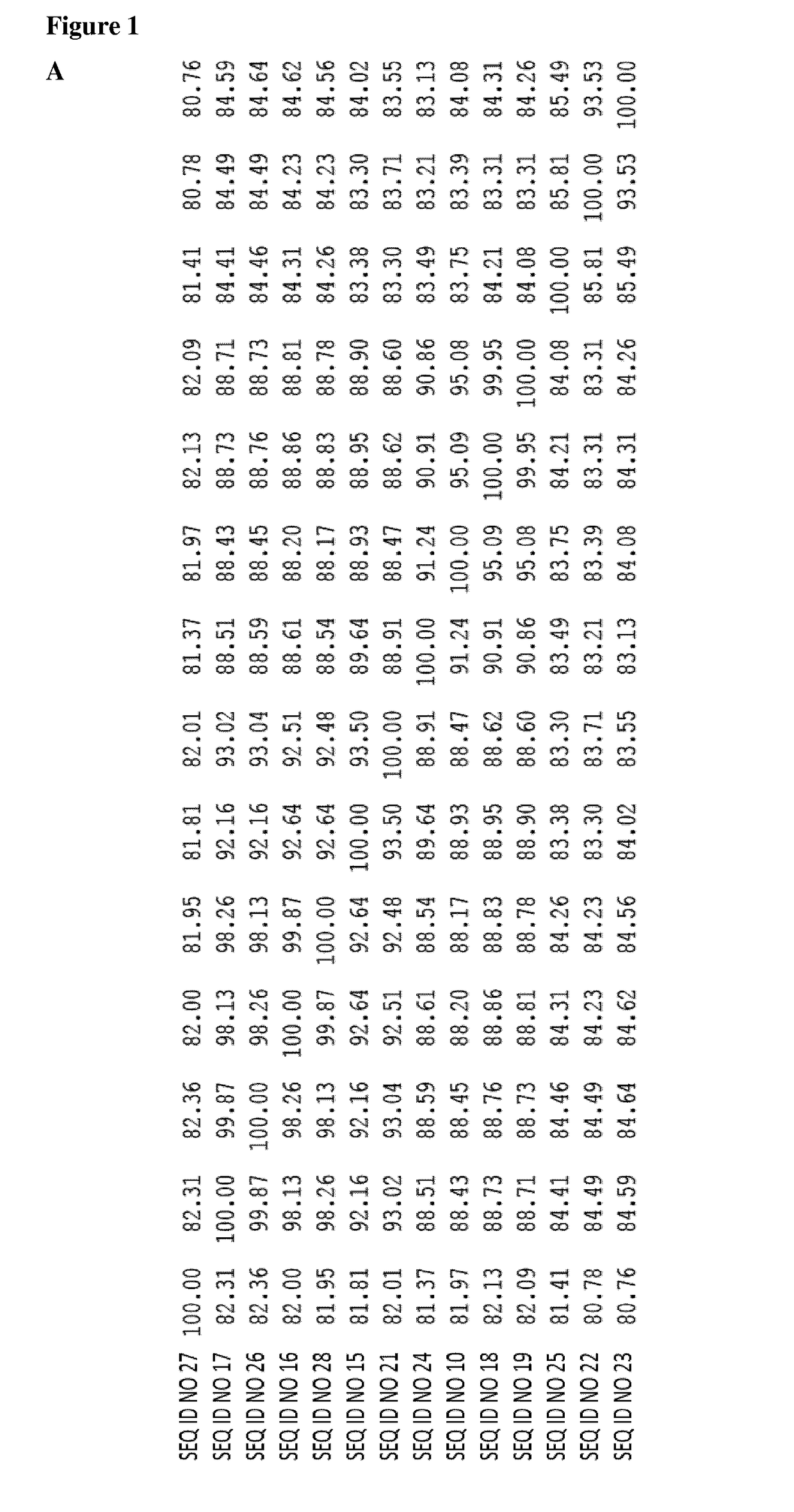

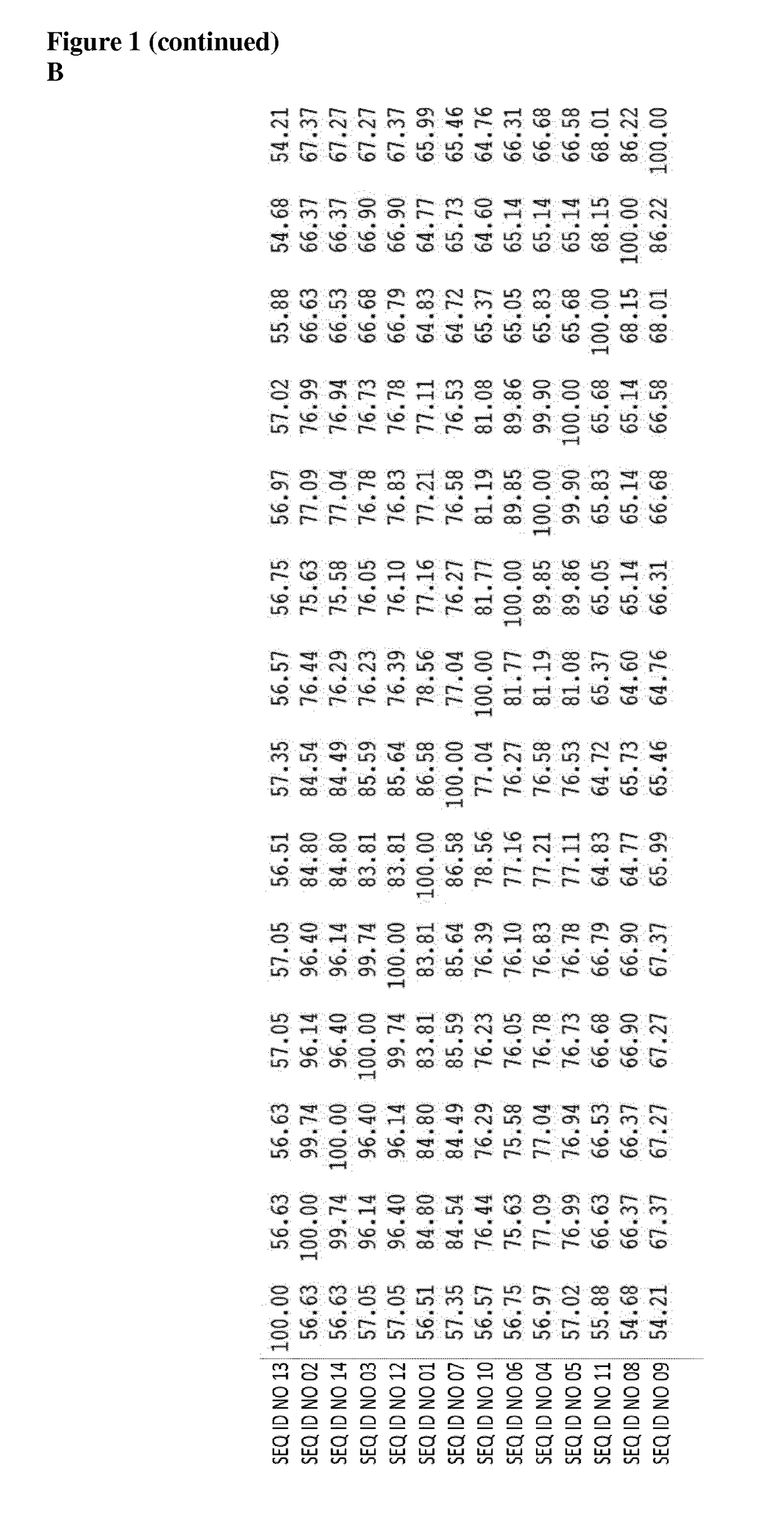

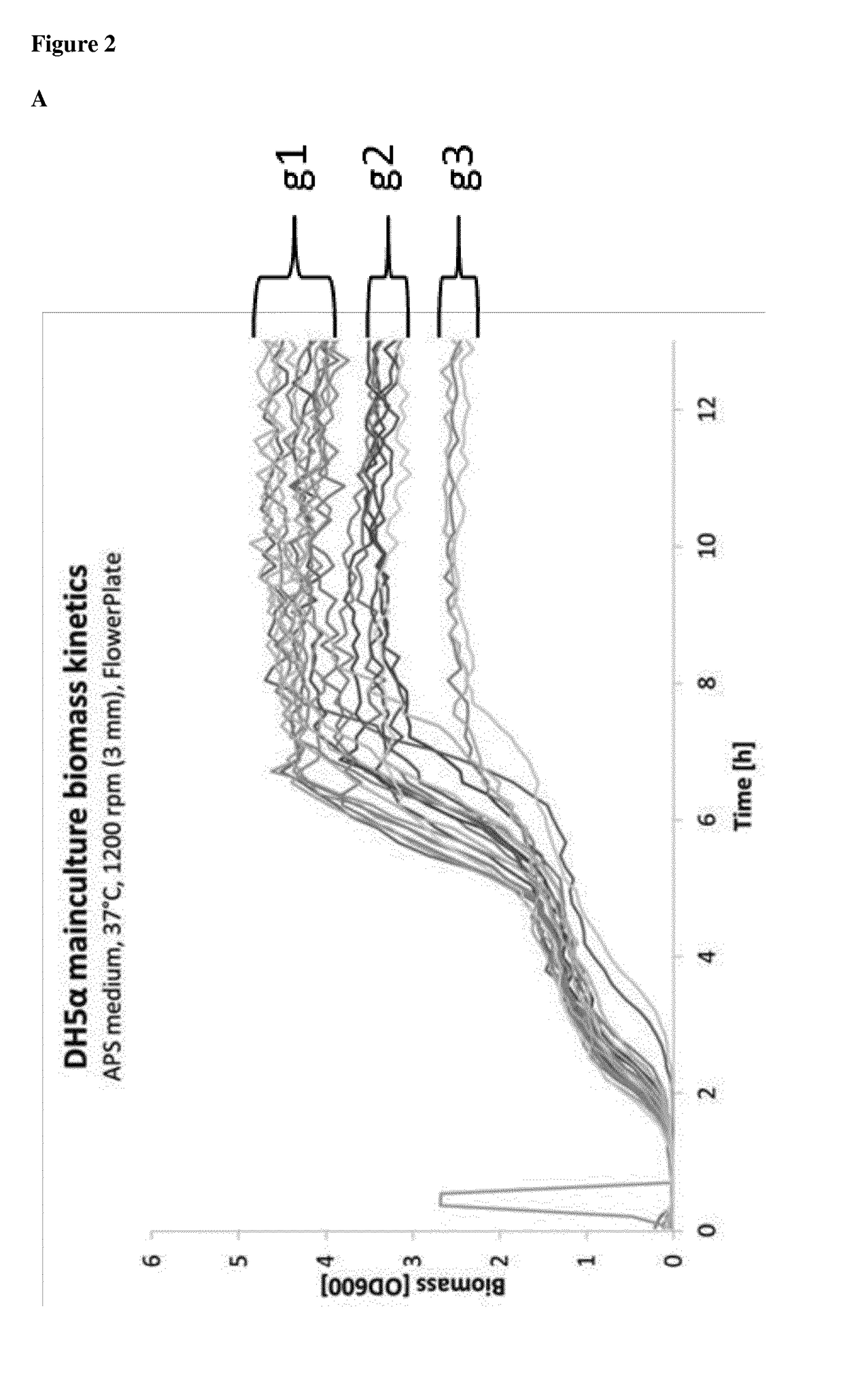

Method for producing RNA molecule compositions

ActiveUS20190083602A1Robust processingImprove resolutionSsRNA viruses negative-sensePeptide/protein ingredientsBiologyDNA

The invention relates to a method for producing a ribonucleic acid (RNA) molecule composition comprising n different RNA molecule species, the method comprising a step of RNA in vitro transcription of a mixture of m different deoxyribonucleic acid (DNA) molecule species in a single reaction vessel in parallel, i.e. simultaneously, and a step of obtaining the RNA molecule composition. Also provided is the RNA composition provided by the inventive method and a pharmaceutical composition comprising the same as well as a pharmaceutical container. Moreover, the invention provides the RNA composition and the pharmaceutical composition for use as medicament.

Owner:CUREVAC SE

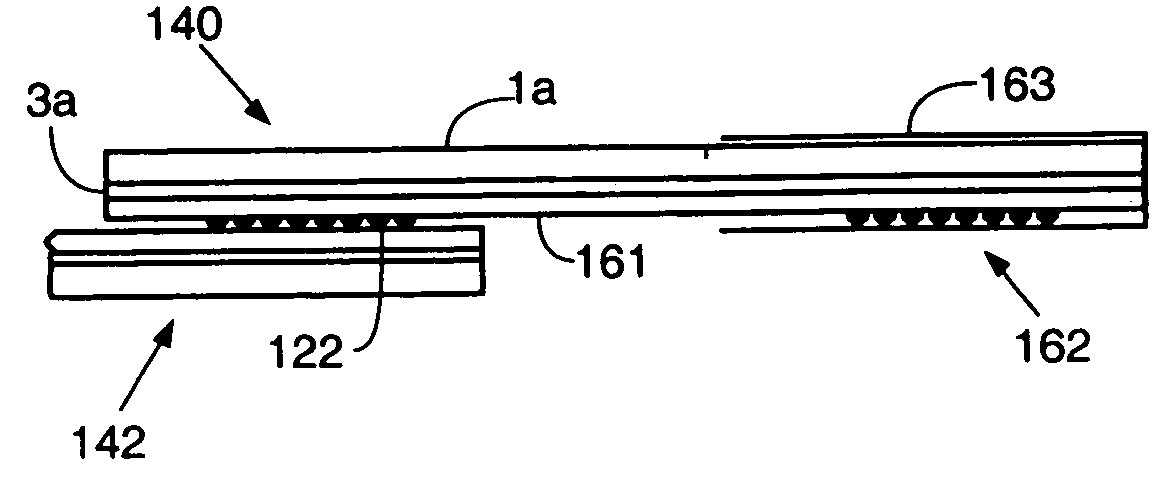

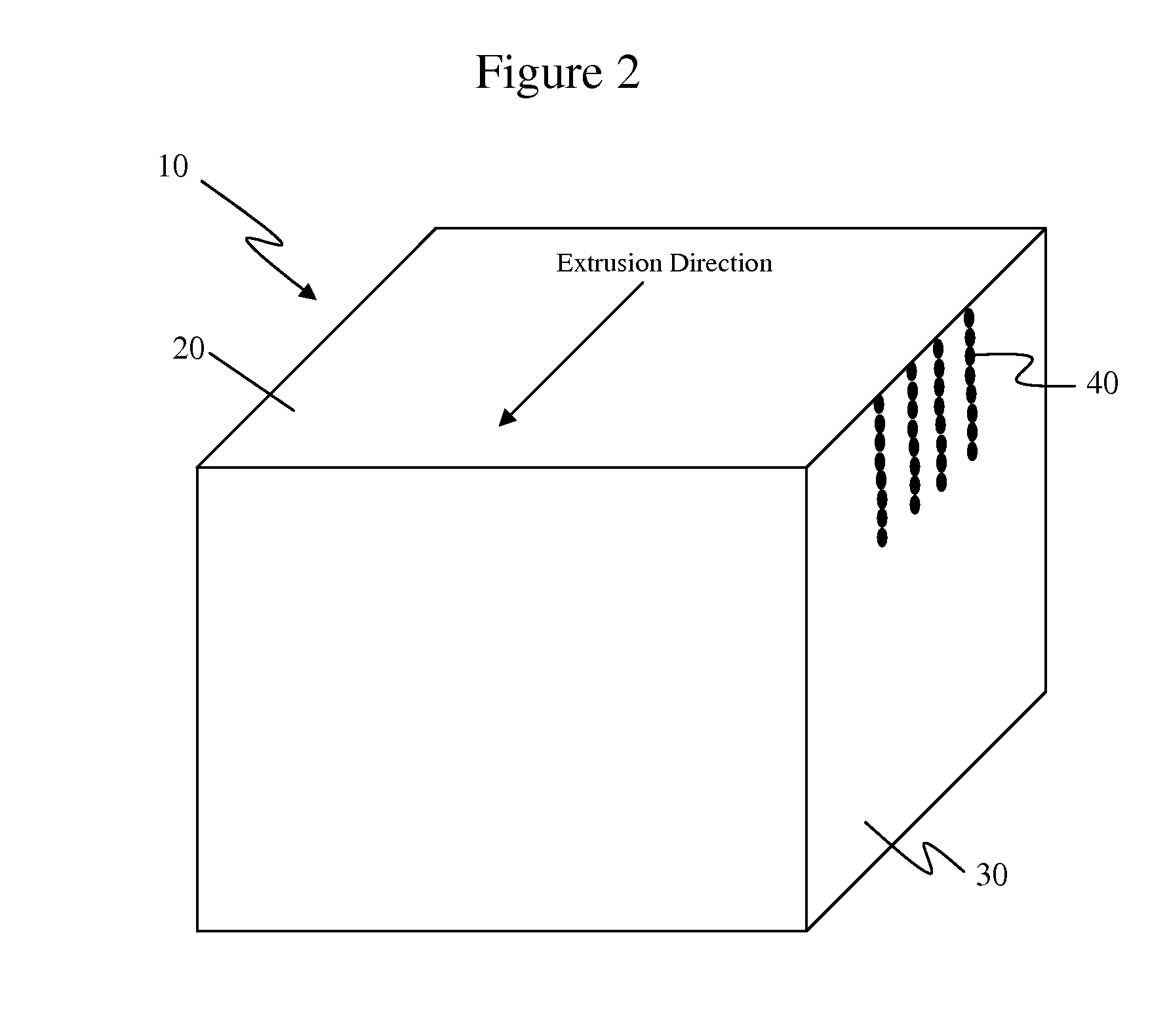

Fabrication methods for electronic system modules

InactiveUS20050140026A1Good dimensional stabilityRobust processingPrinted circuit assemblingFinal product manufactureDielectricElectromagnetic shielding

This specification describes techniques for manufacturing an electronic system module. The module includes flexible multi-layer interconnection circuits with trace widths of 5 microns or less. A glass panel manufacturing facility, similar to those employed for making liquid crystal display, LCD, panels is used to fabricate the interconnection circuits. A polymer base layer is formed on a glass carrier with an intermediate release layer. Alternate layers of metal and dielectric are formed on the base layer, and patterned to create an array of multi-layer interconnection circuits on the glass panel. A thick layer of polymer is deposited on the interconnection circuit, and openings formed at input / output (I / O) pad locations. Solder paste is deposited in the openings to form wells filled with solder. After dicing the glass carrier to form separated interconnection circuits, IC chips are stud bumped and assembled using flip chip bonding, wherein the stud bumps on the components are inserted into corresponding wells on the interconnection circuits. The IC chips are tested and reworked to form tested circuit assemblies. Methods for connecting to testers and to other modules and electronic systems are described. Module packaging layers are provided for hermetic sealing and for electromagnetic shielding. A blade server embodiment is also described.

Owner:SK HYNIX INC

Fabrication method for electronic system modules

InactiveUS7297572B2Good dimensional stabilityLow costPrinted circuit assemblingFinal product manufactureSupercomputerElectromagnetic shielding

This specification describes techniques for manufacturing an electronic system module. The module includes flexible multi-layer interconnection circuits with trace widths as narrow as 5 microns or less. A glass panel manufacturing facility, similar to those employed for making liquid crystal display, LCD, panels is preferably used to fabricate the interconnection circuits. A multi-layer interconnection circuit is fabricated on the glass panel using a release layer. A special assembly layer is formed over the interconnection circuit comprising a thick dielectric layer with openings formed at input / output (I / O) pad locations. Solder paste is deposited in the openings using a squeegee to form wells filled with solder. IC chips are provided with gold stud bumps at I / O pad locations, and these bumps are inserted in the wells to form flip chip connections. The IC chips are tested and reworked. The same bump / well connections can be used to attach fine-pitch cables. Module packaging layers are provided for hermetic sealing and for electromagnetic shielding. A blade server or supercomputer embodiment is also described.

Owner:SK HYNIX INC

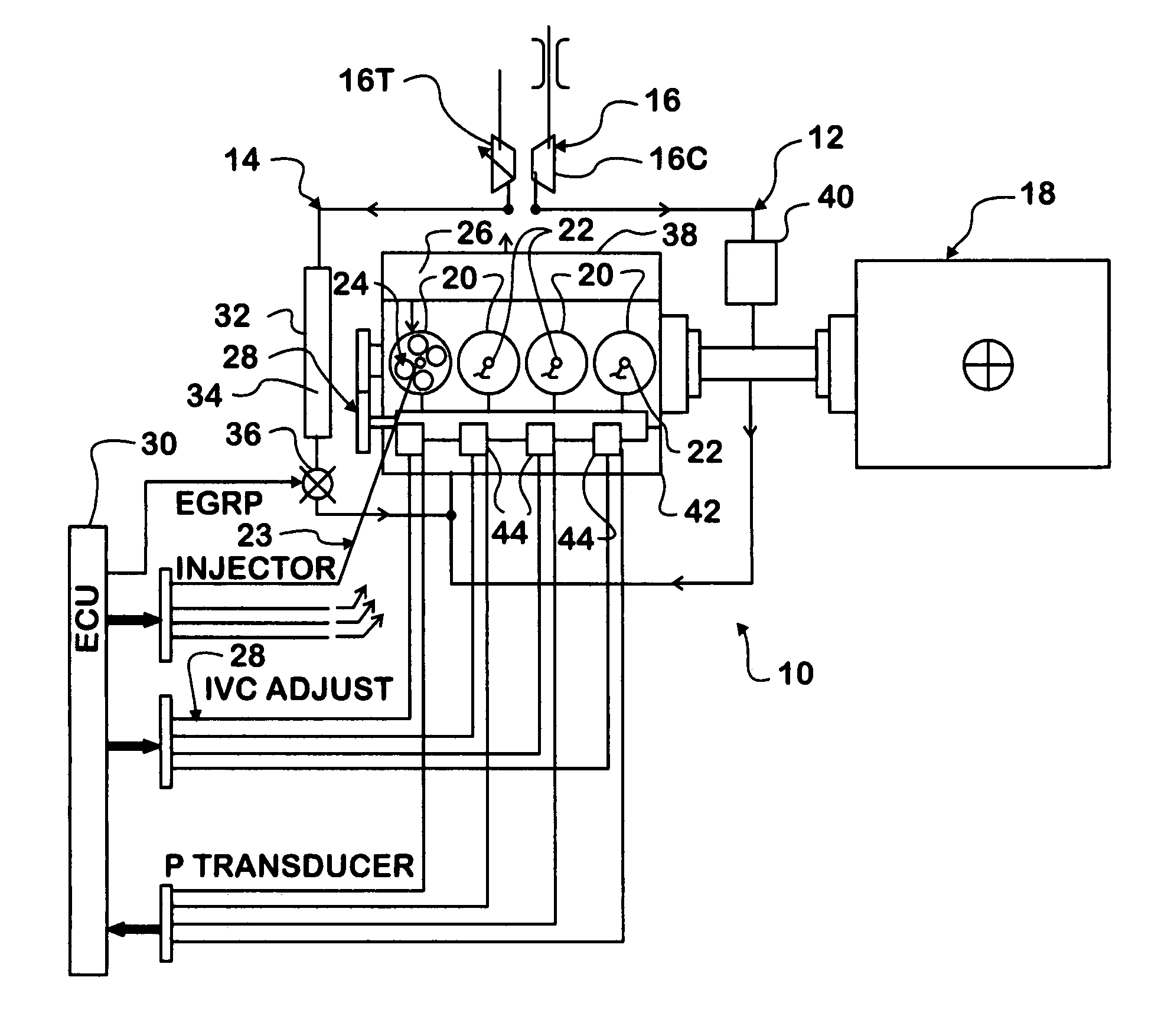

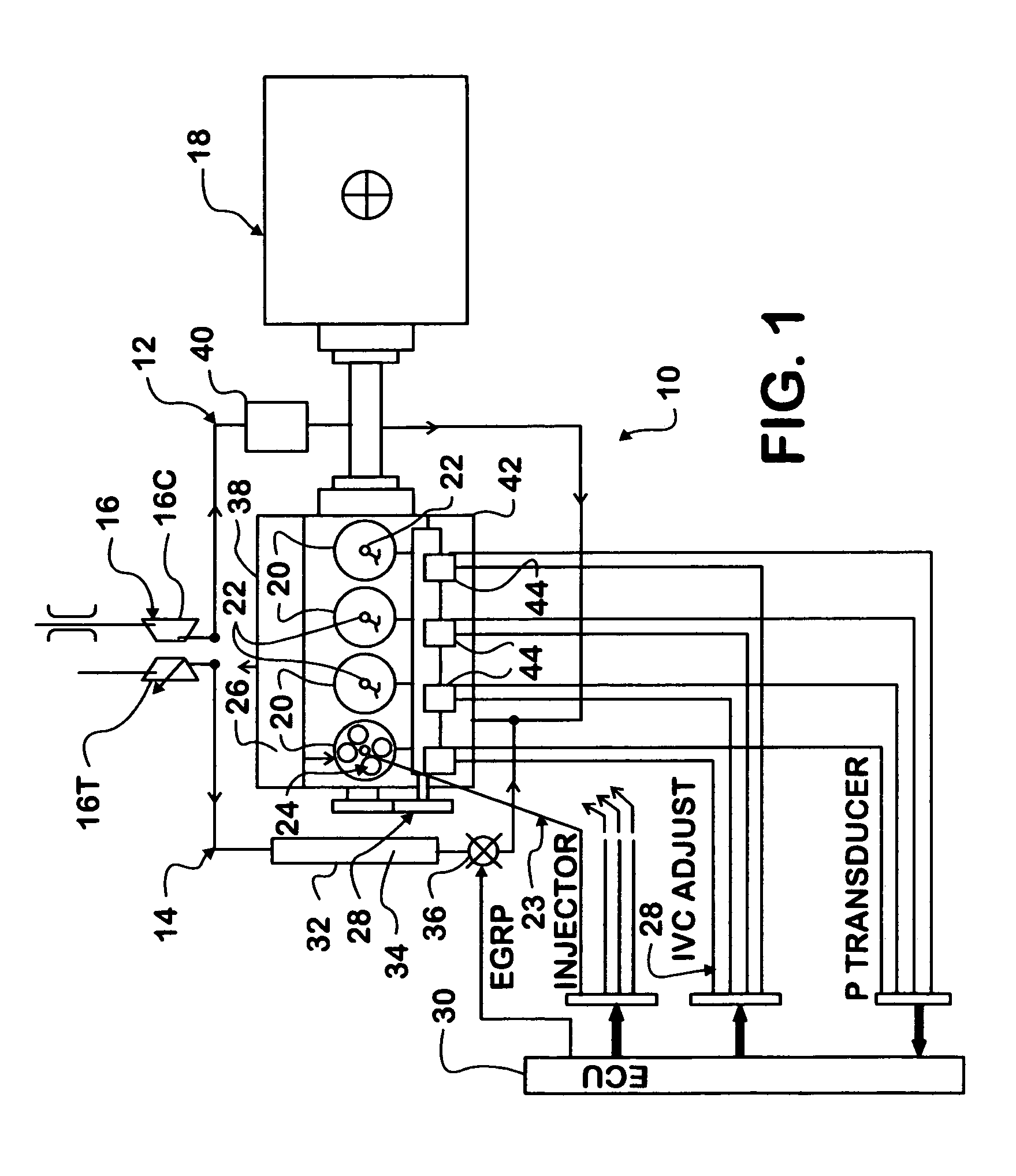

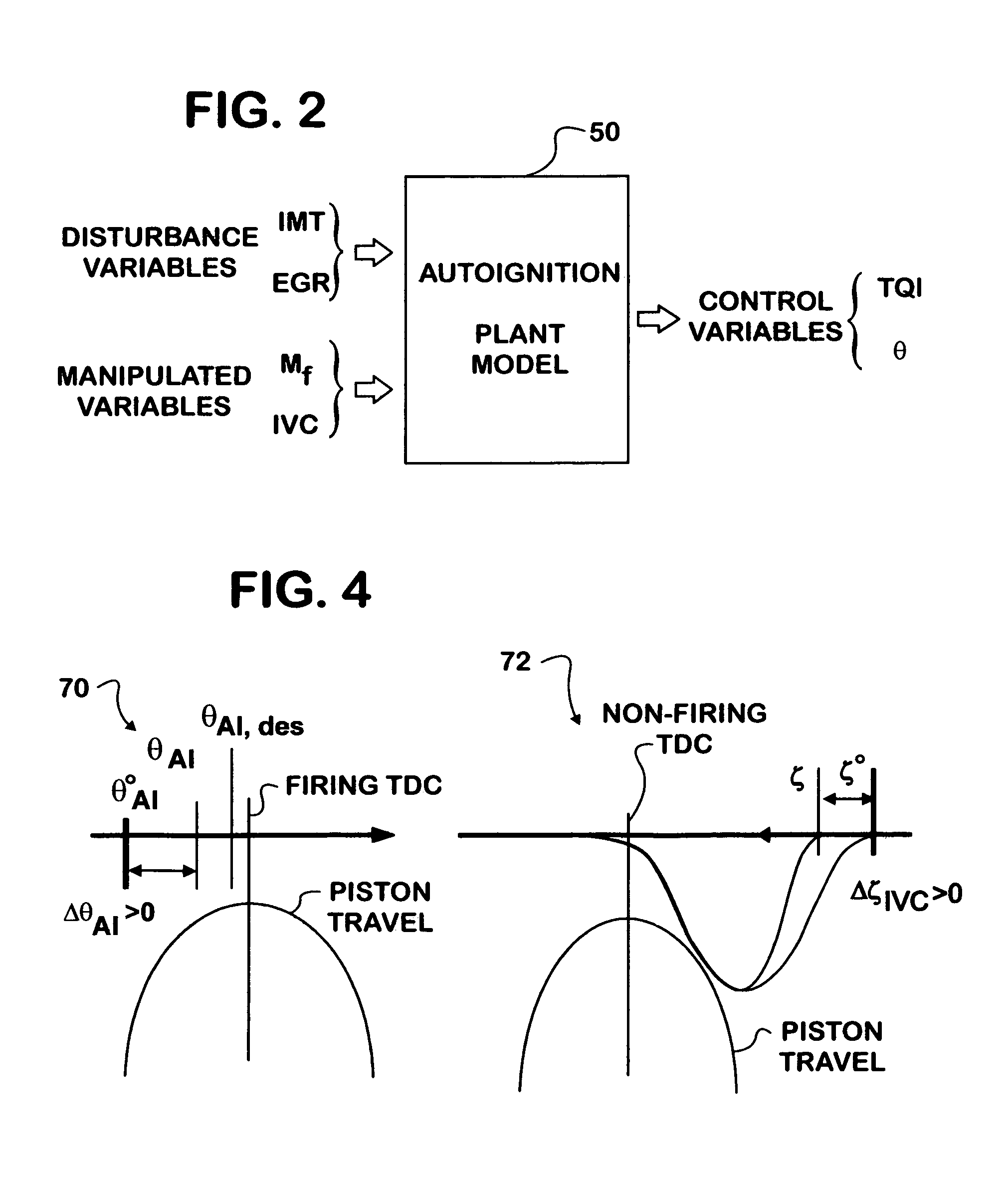

Model-based controller for auto-ignition optimization in a diesel engine

ActiveUS7184877B1Minimize changesWell mixedElectrical controlInternal combustion piston enginesDiesel combustionModel based controller

A diesel engine (10) operates by alternative diesel combustion. Formation of fuel and charge air mixtures is controlled by processing a particular set of values for certain input data according to a predictor algorithm model (50) to develop data values for predicted time of auto-ignition and resulting torque, and also develop data values for control of fuel and air that will produce the predicted time of auto-ignition and resulting torque. The data values developed by the predictor algorithm and data values for at least some of the input data are processed according to a control algorithm (52) that compensates for any disturbance introduced into any of the data values for at least some of the input data being processed by the control algorithm. This causes the systems to be controlled by compensated data values that produce predicted time of auto-ignition and resulting torque in the presence of any such disturbance.

Owner:INT ENGINE INTPROP CO LLC

Process for the purification of antibodies

ActiveUS20070167613A1Robust processingIon-exchange process apparatusIon-exchanger regenerationAntibodyCationic exchange

The present invention relates to a process for the purification of antibodies from one or more impurities in a liquid, which process comprises contacting said liquid with a first chromatography resin comprised of a support to which multi-modal ligands have been immobilised to adsorb the antibodies to the resin, wherein each multi-modal ligand comprises at least one cation-exchanging group and at least one aromatic or heteroaromatic ring system; adding an eluent to release the antibodies from the resin; and contacting the eluate so obtained with a second chromatography resin. In one embodiment, the ring-forming atoms of the aromatic or heteroaromatic entity are selected from the group consisting of C, S and O, and the cation exchanging group is a weak cation exchanger.

Owner:CYTIVA BIOPROCESS R&D AB

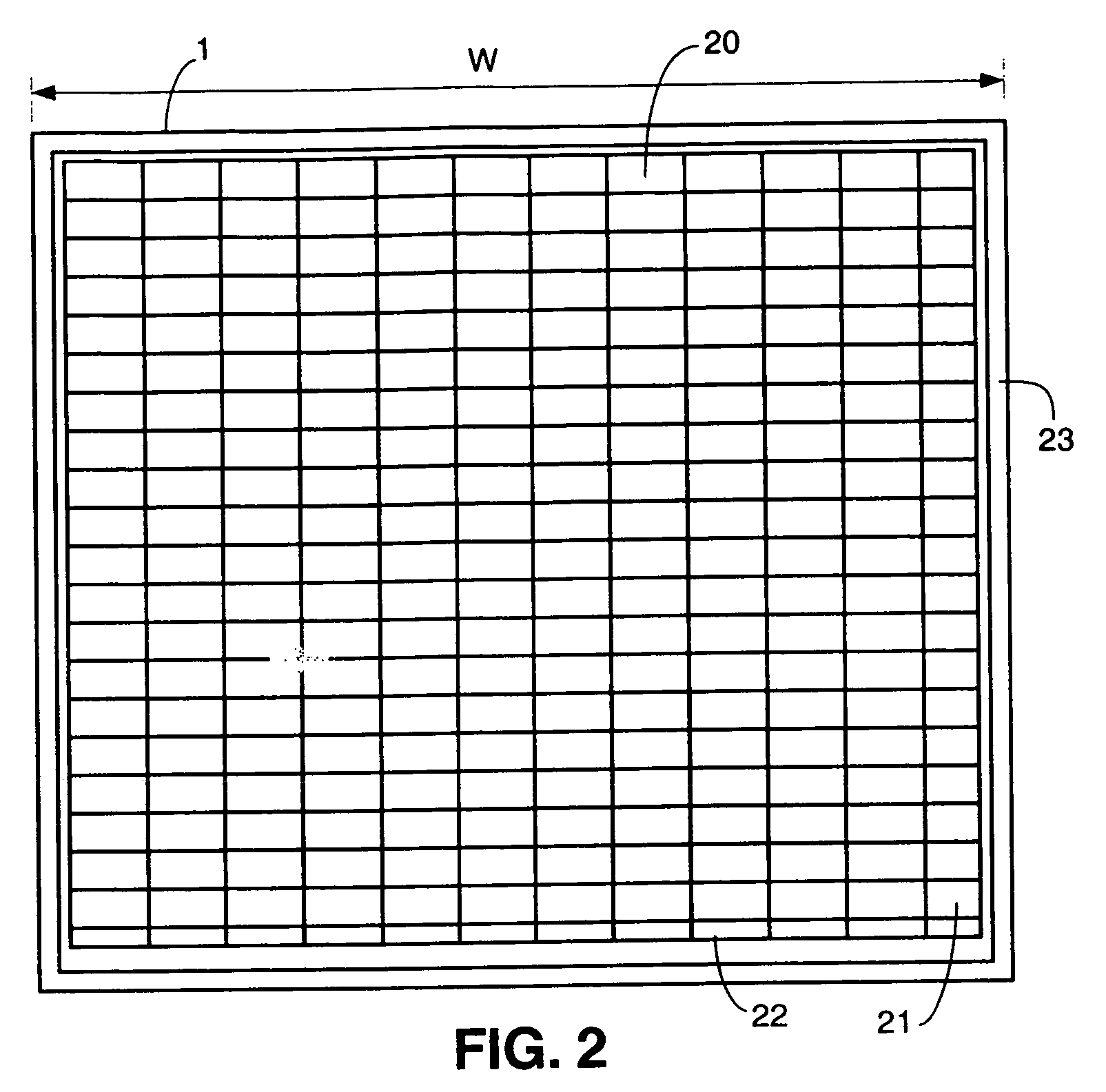

Multicolored mask process for making display circuitry

InactiveUS20090130600A1Robust processingDecorative surface effectsDuplicating/marking methodsDielectricElectrical conductor

A process for forming a pixel circuit is disclosed comprising: (a) providing a transparent support; (b) forming a multicolor mask having at least four different color patterns; (c) forming integrated electronic components of the pixel circuit having at least four layers of patterned functional material comprising a first conductor, a dielectric, a semiconductor, and a second conductor each layer of patterned functional material corresponding to the four different color patterns of the multicolor mask. The functional material is patterned using a photopattern corresponding to each color pattern.

Owner:EASTMAN KODAK CO

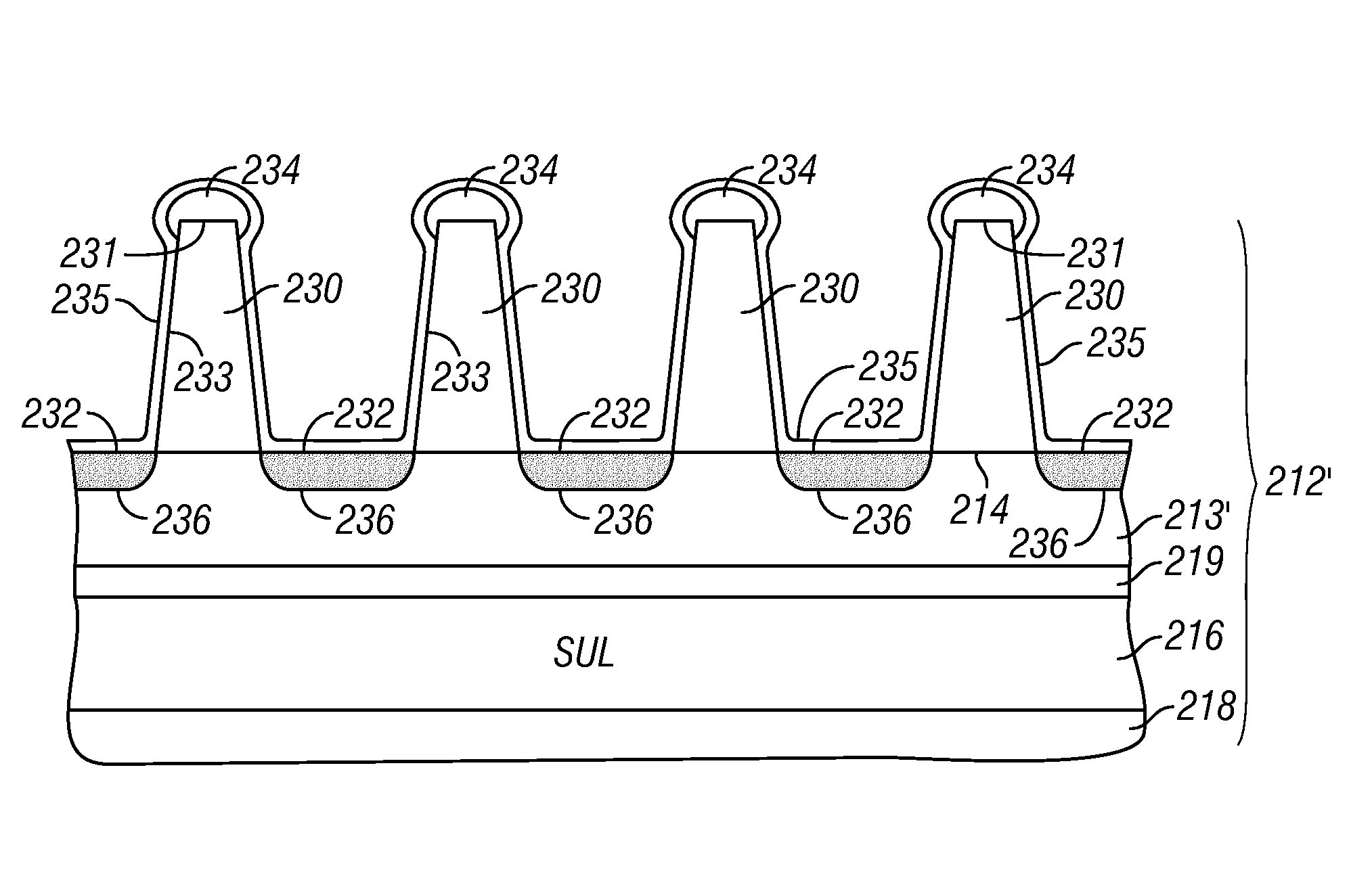

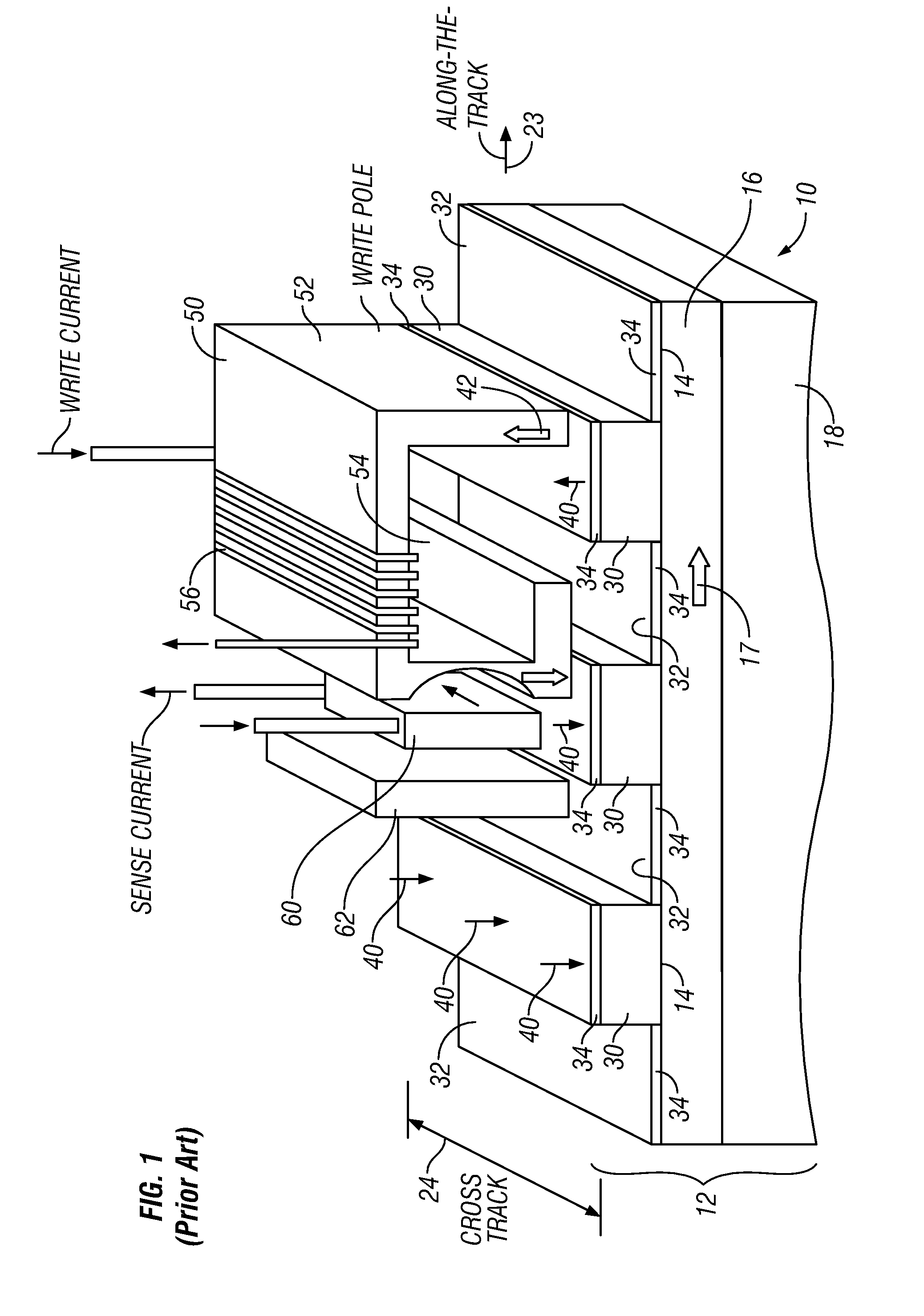

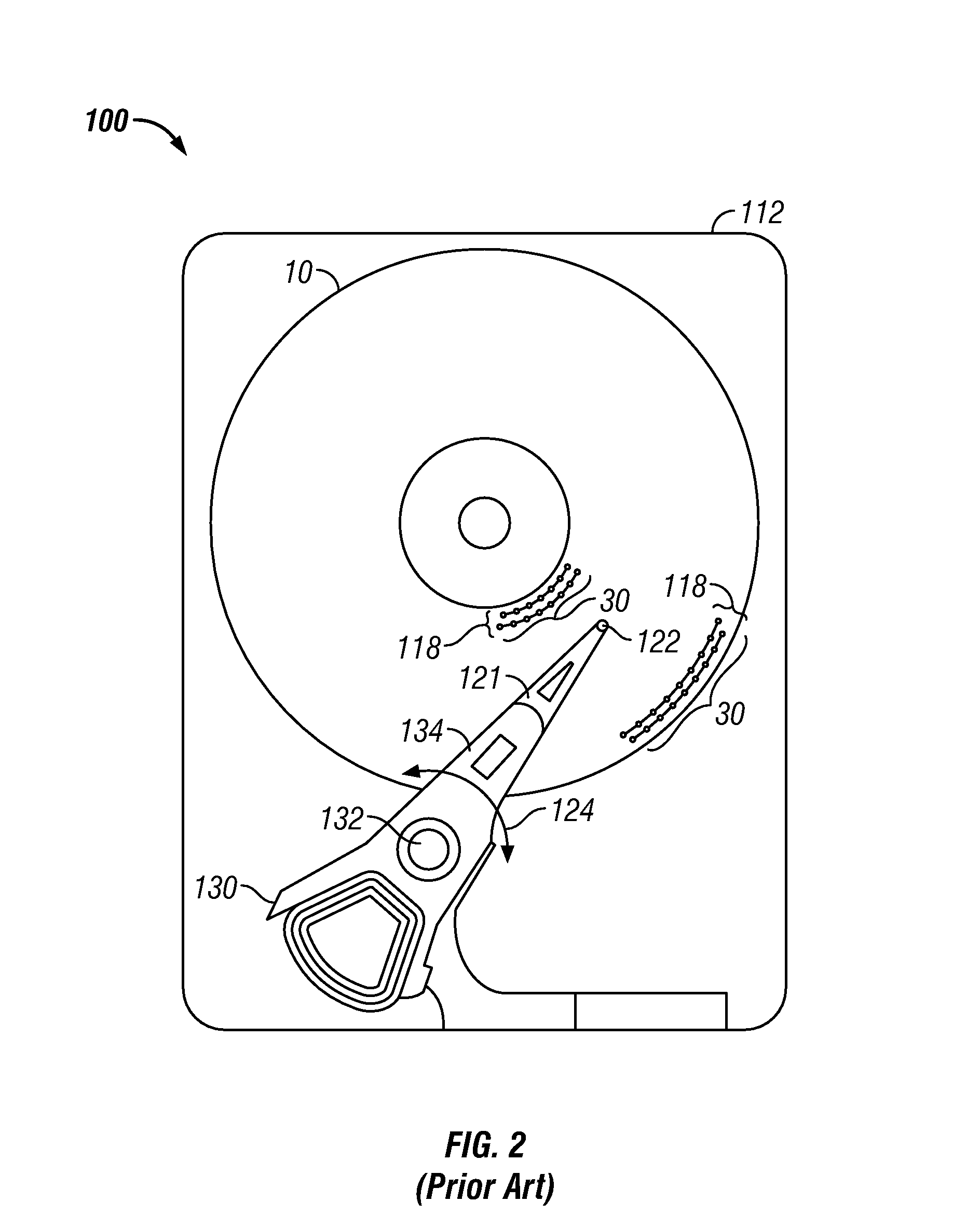

Perpendicular magnetic recording medium with patterned magnetic islands and nonmagnetic trenches and manufacturing method for suppressing surface diffusion of trench material

ActiveUS7670696B2Suppress DiffuseEliminate needRecord information storageCoatingsDiffusionNon magnetic

A patterned perpendicular magnetic recording medium of the type that has spaced-apart pillars with magnetic material on their ends and with trenches between the pillars that are nonmagnetic regions is made with a method that allows use of a pre-etched substrate. A nonmagnetic capping layer is located in the trenches above the nonmagnetic regions. The substrate has diffusion material in the trenches that when heated will diffuse into the magnetic recording layer material and chemically react with it. The pillars are formed of material that will not diffuse into the recording layer. The recording layer is formed over the entire substrate and a nonmagnetic capping layer that is not chemically reactive with the diffusion material is formed over the recording layer in the trenches. The substrate is annealed to cause the recording layer material in the trenches and the material in the substrate to diffuse into one another and chemically react to render the trenches nonmagnetic. The capping layer suppresses the diffusion of material from the substrate to the surface in the trenches and thus prevents migration of diffusion material to the recording layer material on the ends of the pillars.

Owner:WESTERN DIGITAL TECH INC

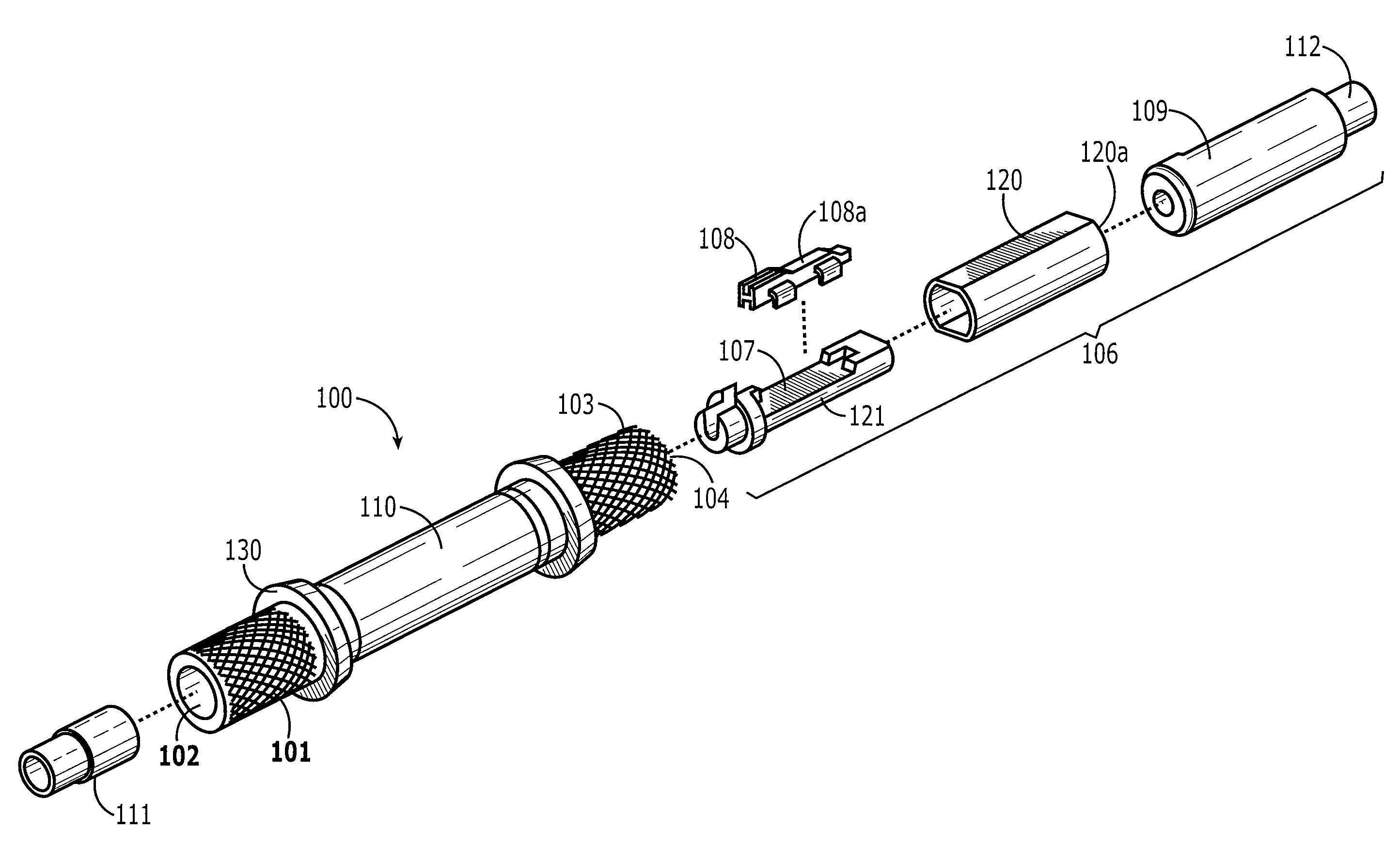

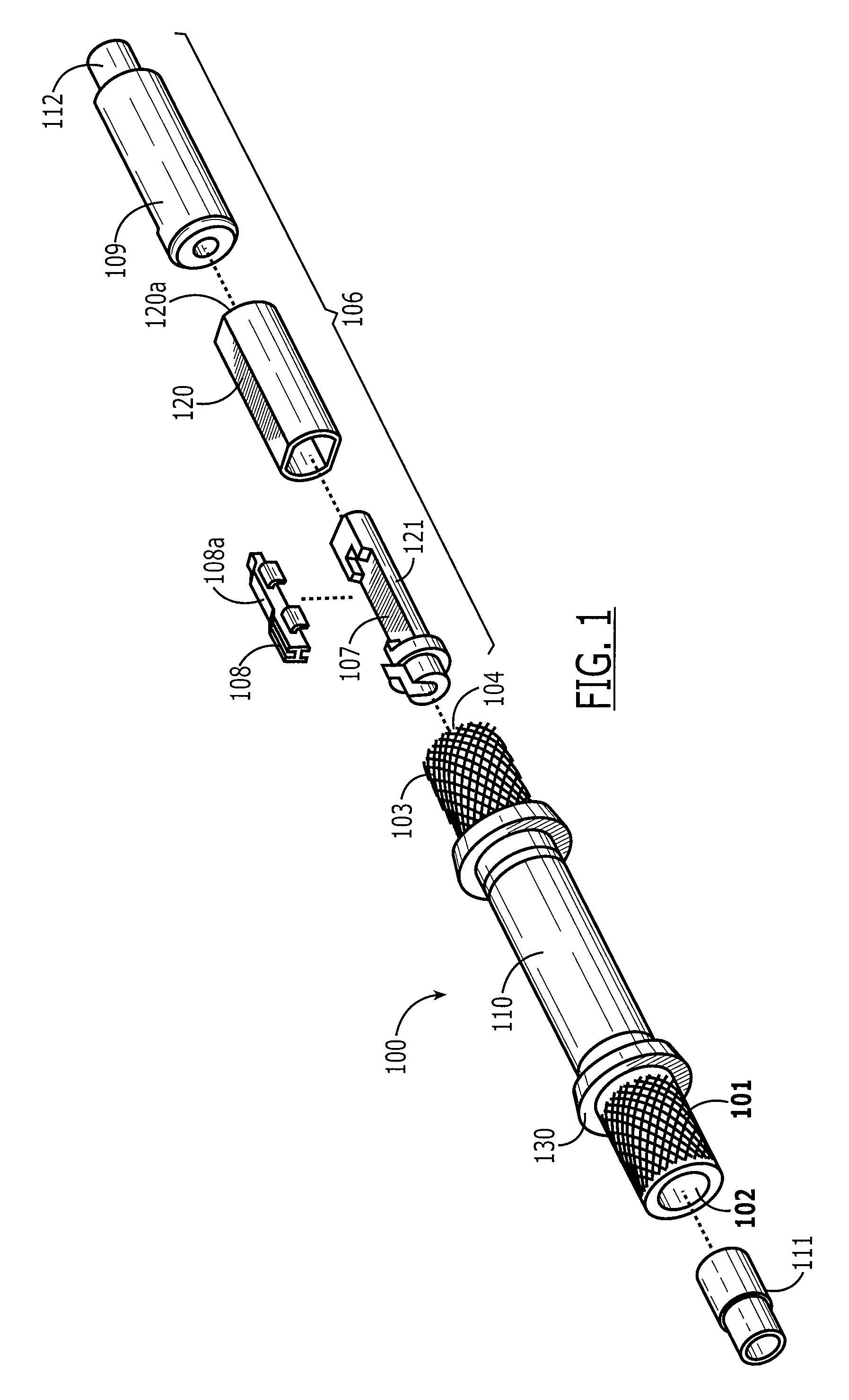

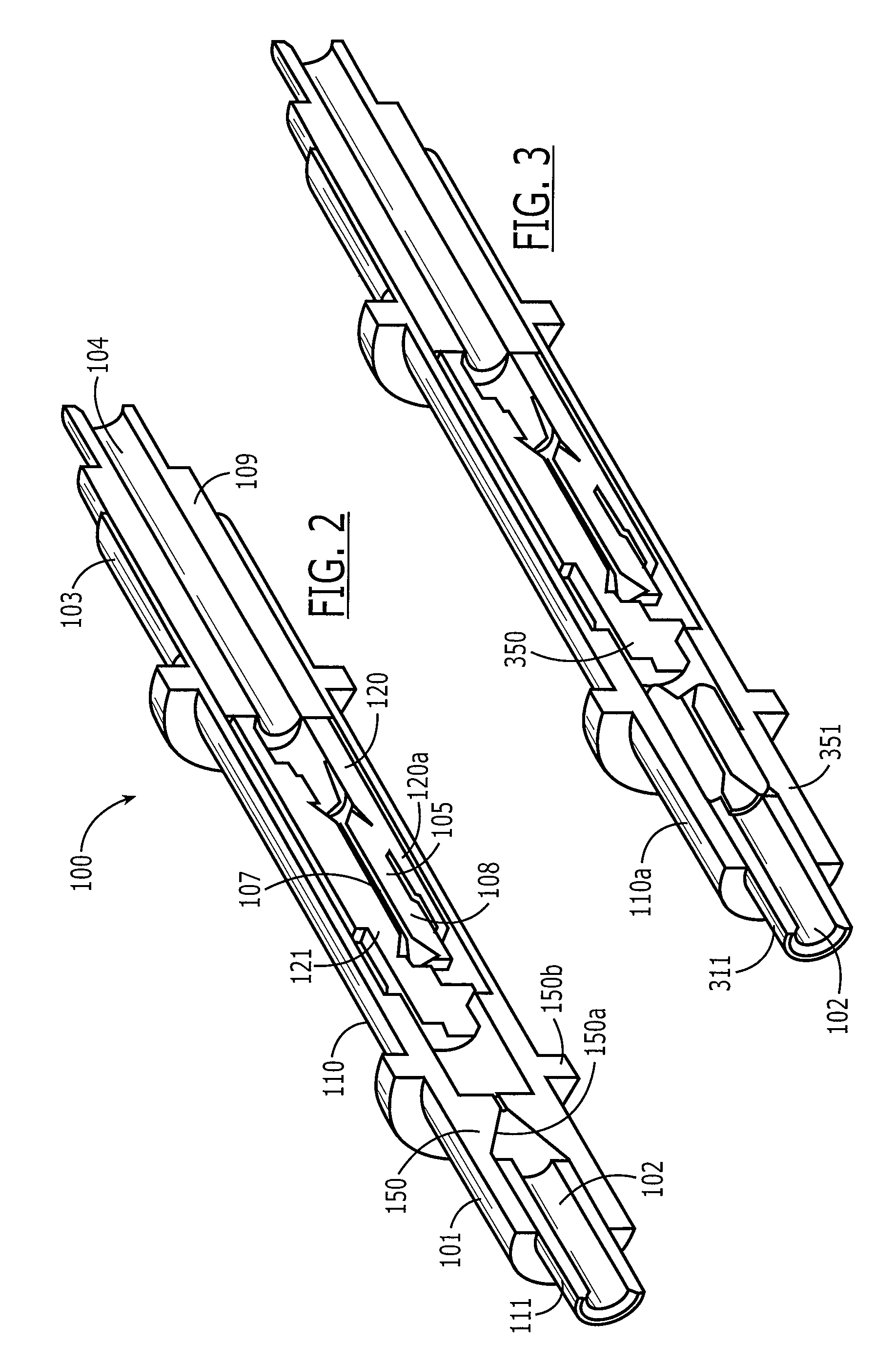

Field-installable optical splice

A splice for connecting two segments of optical fiber cable, the splice comprising: (a) an elongated housing having a first end with a first opening, a second end with a second opening, and a central cavity, the housing being essentially seamless between the first and second ends; (b) a clamping mechanism disposed in the central cavity and comprising at least a platform defining a fiber-receiving channel open to both first and second openings, a first member adjacent to the fiber-receiving channel and having at least one cam surface, and a second member having a second cam surface, the first and second cam surfaces cooperating such that relative movement of the first and second members toward the first end causes the first member to move toward the fiber-receiving channel and an actuator to cause relative movement of the first and second members toward the first end; (c) a first buffer crimp disposed at the first opening; and (d) a second buffer crimp disposed at the second opening.

Owner:TE CONNECTIVITY CORP

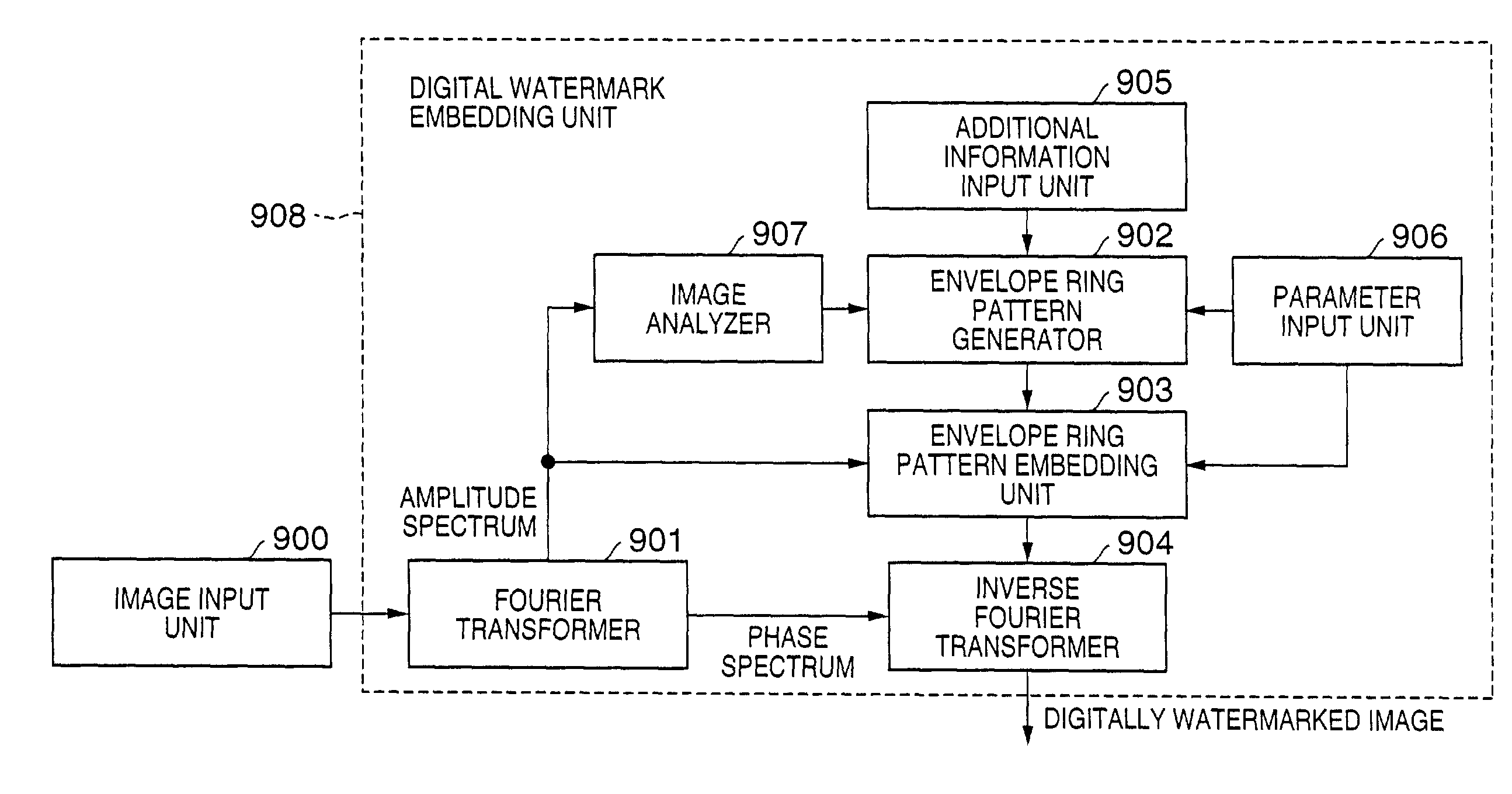

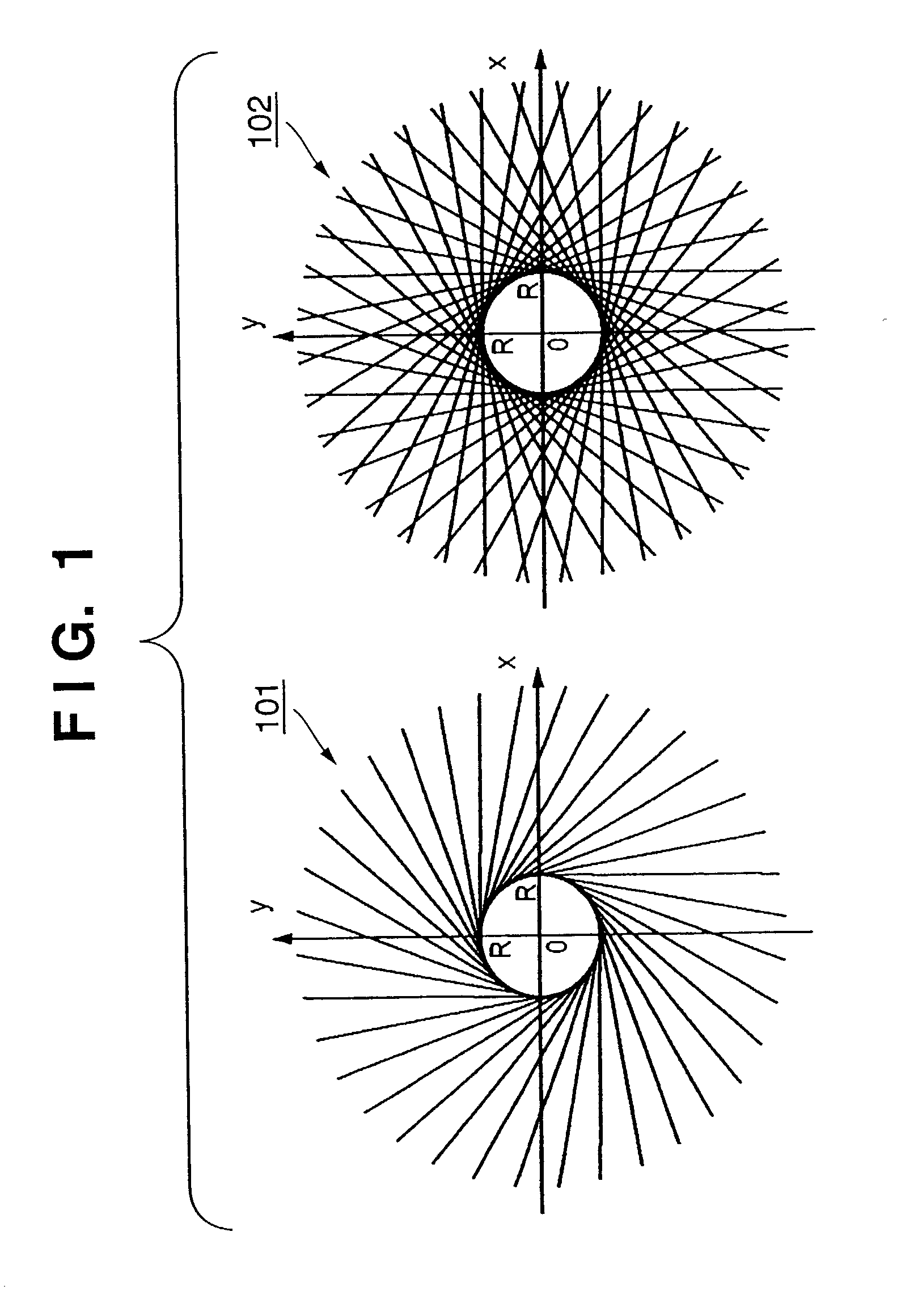

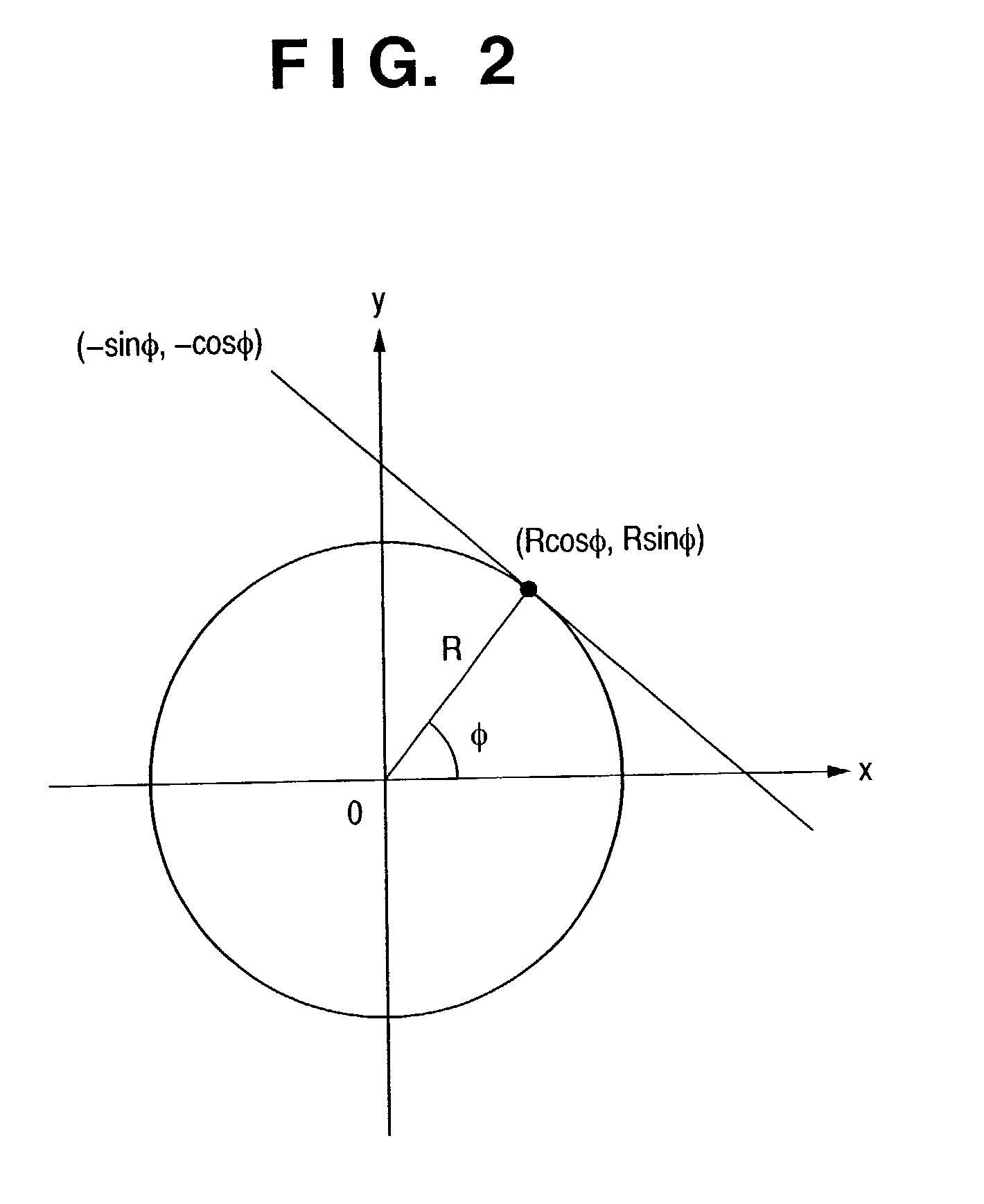

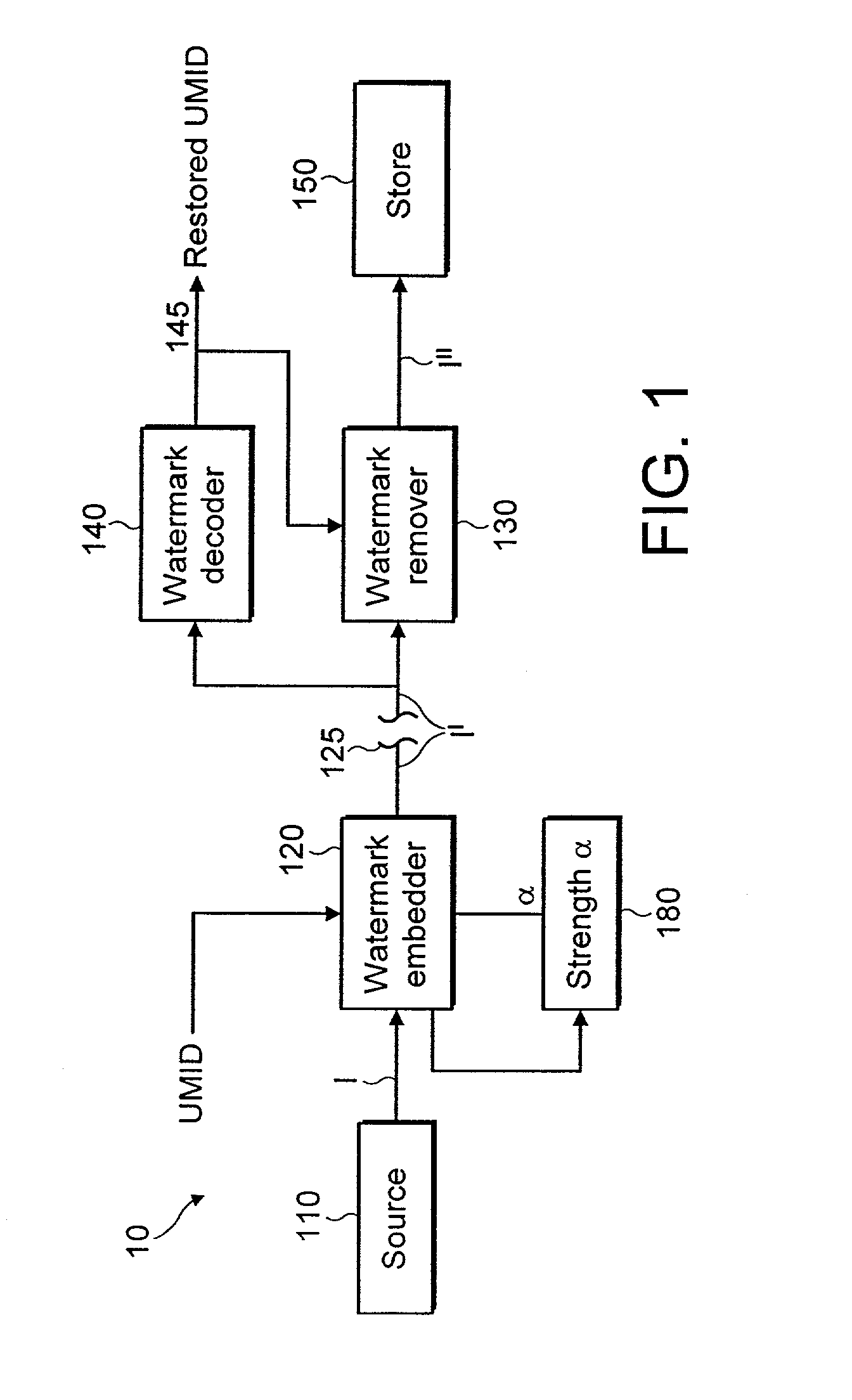

Image processing apparatus and method

InactiveUS7065237B2Accurate extractionRobust processingCharacter and pattern recognitionImage data processing detailsImaging processingTransformer

This invention provides an image processing apparatus and method, which embed a digital watermark having strong robustness against geometrical transformation / edit processes such as rotation, scaling, translation, and the like, and an image processing apparatus and method, which can accurately extract the embedded digital watermark even after the conversion / edit process such as rotation of an image or the like. A Fourier transformer (901) converts an image input from an image input unit (900) into amplitude component data, and phase component data. An envelope ring pattern generator (902) generates an embedding pattern of digital watermark information, which is expressed by a set of lines that define a circle as an envelope, on the amplitude component data. An envelope ring pattern embedding unit (903) embeds digital watermark information at predetermined positions on the line. An inverse Fourier transformer (904) computes the inverse frequency transforms of the amplitude component data embedded with the digital watermark information using the phase component data.

Owner:CANON KK

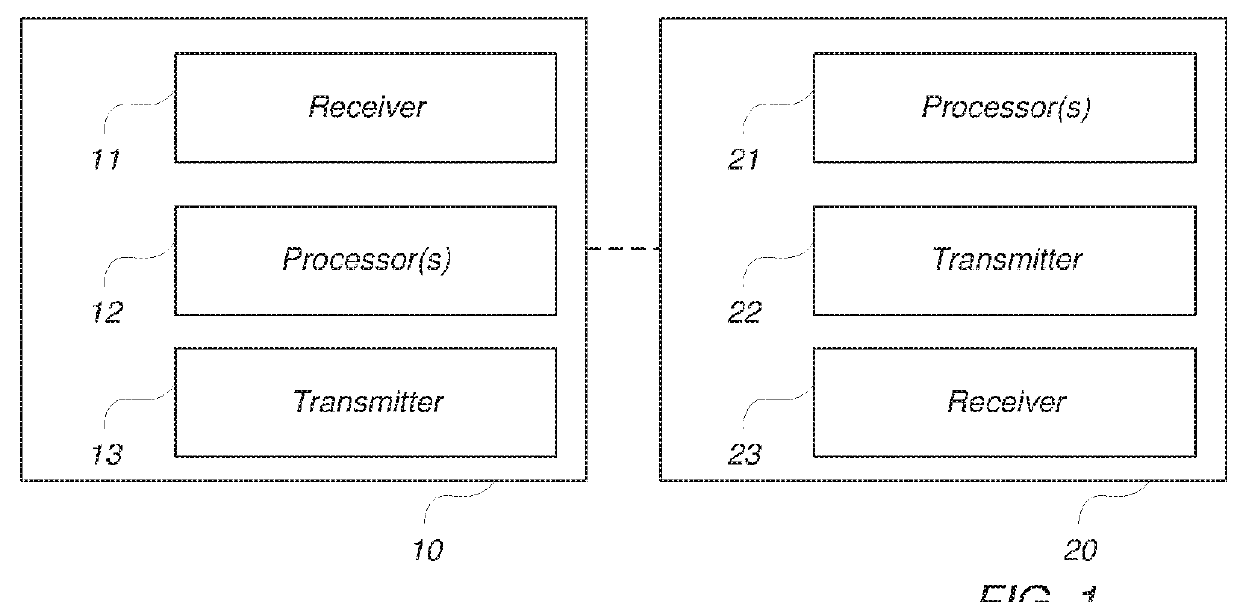

Variable Transport Format Parameters for Fast Acknowledgment Feedback Mechanism

ActiveUS20180109355A1Solve excessive overheadHigh maximum stall-free data rateNetwork traffic/resource managementError prevention/detection by transmission repeatComputer hardwareCoding block

A first communication node (110) receives a stream of code blocks from a second communication node (120) over an acknowledged connection (131.). The first communication node processes the received code blocks in accordance with at least one transport format parameter, TFP, detects errors in received code blocks, and transmits an acknowledgment in respect of groups of code blocks indicating whether at least one error was detected in the group. A first subset of the code blocks of a group are transmitted (e.g., modulated and demodulated) in accordance with a first TFP value, and a remainder of the code blocks are transmitted in accordance with a second TFP value. Because the first and second TFP values are independent, it is possible either to shorten the necessary processing time in the first communication node or, in connection with a predictive acknowledgment mechanism, to make the receiving-side processing of code blocks that do not contribute to the value of the transmitted acknowledgment more robust.

Owner:TELEFON AB LM ERICSSON (PUBL)

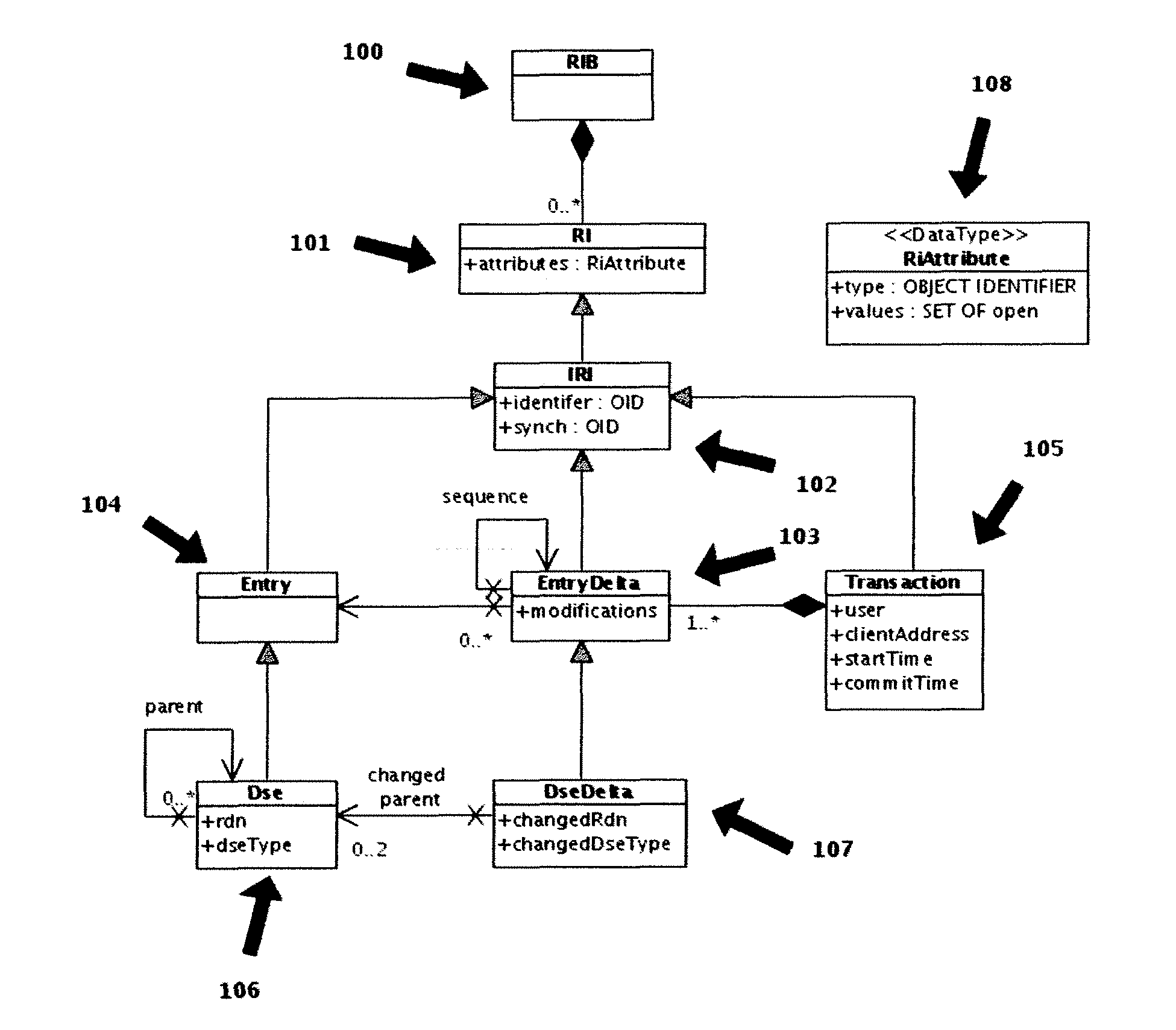

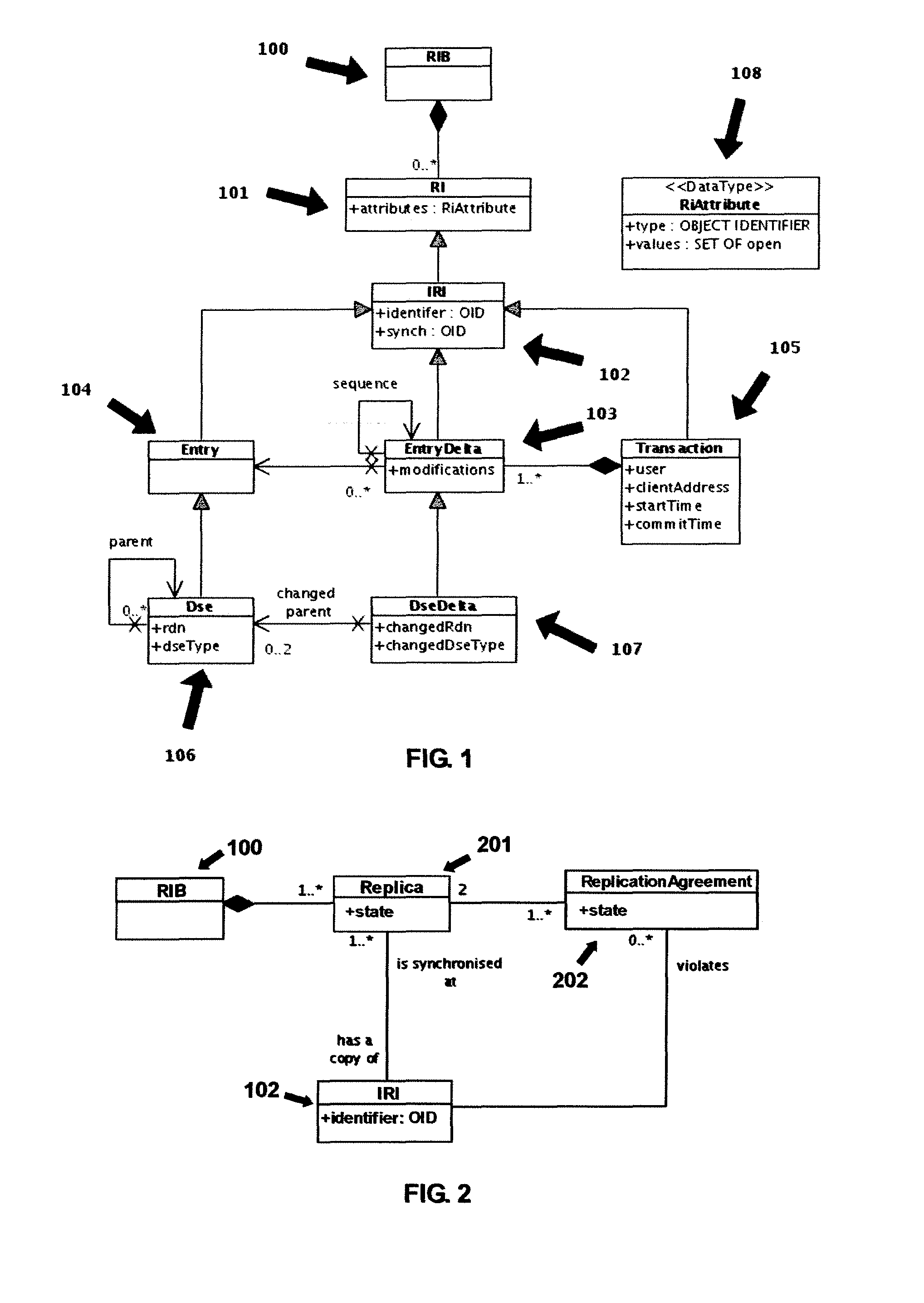

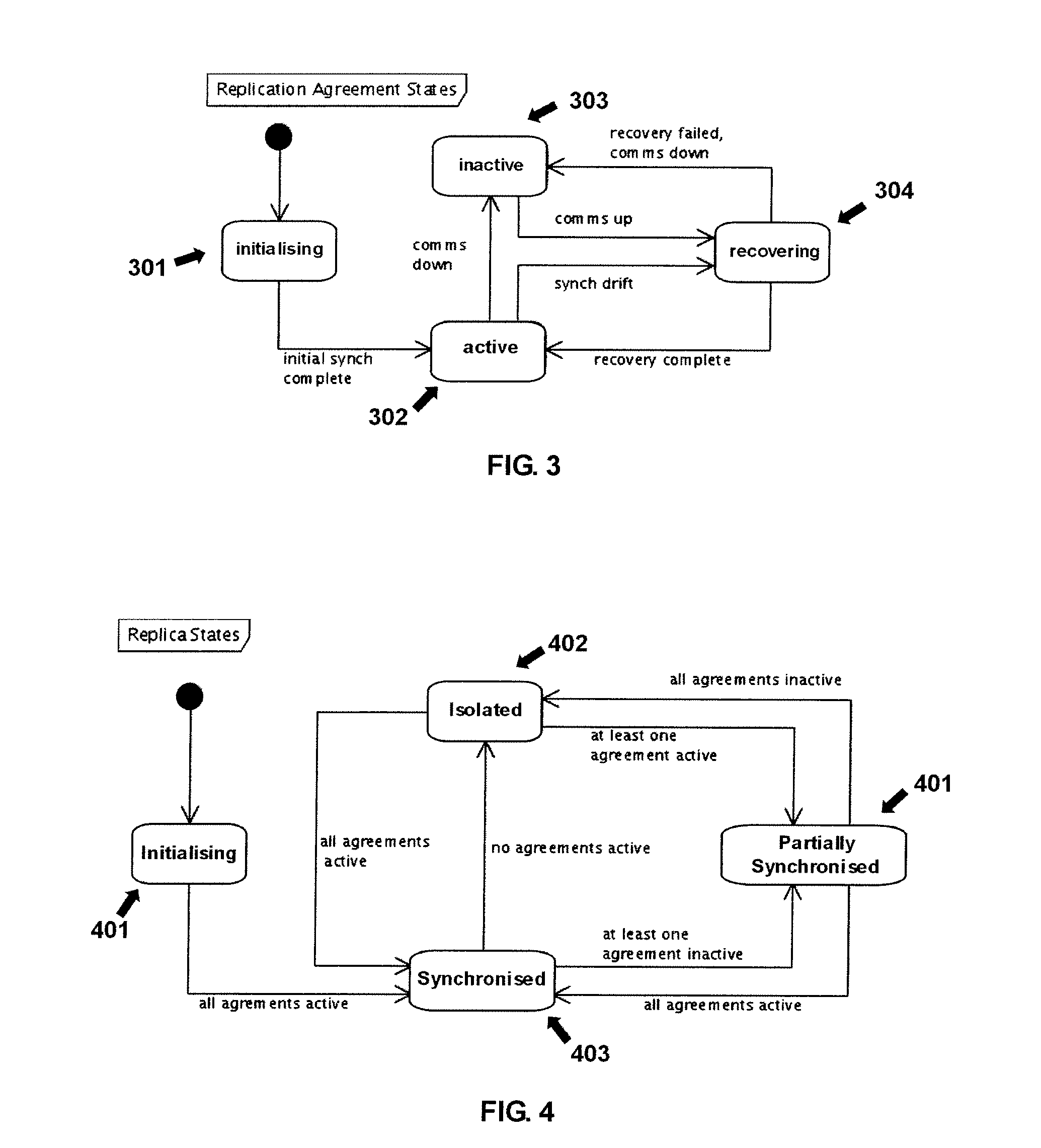

System and Method for Replication and Synchronisation

ActiveUS20100223232A1Robust processingError detection/correctionDigital data processing detailsEntry LevelDistributed computing

Embodiments of the invention provide a replication and synchronization mechanism that is peer to peer and multi-threaded. Embodiments of the invention may further enable a useable alternative service in the event of a loss of communications between replicas and a fully automated recovery upon the recovery of communications between the replicas. A replication and synchronization mechanism may further provide entry level synchronization and support for transactions. The replication and synchronization mechanism merges changes that have been made independently as a result of the loss of communication between peers.

Owner:NOKIA SOLUTIONS & NETWORKS OY

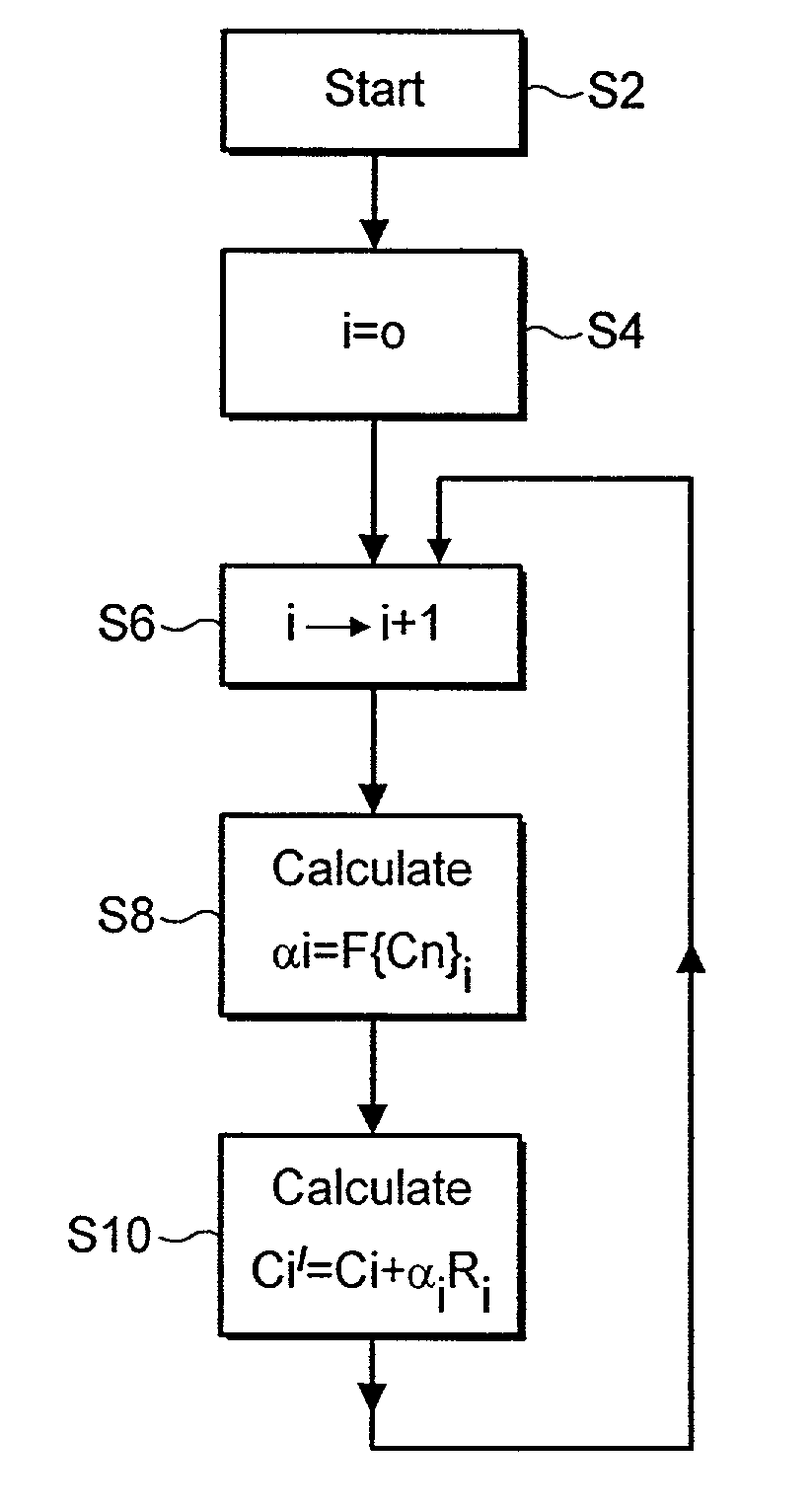

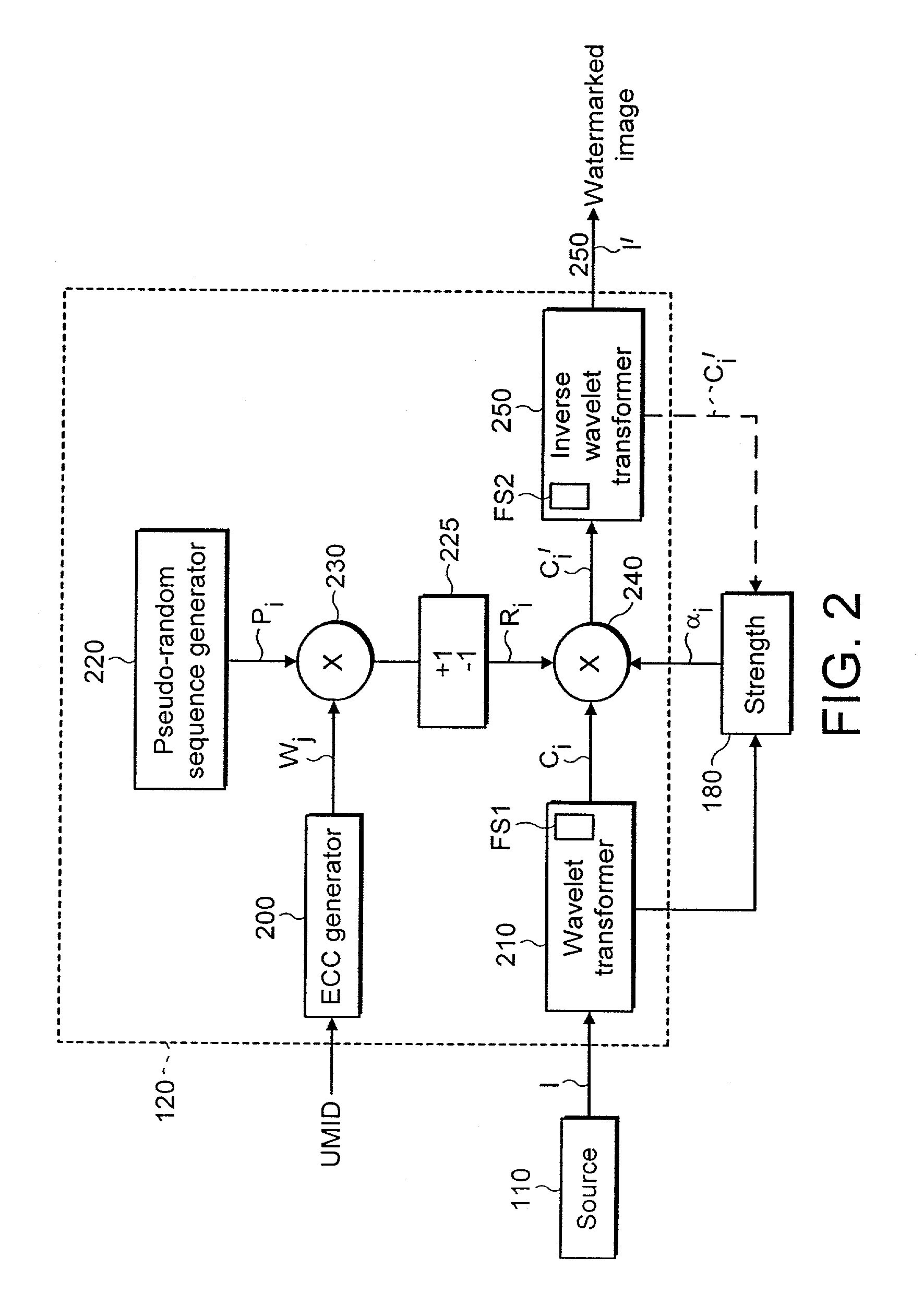

Embedding data in material

InactiveUS7088843B2Minimizing degradation of materialRobust processingUser identity/authority verificationCharacter and pattern recognitionComputer scienceSpatial frequency

A method of embedding data in material comprises the steps of:embedding data in original material to produce data embedded material;removing the watermark from the data embedded material to produce recovered material;comparing the original and recovered material to determine the differences and locations of differences therebetween; andstoring the said locations and corrections which correct the said differences.A method of removing the data embedded in the material, comprises the steps of:removing the data from the material to produce recovered material;deriving the said corrections and locations from the said store; andusing the corrections to correct the recovered material at the said locations.A method of embedding data in material, preferably comprises the steps of:producing transform coefficients Ci representing a spatial frequency transform of the material, andcombining the coefficients Ci with the data bits Ri to produce a modified coefficient Ci′ whereCi′=Ci+αiRi the method further comprising determining αi for each unmodified coefficient Ci as a function F{Cn}i of a predetermined set {Cn}i of transform coefficients Cn which set excludes the coefficient Ci.

Owner:SONY UK LTD

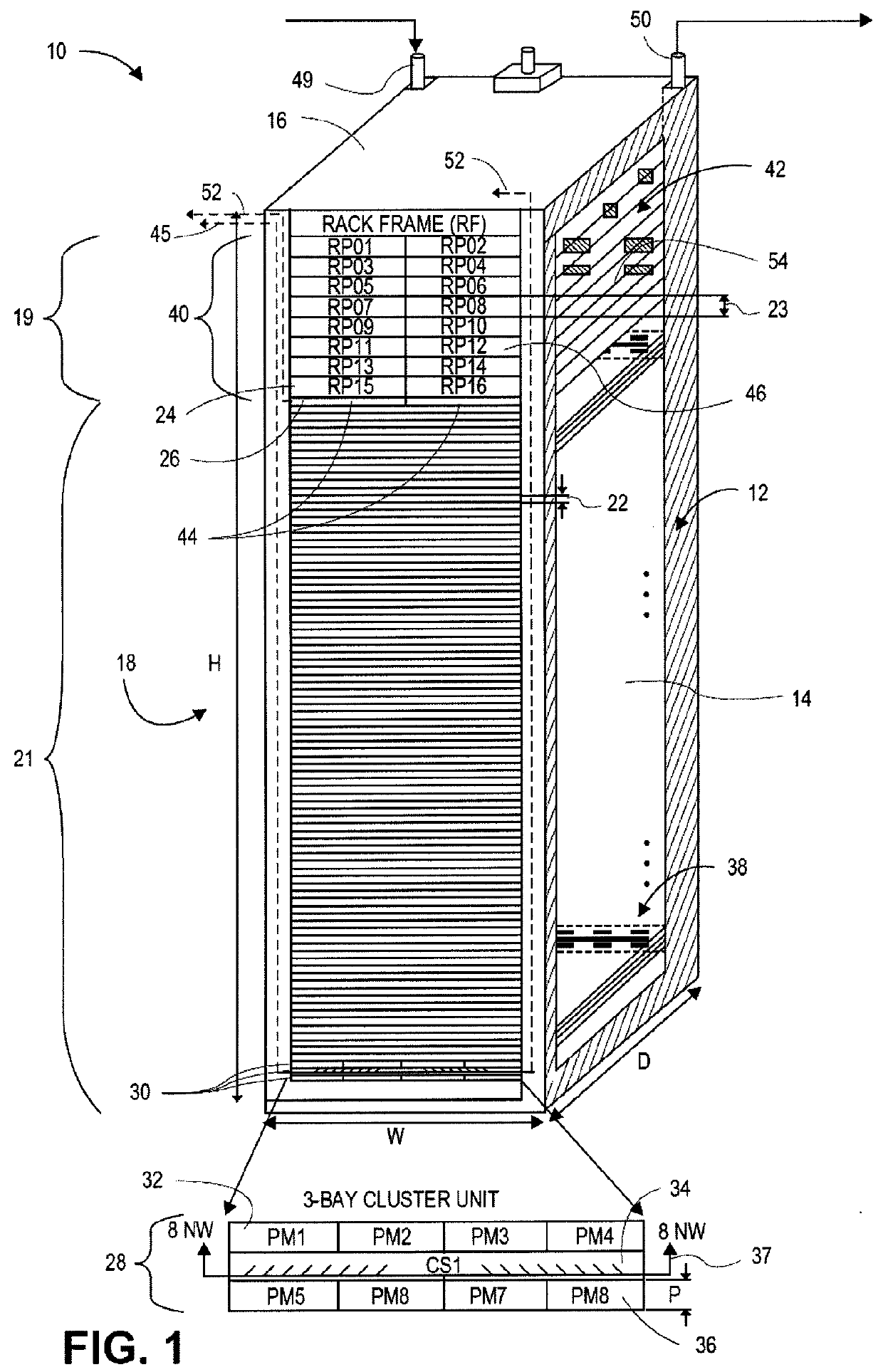

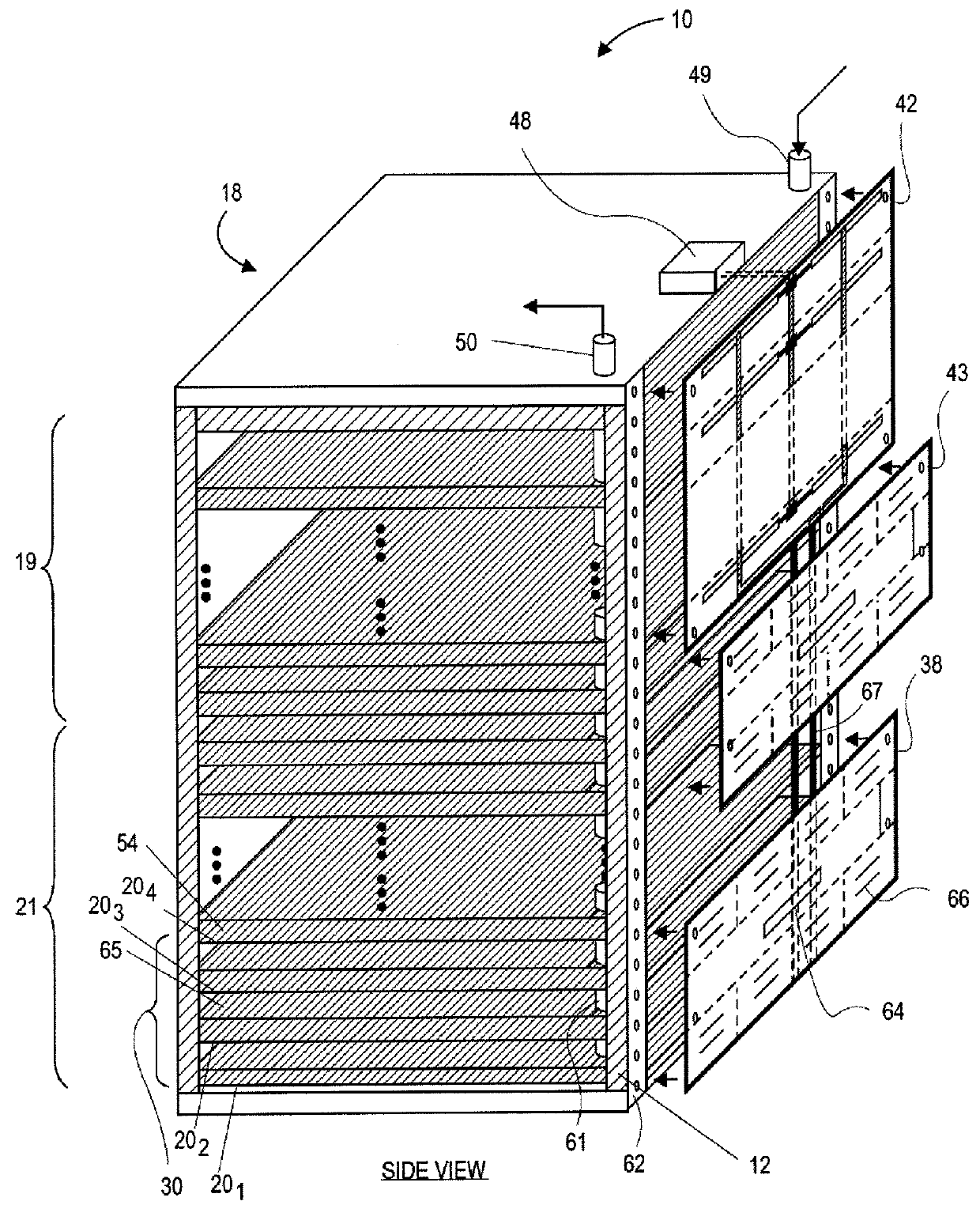

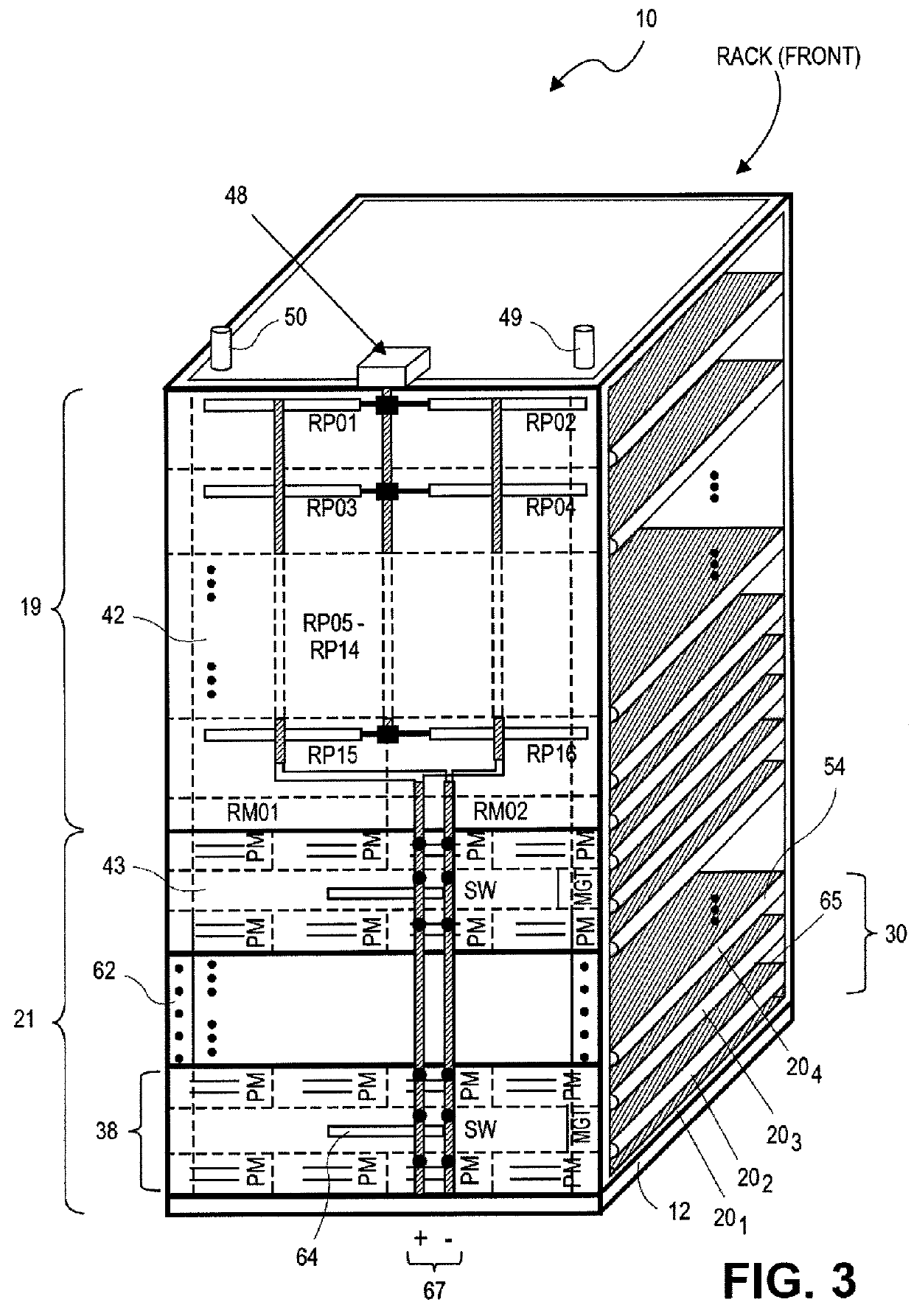

Mobile universal hardware platform

InactiveUS8259450B2Low costLess complexSubstation/switching arrangement detailsDomestic cooling apparatusEmbedded systemElectric power

A mobile container may include a bottom element, a top element, a front element, a back element, and two side elements defining a containment volume. The two side elements may have a length longer than a length of either the front element or the back element. The containment volume may be configured to include a plurality of rack frames. Each rack frame may include a module insertion area on a first side of the rack frame, a universal backplane area, and a power bus. The universal backplane area may be positioned on a second side of the rack frame opposite to the first side and may include at least one mounting surface configured to mount two or more backplane boards. At least two of the backplane boards may be configured to couple to two respective modules that each have at least two different functions and are insertable through the module insertion area. The at least two different functions of at least one backplane board may include rack power and management functions. The power bus may provide power to the two or more backplane boards mounted in the universal backplane area.

Owner:BIRCHBRIDGE

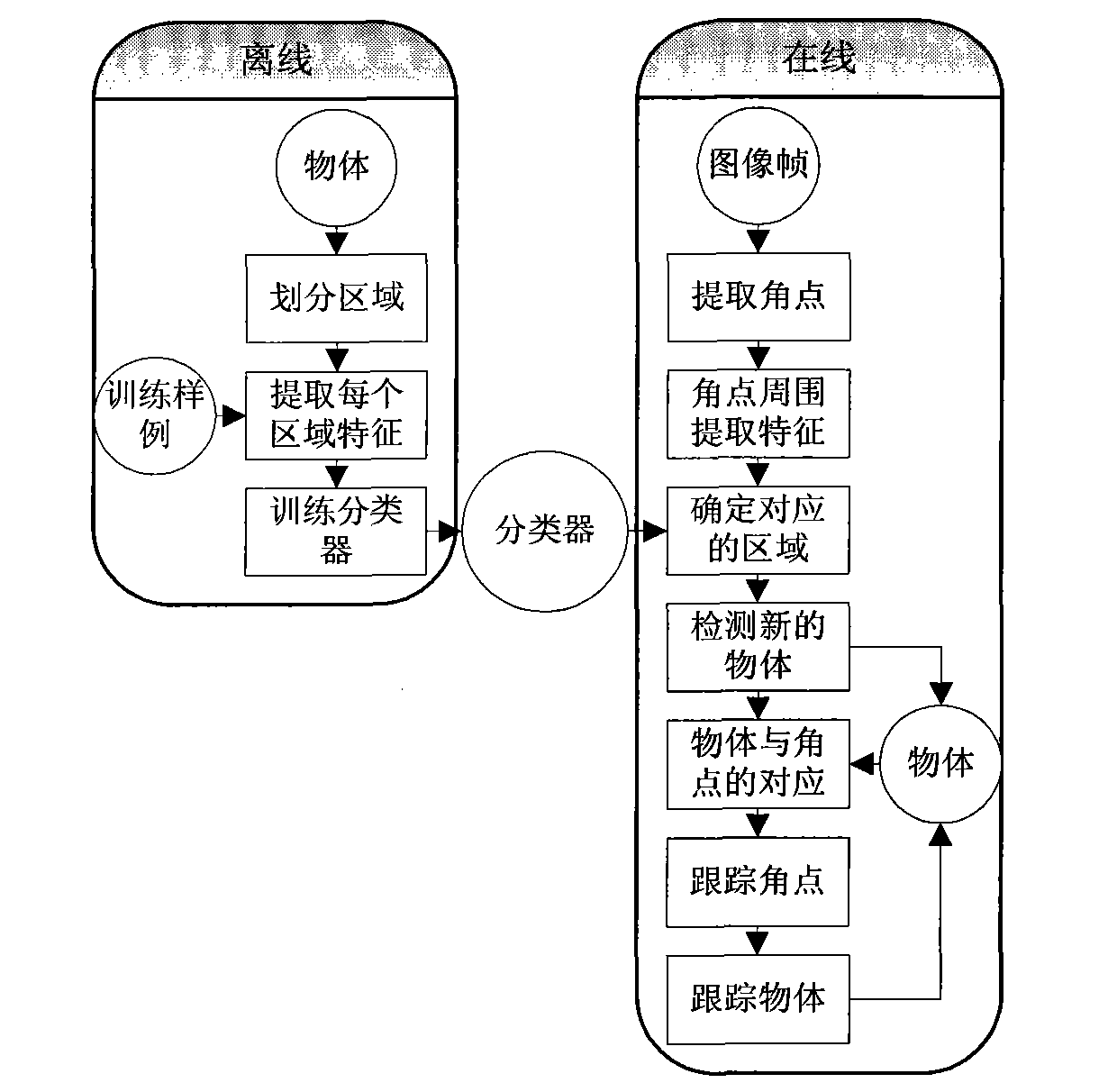

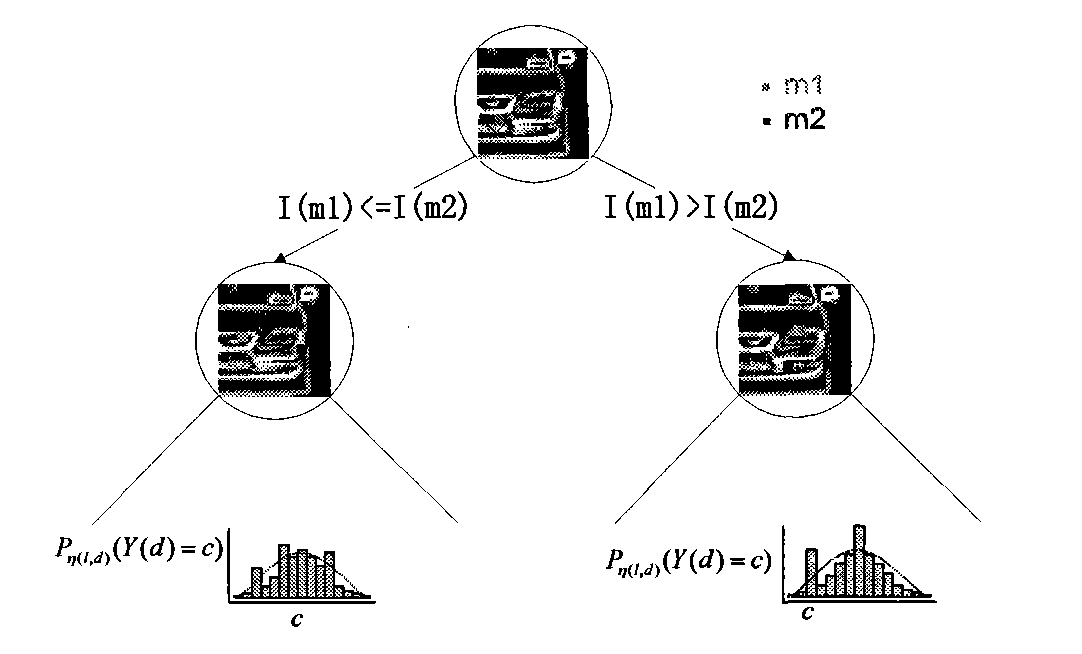

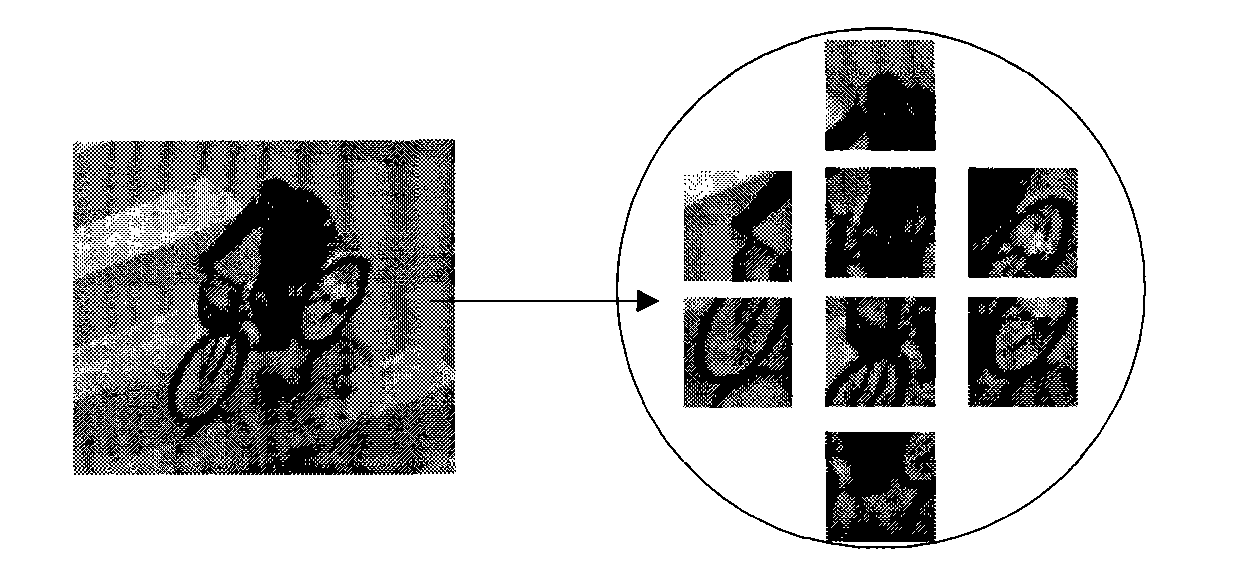

Method for detecting and tracking multi targets at real time in monitoring videotape based on characteristic point classification

ActiveCN101901354AHigh speedRobust processingCharacter and pattern recognitionClosed circuit television systemsObject basedRandom tree

The invention discloses a method for detecting and tracking multi targets at real time in a monitoring videotape based on characteristic point classification. The method comprises a step of off-time pre-processing: according to the distribution of the characteristic points on a target object, dividing the target object into a plurality of sections, taking the character of each section to train a classifier. The method also comprises a step of taking a character around the character points on line: confirming the object part corresponding to the character point by using the trained classifier and calculating a center point of the corresponding target, detecting the target according to the distribution of the center point and finally tracking the target object based on a tracked character point. The method needs no step of estimating the static background, so the method has better robustness on illumination change and the camera vibration. The method utilizes the rapid stable random tree as the classifier and the gradient of the around character points as the classification data, so the method has excellent detecting and tracking effect and meets the real-time demand.

Owner:ZHEJIANG SENSETIME TECH DEV CO LTD

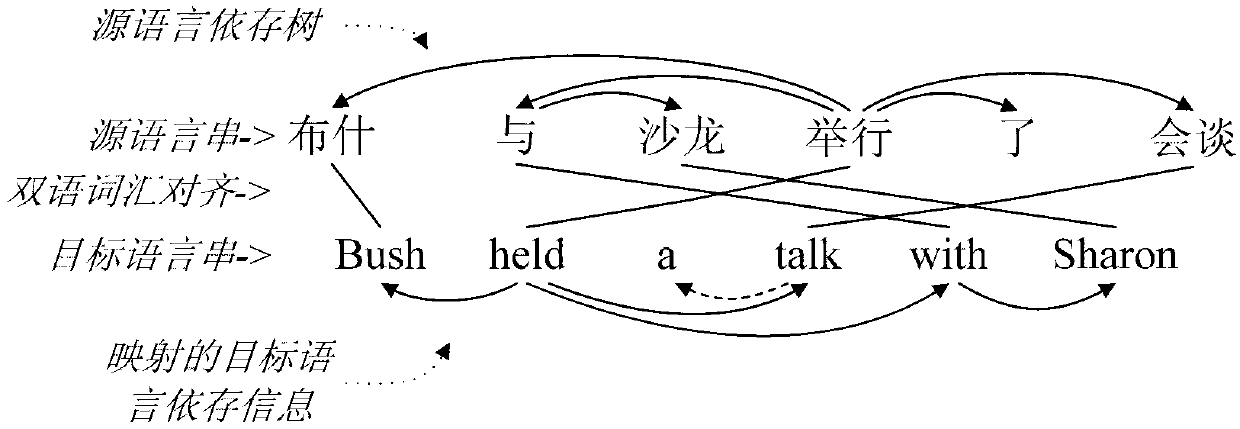

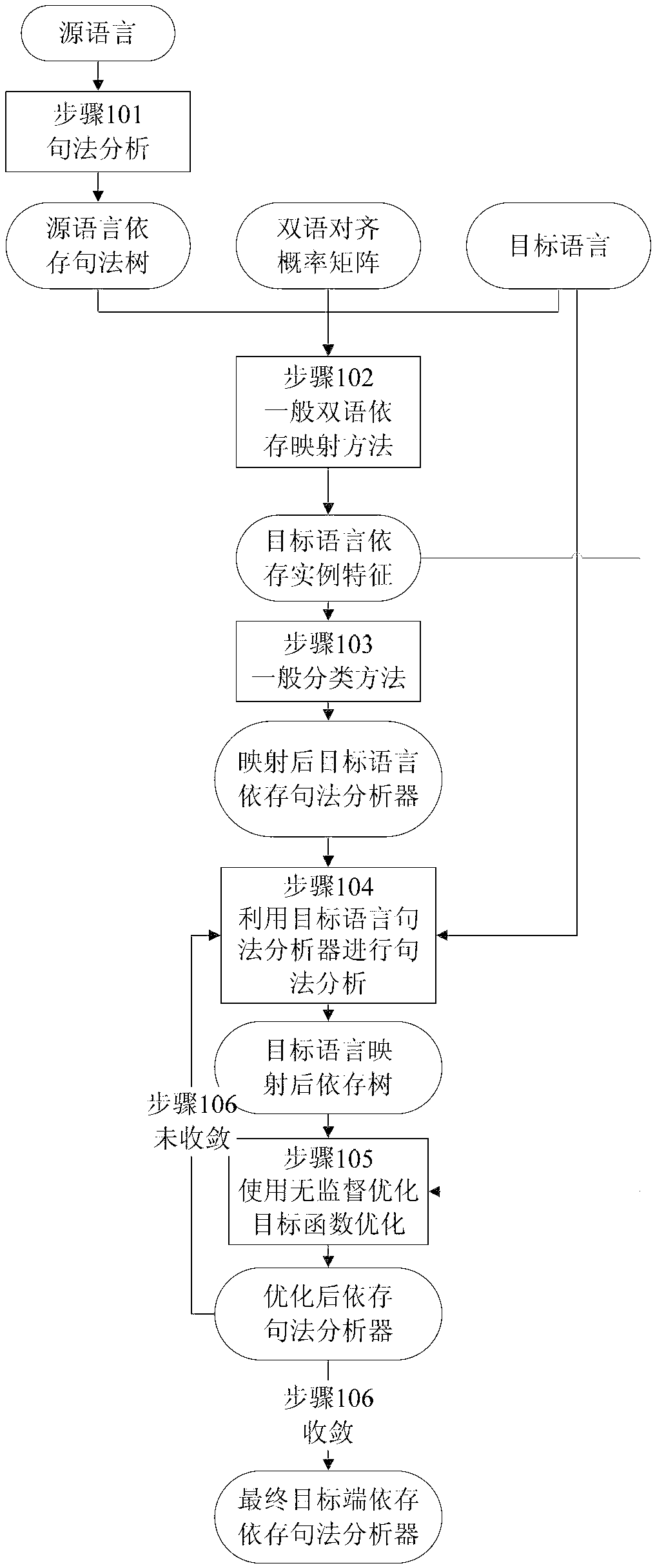

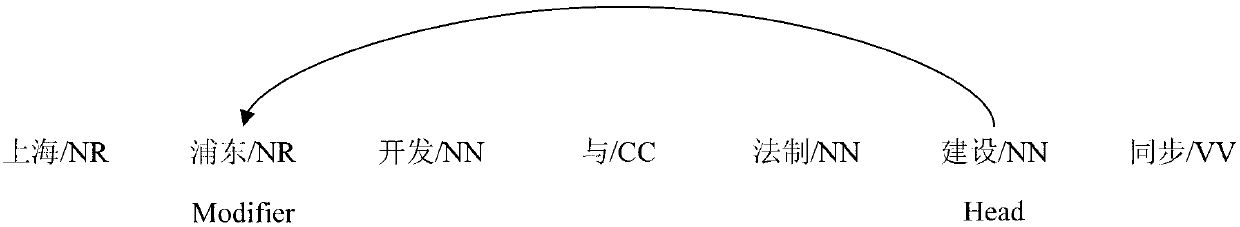

Dependence mapping method and system

The invention provides a dependence mapping method. The method comprises the following steps of: firstly based on a bilingual language database of a source language and a target language, acquiring dependence syntactical information of a target language through dependence mapping, and establishing a dependence syntactical analysis model and a dependence syntactical analyzer of the current target language; and then based on a mapping dependence feature instance set and a supervision-free feature instance set, training the dependence syntactical model of the target language so as to obtain an optimal dependence syntactical analysis model, and constructing a final target dependence syntactic analyzer through the optimal dependence syntactical analysis model, wherein the mapping dependence feature instance set is extracted from dependence syntactical information of the target language after the dependence mapping, and the supervision-free feature instance set is extracted from a dependence tree obtained from the syntactical analysis of a target language database by the dependence syntactical analyzer of the current target language. The dependence mapping method can keep the mapping dependence information to the greatest extent, and can process noise information in a robust mode.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

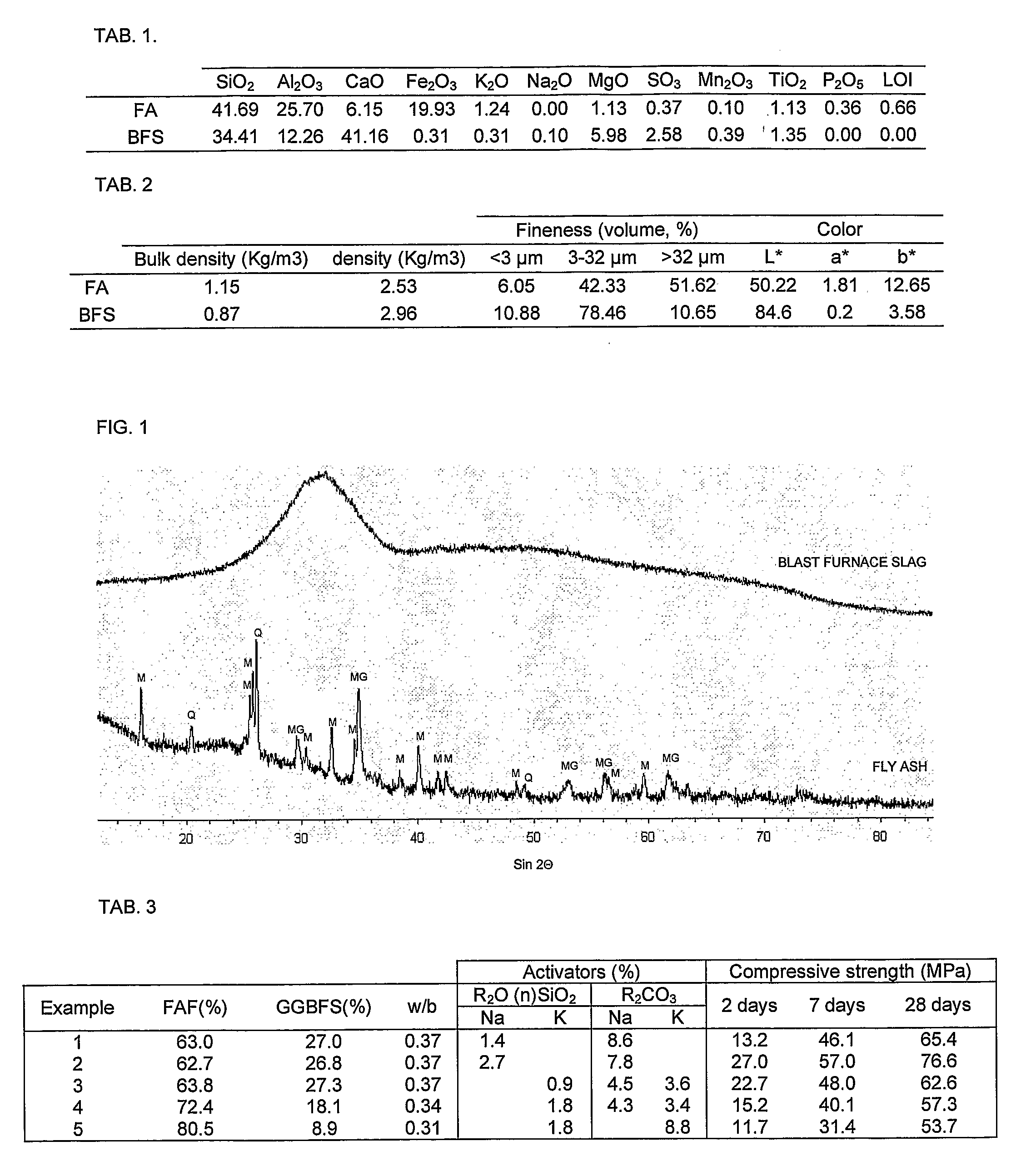

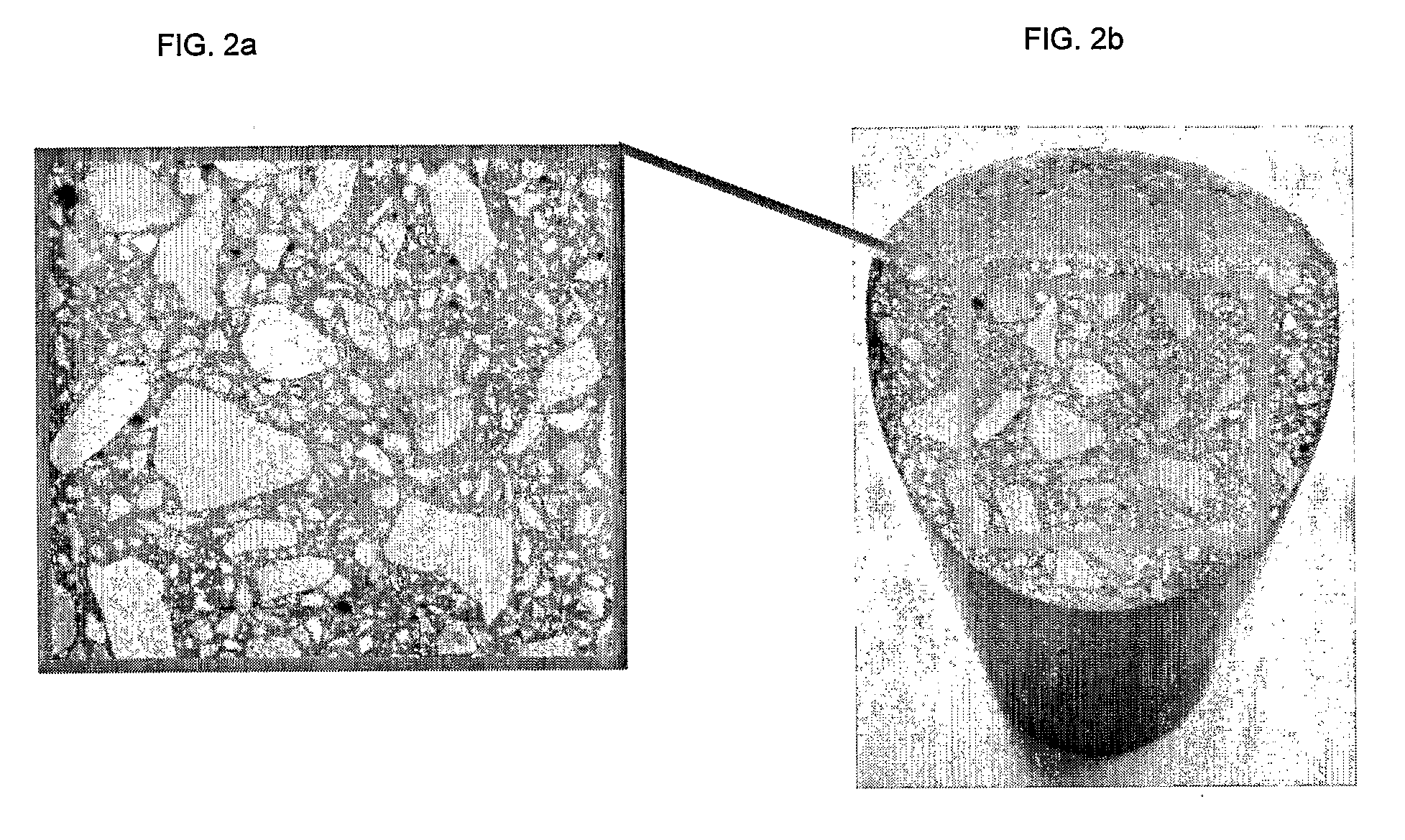

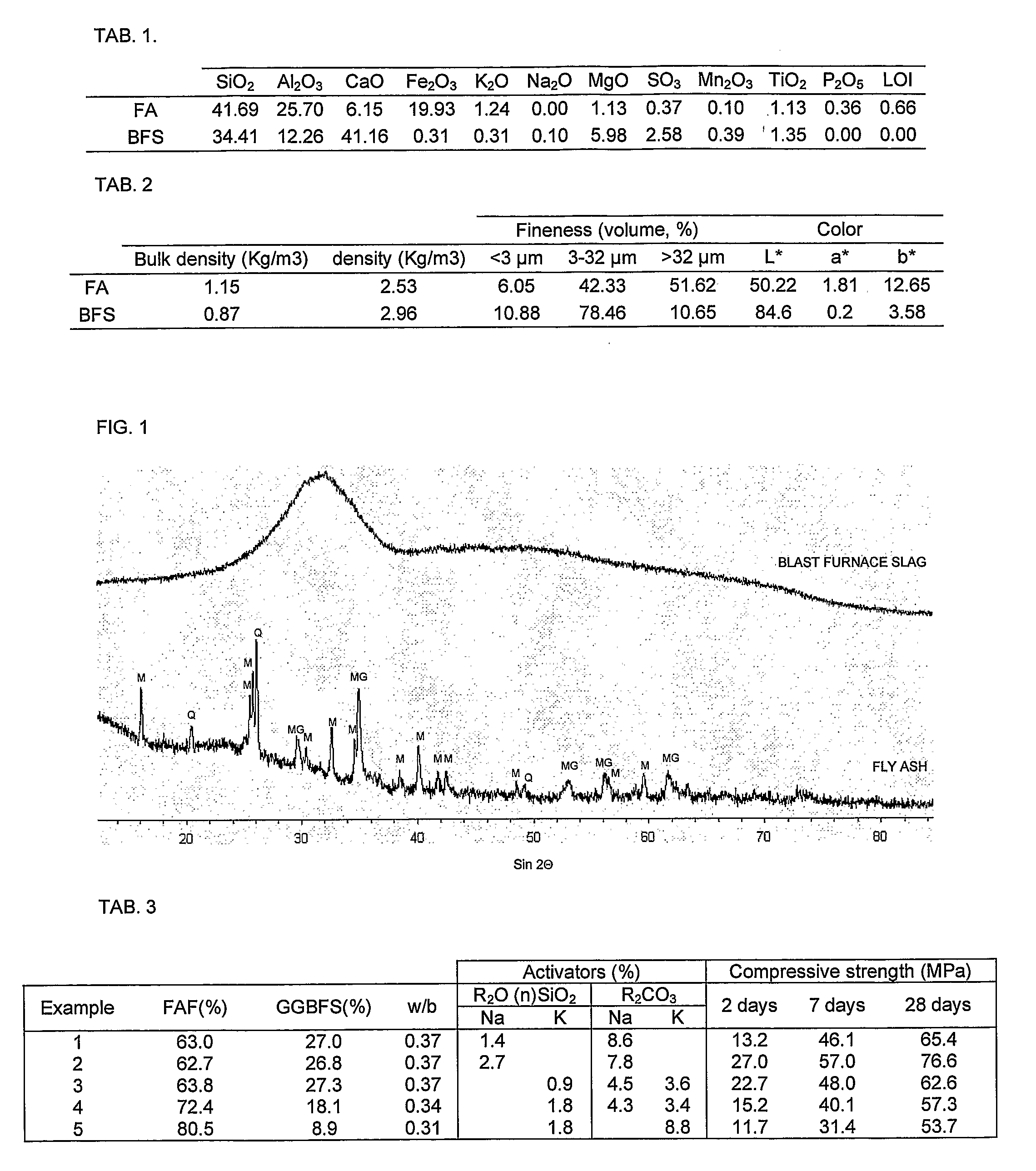

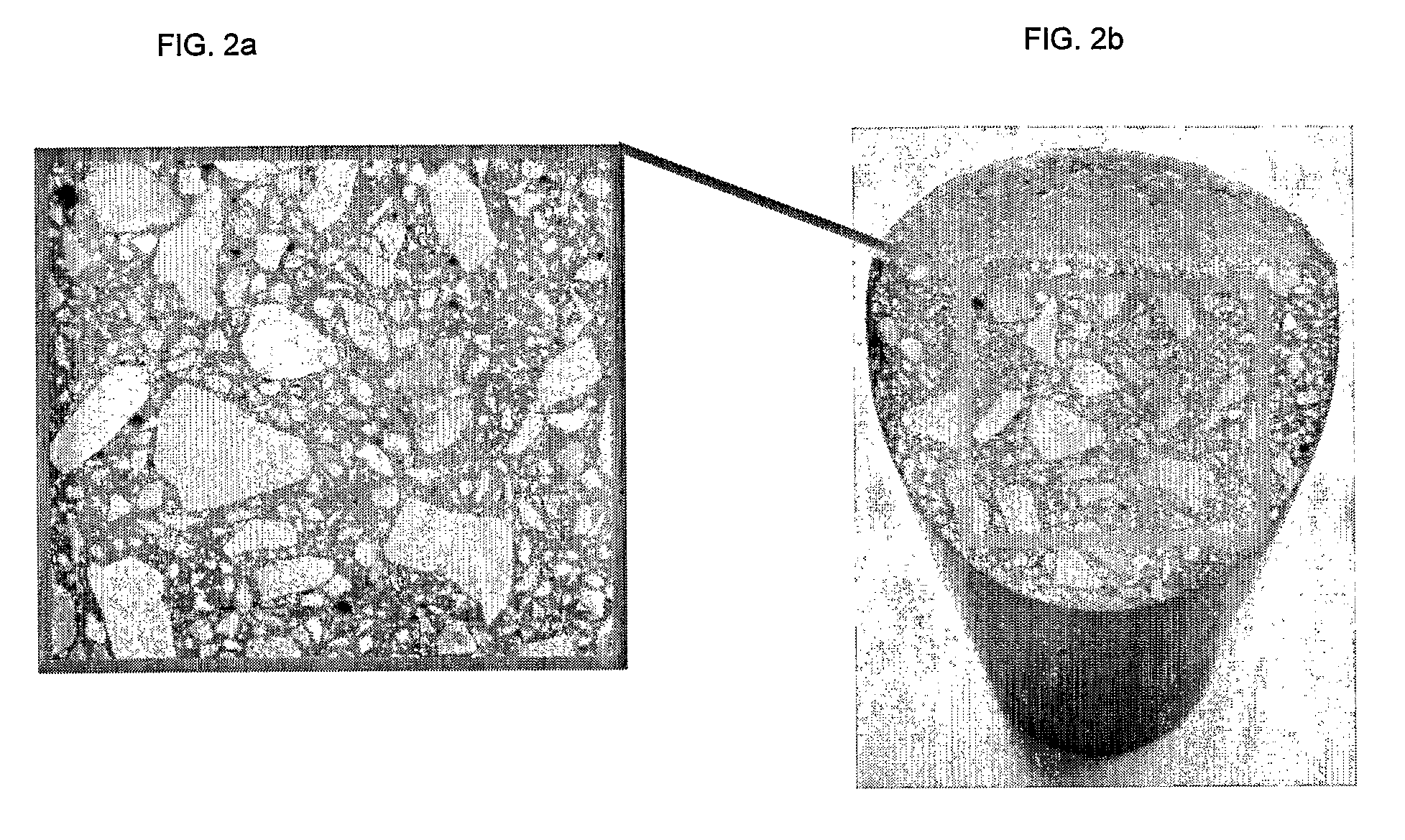

Universal Hydraulic Binder Based On Fly Ash Type F

The present invention concerns the development of a simple, multipurpose, low cost, environmental friendly and safe binder formulation and related process, based on high volumes of alkaline activated class F fly ash residue (>760%) without ordinary Portland cement and related products, offering a wide scope of applications. More specifically, the universal binder is based on a very limited number of components (fly ash type F, Blast Furnace Slag and a mixture of alkali silicates and carbonates). The binder allows developing considerable strength at the early stage (at room temperature) and very high resistances at 28 days. The binder applies to pastes, mortars concretes and pre-cast with the same flexibility of an Ordinary Portland Cement.

Owner:CEMEX INNOVATION HLDG LTD

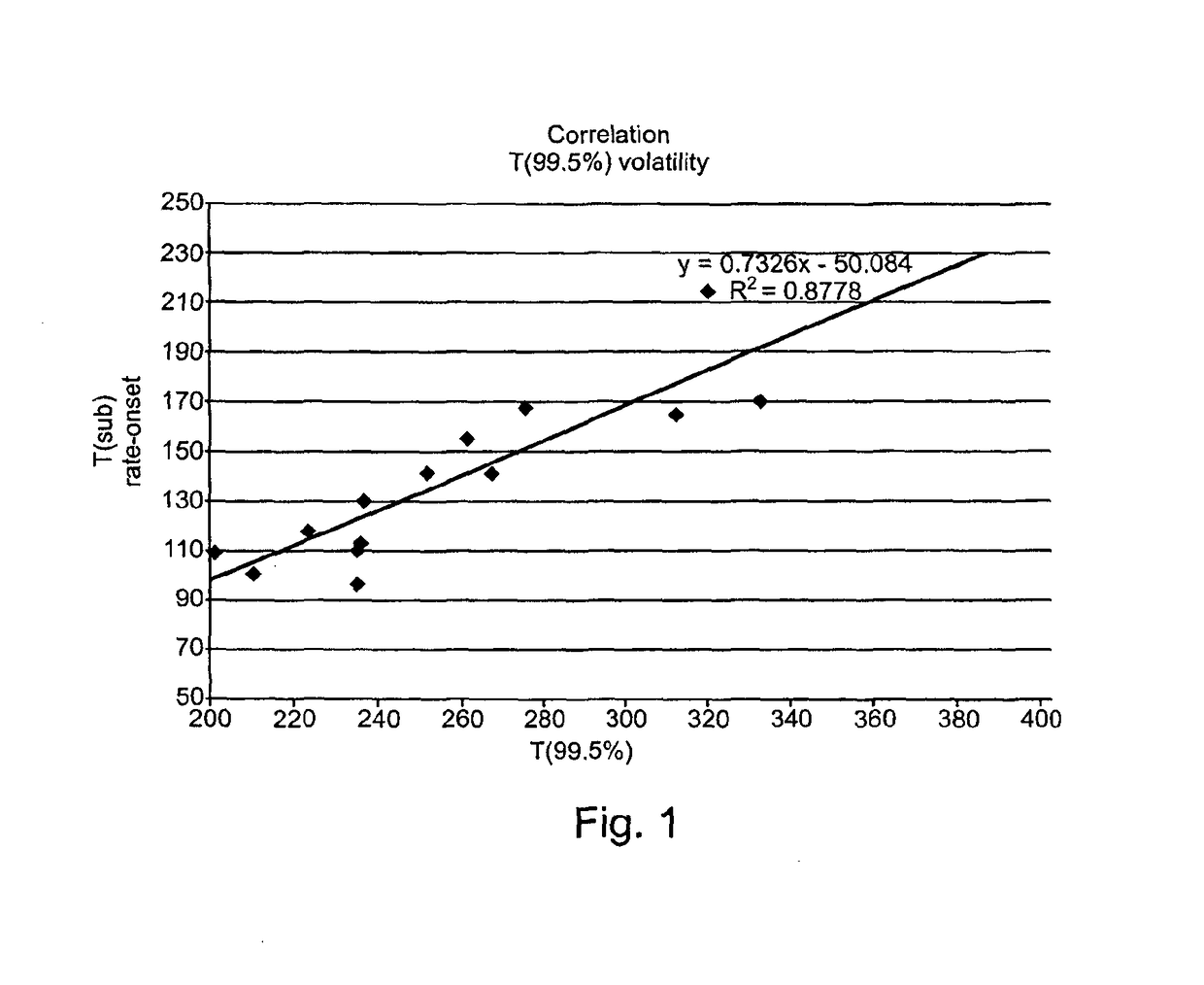

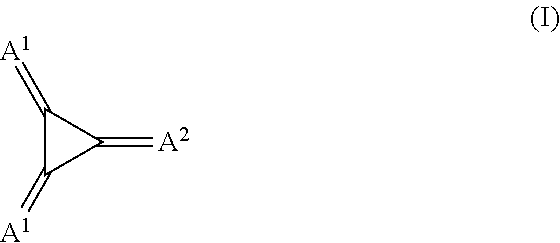

Substituted 1,2,3-Triylidenetris(cyanomethanylylidene) Cyclopropanes for VTE, Electronic Devices and Semiconducting Materials Using Them

ActiveUS20170373251A1High yieldHigh purityOrganic chemistrySolid-state devicesTetrafluoroethyleneDopant

The present invention relates to a process for preparation of an electrically doped semiconducting material comprising a [3]-radialene p-dopant or for preparation of an electronic device containing a layer comprising a [3]-radialene p-dopant, the process comprising the steps: (i) loading an evaporation source with the [3]-radialene p-dopant; and (ii) evaporating the [3]-radialene p-dopant at an elevated temperature and at a reduced pressure, wherein the [3]-radialene p-dopant is selected from compounds having a structure according to formula (I) wherein A1 and A2 are independently aryl- or heteroaryl-substituted cyanomethylidene groups, the aryl and / or heteroaryl is selected independently in A1 and A2 from 4-cyano-2,3,5,6-tetrafluorphenyl,2,3,5,6-tetrafluorpyridine-4-yl, 4-trifluormethyl-2,3,5,6-tetrafluorphenyl, 2,4-bis(trifluormethyl)-3,5,6-trifluorphenyl, 2,5-bis(trifluormethyl)-3,4,6-trifluorphenyl, 2,4,6-tris(trifluormethyl)-1,3-diazine-5-yl, 3,4-dicyano-2,5,6-trifluorphenyl, 2-cyano-3,5,6-trifluorpyridine-4-yl, 2-trifluormethyl-3,5,6-trifluorpyridine-4-yl, 2,5,6-trifluor-1,3-diazine-4-yl and 3-trifluormethyl-4-cyano-2,5,6-trifluophenyl), and at least one aryl or heteroaryl is 2,3,5,6-tetrafluorpirydine-4-yl, 2,4-bis(trifluormethyl)-3,5,6-trifluorphenyl, 2,5-bis(trifluormethyl)-3,4,6-trifluorphenyl, 2,4,6-tris(trifluormethyl)-1,3-diazine-5-yl, 3,4-dicyano-2,5,6-trifluorphenyl, 2-cyano-3,5,6-trifluorpyridine-4-yl, 2-trifluormethyl-3,5,6-trifluorphenyl, provided that the heteroaryl in both A1 and A2 cannot be 2,3,5,6-tetrafluorpyridine-4-yl at the same time, respective [3]-radialene compounds, and semiconducting materials and layer, and electronic devices comprising said compounds.

Owner:NOVALED GMBH

Universal hydraulic binder based on fly ash type F

ActiveUS7727330B2Low costRobust processingSolid waste managementCement productionHigh resistanceSlag

The present invention concerns the development of a simple, multipurpose, low cost, environmental friendly and safe binder formulation and related process, based on high volumes of alkaline activated class F fly ash residue (>760%) without ordinary Portland cement and related products, offering a wide scope of applications. More specifically, the universal binder is based on a very limited number of components (fly ash type F, Blast Furnace Slag and a mixture of alkali silicates and carbonates). The binder allows developing considerable strength at the early stage (at room temperature) and very high resistances at 28 days. The binder applies to pastes, mortars concretes and pre-cast with the same flexibility of an Ordinary Portland Cement.

Owner:CEMEX INNOVATION HLDG LTD

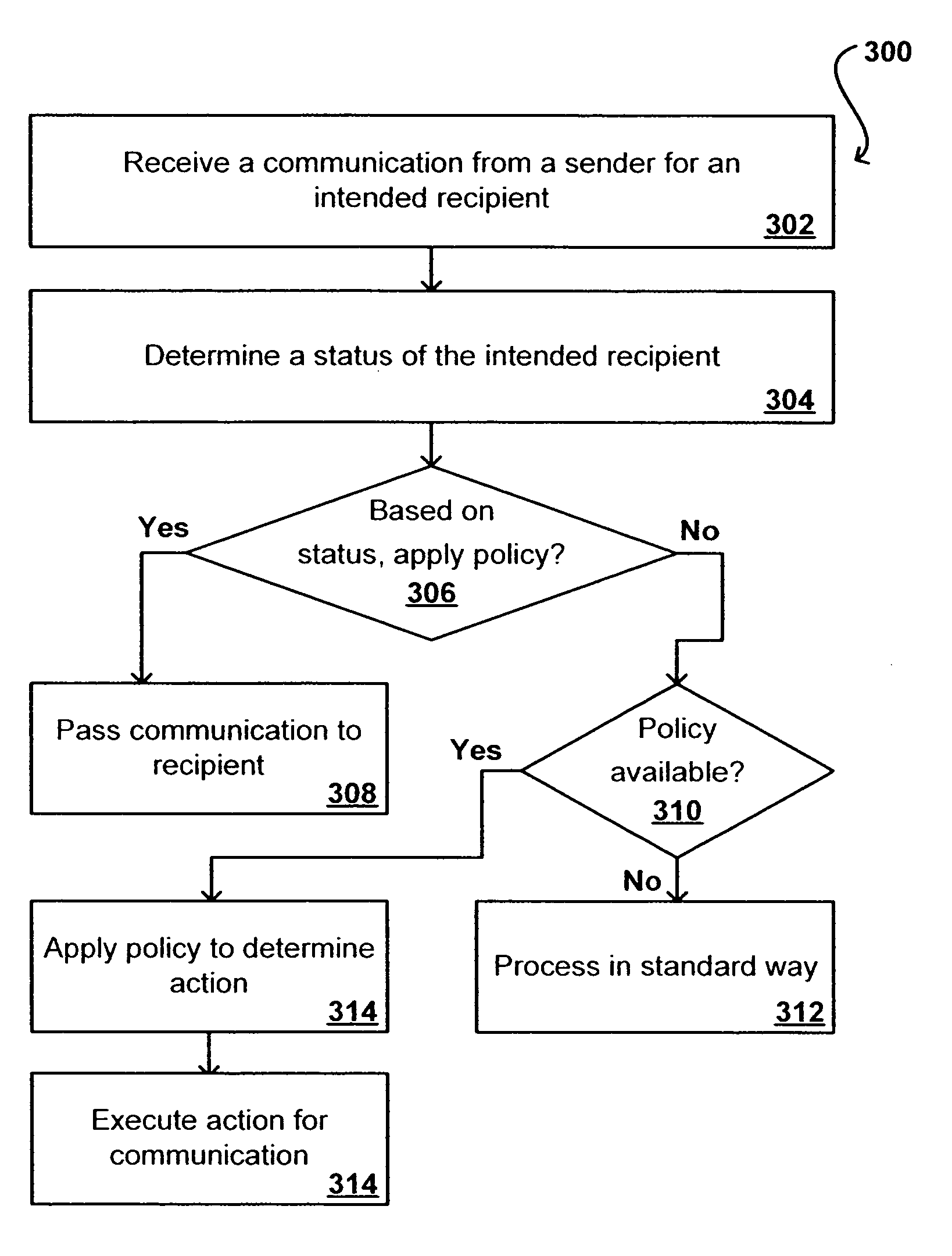

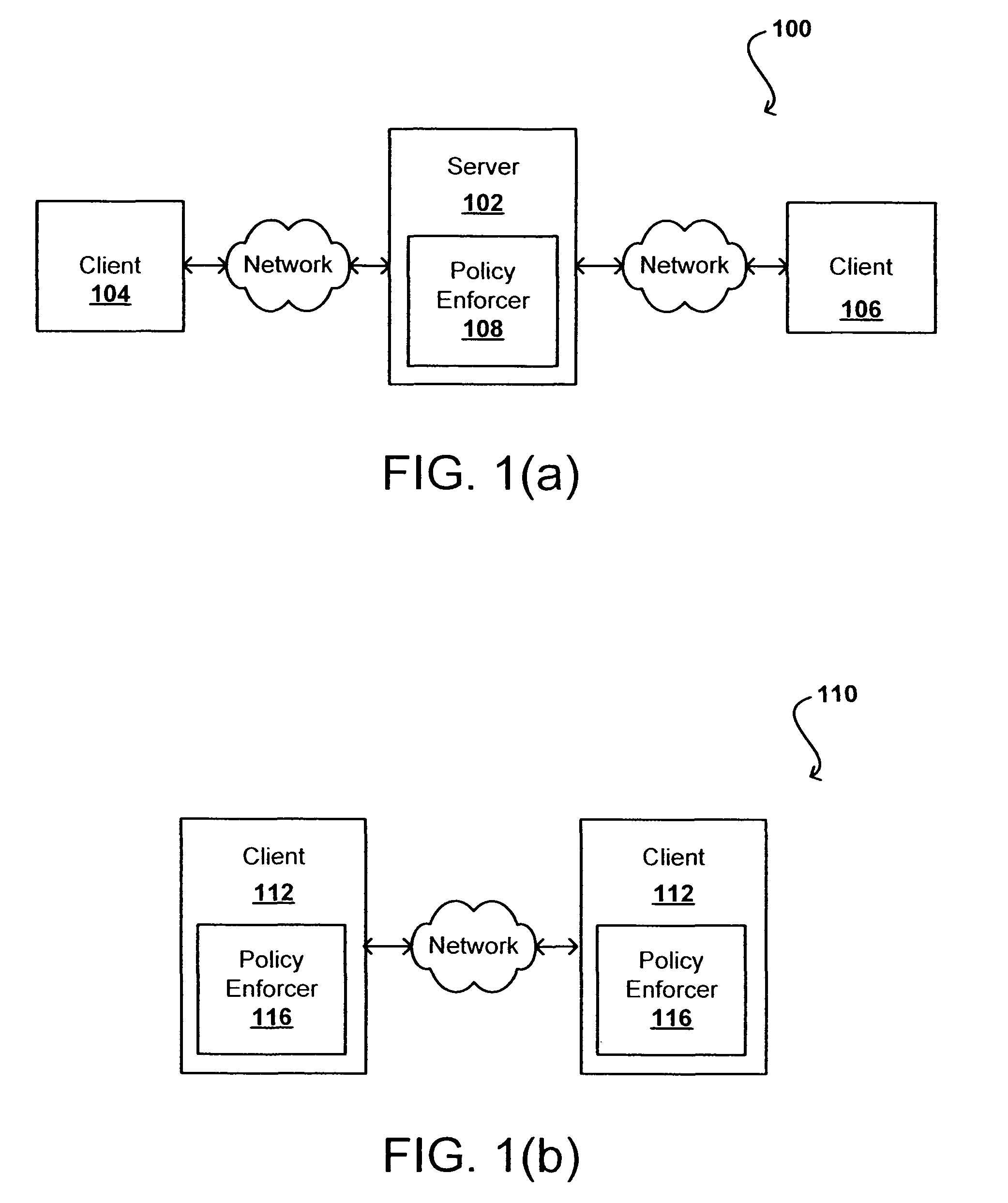

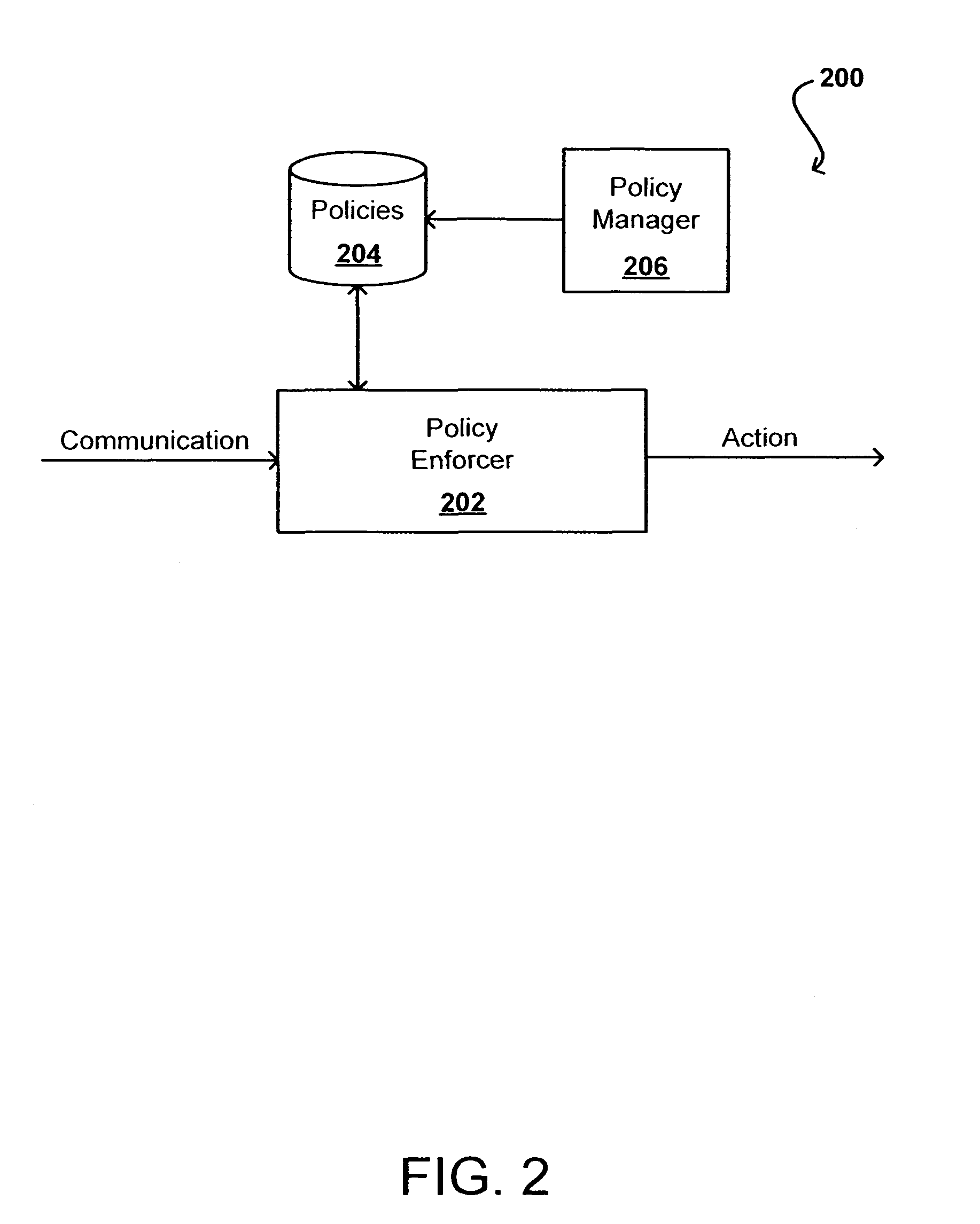

Techniques for applying policies for real time collaboration

ActiveUS7996467B2Robust processingPowerful toolMultiple digital computer combinationsData switching networksClient-sideComputer science

When a communication is received for a user, an appropriate policy can be determined and applied to the communication. For example, a policy can be applied if the user is not present at the appropriate client. A policy can be applied based upon information for the communication, and can include one or more conditions and one or more actions. Depending on the conditions that are satisfied, at least one action is determined and executed for the communication.

Owner:ORACLE INT CORP

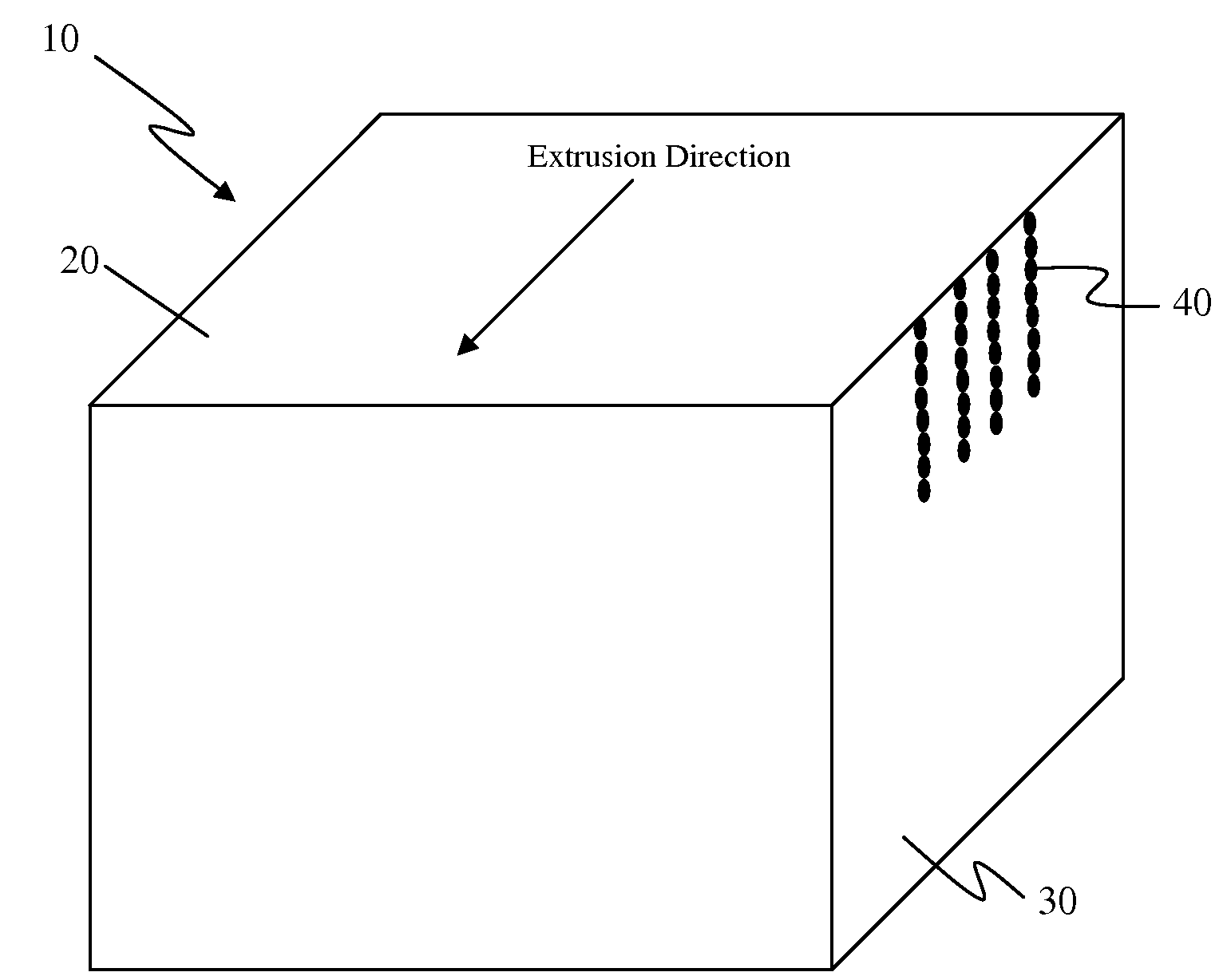

Oriented polymer composition with a deoriented surface layer

ActiveUS20090155534A1Great extent of orientationHigh modulusLayered productsThin material handlingPolymer scienceSurface layer

Prepare an oriented polymer composition that is cavitated, has cross sectional dimensions all at least three millimeters and at least one de-oriented surface layer having a thickness of at least 80 microns and at least 50 microns less than half the thickness of the oriented polymer composition, the de-oriented surface layer having a lower degree of polymer orientation than a 100 micron thick portion of the oriented polymer composition adjacent to and below the de-oriented surface layer by sufficiently heat treating a surface of a cavitated oriented polymer composition.

Owner:EOVATIONS

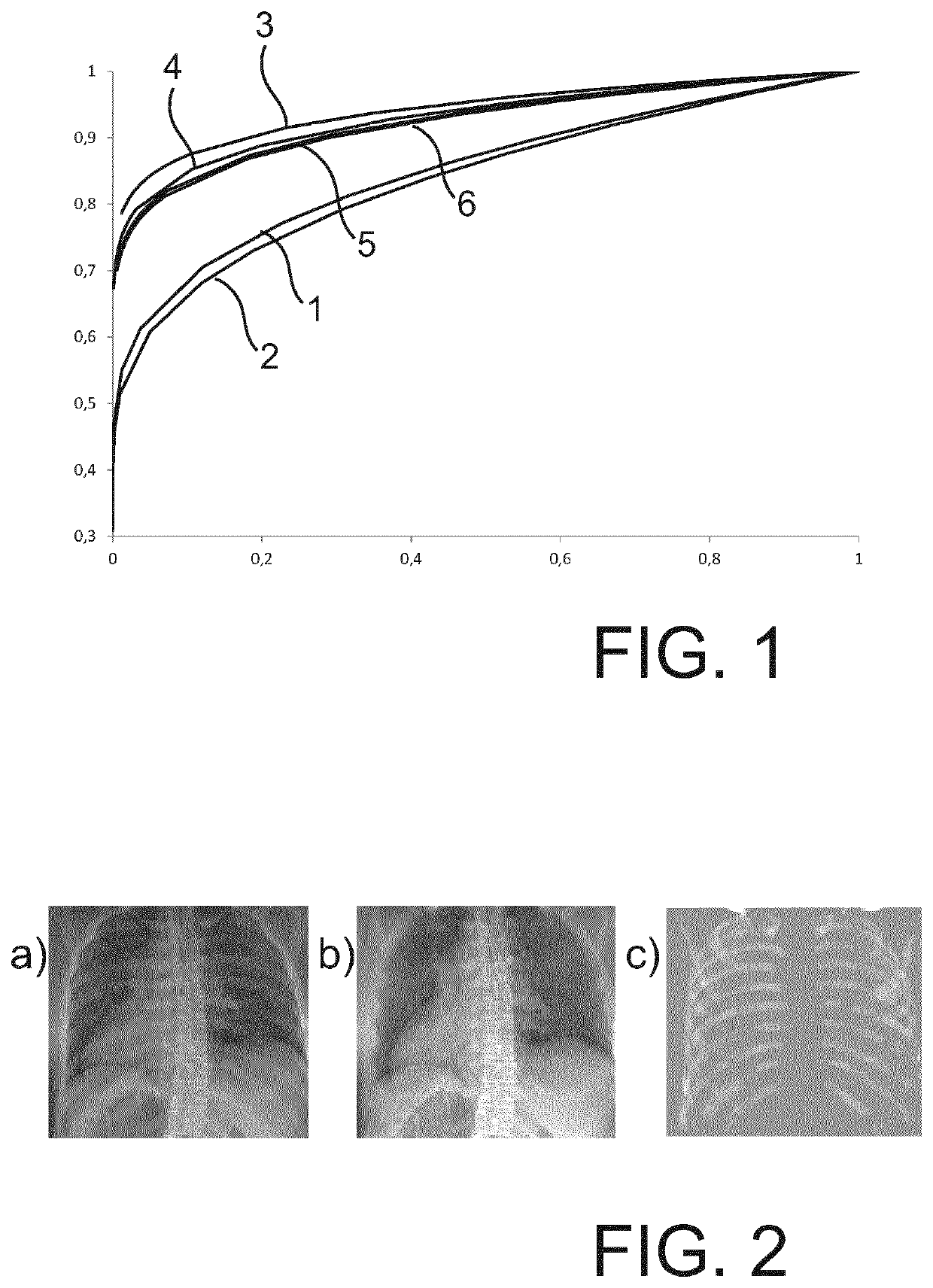

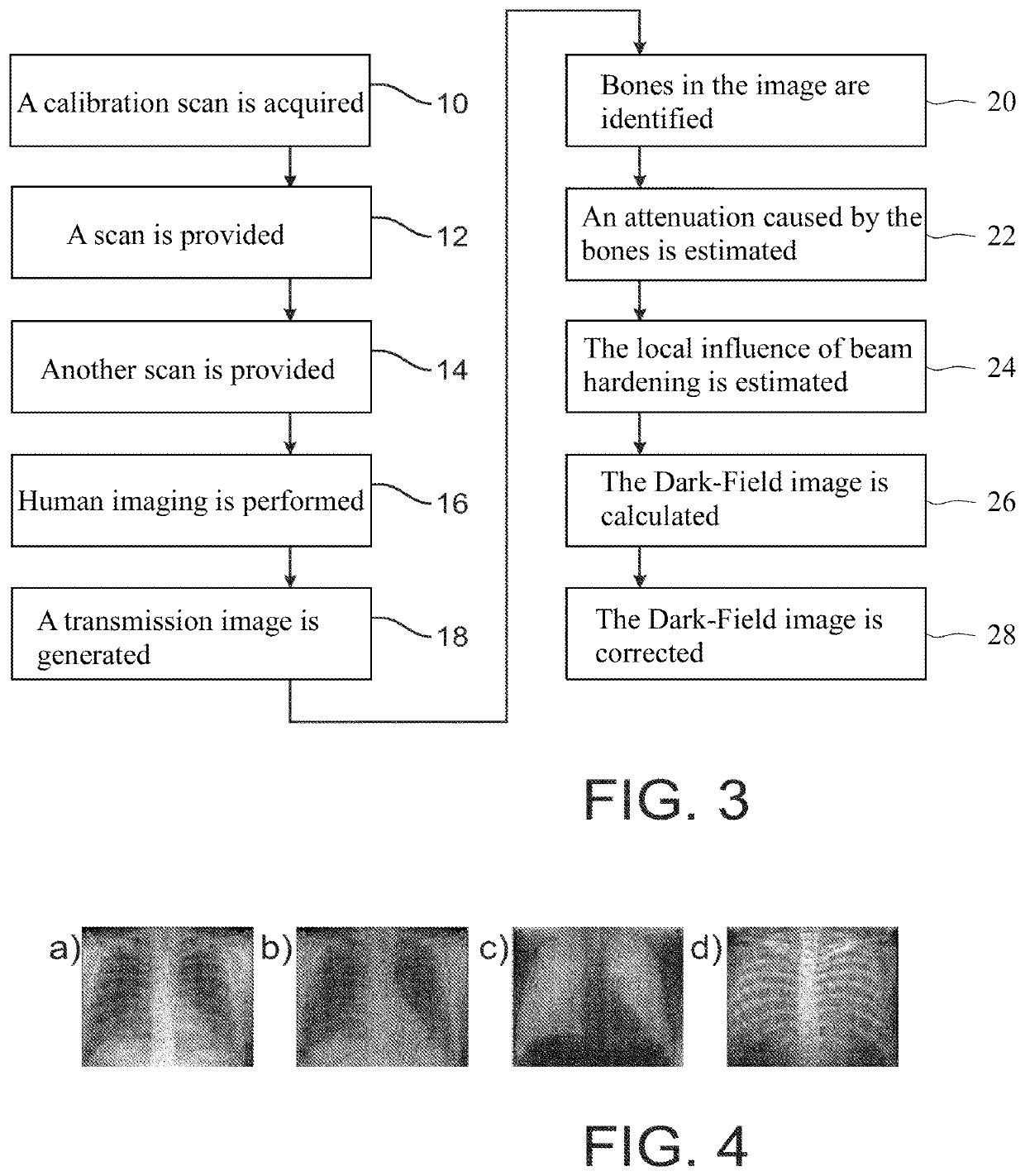

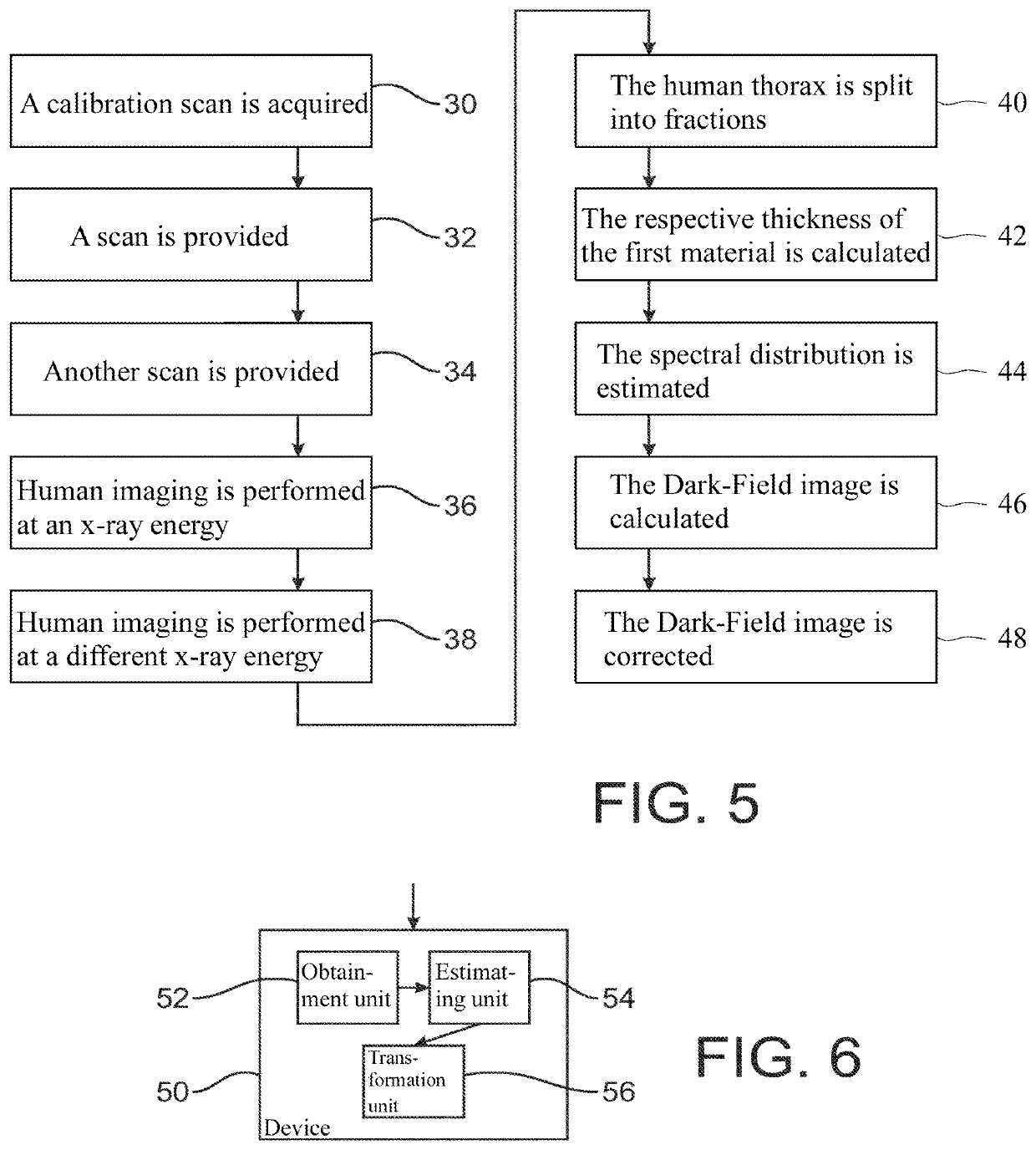

Beam hardening correction in x-ray dark-field imaging

ActiveUS11116470B2Robust processingMaterial analysis using wave/particle radiationRadiation measurementLight beamBeam hardening

The invention relates to beam hardening correction in X-ray Dark-Field imaging of a subject including a first material and a second material, the first and second material having different beam hardening properties. As the X-ray imaging data includes information on the internal structure of the imaged subject, such information may be used, together with appropriate calibration data to identify the beam hardening contributions occurring in the imaged area of the subject, so to allow for a correction of artifacts due to beam hardening in X-ray Dark-Field imaging.

Owner:KONINKLJIJKE PHILIPS NV

Fabrication Method For Electronic System Modules

InactiveUS20070245554A1Conveniently formMaintain dimensional accuracyPrinted circuit assemblingFinal product manufactureSurface plateElectromagnetic shielding

This specification describes techniques for manufacturing an electronic system module. The module includes flexible multi-layer interconnection circuits with trace widths as narrow as 5 microns or less. A glass panel manufacturing facility, similar to those employed for making liquid crystal display, LCD, panels is preferably used to fabricate the interconnection circuits. A multi-layer interconnection circuit is fabricated on the glass panel using a release layer. A special assembly layer is formed over the interconnection circuit comprising a thick dielectric layer with openings formed at input / output (I / O) pad locations. Solder paste is deposited in the openings using a squeegee to form wells filled with solder. IC chips are provided with gold stud bumps at I / O pad locations, and these bumps are inserted in the wells to form flip chip connections. The IC chips are tested and reworked. The same bump / well connections can be used to attach fine-pitch cables. Module packaging layers are provided for hermetic sealing and for electromagnetic shielding. A blade server or supercomputer embodiment is also described.

Owner:SK HYNIX INC

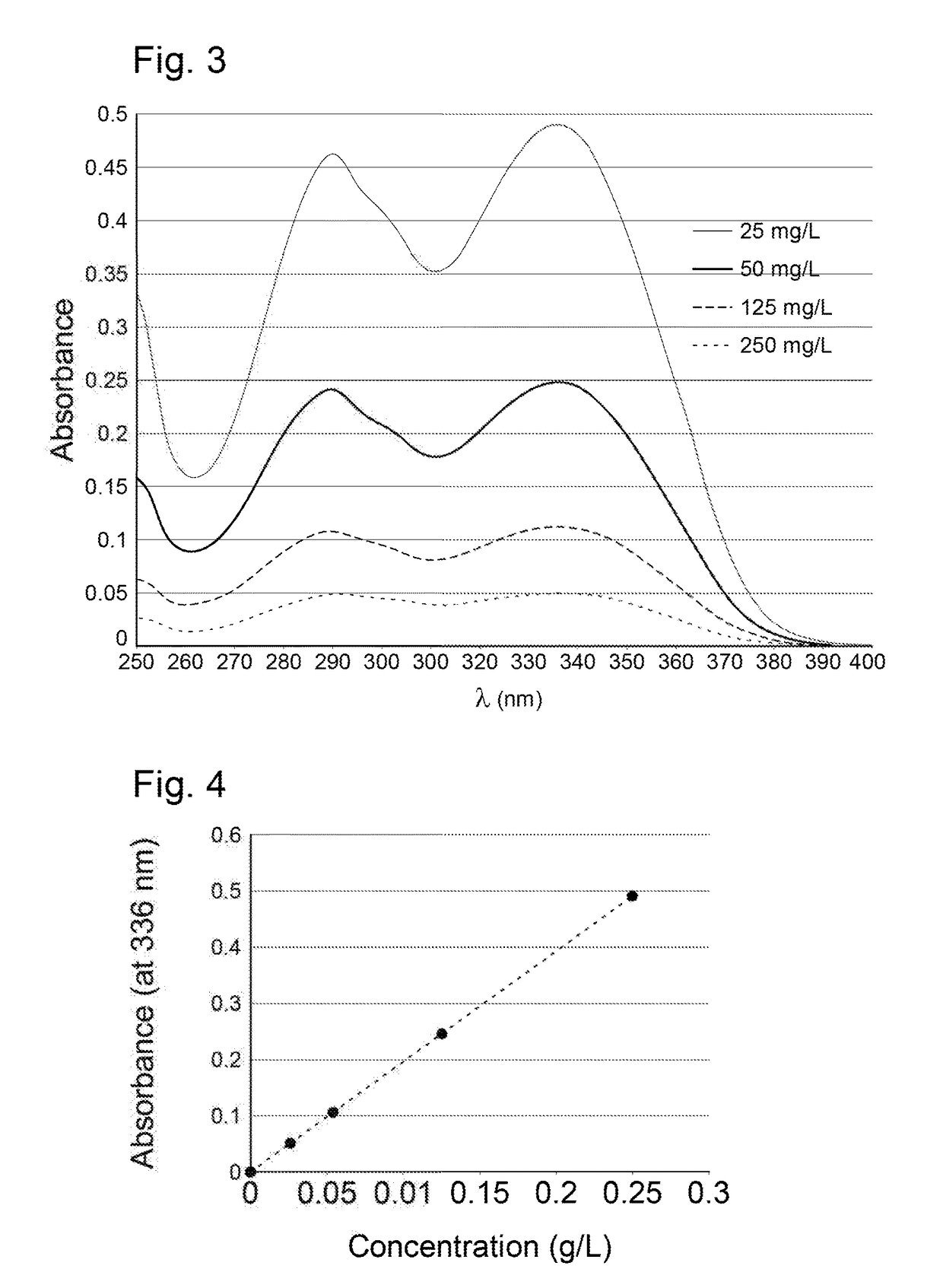

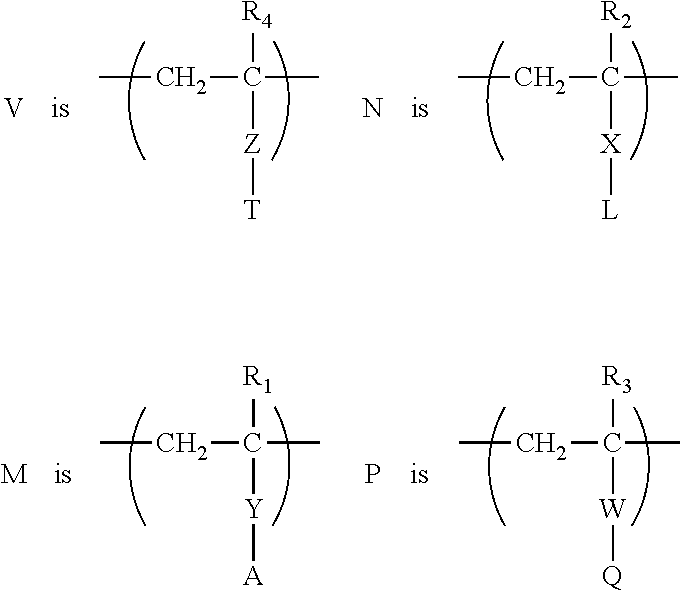

Substrate including a surface coated with an epilame agent and method for coating such a substrate with epilame

The invention relates to a copolymer and a substrate having a surface, at least one part of which is coated with an epilame agent comprising at least one compound in the form of a copolymer comprising V units, N units, optionally at least one M unit, and optionally at least one P unit, linked by covalent bonds by their main chains, whereinwherein W, X, Y, Z are spacer arms, T is a tracer group arranged to determine the concentration of epilame agent in an epilame-coating bath, L is a halogenated, preferably fluorinated, C1-C20 carbon moiety, A is a substrate anchoring moiety, Q is H, CH3, or a hydrocarbon chain different from T.The invention also concerns a method for coating such a substrate with epilame, said method comprising a step of checking the concentration of epilame agent in the epilame-coating bath by means of the tracer group and if necessary, a step of readjusting the concentration of epilame agent in the epilame-coating bath.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com