Patents

Literature

45 results about "Model based controller" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

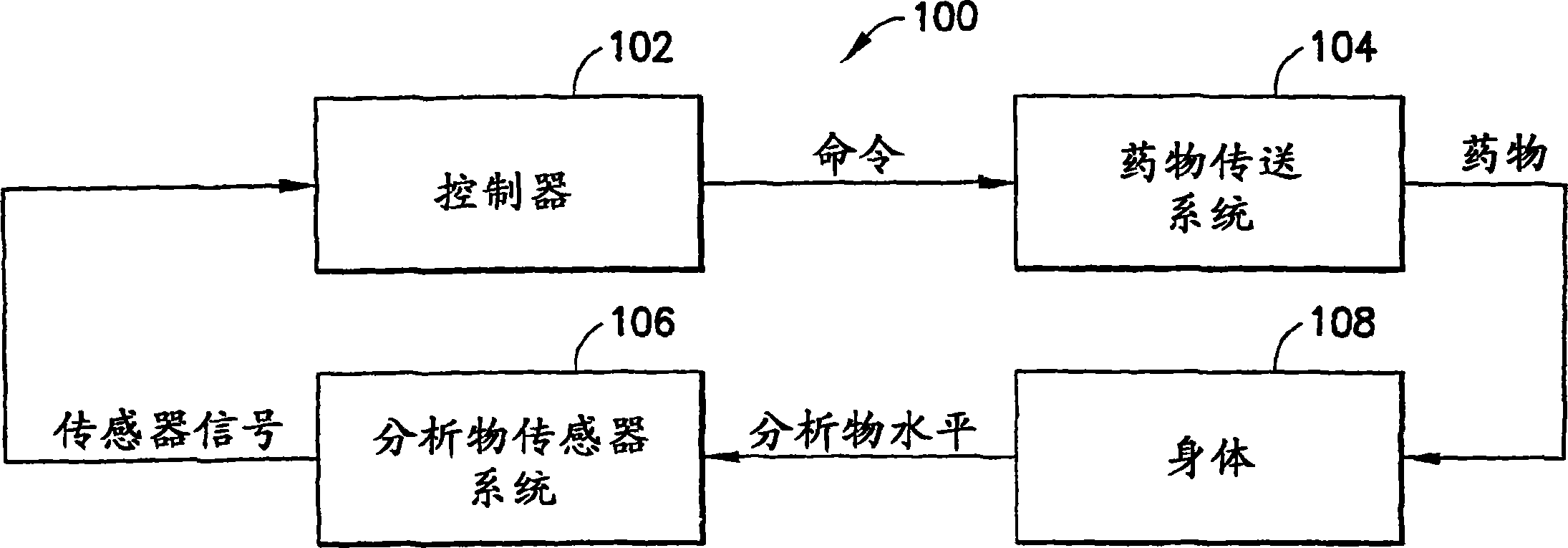

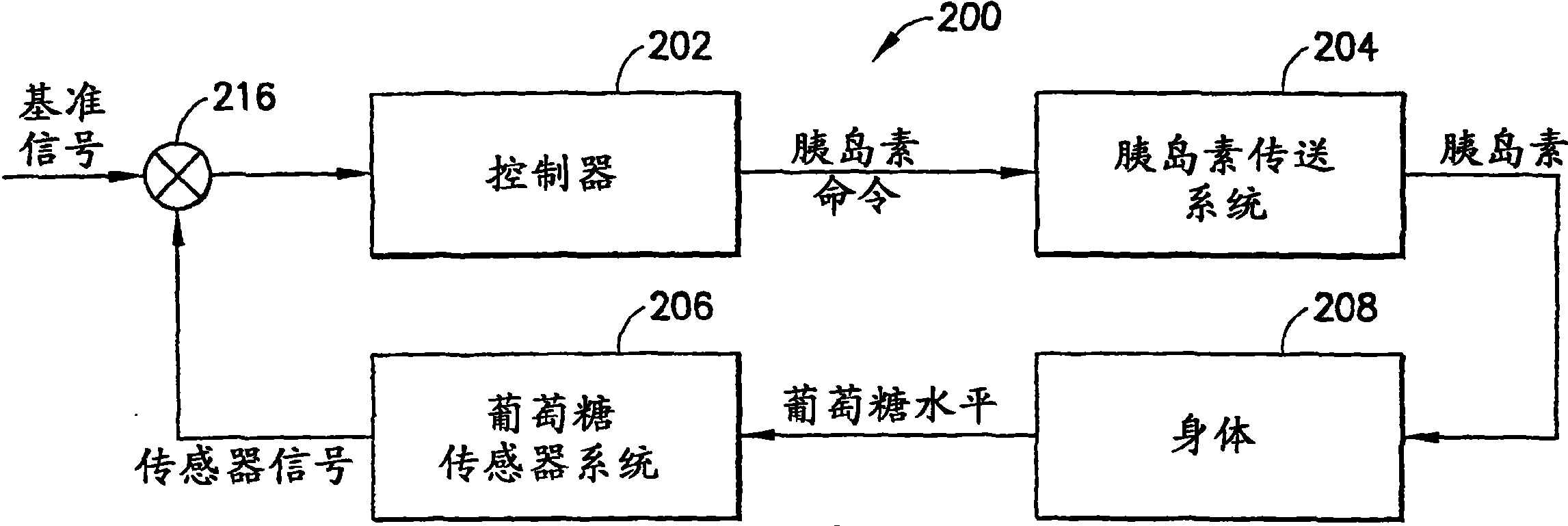

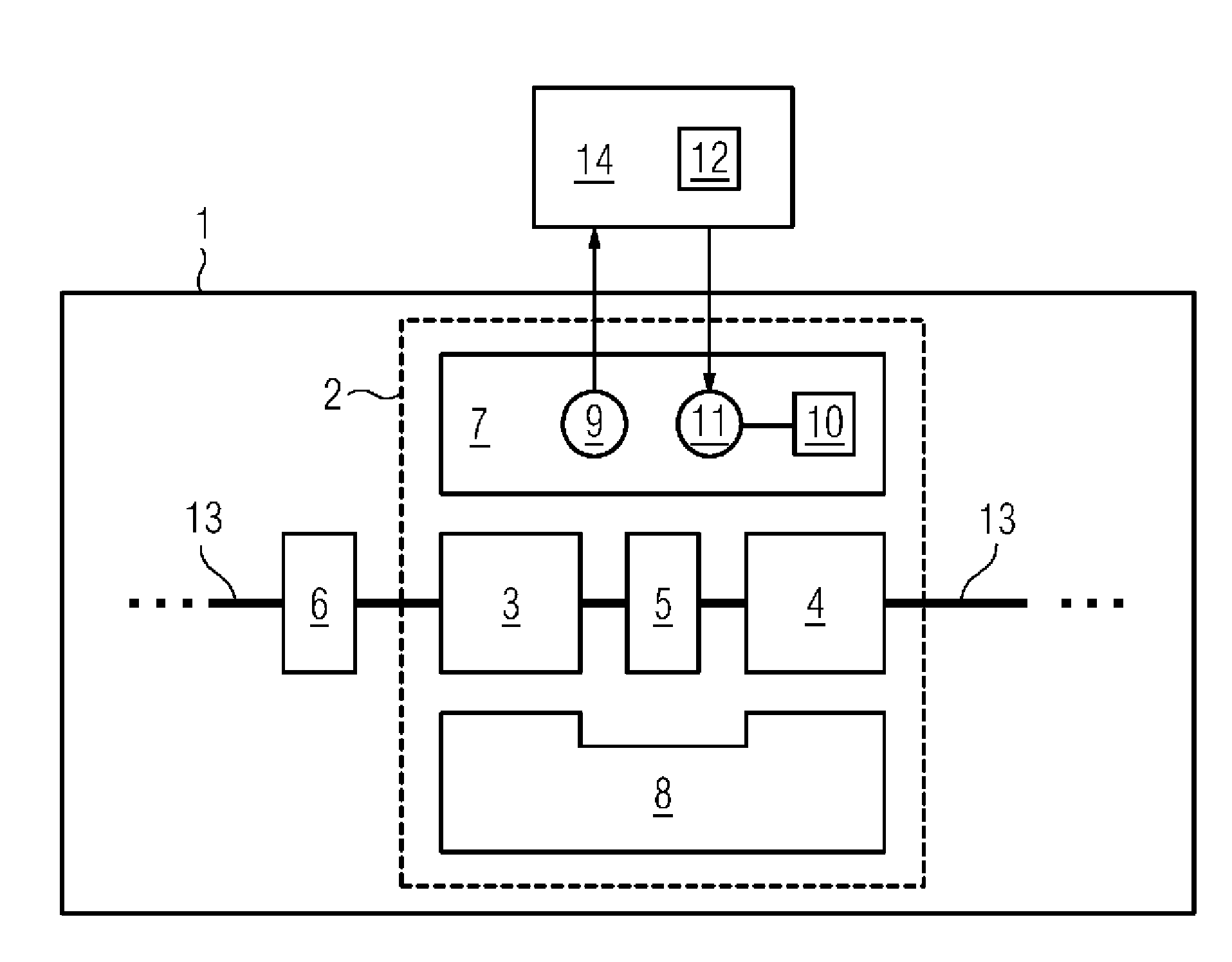

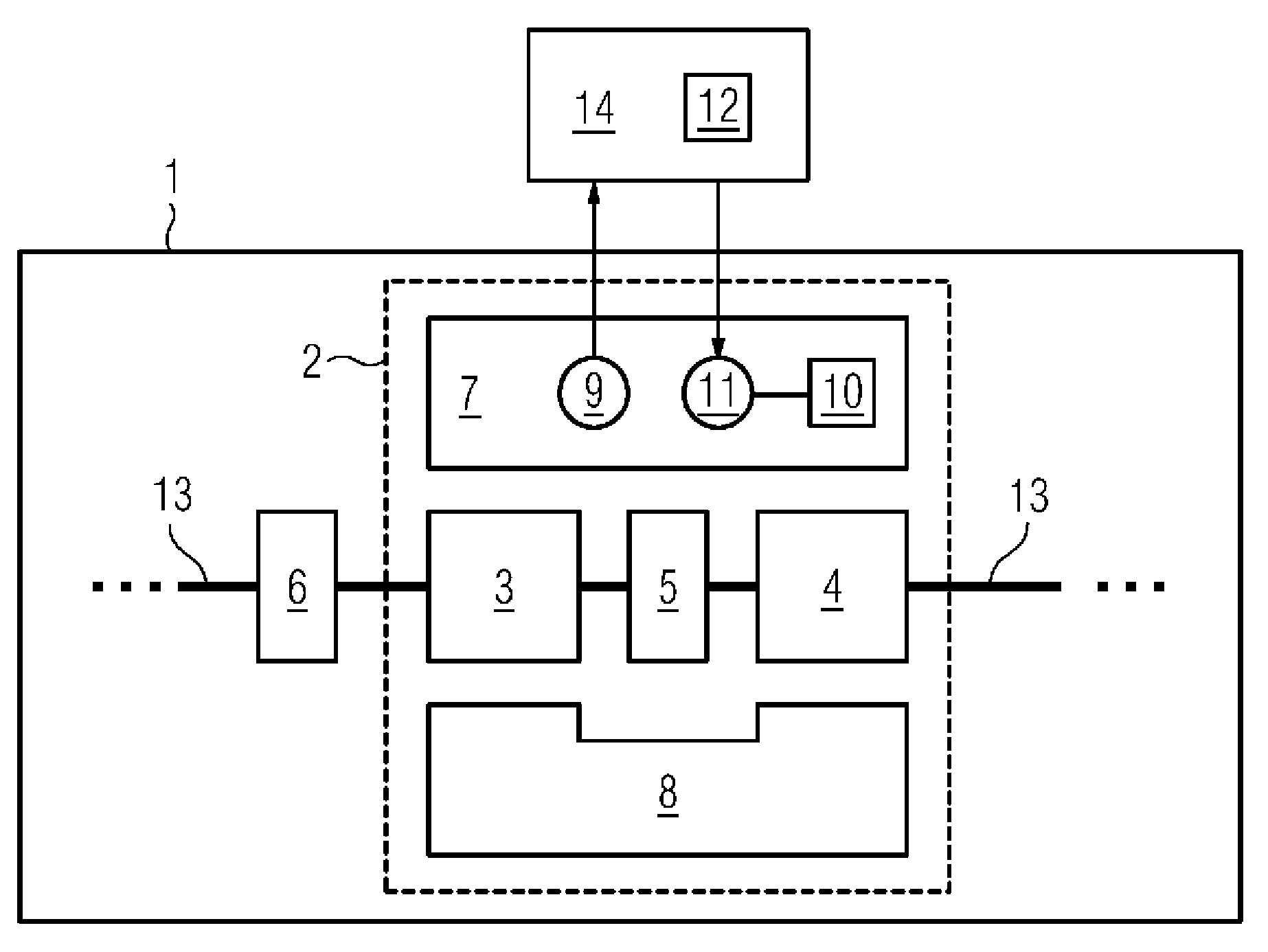

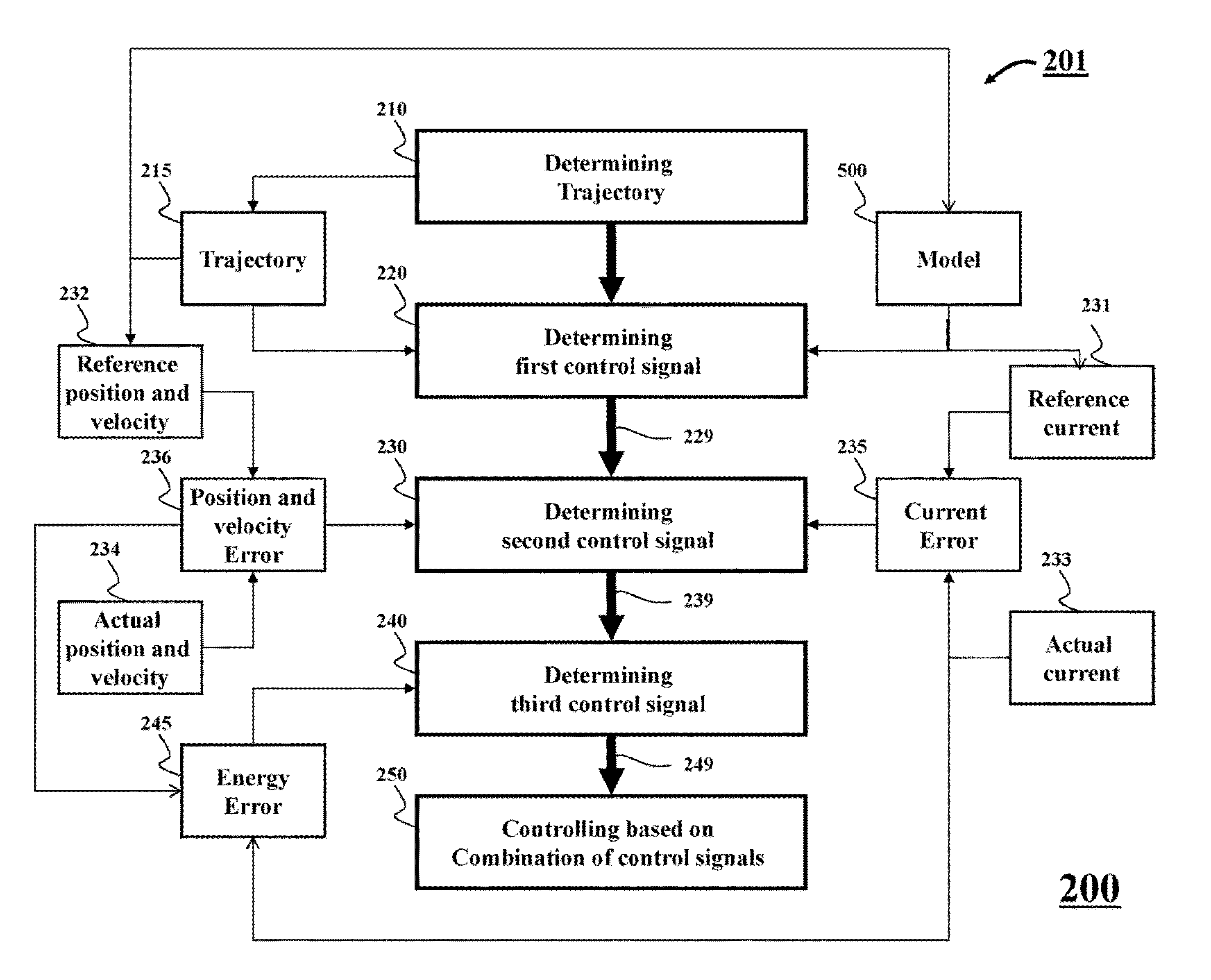

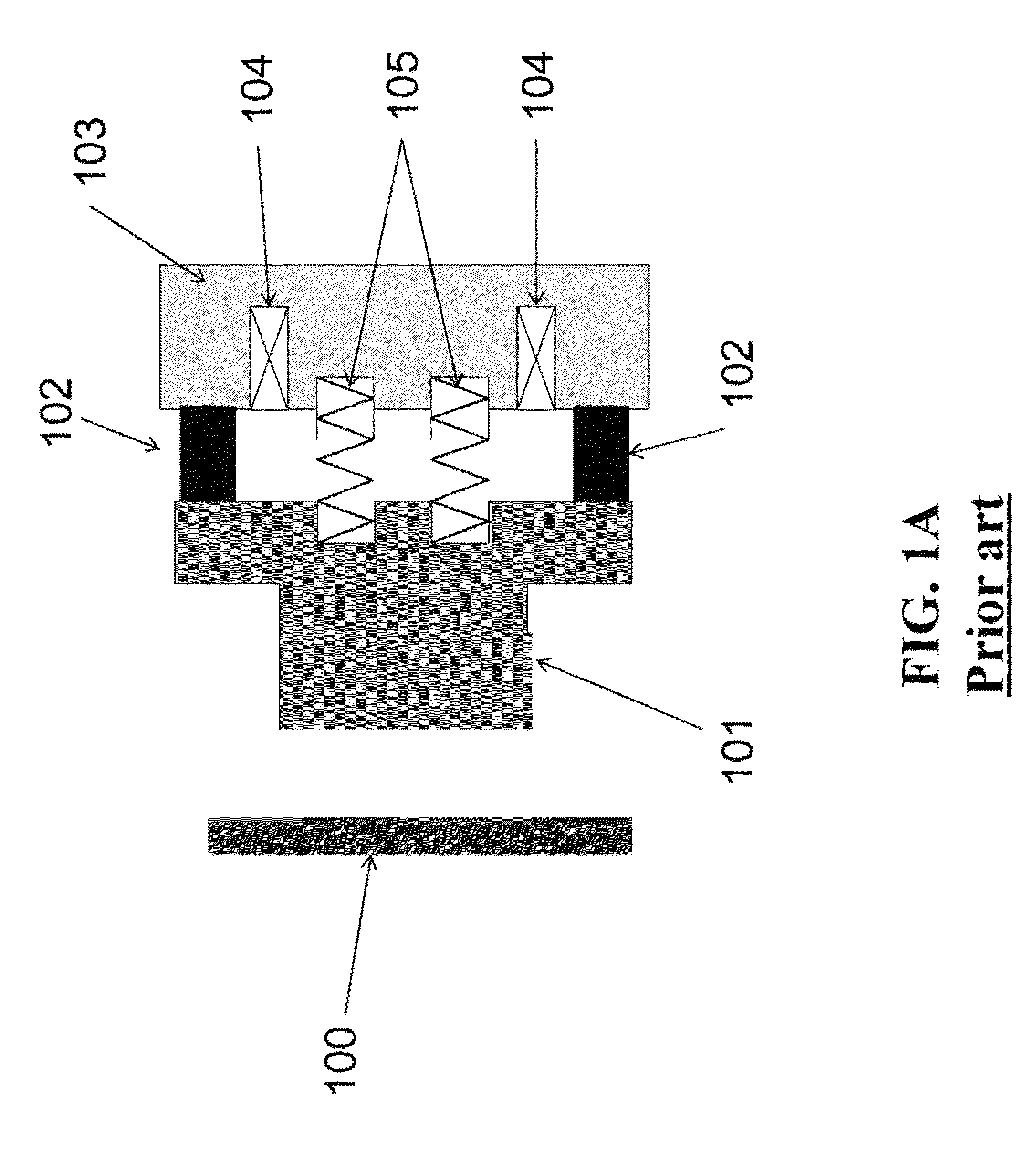

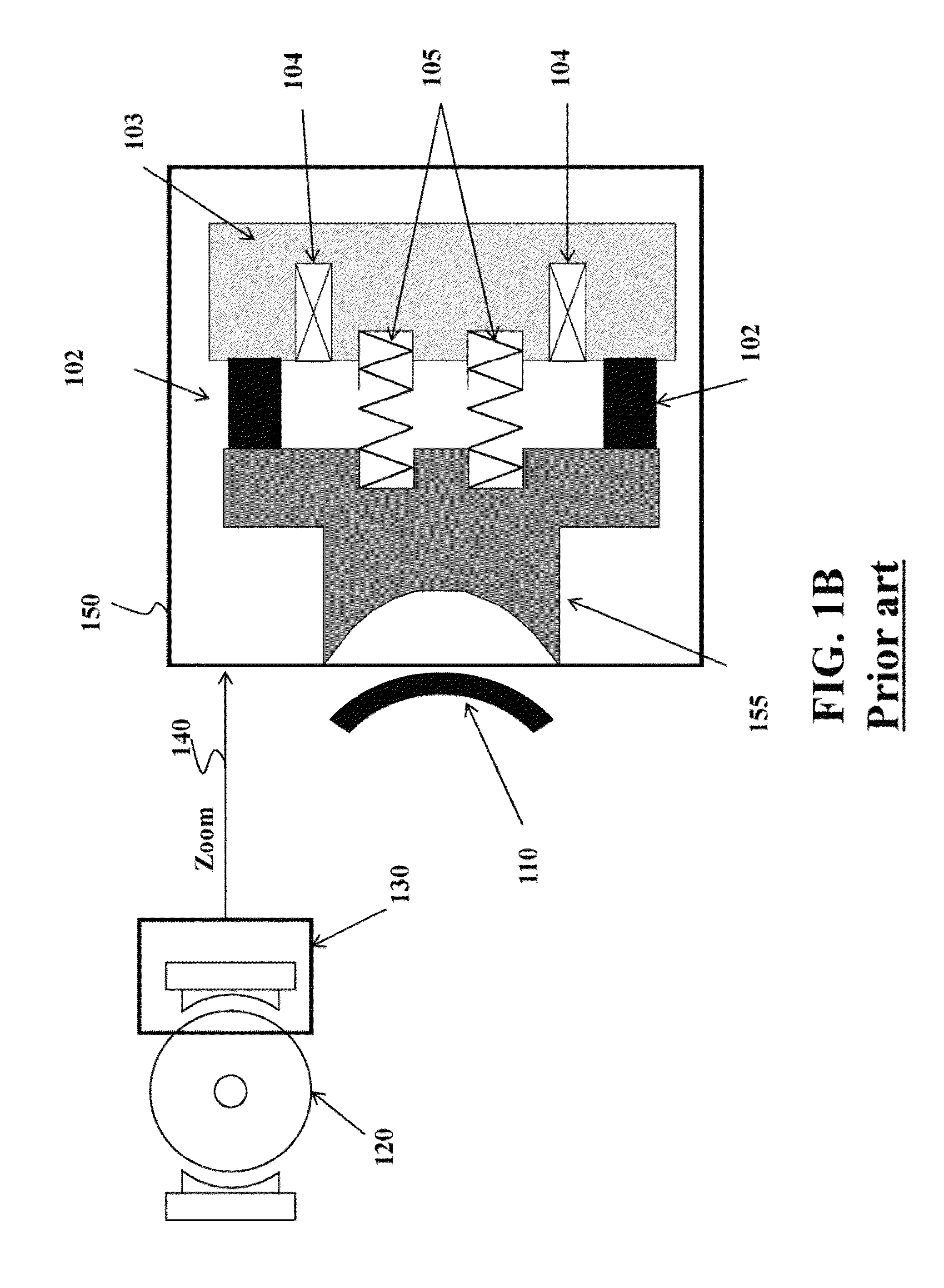

System and method for initiating and maintaining continuous, long-term control of a concentration of a substance in a patient using a feedback or model-based controller coupled to a single-needle or multi-needle intradermal (ID) delivery device

ActiveUS7060059B2Maintaining continuous, long-term control of the blood glucose concentrationsImprove performancePeptide/protein ingredientsDrug and medicationsInsulin infusionClosed loop

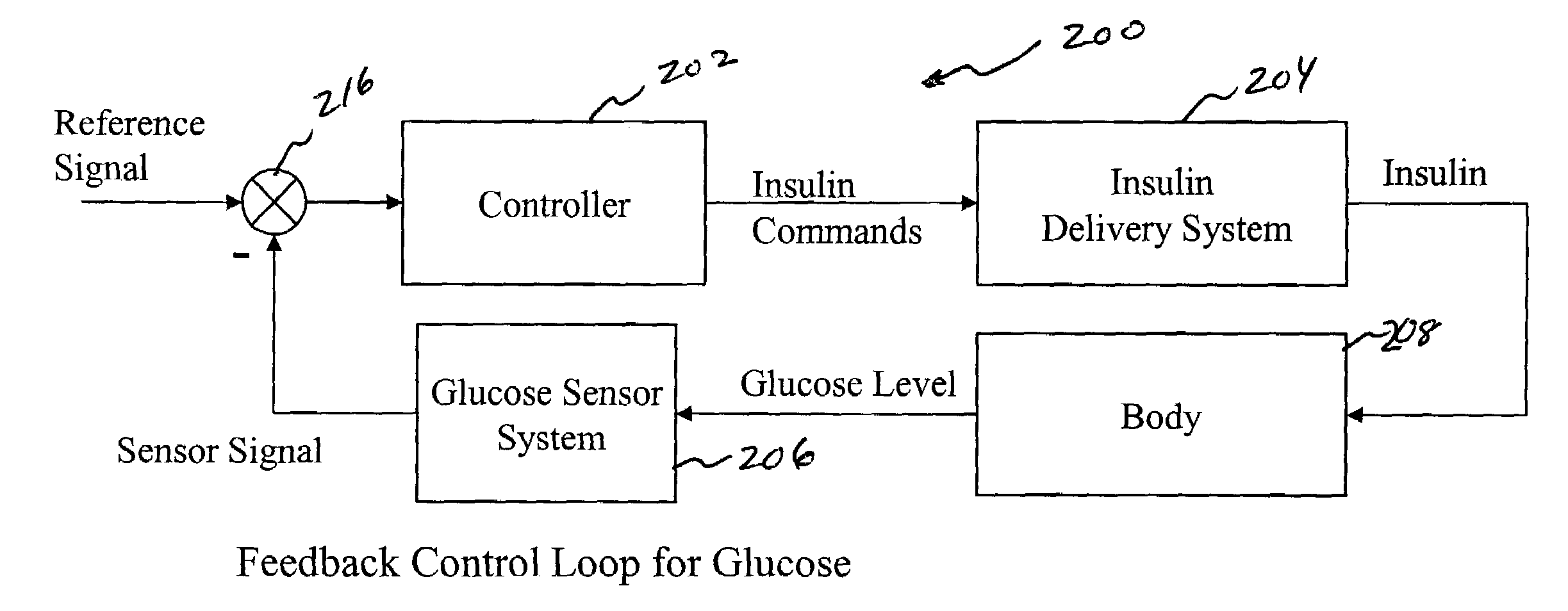

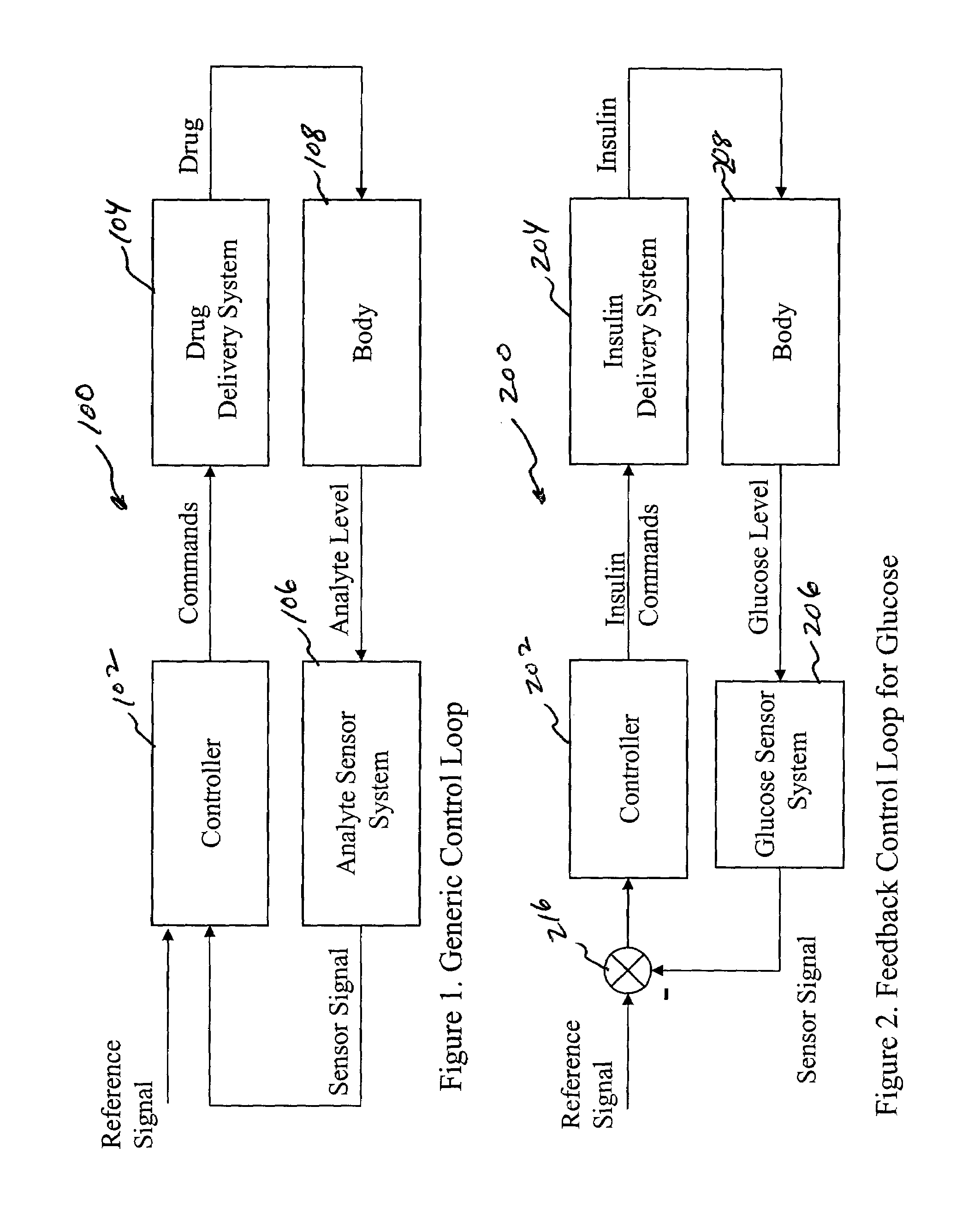

A closed loop therapy system for controlling a concentration of a substance, such as blood glucose concentration, in the body of a user. The system and method employ a sensor system that measures a glucose level in the body, a controller that uses the measured glucose levels to generate an output that can be used to automatically or manually control an intradermal insulin infusion system to set a constant or time-varying profile of target blood glucose concentrations in a user, and then infuse an appropriate amount of insulin into the body of the user so as to reach and maintain the target values of the blood glucose concentration.

Owner:BECTON DICKINSON & CO

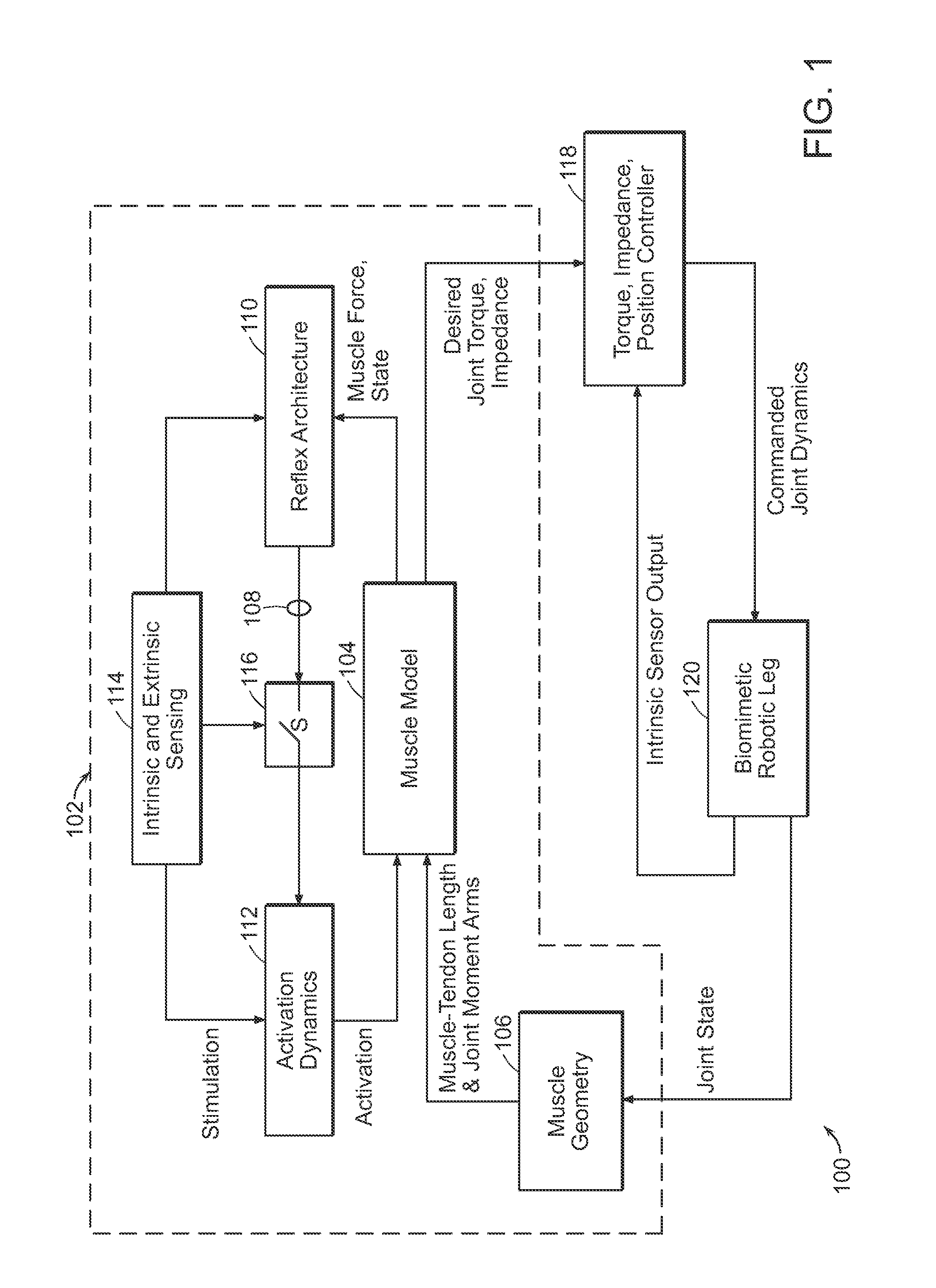

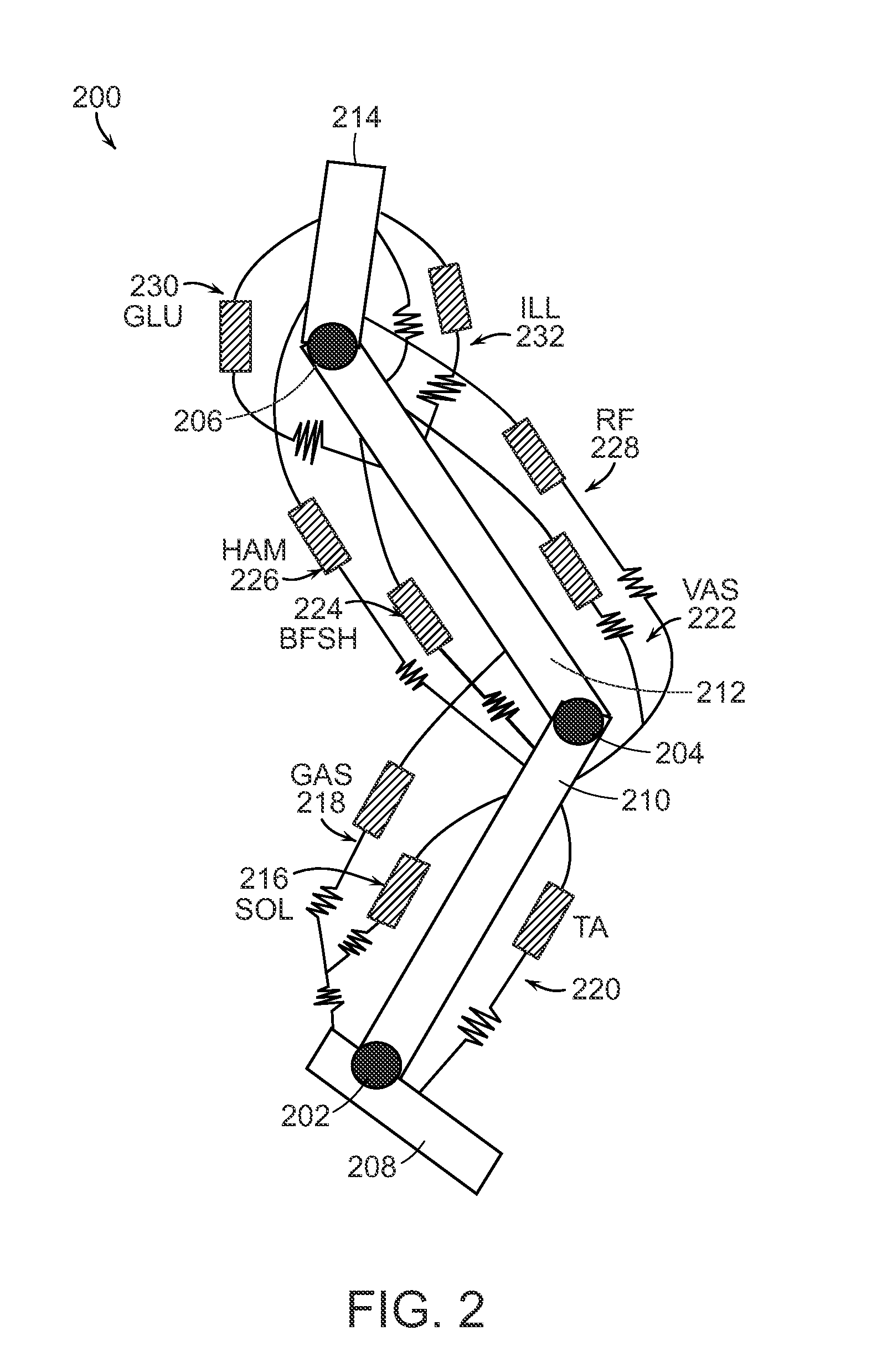

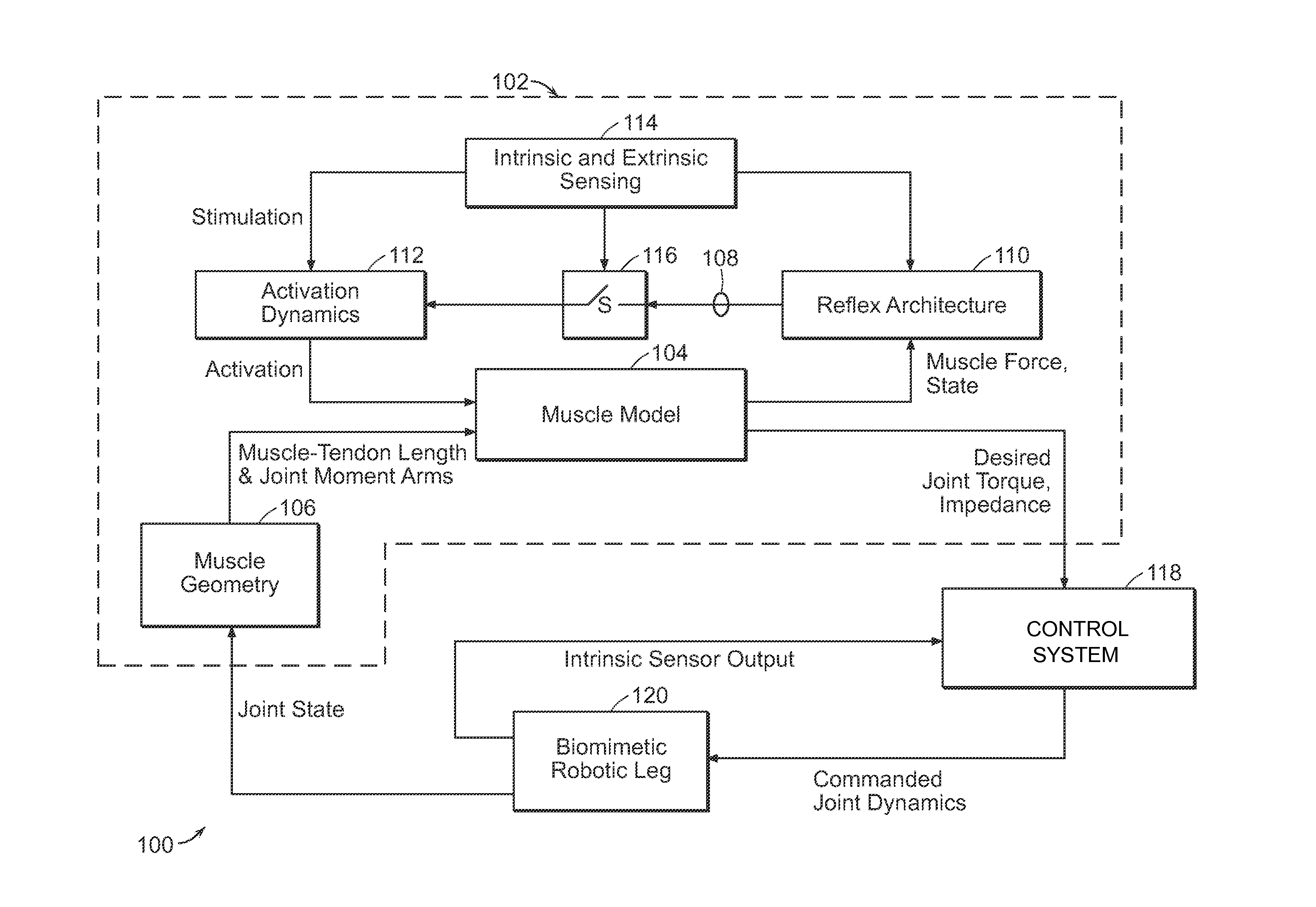

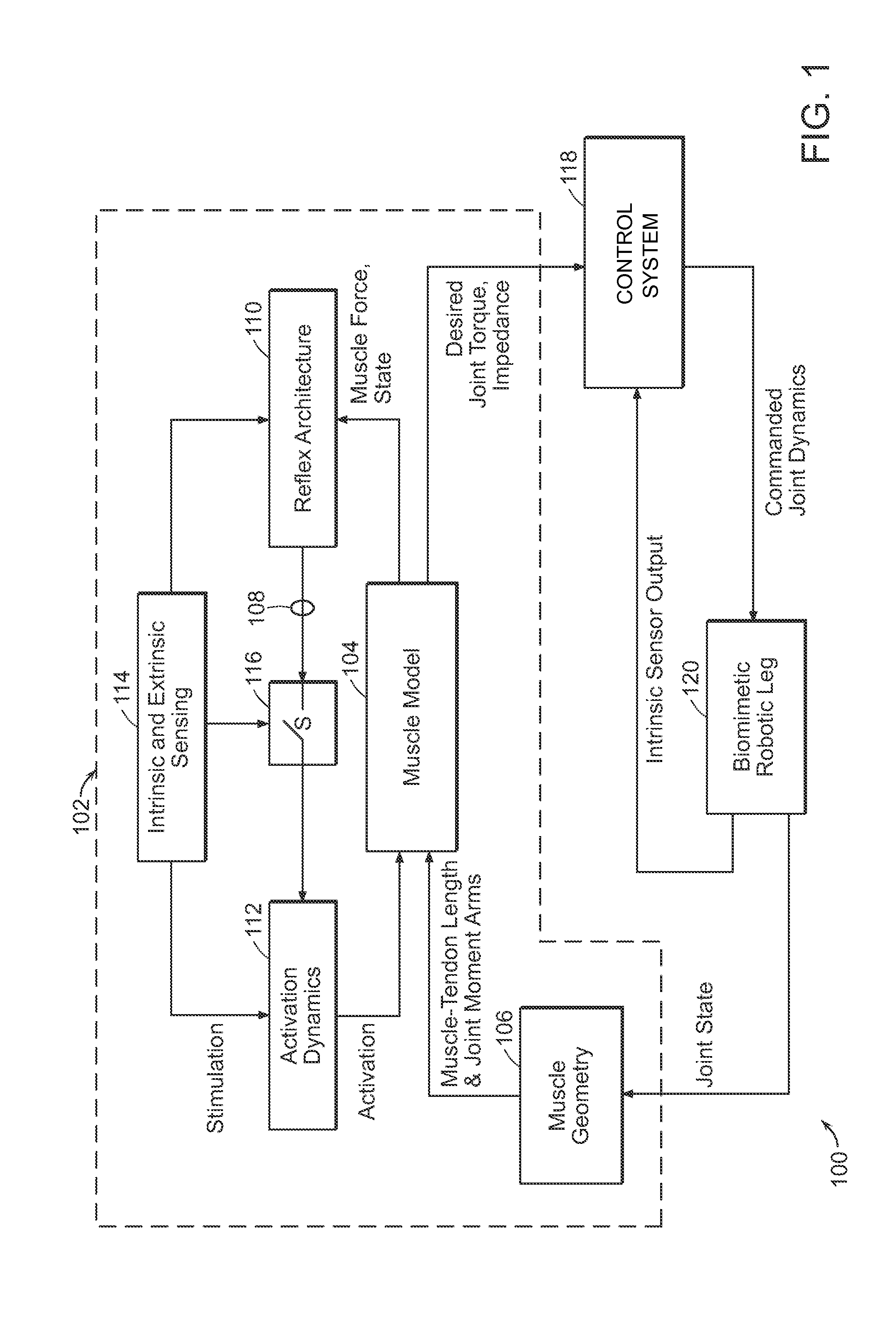

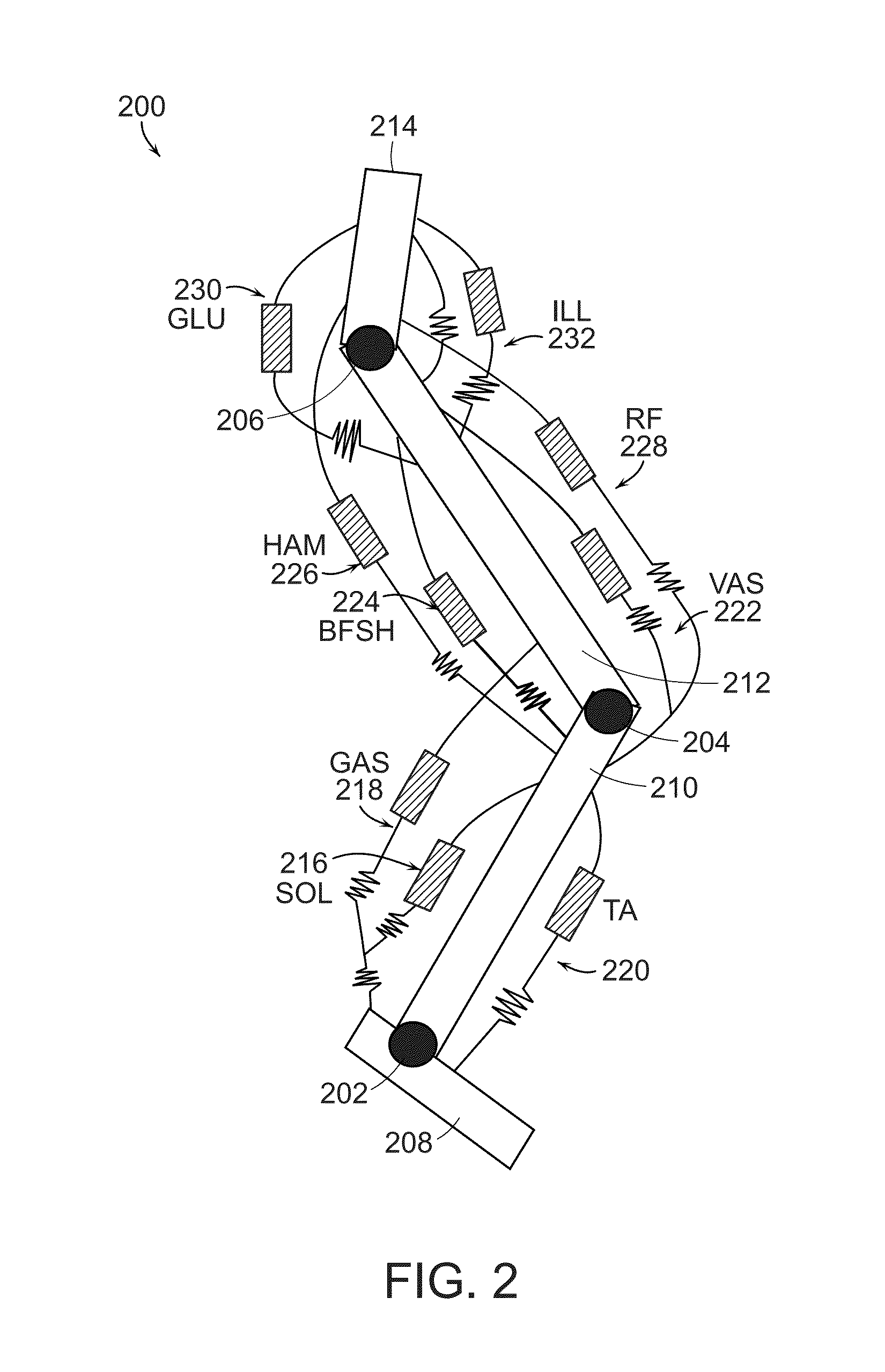

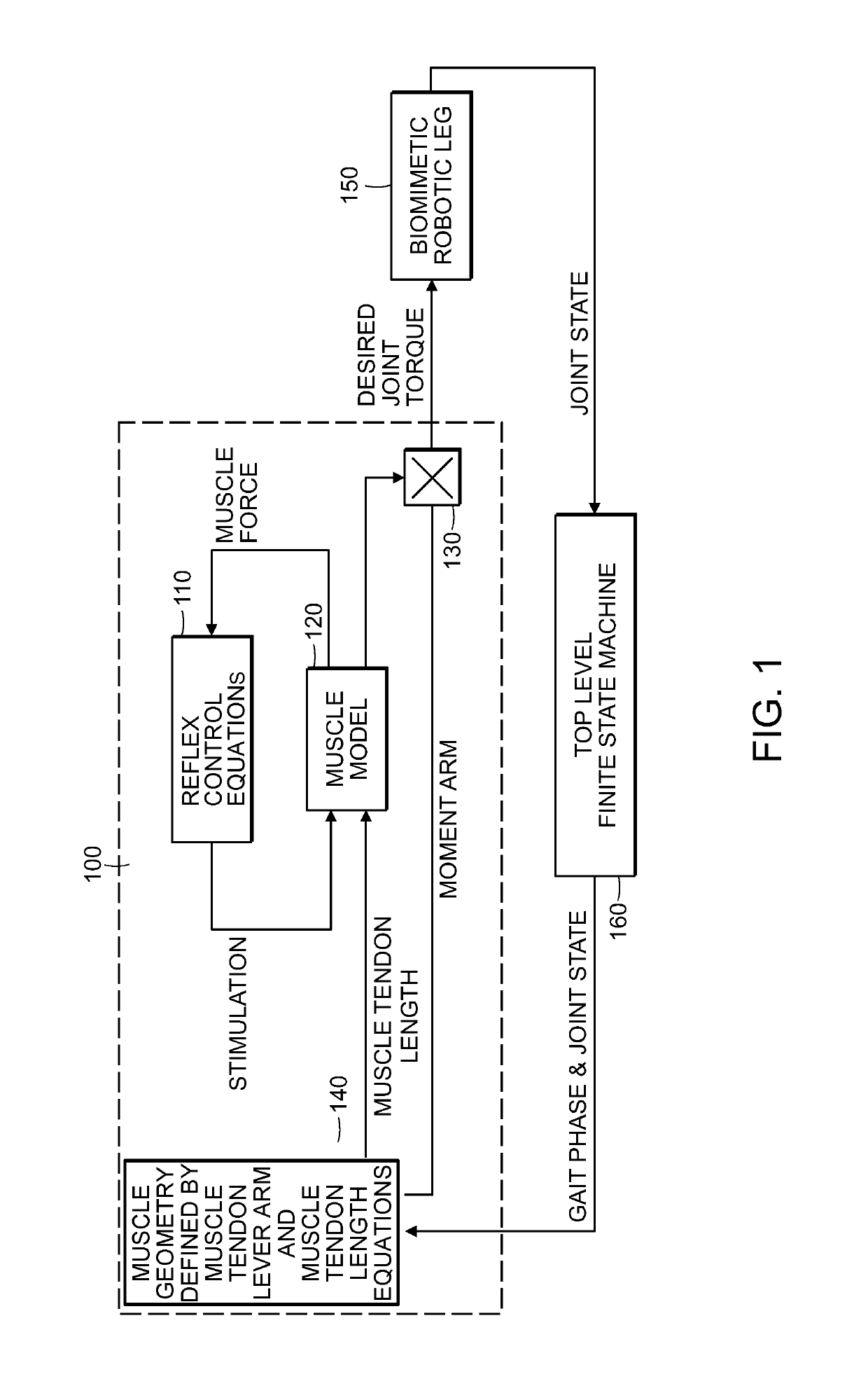

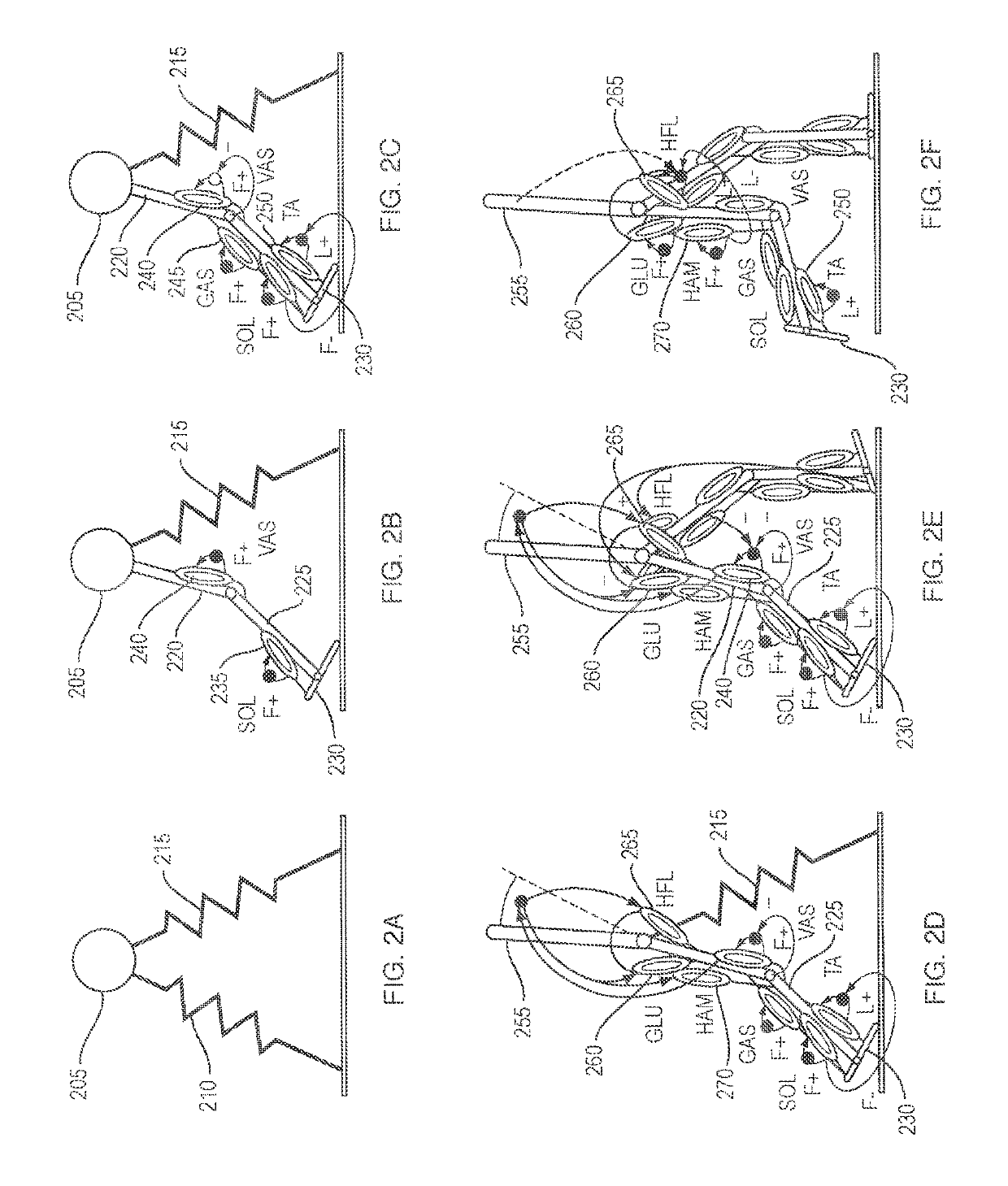

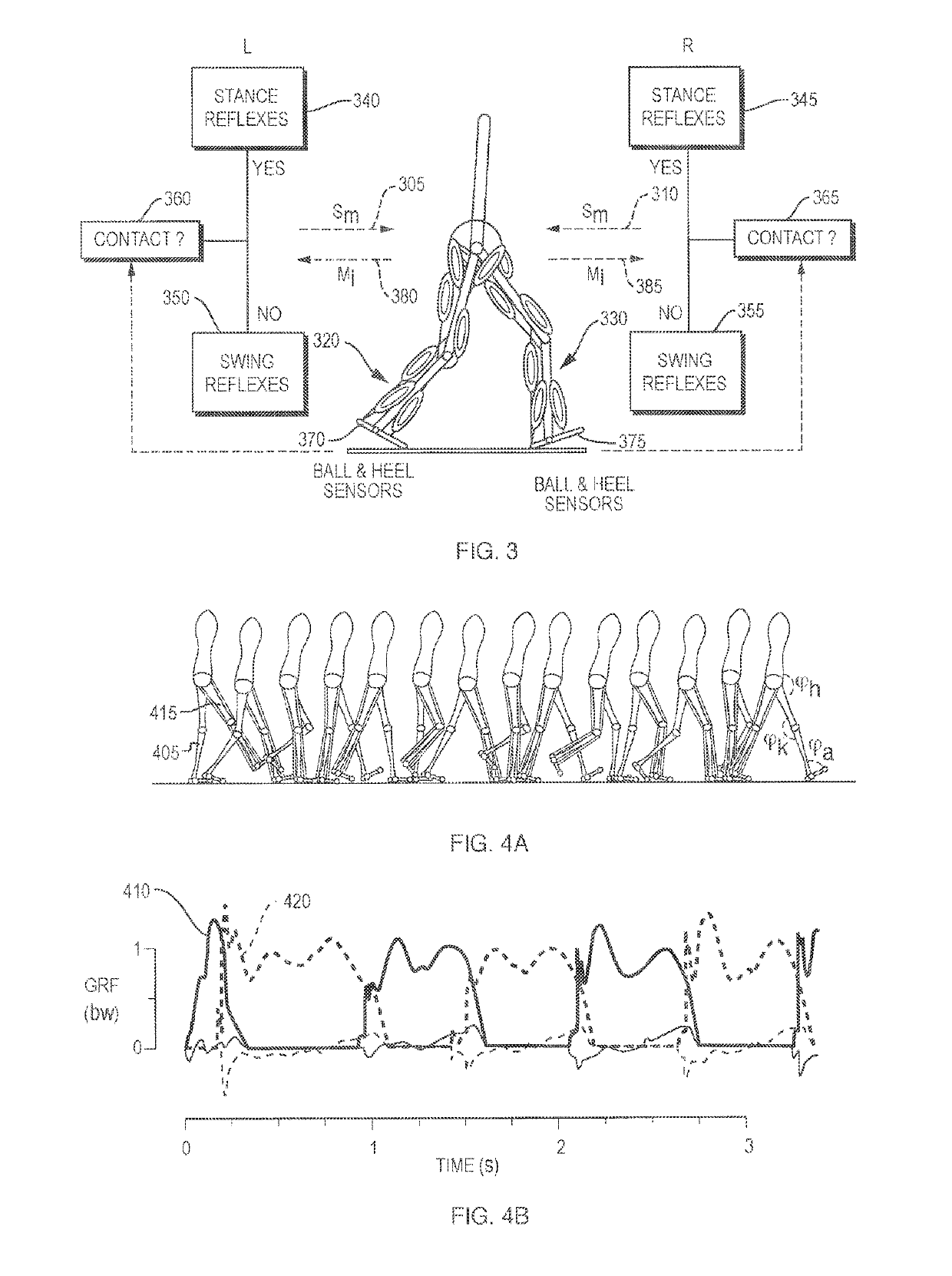

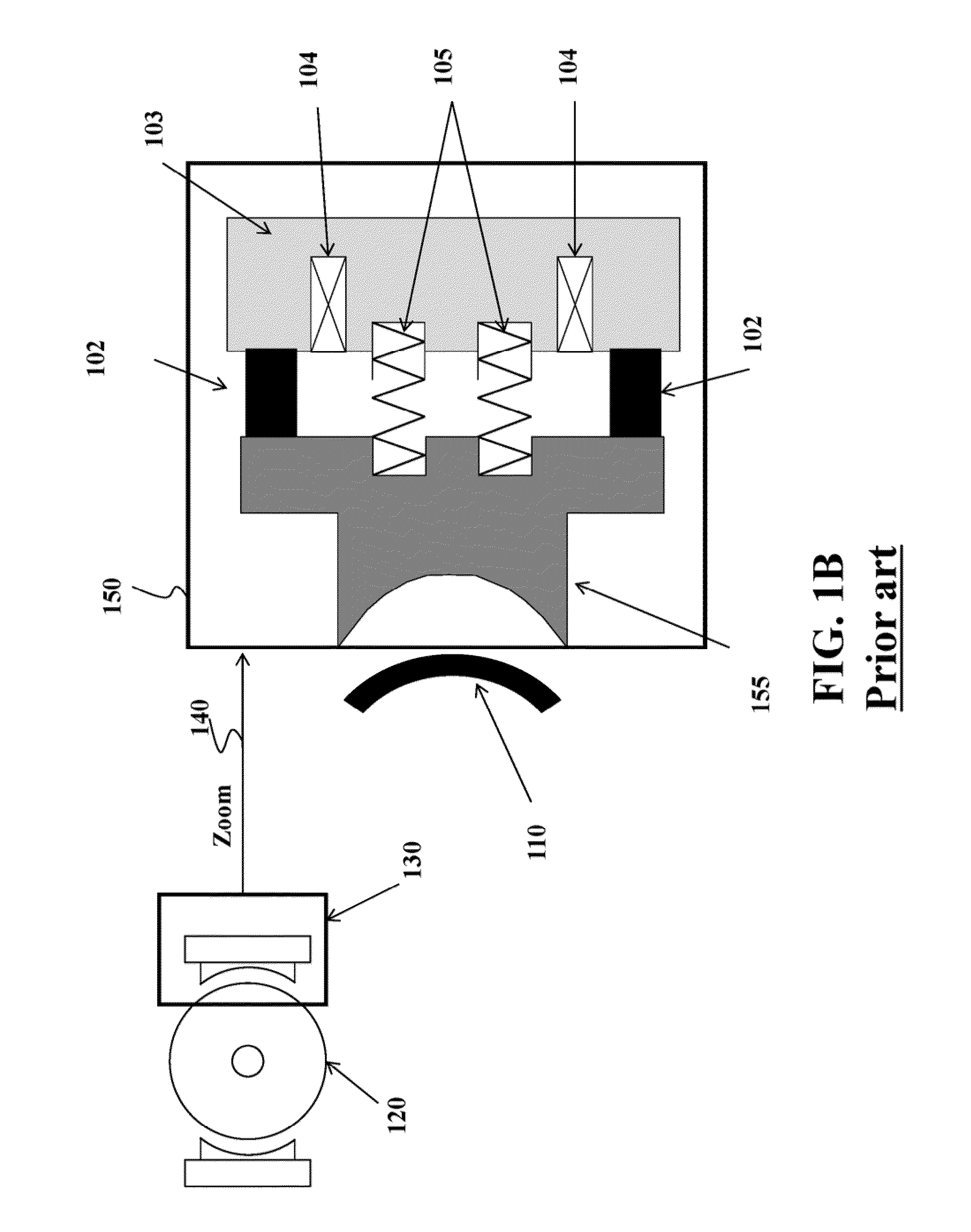

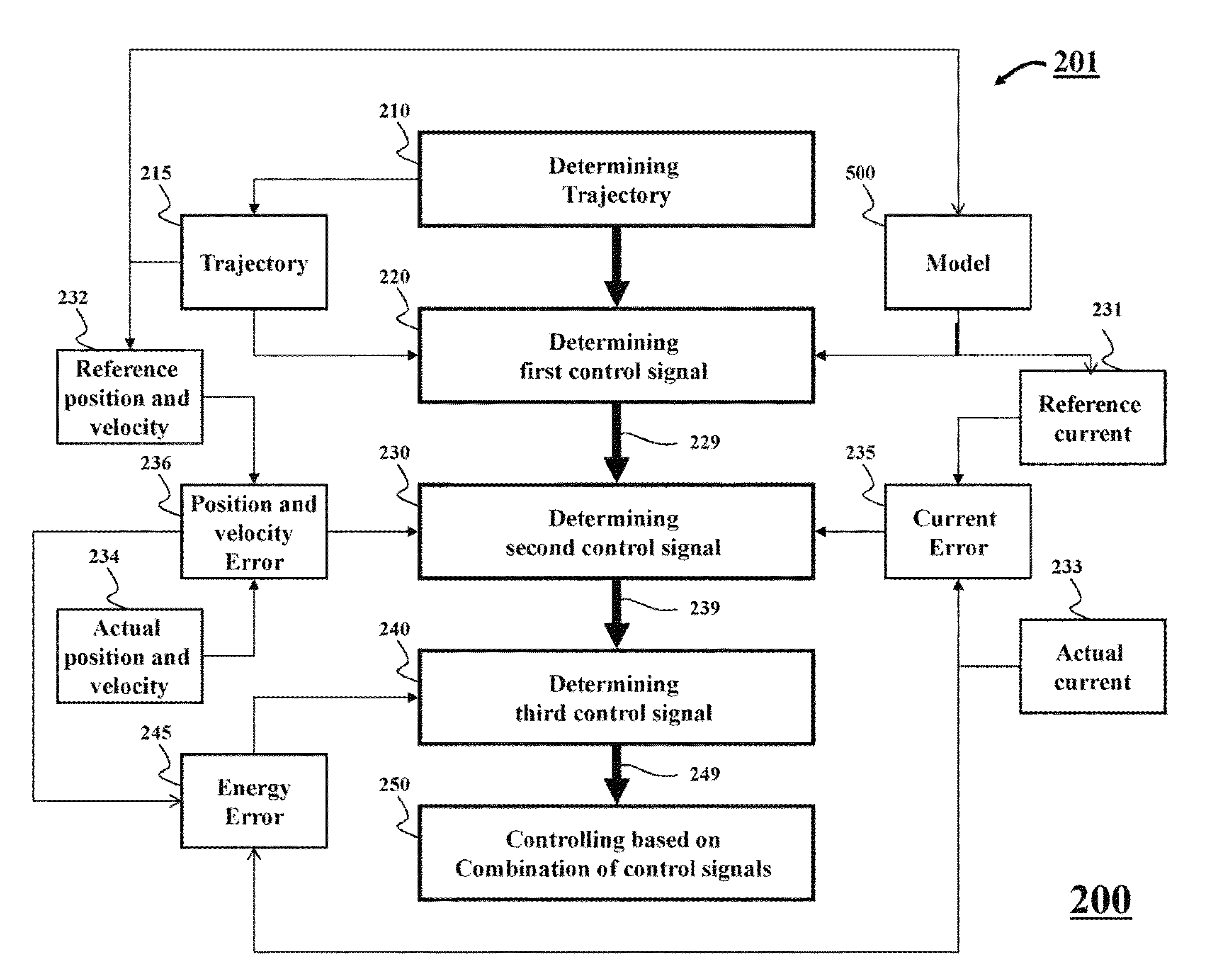

Neuromuscular Model-Based Sensing And Control Paradigm For A Robotic Leg

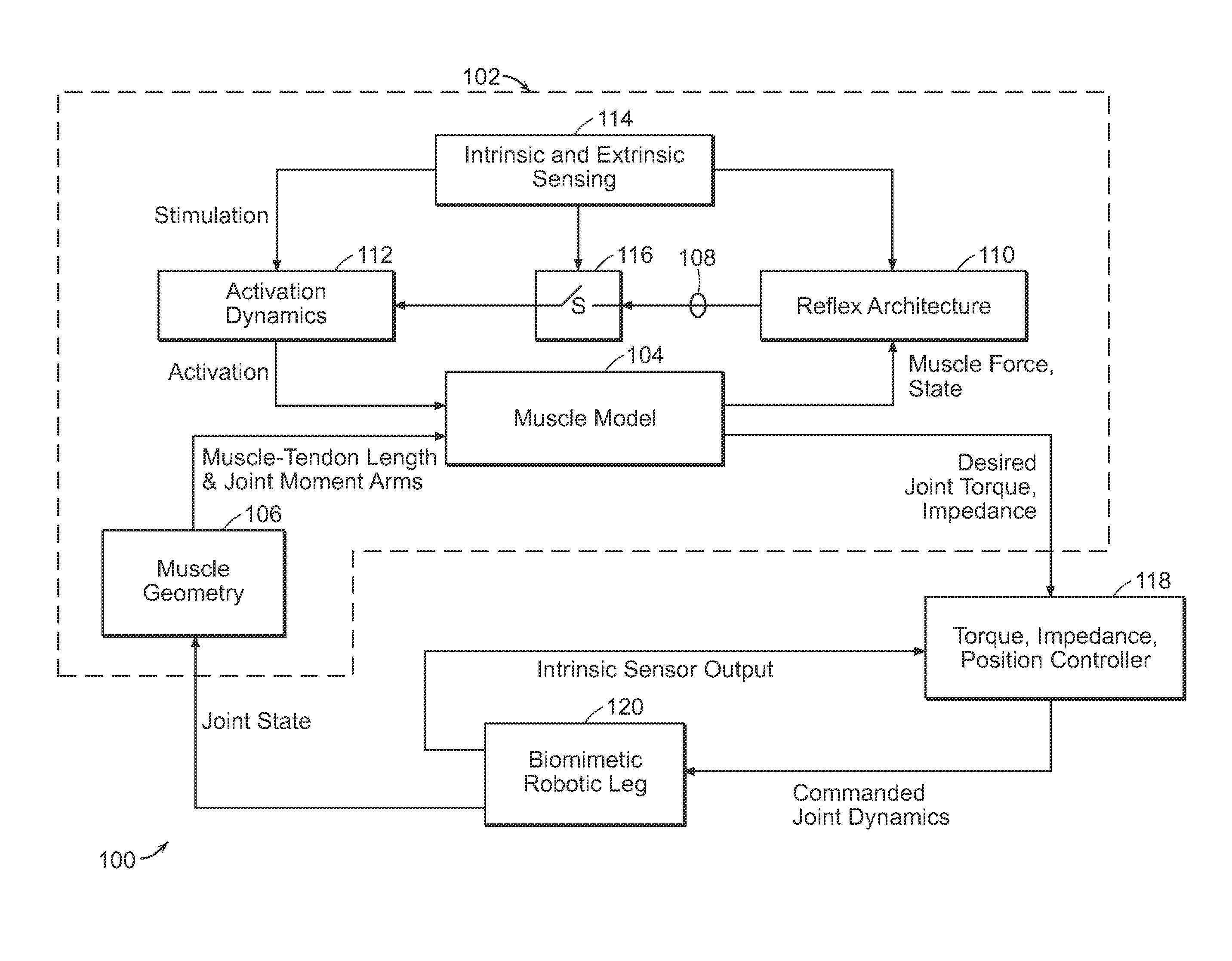

A neuromuscular model-based controller for a robotic limb having at least one joint includes a neuromuscular model having a muscle model, muscle geometry and reflex feedback loop to determine at least one torque or impedance command to be sent to the robotic limb. One or more parameters that determine relation between feedback data and activation of the muscle model are adjusted consequent to sensory data from at least one of an intrinsic sensor and an extrinsic sensor. A controller in communication with the neuromuscular model is configured to receive the at least one torque or impedance command and controls at least one of position, torque and impedance of the robotic limb joint.

Owner:MASSACHUSETTS INST OF TECH

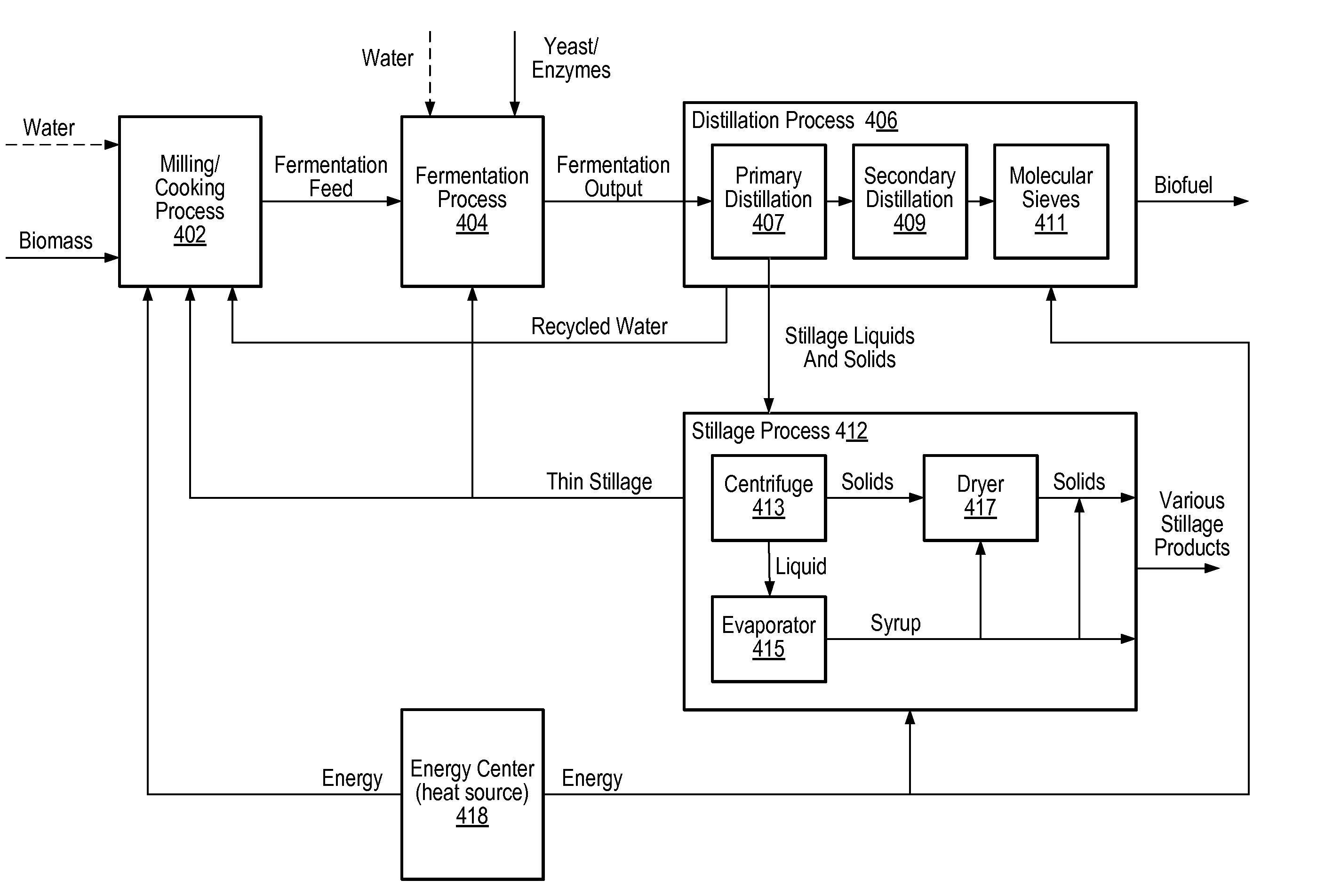

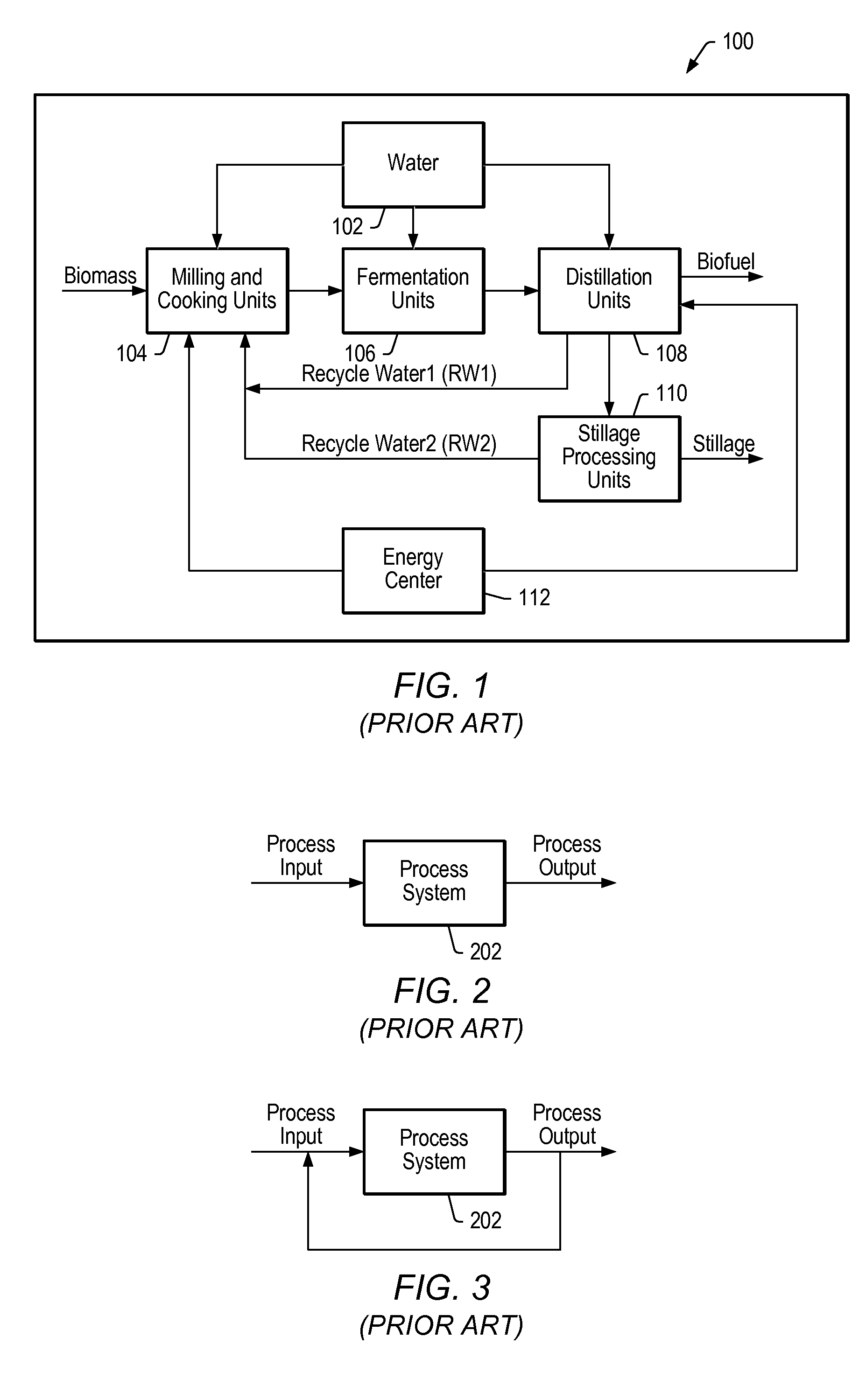

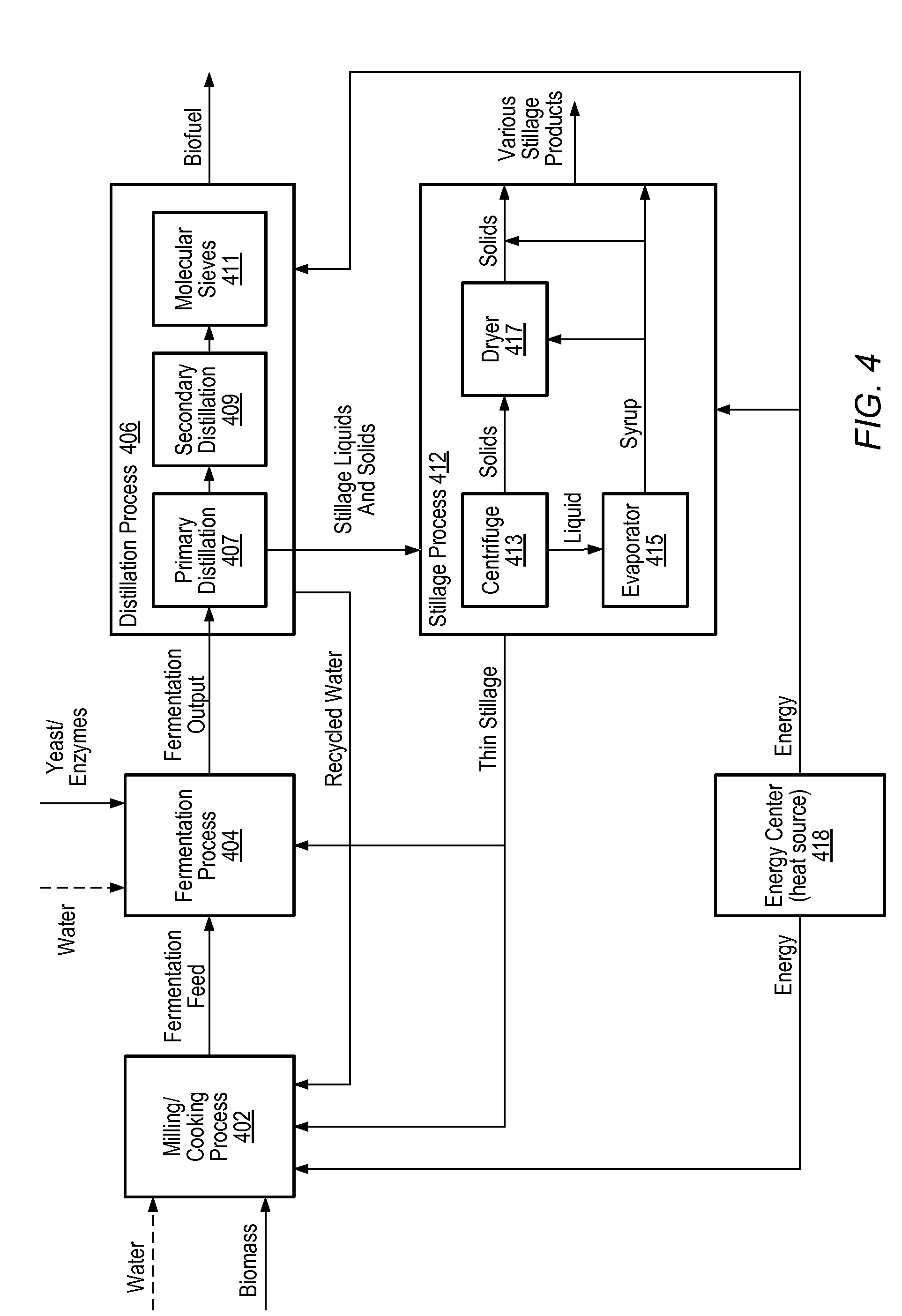

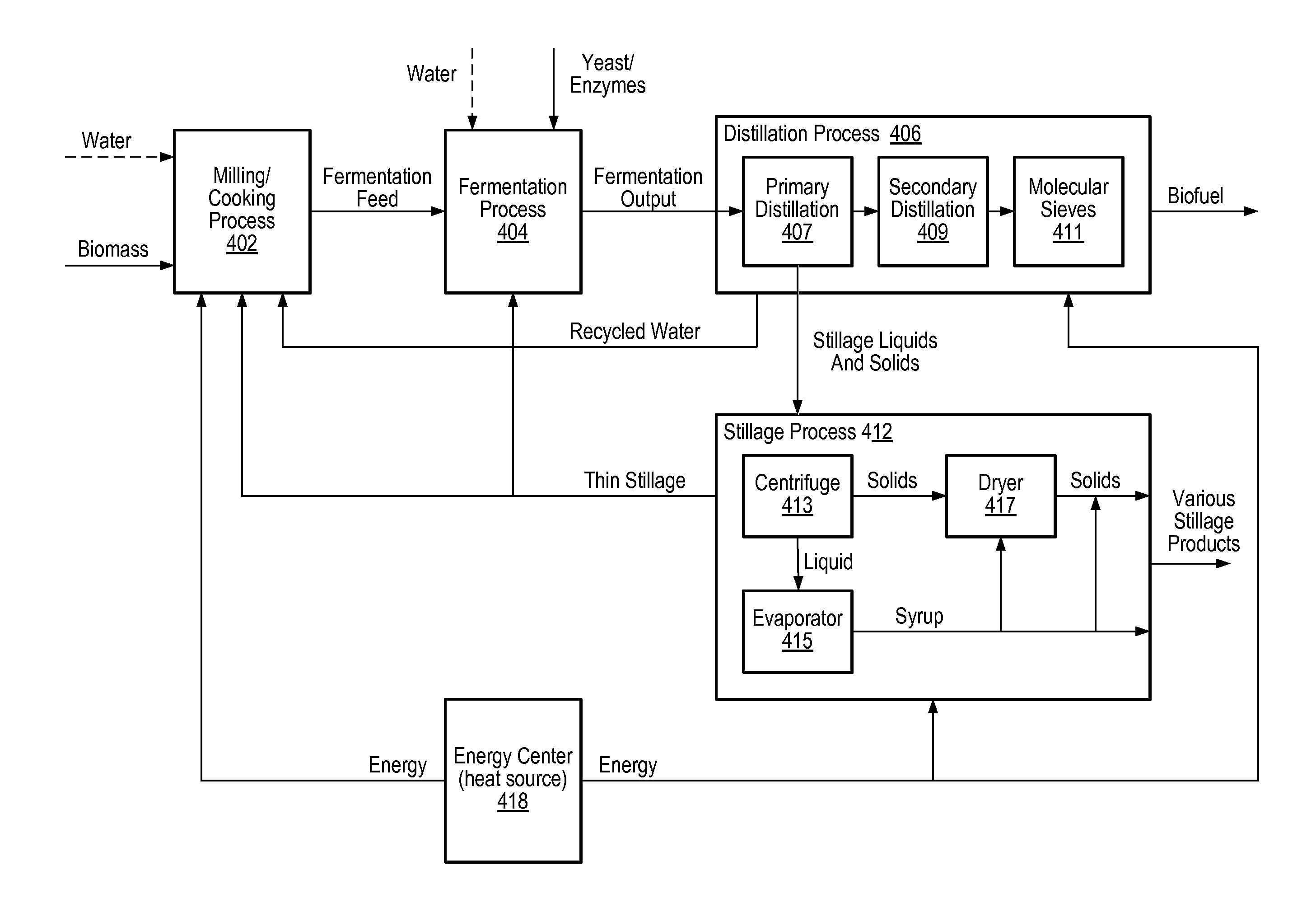

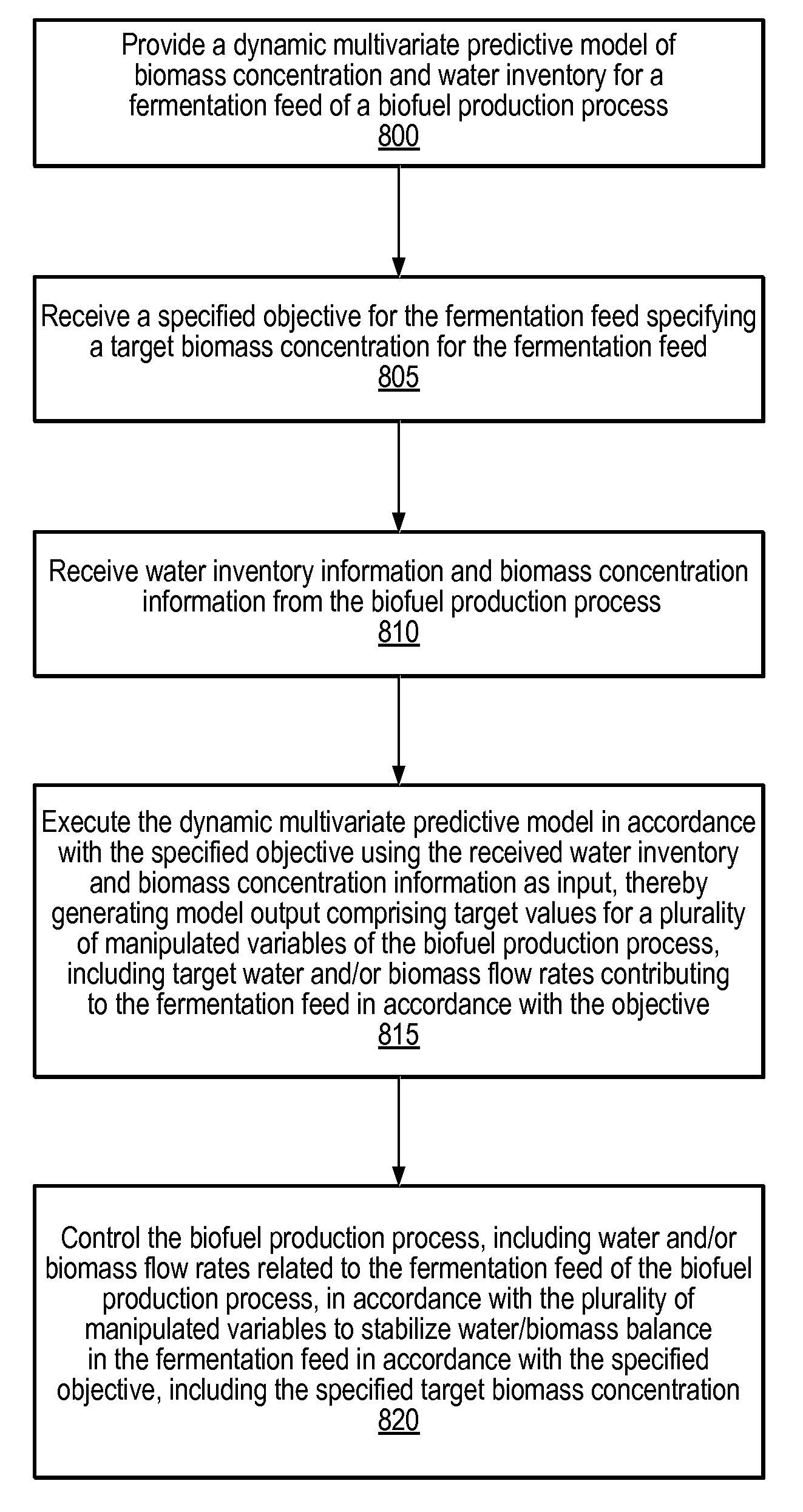

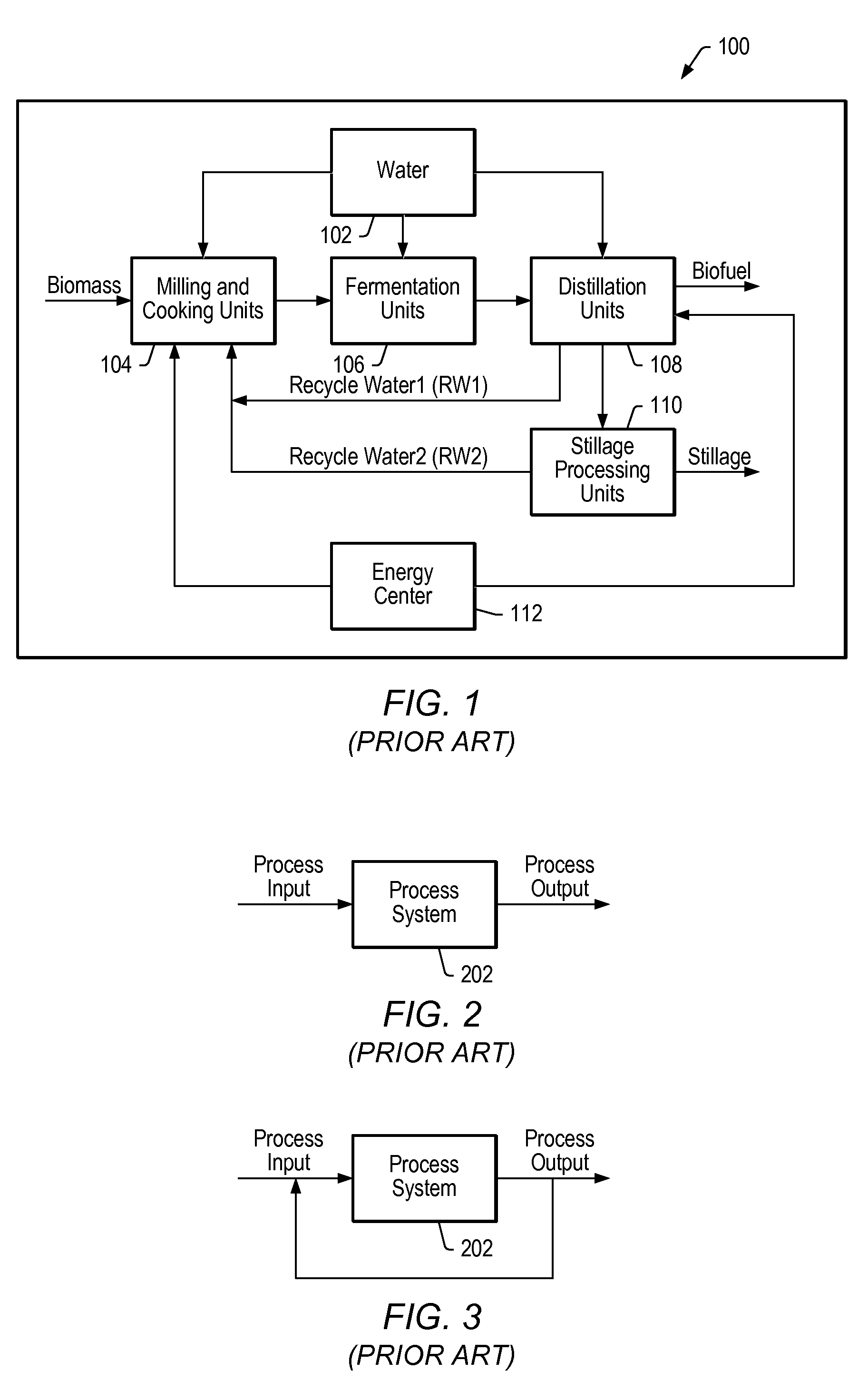

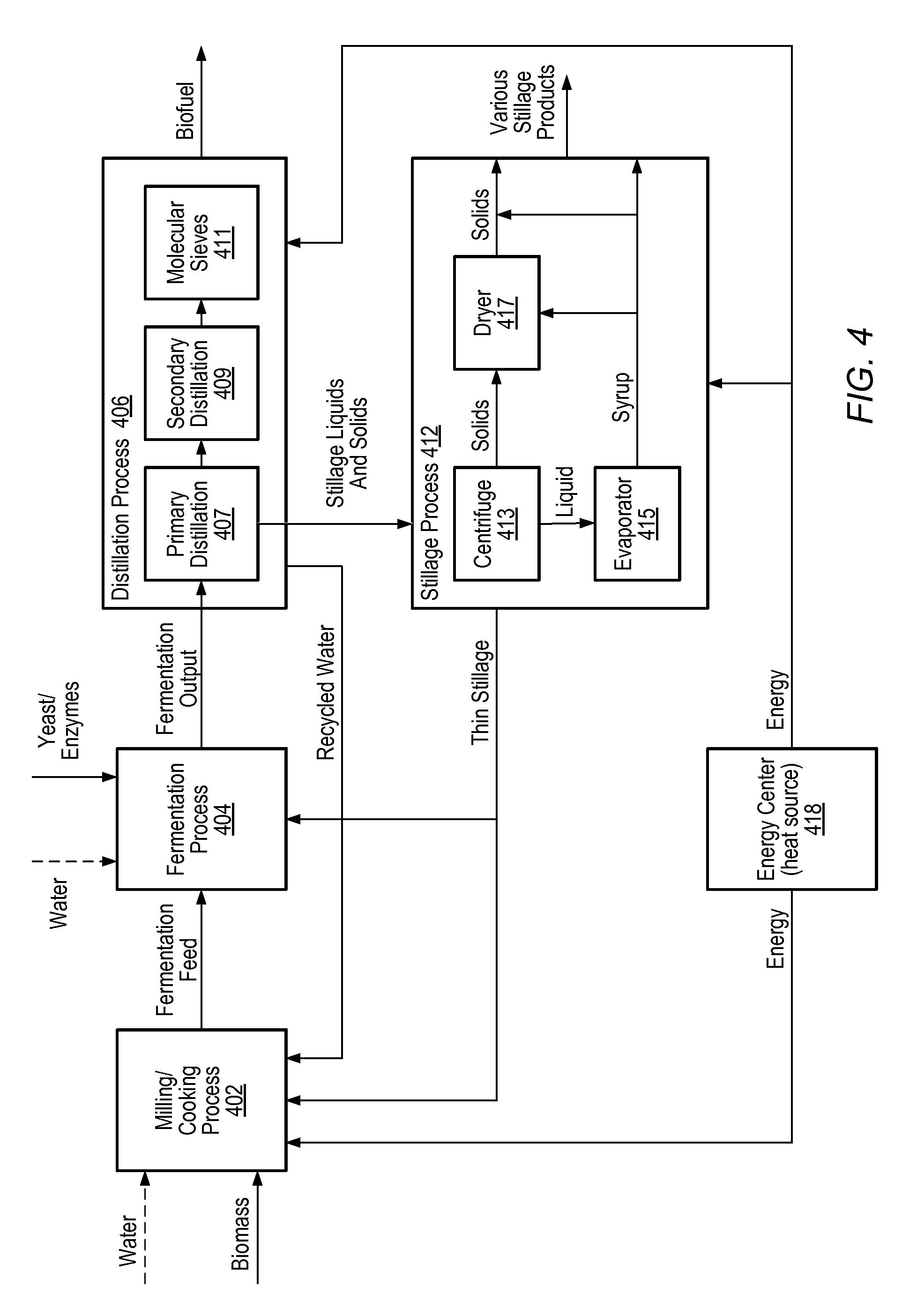

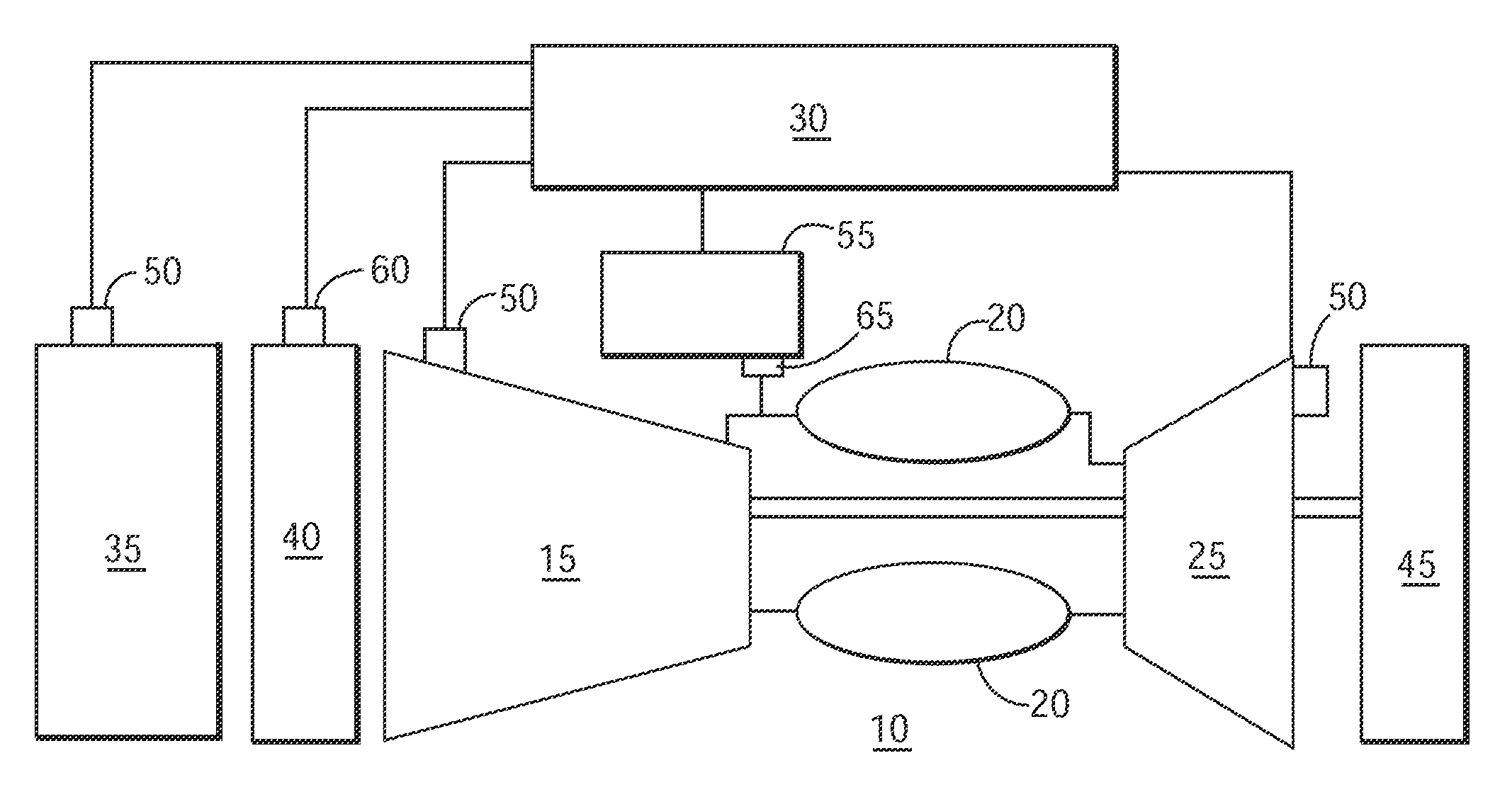

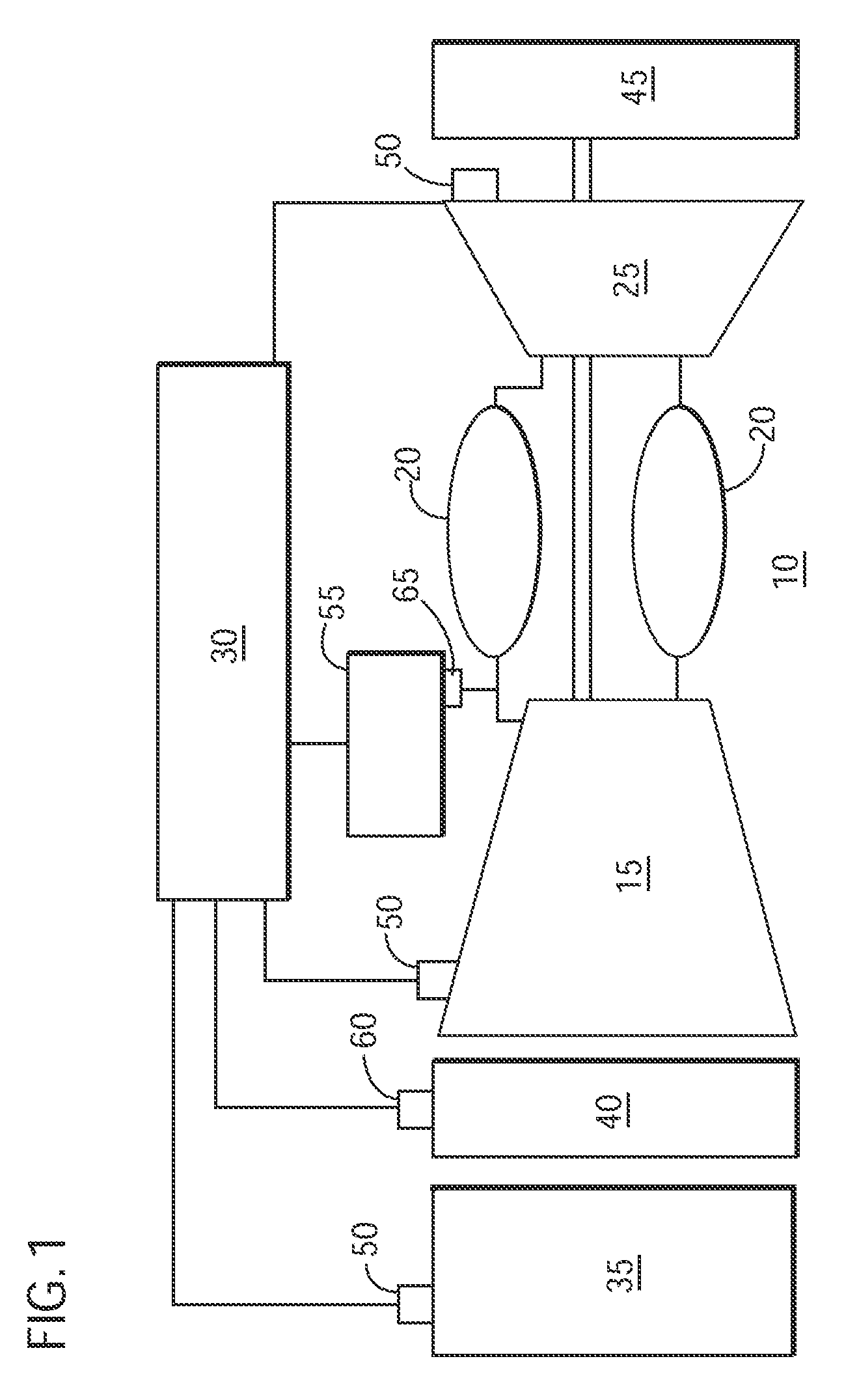

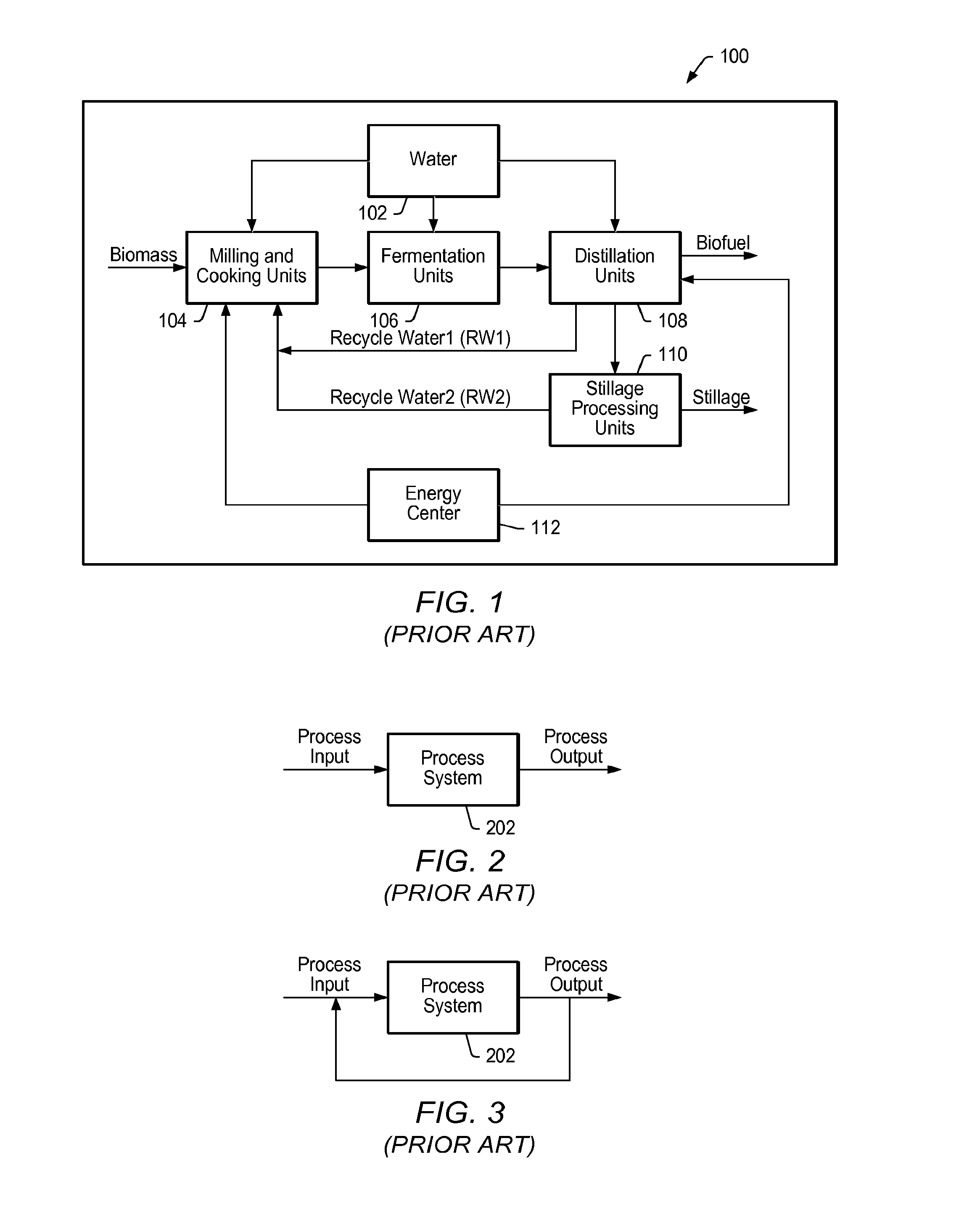

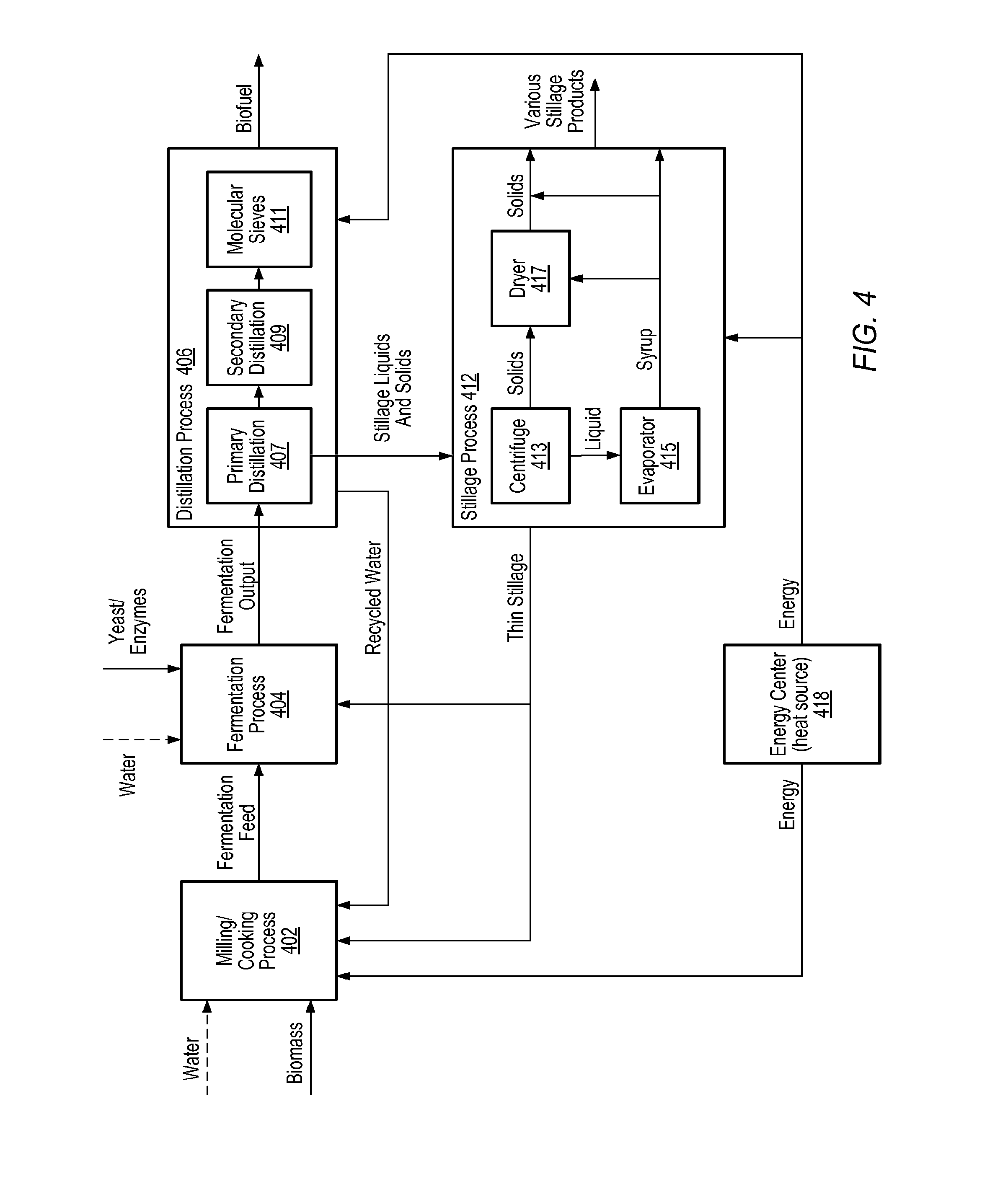

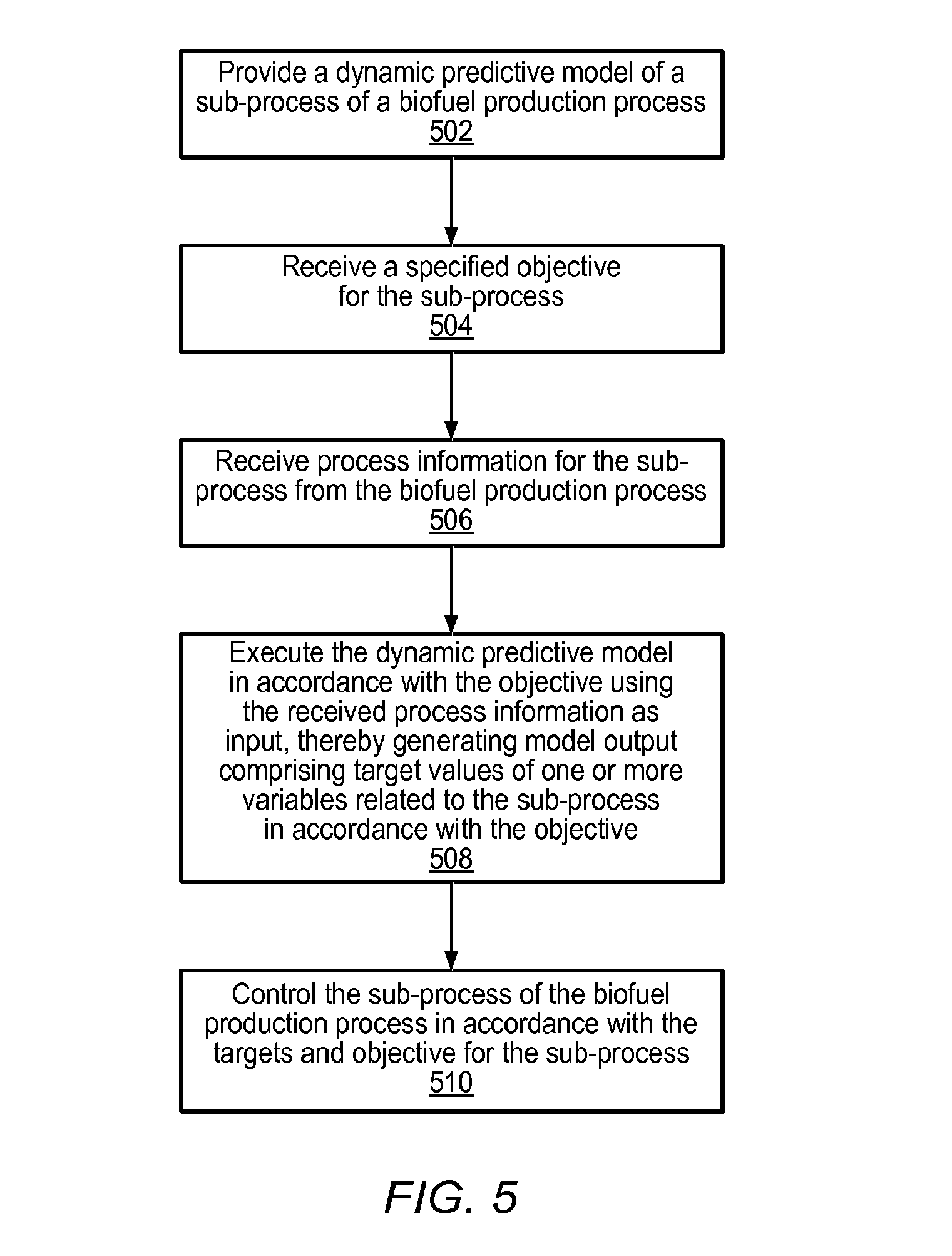

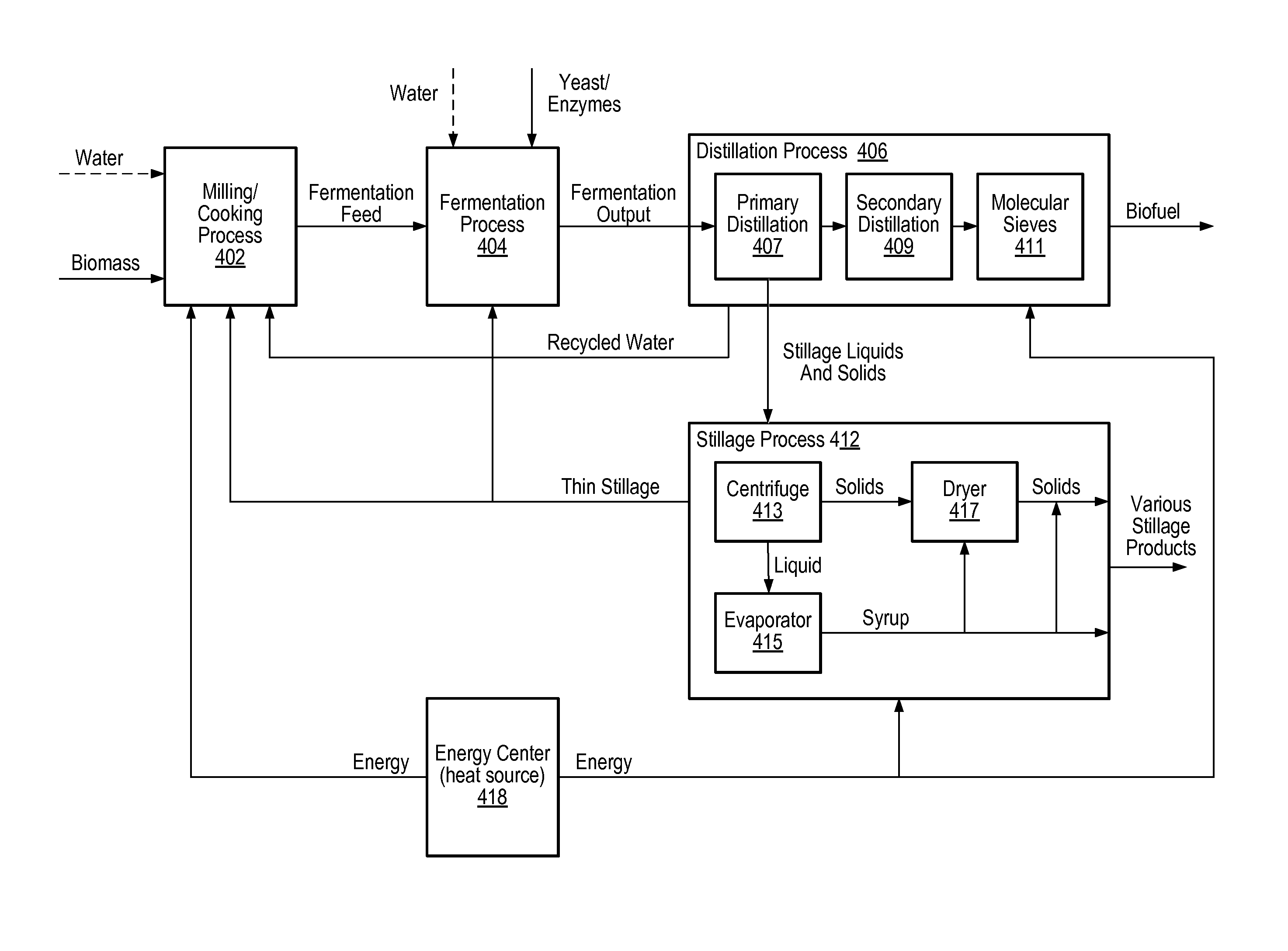

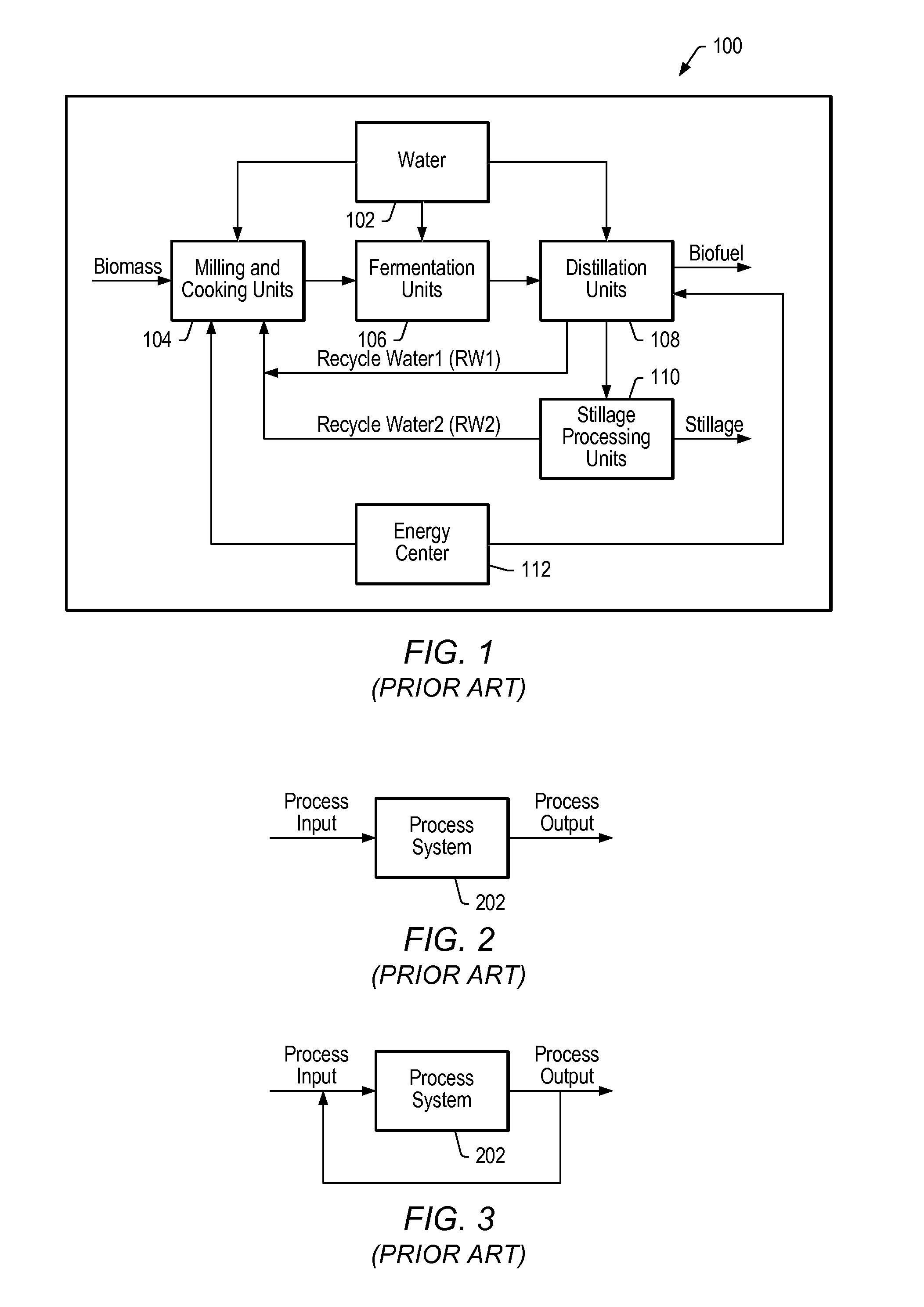

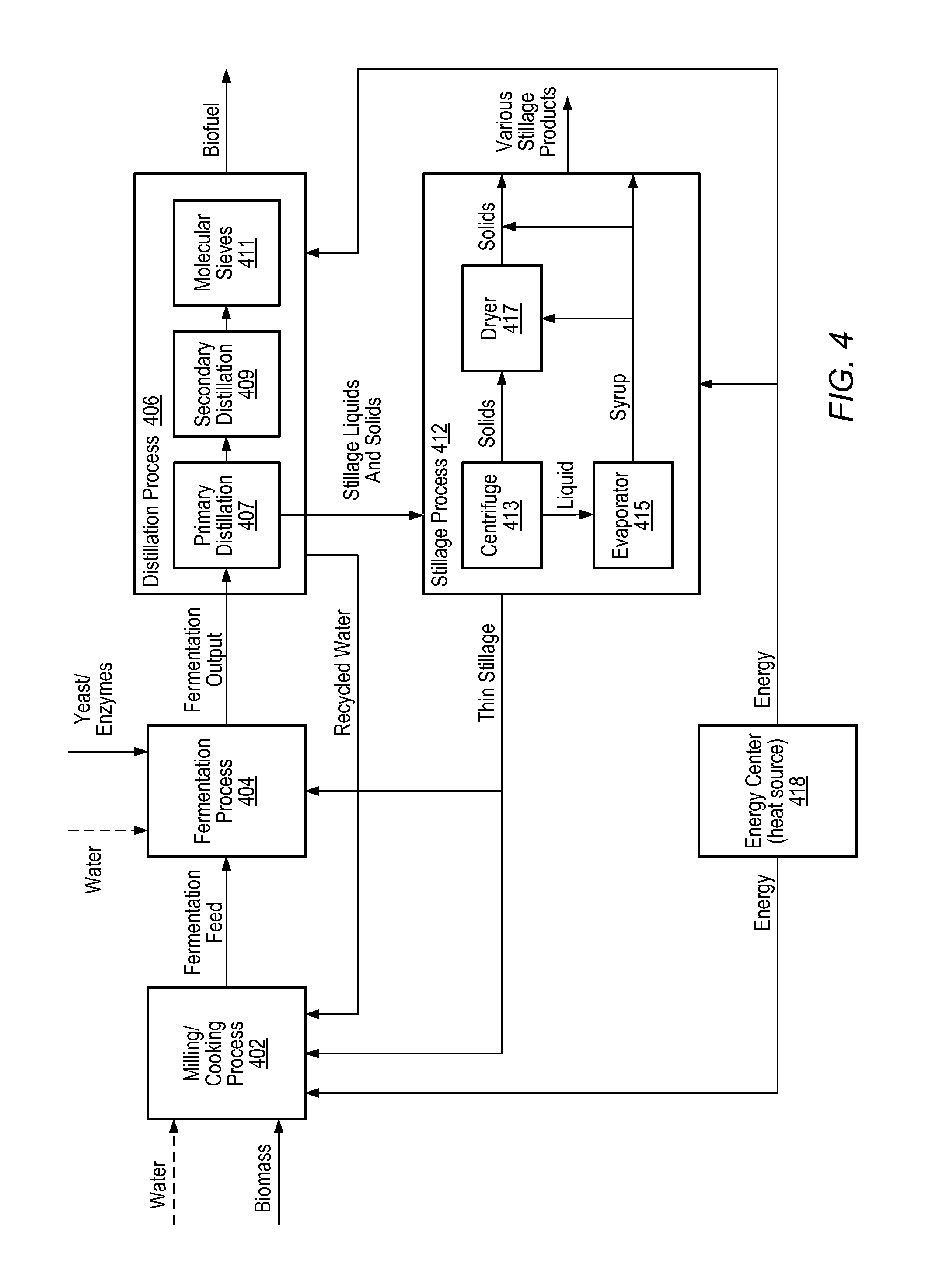

Model predictive control of a fermentation feed in biofuel production

ActiveUS20080104003A1Guaranteed balance and stabilityBioreactor/fermenter combinationsSimulator controlBiofuelModel based controller

System and method for managing fermentation feed in a biofuel production process, comprising a dynamic multivariate predictive model-based controller coupled to a dynamic multivariate predictive model. The model is executable to: receive process information, including water inventory and biomass information, from the biofuel production process; receive a specified objective for the fermentation feed specifying a target biomass concentration; and generate model output comprising target values for a plurality of manipulated variables of the biofuel production process, including target flow rates of water and / or biomass contributing to the fermentation feed in accordance with the specified objective. The controller is operable to dynamically control the biofuel production process by adjusting the plurality of manipulated variables to model-determined target values to stabilize water / biomass balance in the fermentation feed in accordance with the specified objective, including the specified target biomass concentration.

Owner:ROCKWELL AUTOMATION TECH

Neuromuscular model-based sensing and control paradigm for a robotic leg

A neuromuscular model-based controller for a robotic limb having at least one joint includes a neuromuscular model having a muscle model, muscle geometry and reflex feedback loop to determine at least one torque or impedance command to be sent to the robotic limb. One or more parameters that determine relation between feedback data and activation of the muscle model are adjusted consequent to sensory data from at least one of an intrinsic sensor and an extrinsic sensor. A controller in communication with the neuromuscular model is configured to receive the at least one torque or impedance command and controls at least one of position, torque and impedance of the robotic limb joint.

Owner:MASSACHUSETTS INST OF TECH

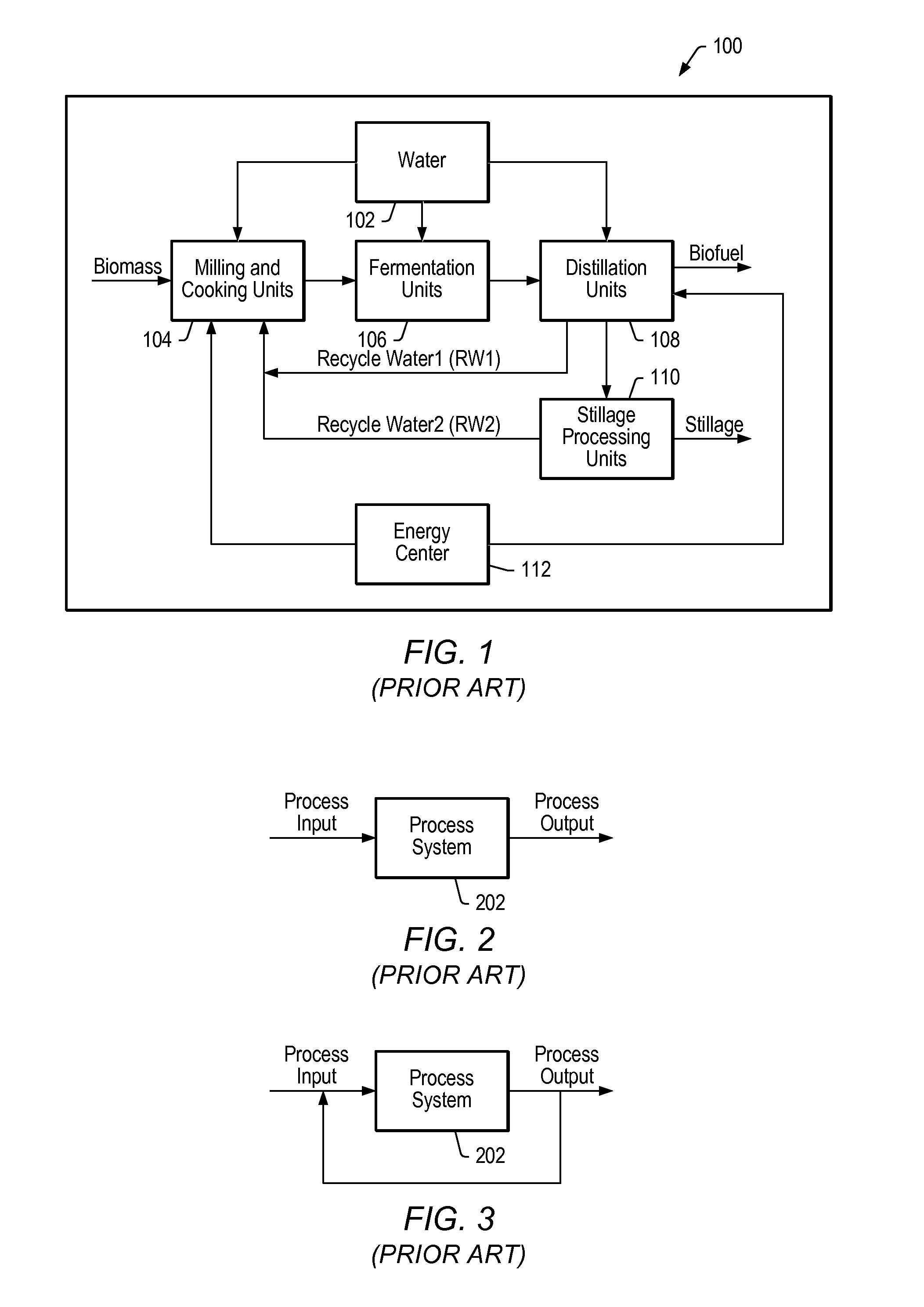

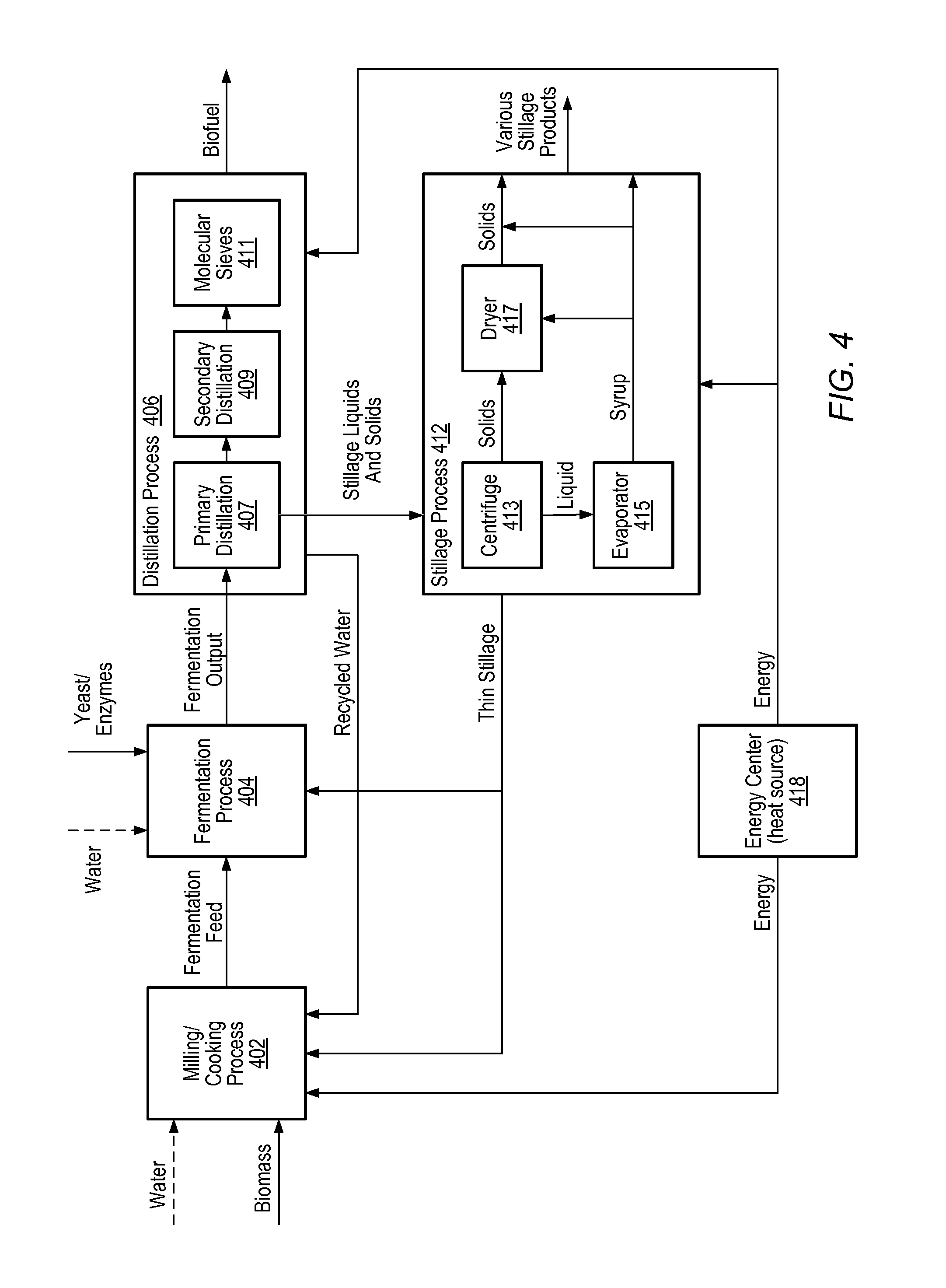

Integrated model predictive control of distillation and dehydration sub-processes in a biofuel production process

ActiveUS20080103748A1Efficiently manipulatedBioreactor/fermenter combinationsAnalogue computers for chemical processesProcess systemsProduction rate

System and method for integrated management of a biofuel distillation process and a biofuel dehydration process of a biofuel production process, comprising a dynamic multivariate model-based controller coupled to a dynamic multivariate predictive model. The model is executable to: receive distillation and dehydration process information including biofuel compositions, receive an objective for biofuel production output from the distillation and dehydration processes, e.g., target product composition, production rate, and / or feed rate, and generate model output comprising target values for a plurality of manipulated variables related to the distillation and dehydration processes in accordance with the objective. The controller is operable to dynamically control the biofuel production process by adjusting the plurality of manipulated variables to the model-determined target values in accordance with the objective for biofuel production.

Owner:ROCKWELL AUTOMATION TECH

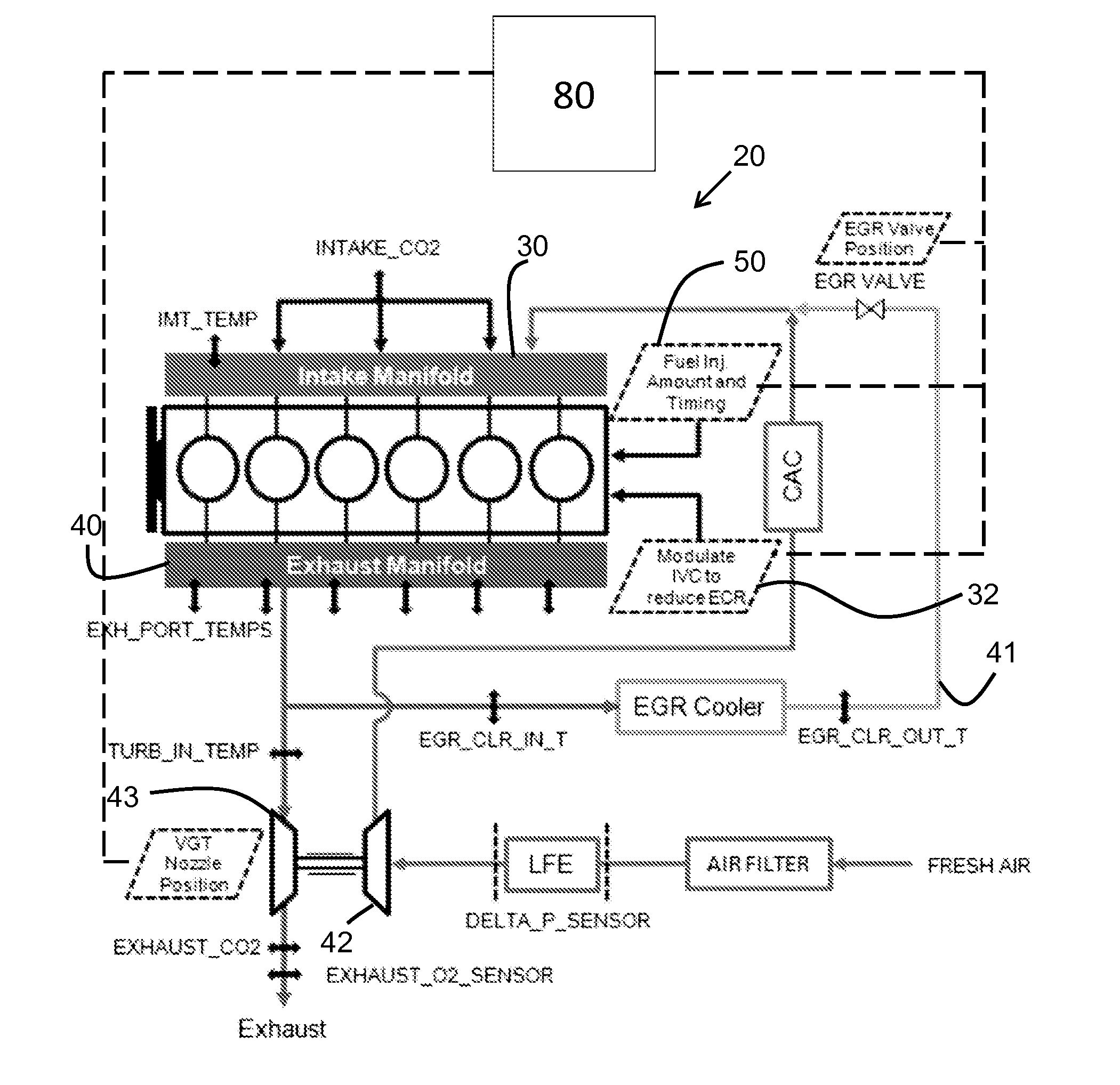

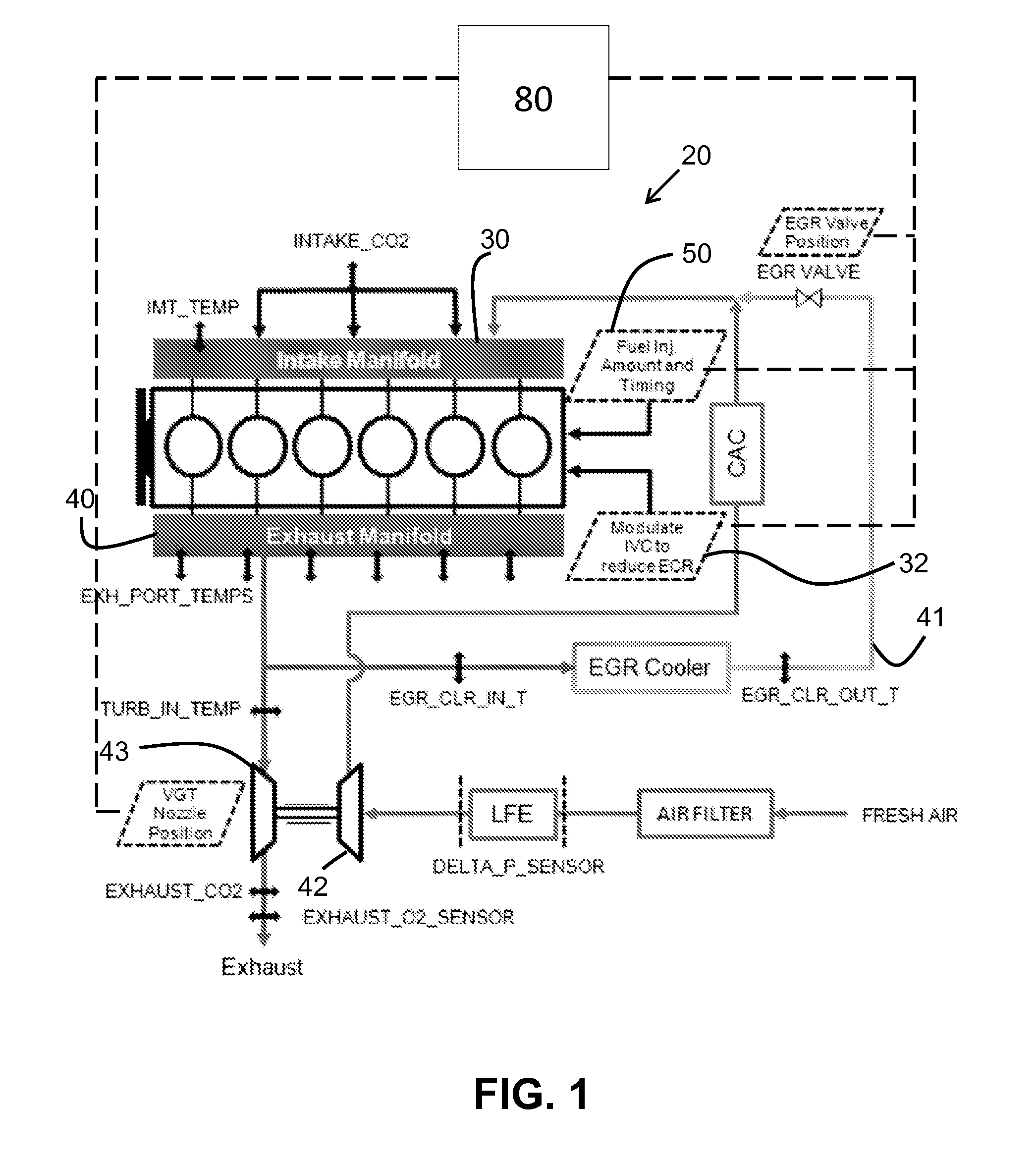

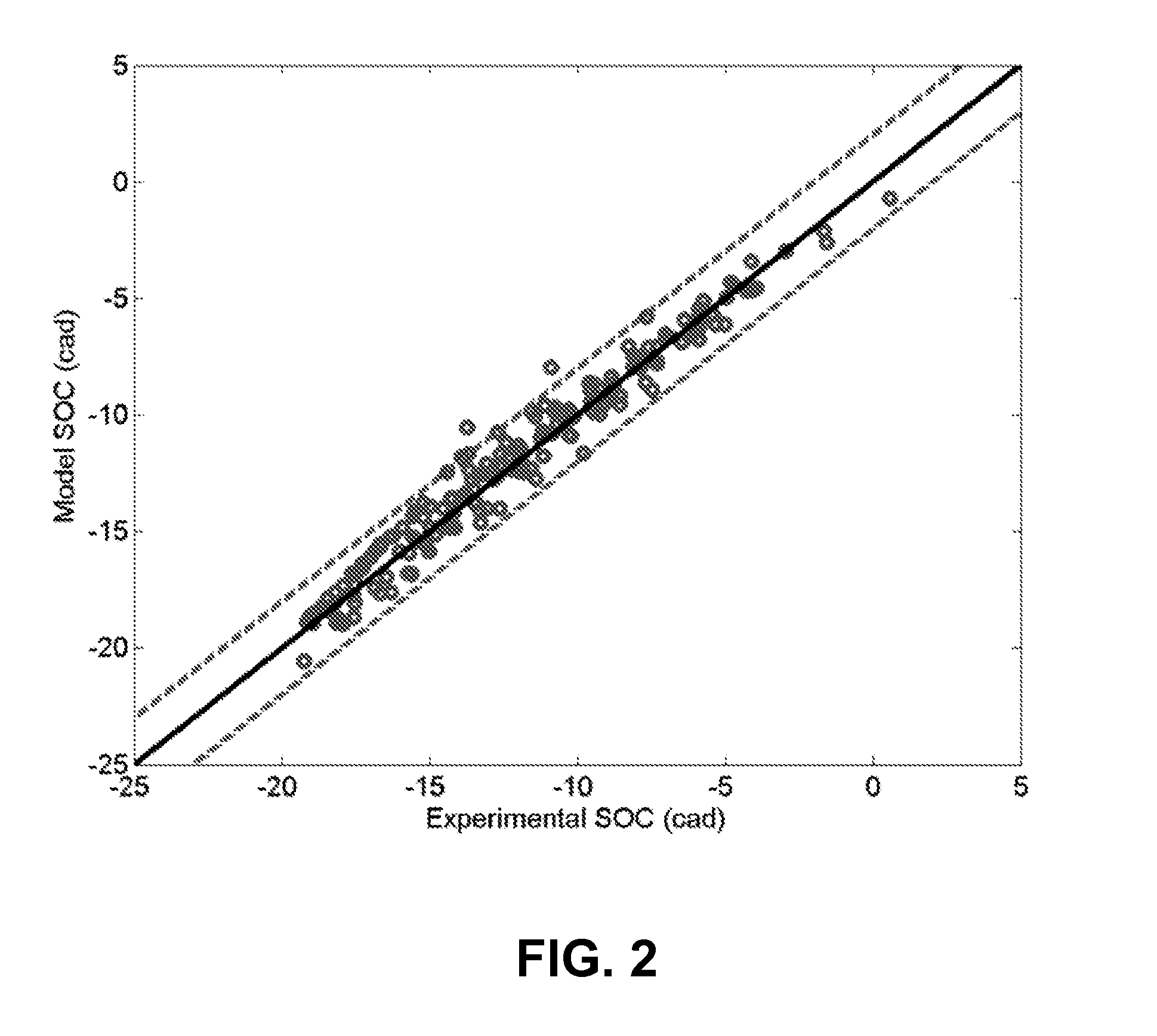

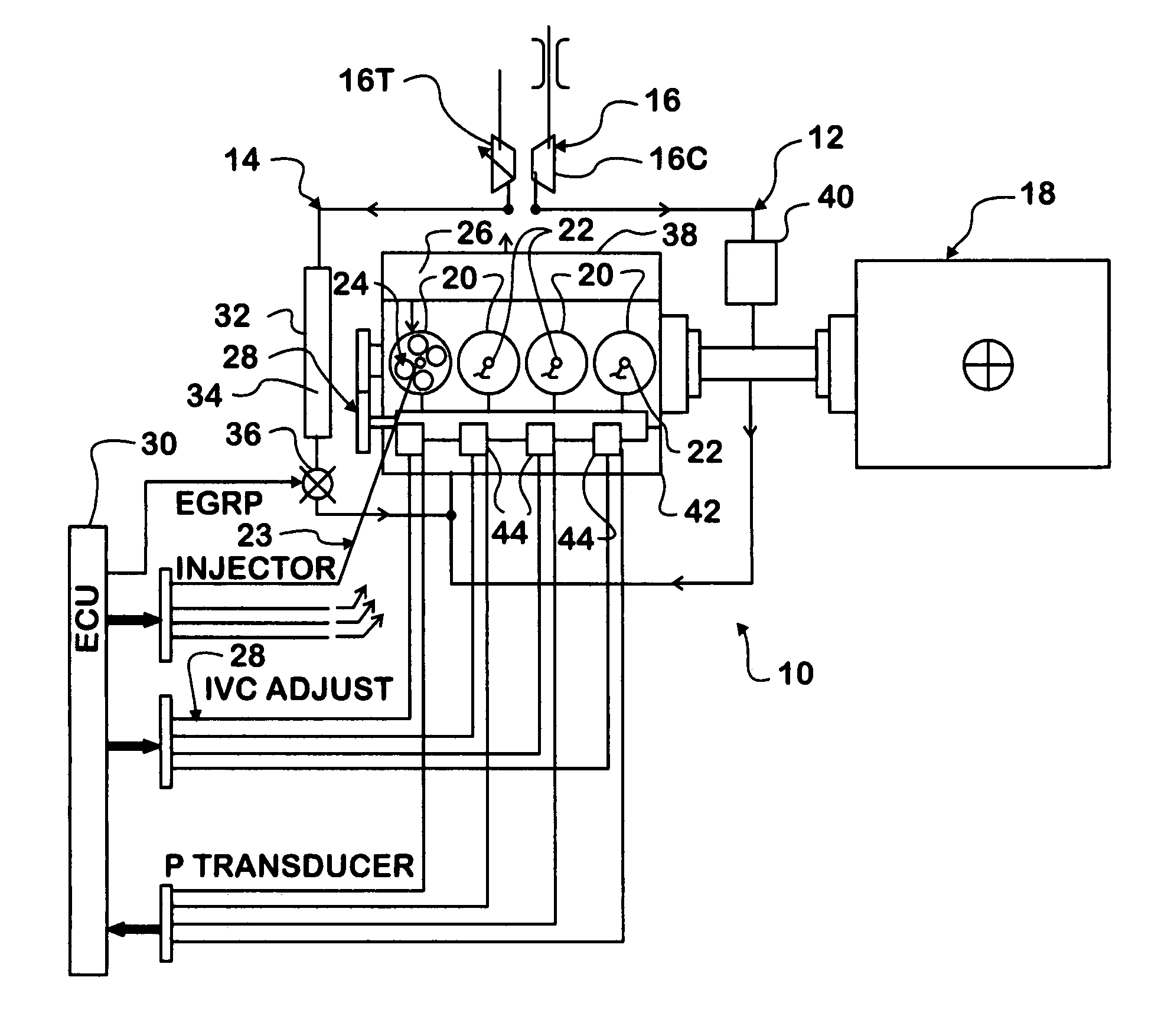

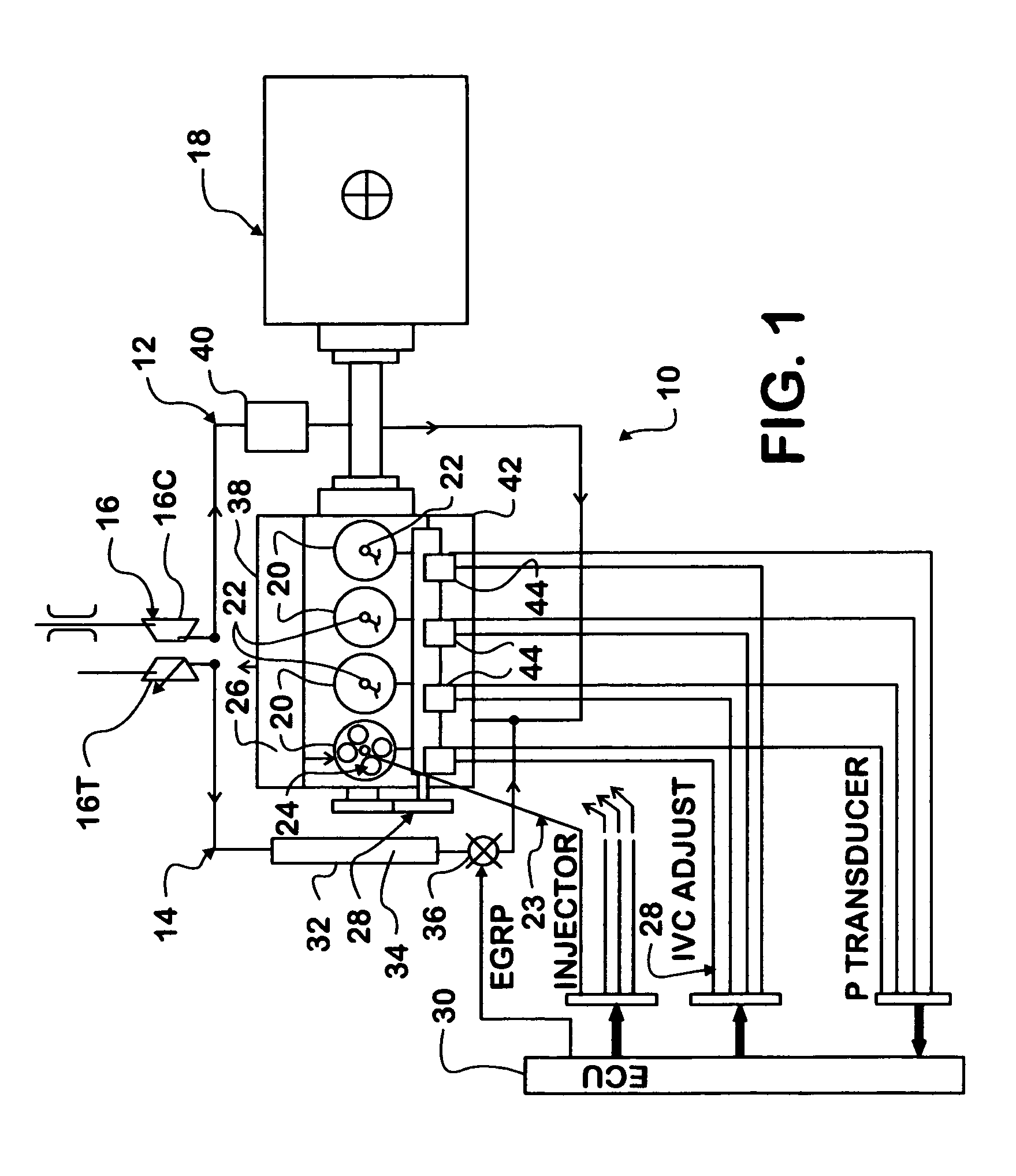

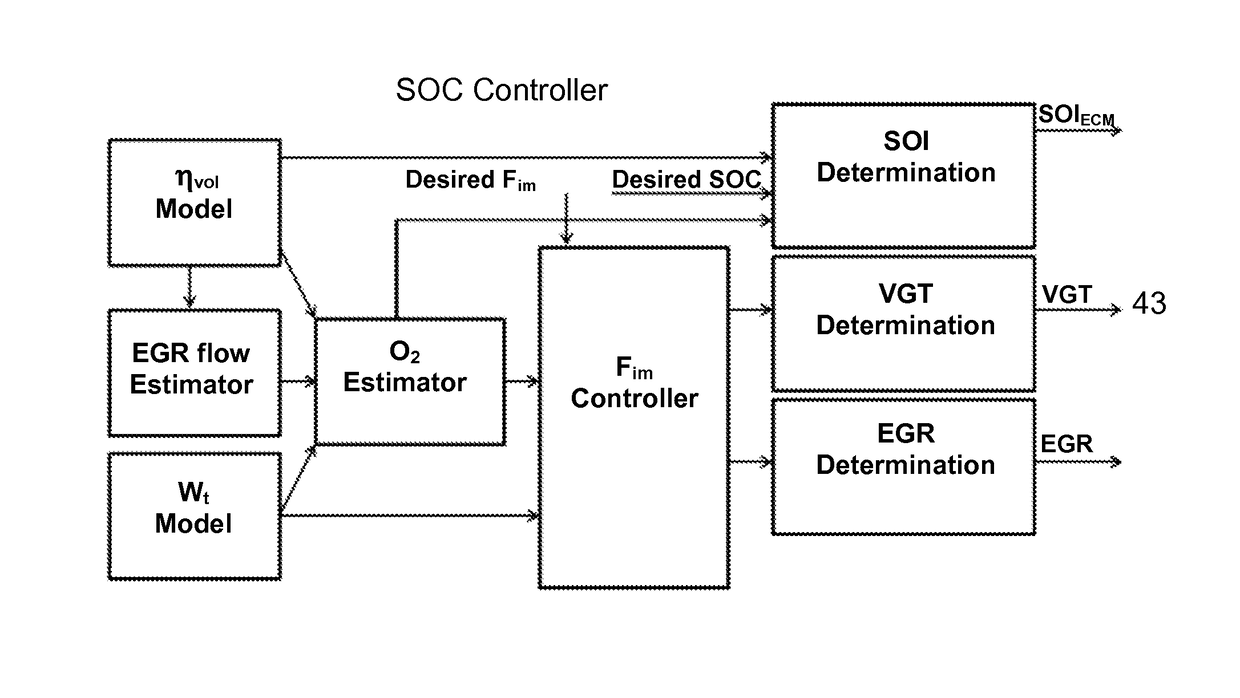

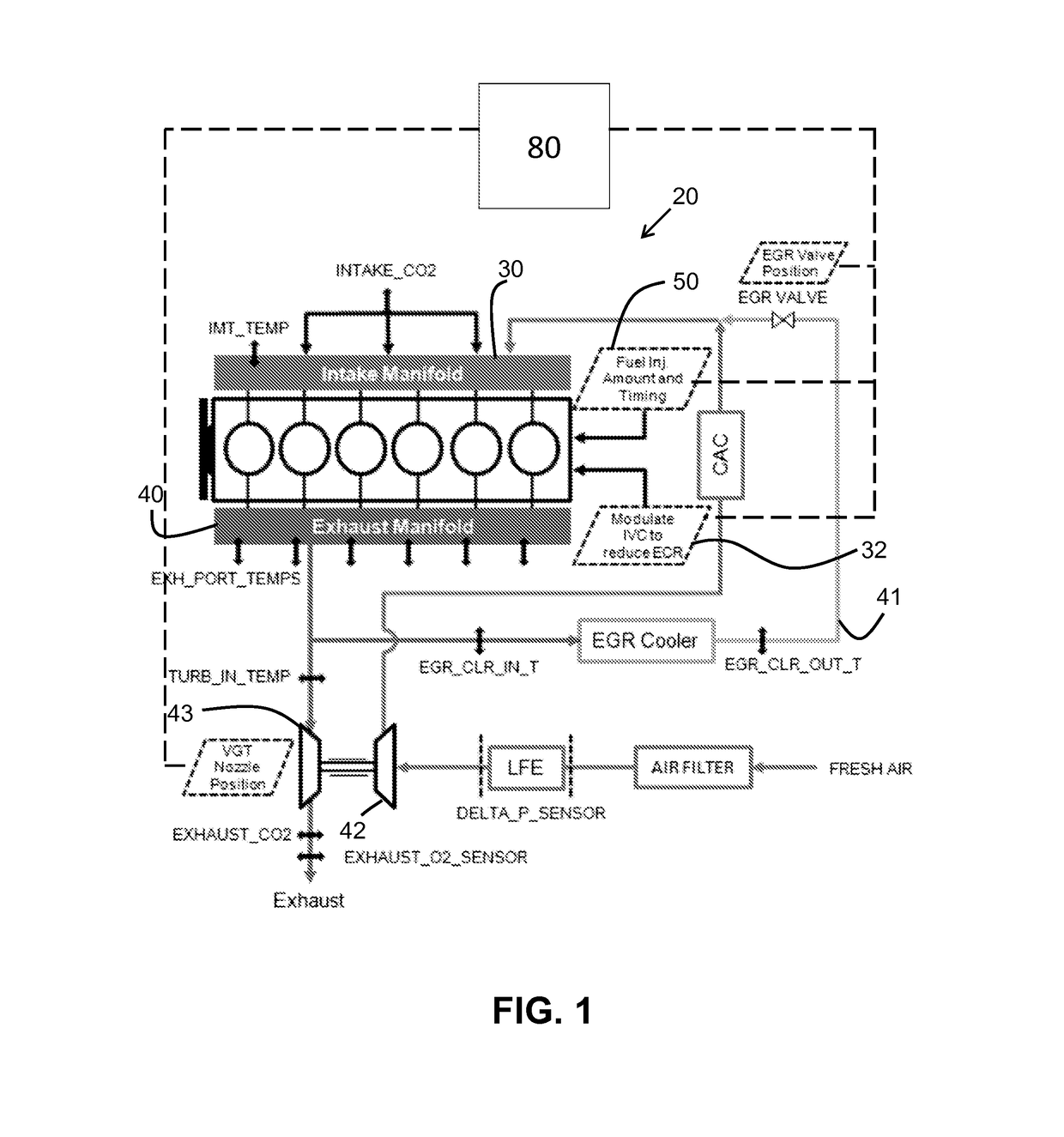

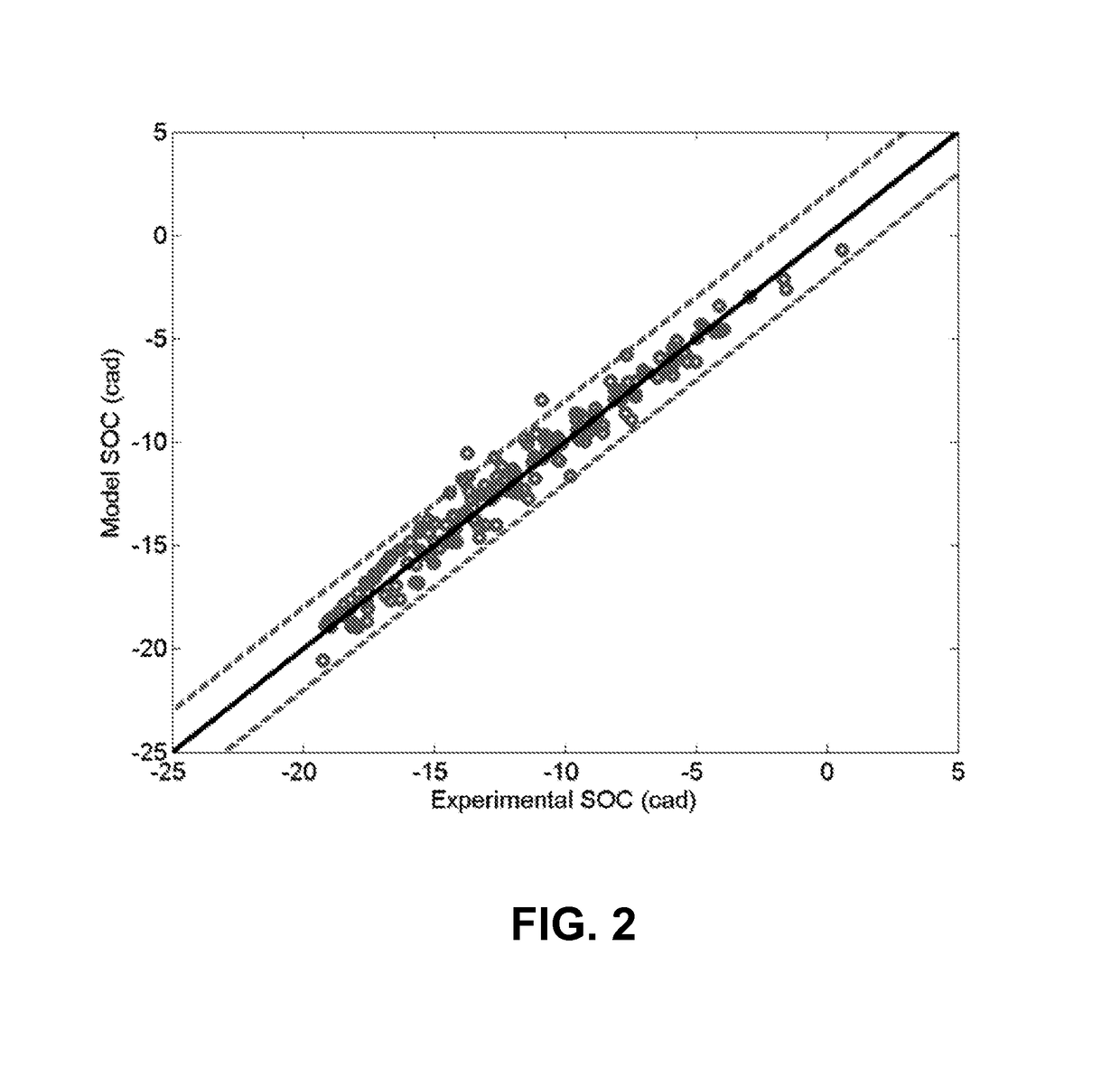

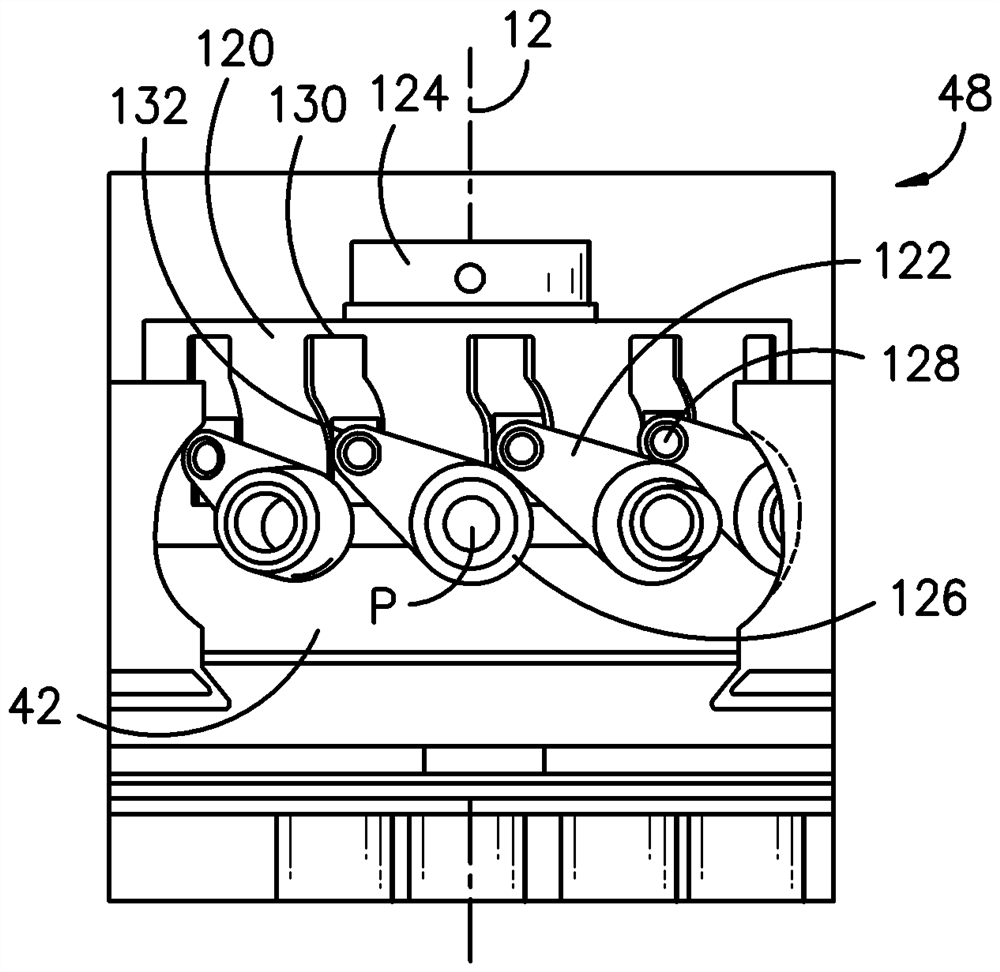

Nonlinear model-based controller for premixed charge compression ignition combustion timing in diesel engines

ActiveUS20150330326A1Electrical controlInternal combustion piston enginesNonlinear modelModel based controller

Advanced combustion modes, such as PCCI, operate near the system stability limits. In PCCI, the combustion event begins without a direct combustion trigger in contrast to traditional spark-ignited gasoline engines and direct-injected diesel engines. The lack of a direct combustion trigger encourages the usage of model-based controls to provide robust control of the combustion phasing. The nonlinear relationships between the control inputs and the combustion system response often limit the effectiveness of traditional, non-model-based controllers. Accurate knowledge of the system states and inputs is helpful for implementation of an effective nonlinear controller. A nonlinear controller is developed and implemented to control the engine combustion timing during diesel PCCI operation by targeting desired values of the in-cylinder oxygen concentration, pressure, and temperature during early fuel injection.

Owner:PURDUE RES FOUND INC

System and method for initiating and maintaining continuous, long-term control of a concentration of a substance in a patient using a feedback or model-based controller coupled to a single-needle or I

InactiveCN1859943AControl blood glucose concentrationPeptide/protein ingredientsMetabolism disorderInsulin infusionConcentrations glucose

A closed loop therapy system (200) for controlling a concentration of a substance, such as blood glucose concentration, in the body of a user. The system and method employ a sensor system (206) that measures a glucose level in the body, a controller (202) that uses the measured glucose levels to generate an output that can be used to automatically or manually control an intradermal insulin infusion system to set a constant or time-varying profile of target blood glucose concentrations in a user, and then infuse an appropriate amount of insulin into the body of the user so as to reach and maintain the target values of the blood glucose concentration.

Owner:BECTON DICKINSON & CO

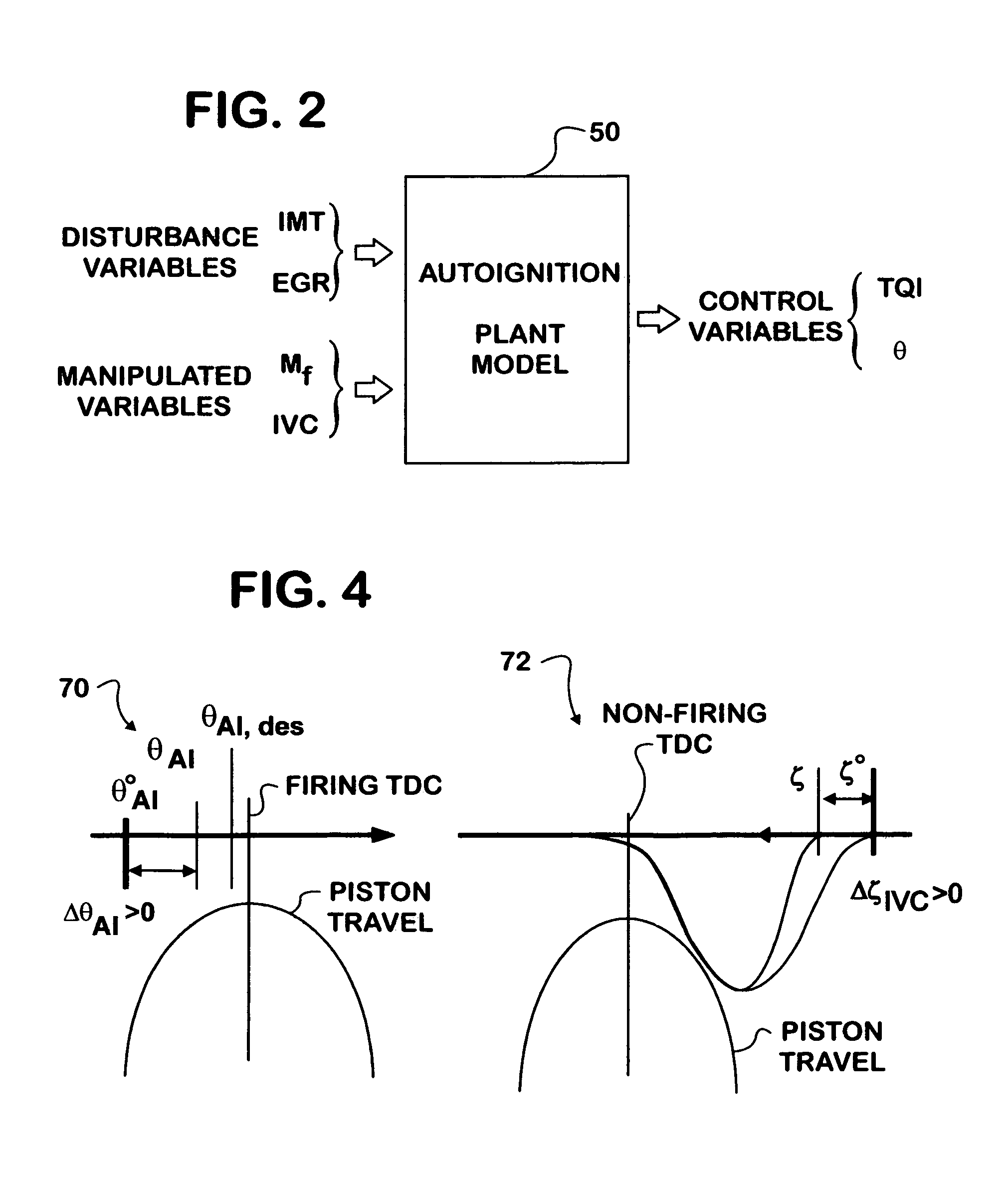

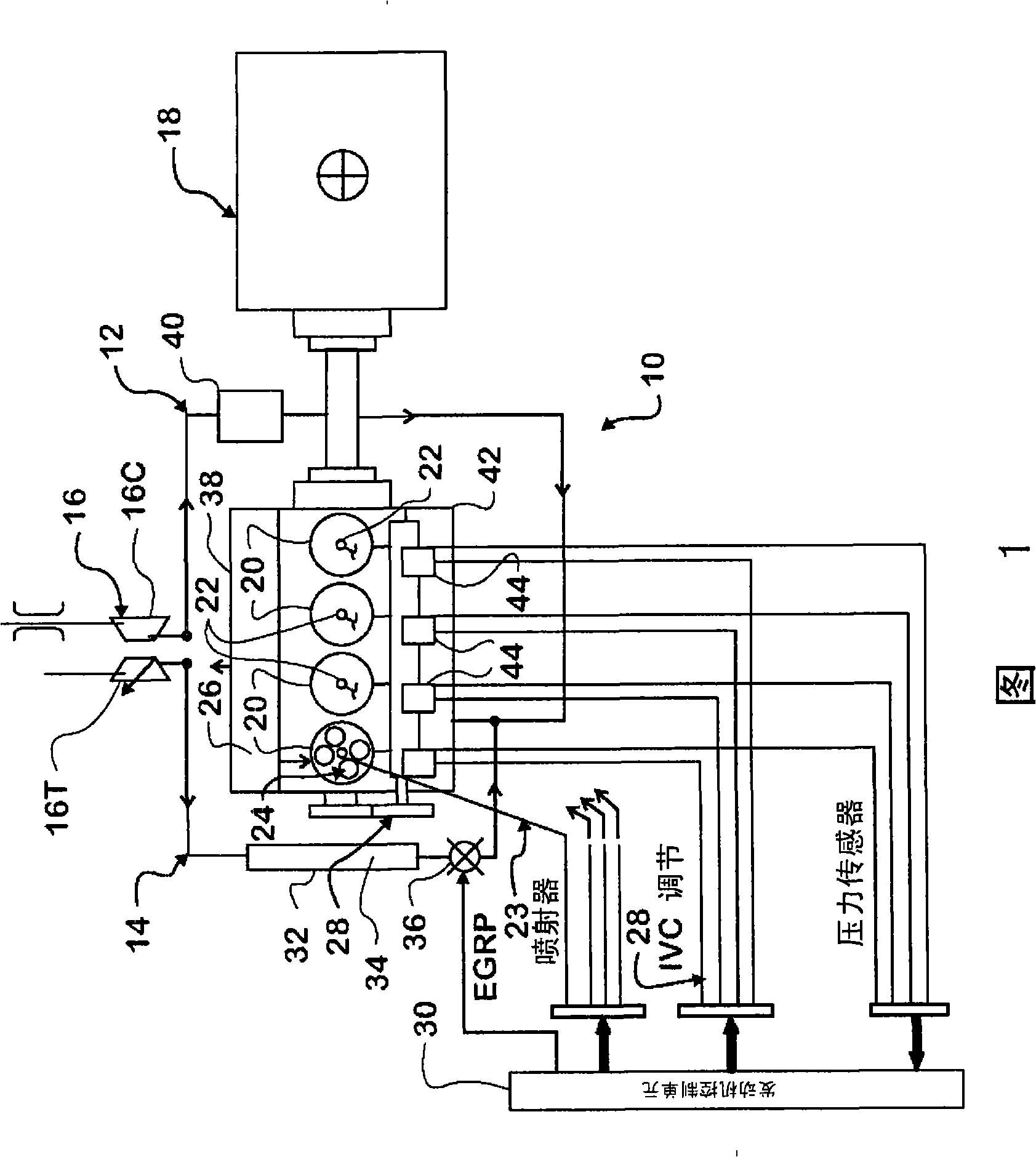

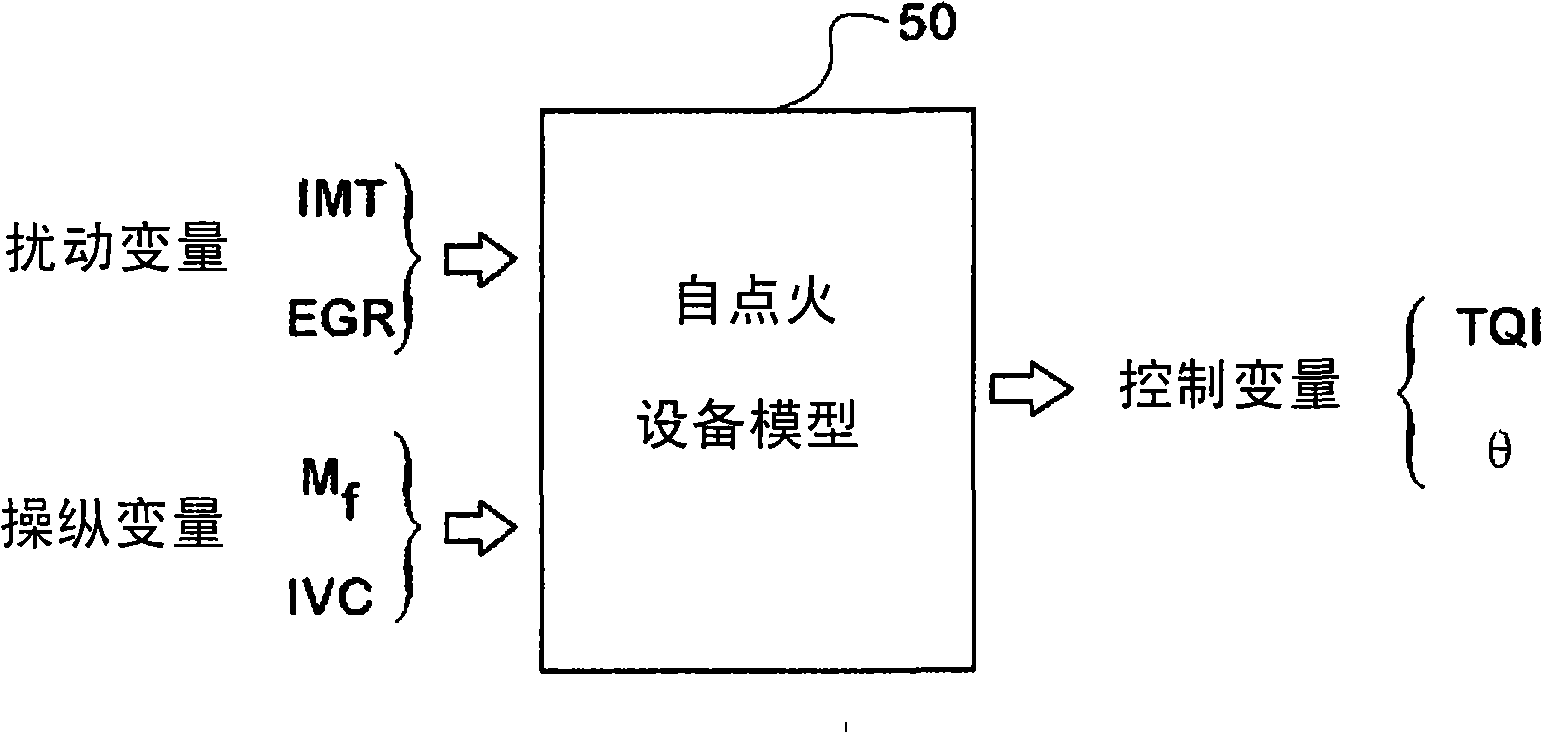

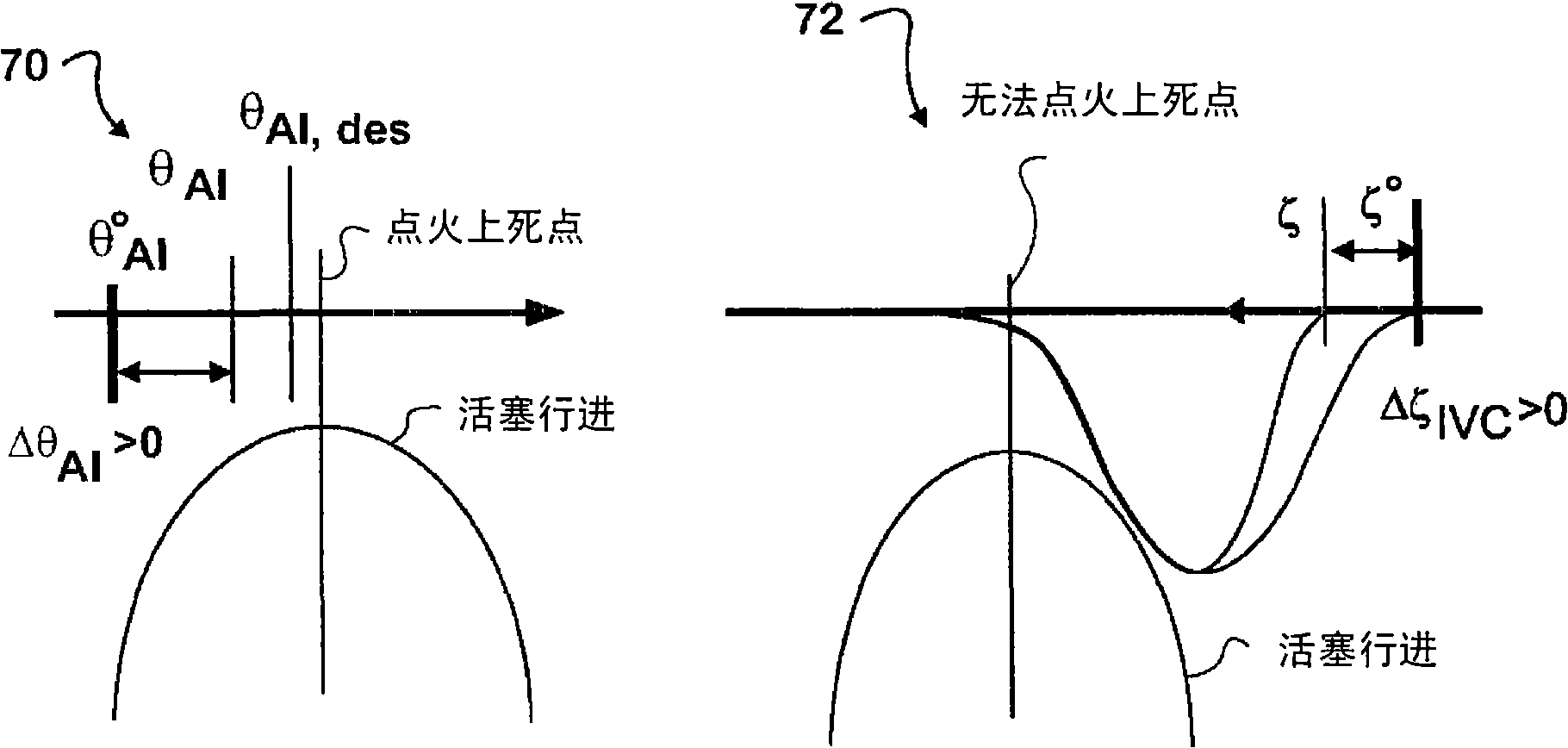

Model-based controller for auto-ignition optimization in a diesel engine

ActiveUS7184877B1Minimize changesWell mixedElectrical controlInternal combustion piston enginesDiesel combustionModel based controller

A diesel engine (10) operates by alternative diesel combustion. Formation of fuel and charge air mixtures is controlled by processing a particular set of values for certain input data according to a predictor algorithm model (50) to develop data values for predicted time of auto-ignition and resulting torque, and also develop data values for control of fuel and air that will produce the predicted time of auto-ignition and resulting torque. The data values developed by the predictor algorithm and data values for at least some of the input data are processed according to a control algorithm (52) that compensates for any disturbance introduced into any of the data values for at least some of the input data being processed by the control algorithm. This causes the systems to be controlled by compensated data values that produce predicted time of auto-ignition and resulting torque in the presence of any such disturbance.

Owner:INT ENGINE INTPROP CO LLC

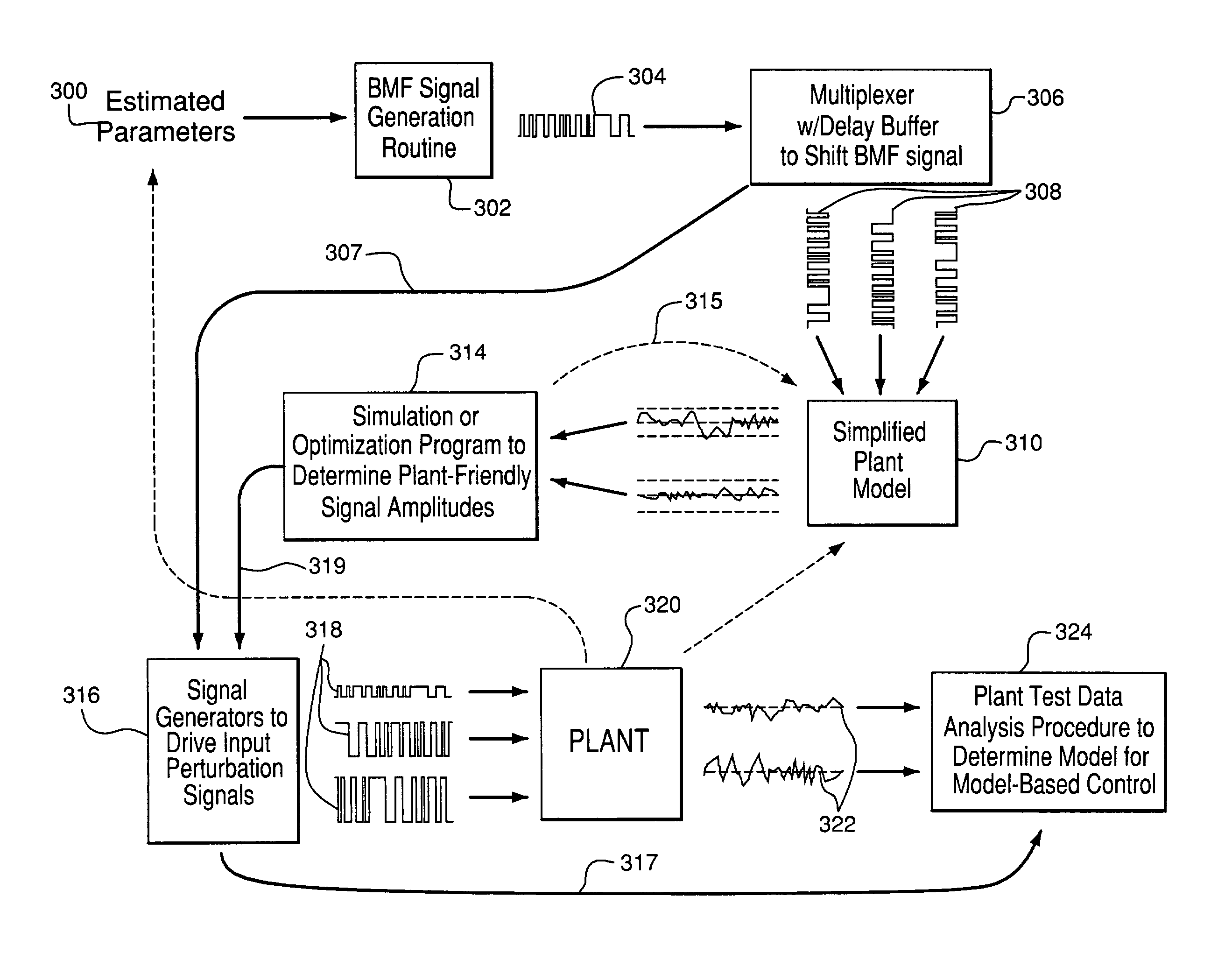

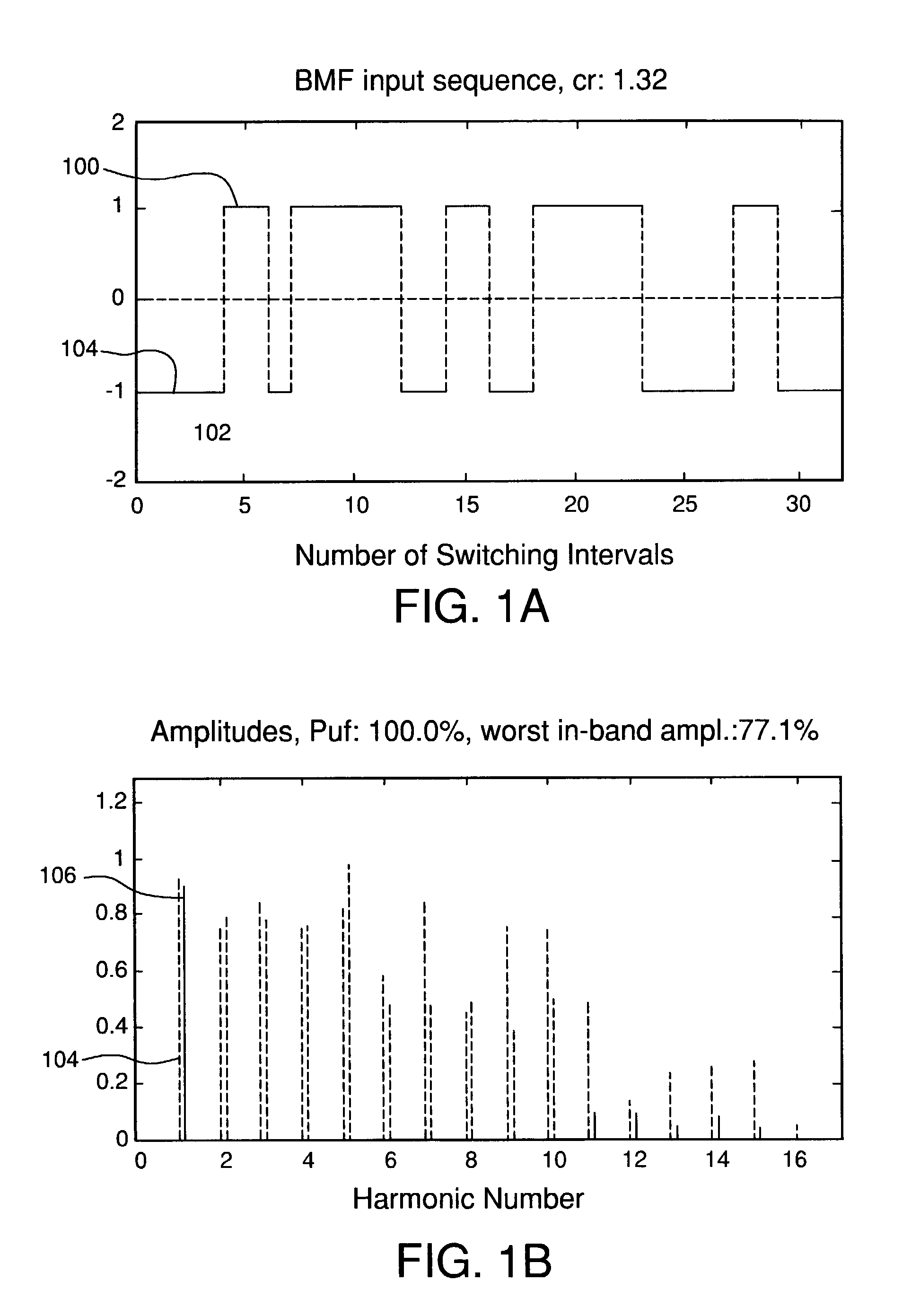

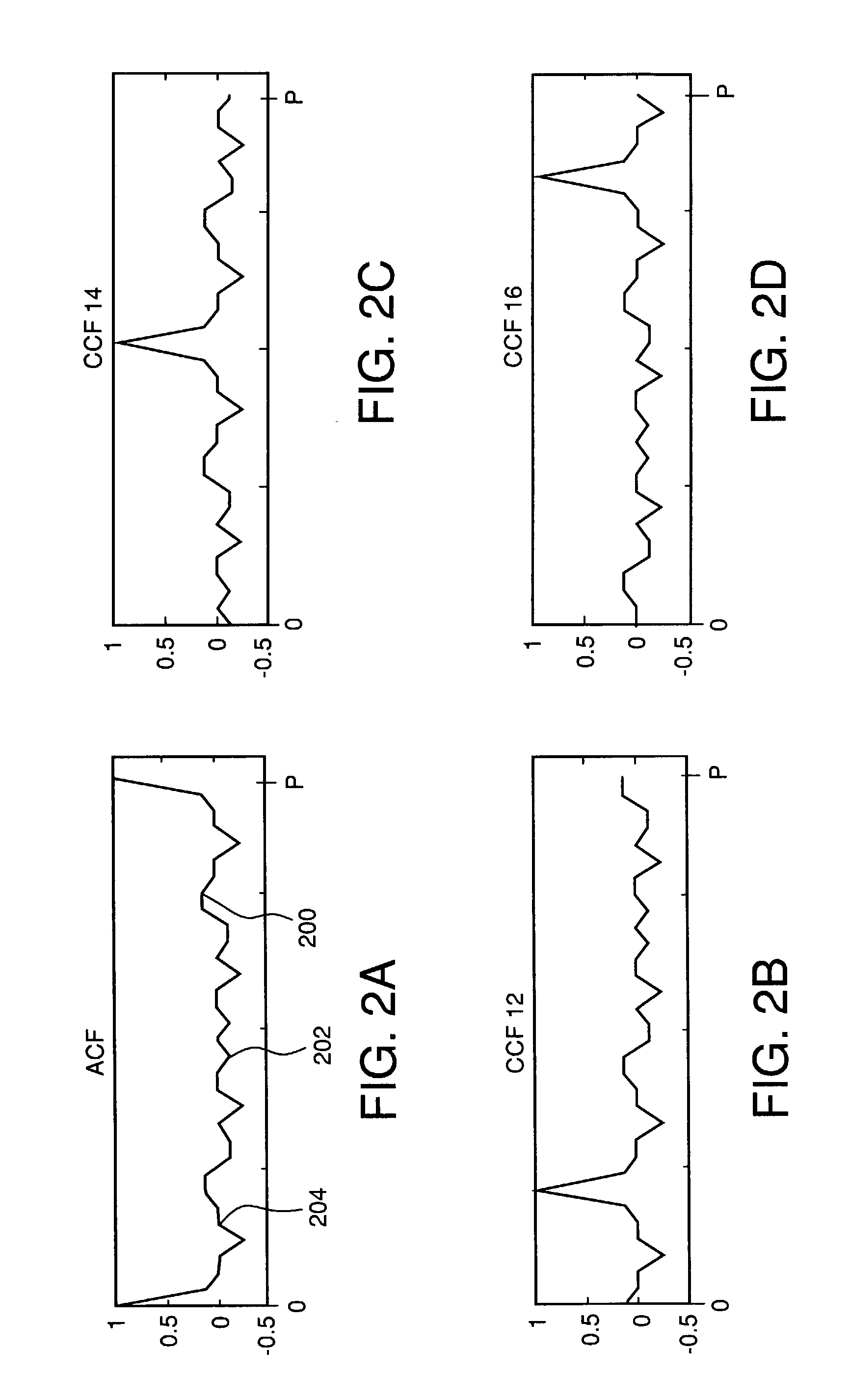

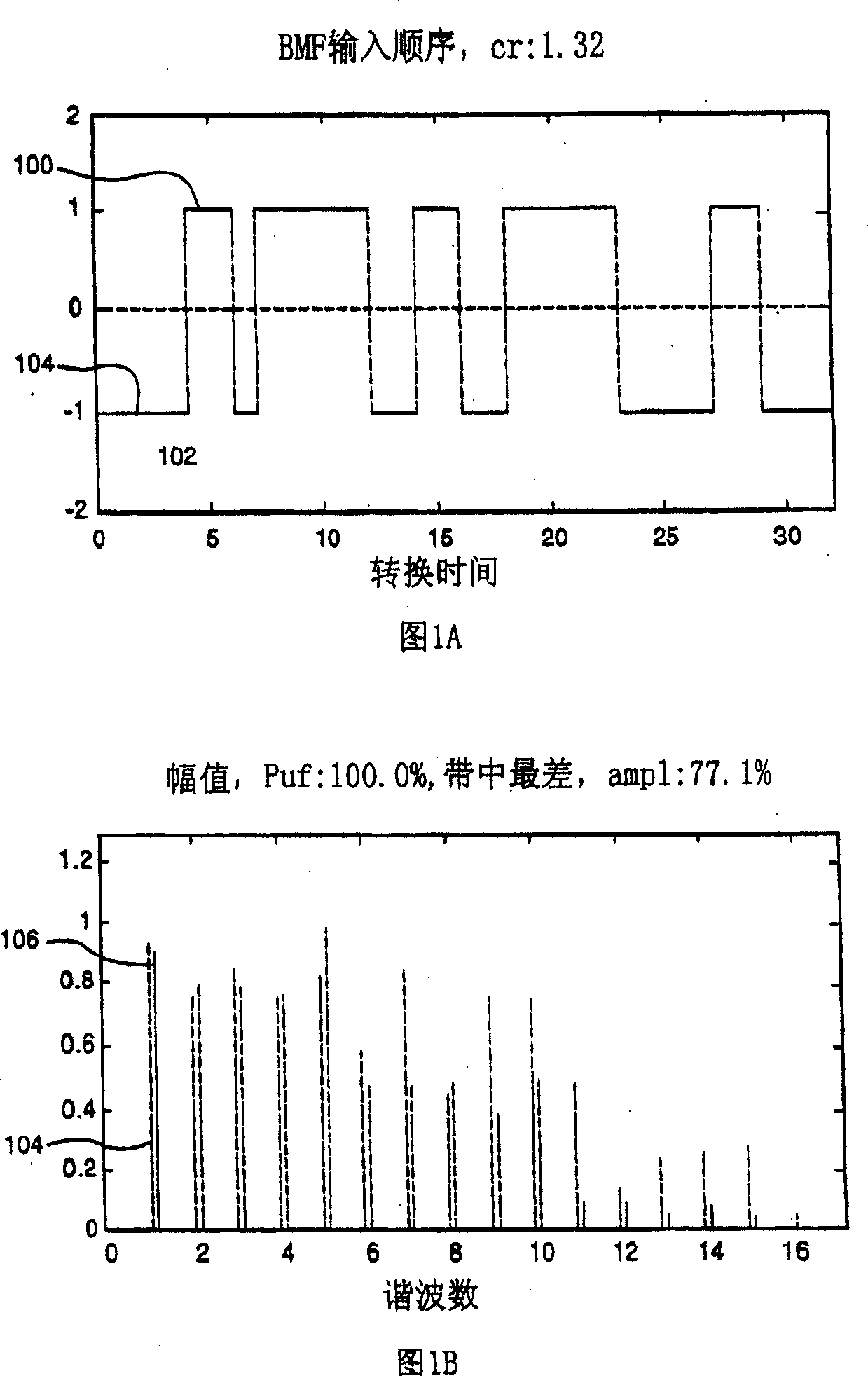

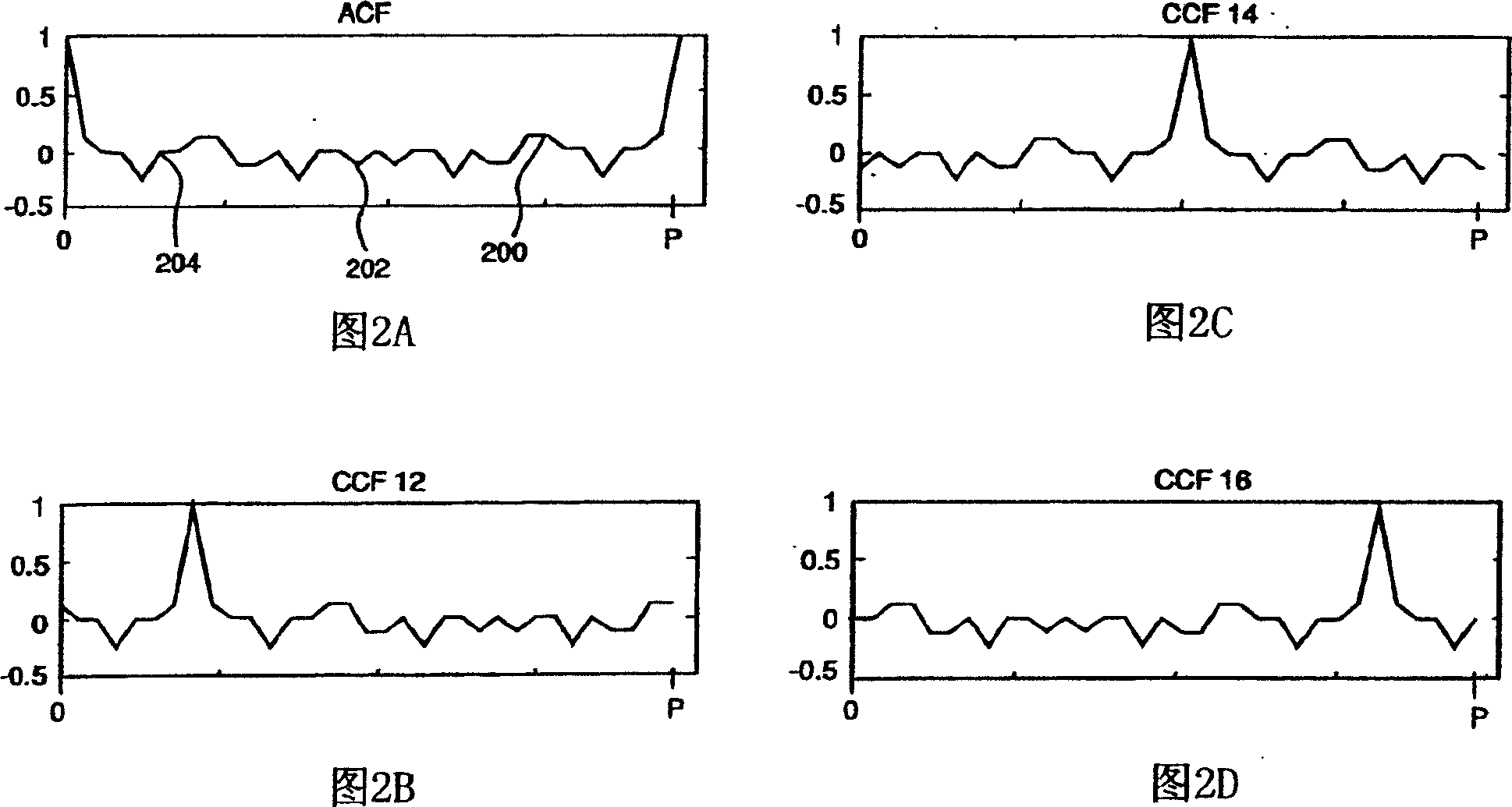

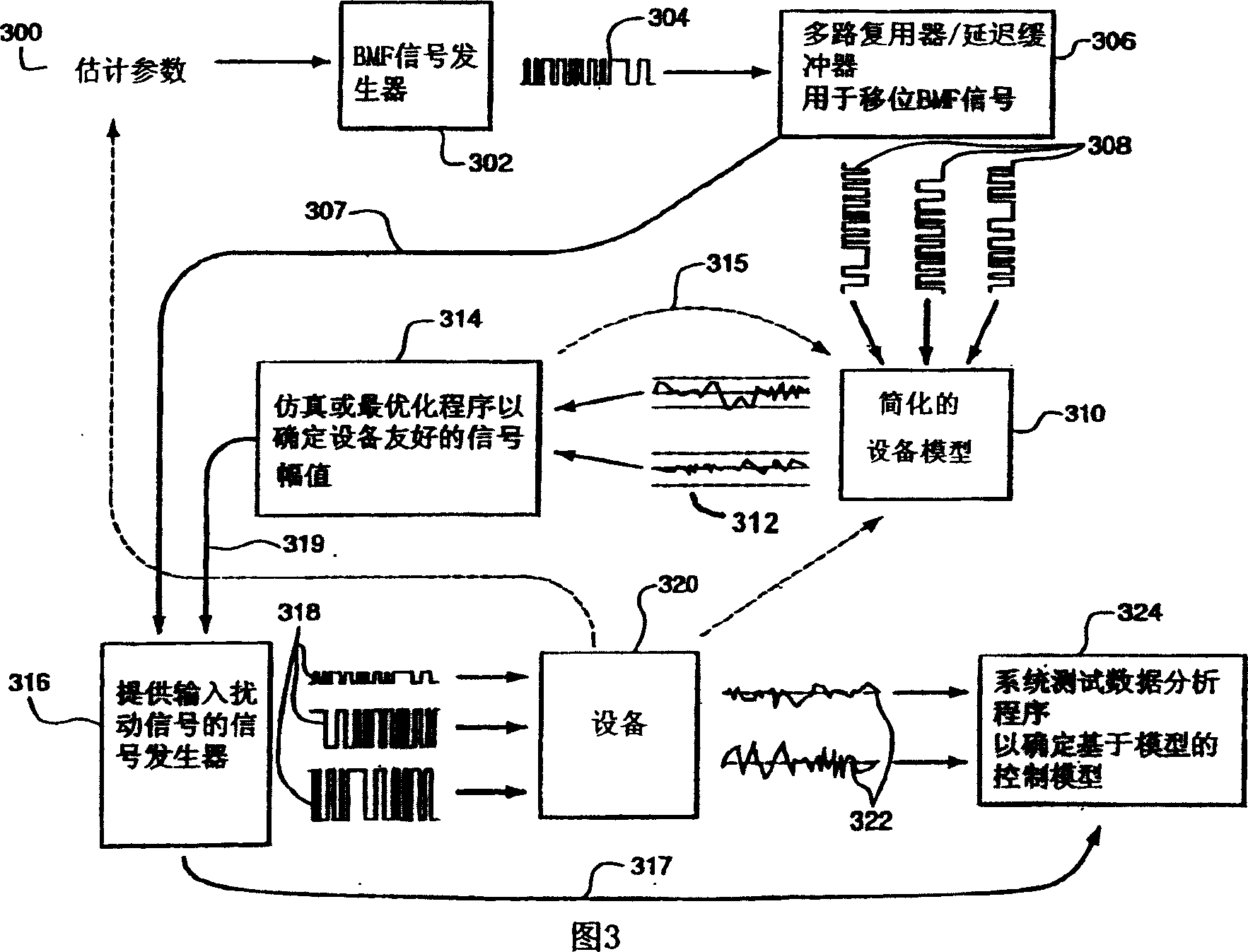

Fast plant test for model-based control

InactiveUS7194317B2Simple modelData processing applicationsElectronic circuit testingFrequency spectrumModel based controller

A method and apparatus for designing perturbation signals to excite a number of input variables of a system, in order to test that system for the purpose of obtaining models for the synthesis of a model-based controller. The method begins with providing input parameters of the system. A plurality of binary multi-frequency (BMF) signals are generated based on these input parameters and the frequency spectra of these BMF signals are calculated. One BMF signal is selected out of the set of BMF signals so that the frequency spectrum of the selected BMF signal most closely matches a desired frequency spectrum specified by the input parameters. The selected BMF signal is used as a first perturbation signal for testing the system. The selected BMF signal is also shifted by predetermined amounts of samples to create delayed copies of the original BMF signal to be used as additional perturbation signals.

Owner:AIR PROD & CHEM INC

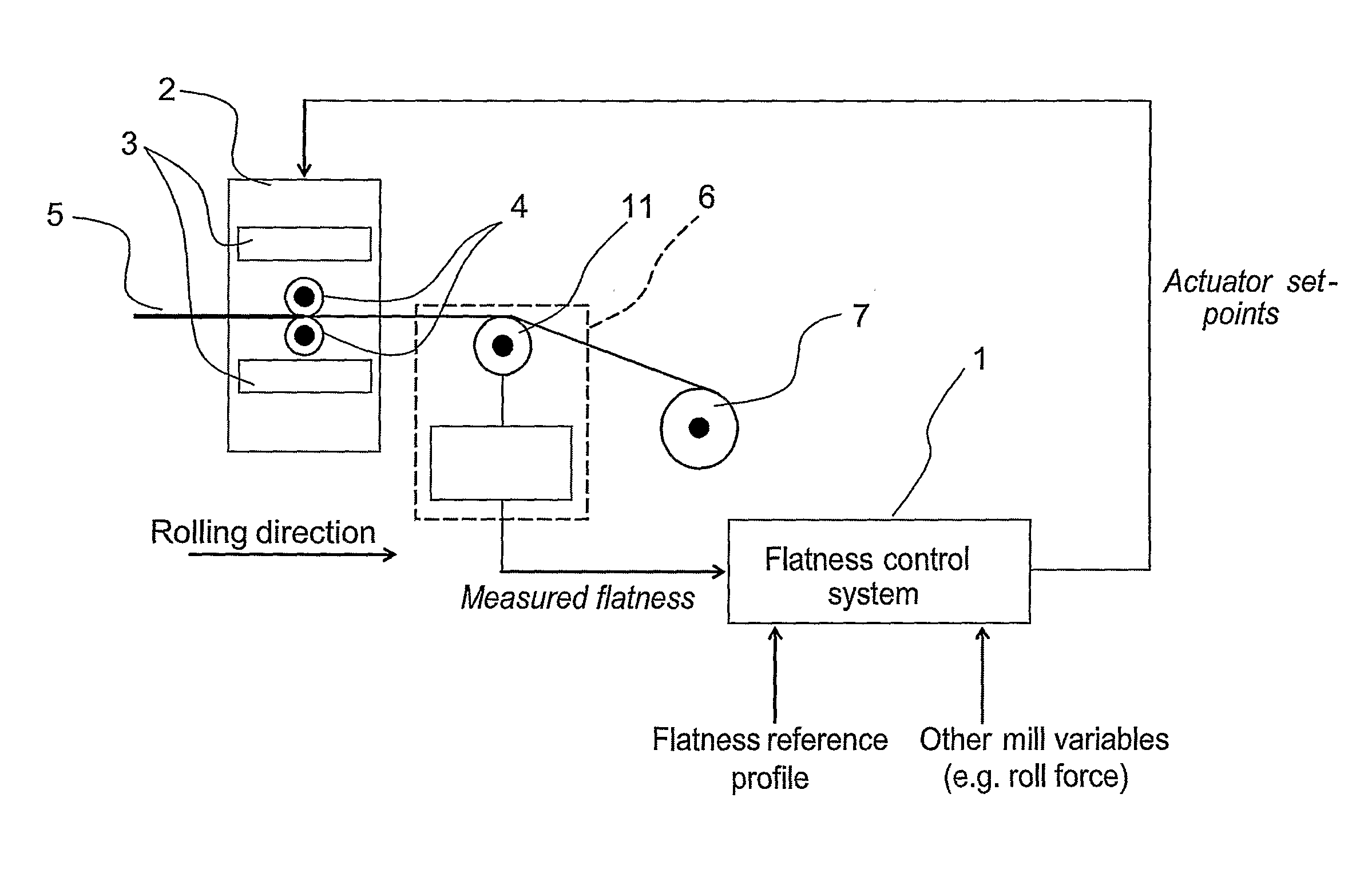

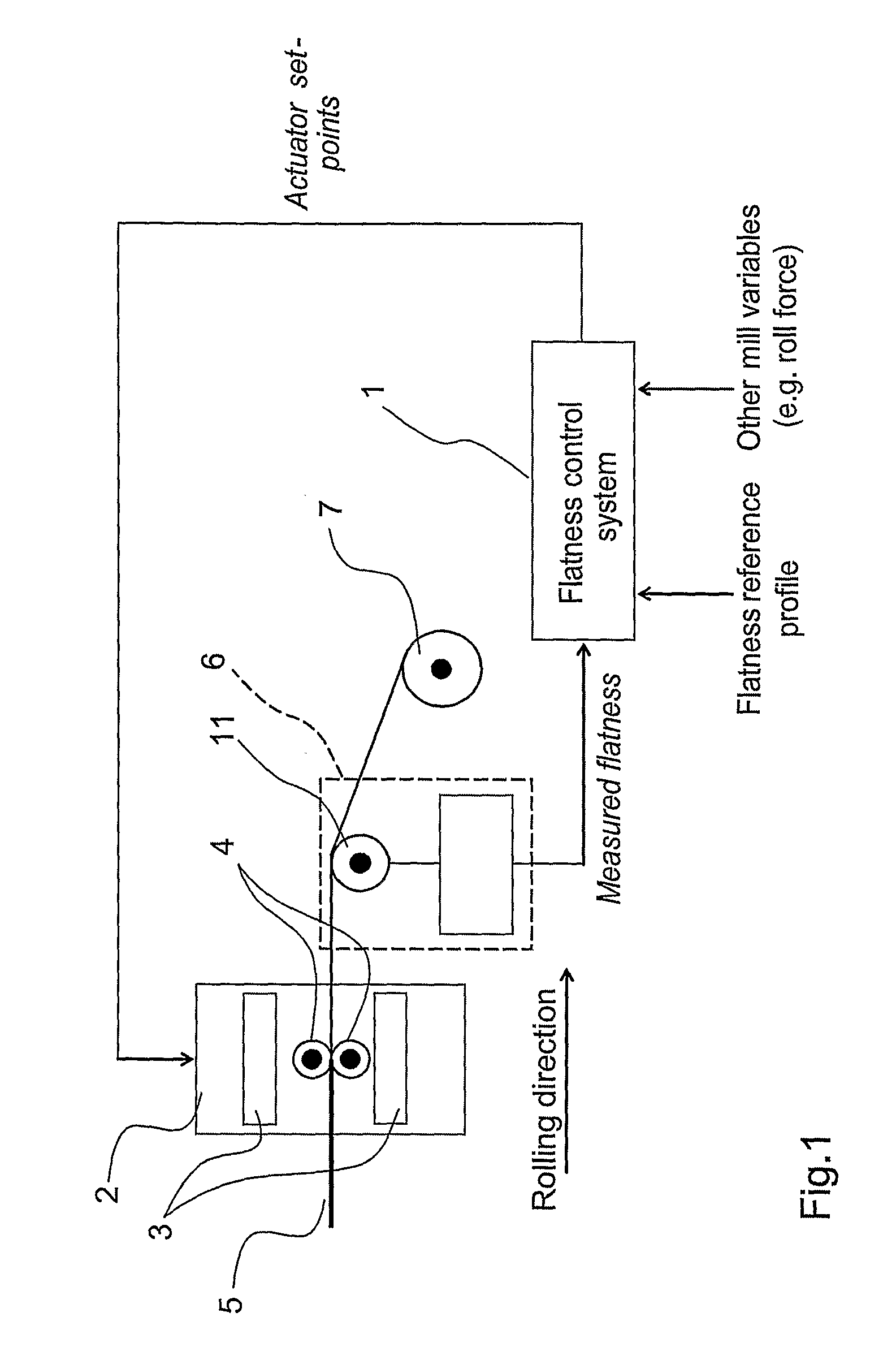

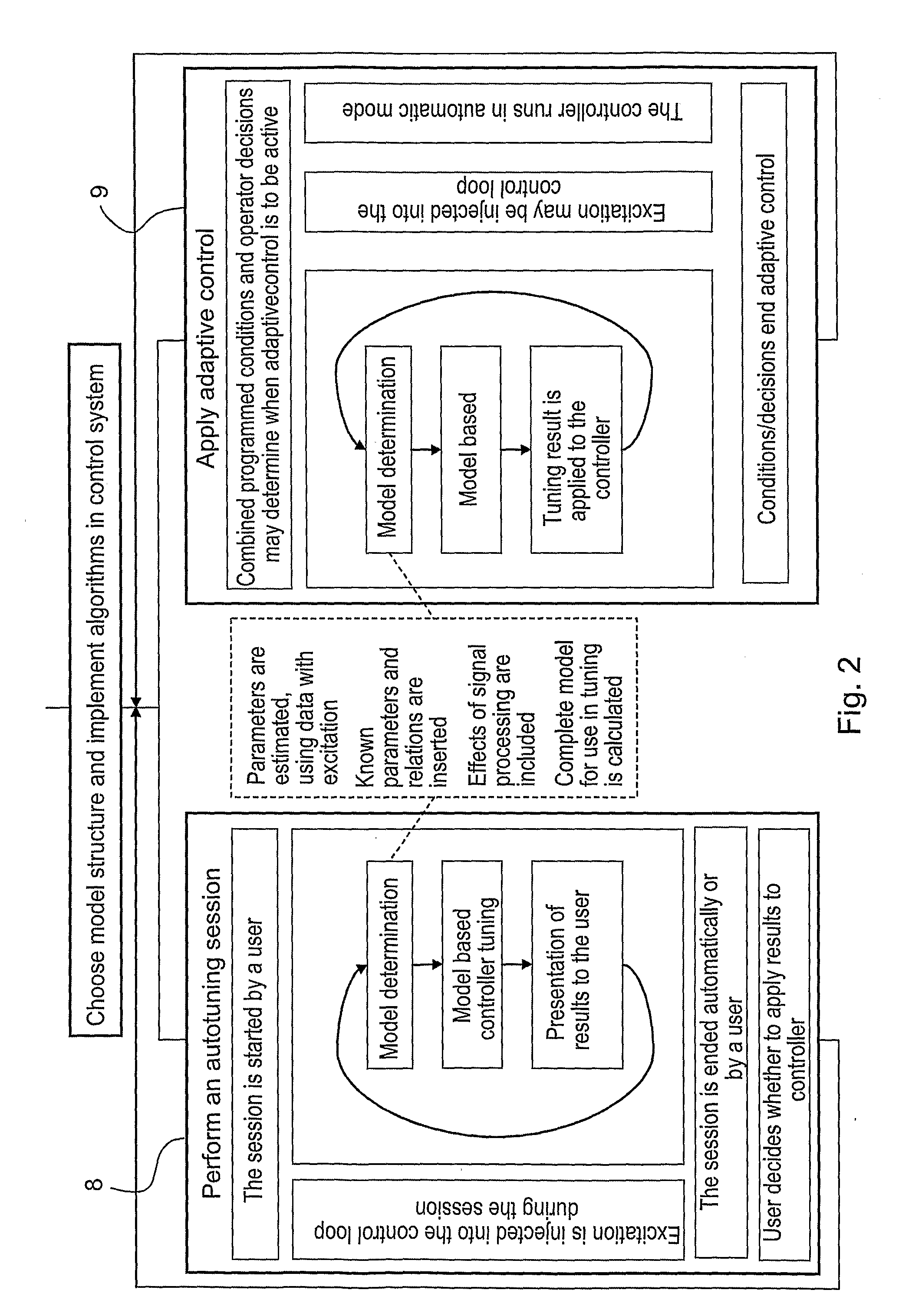

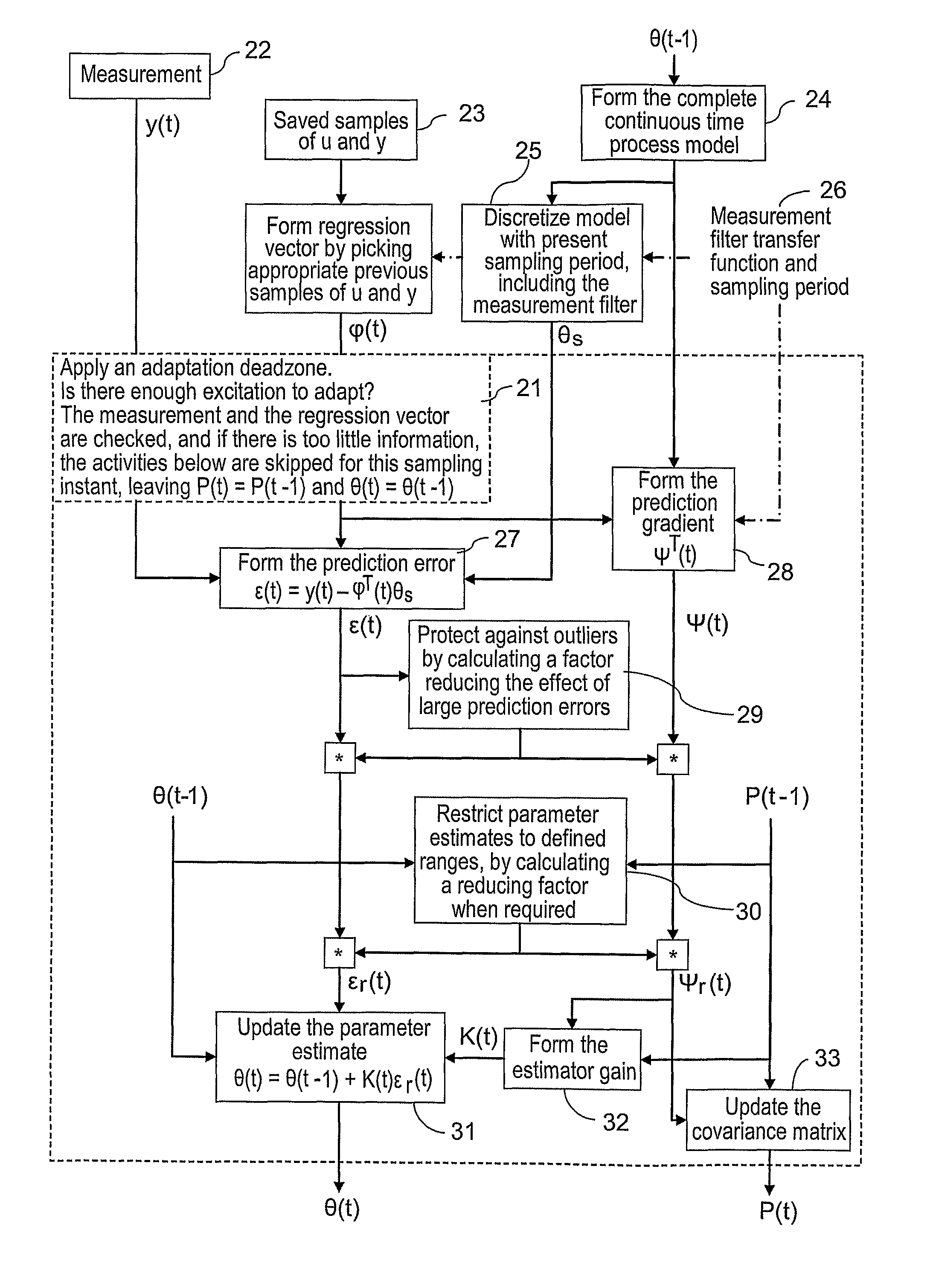

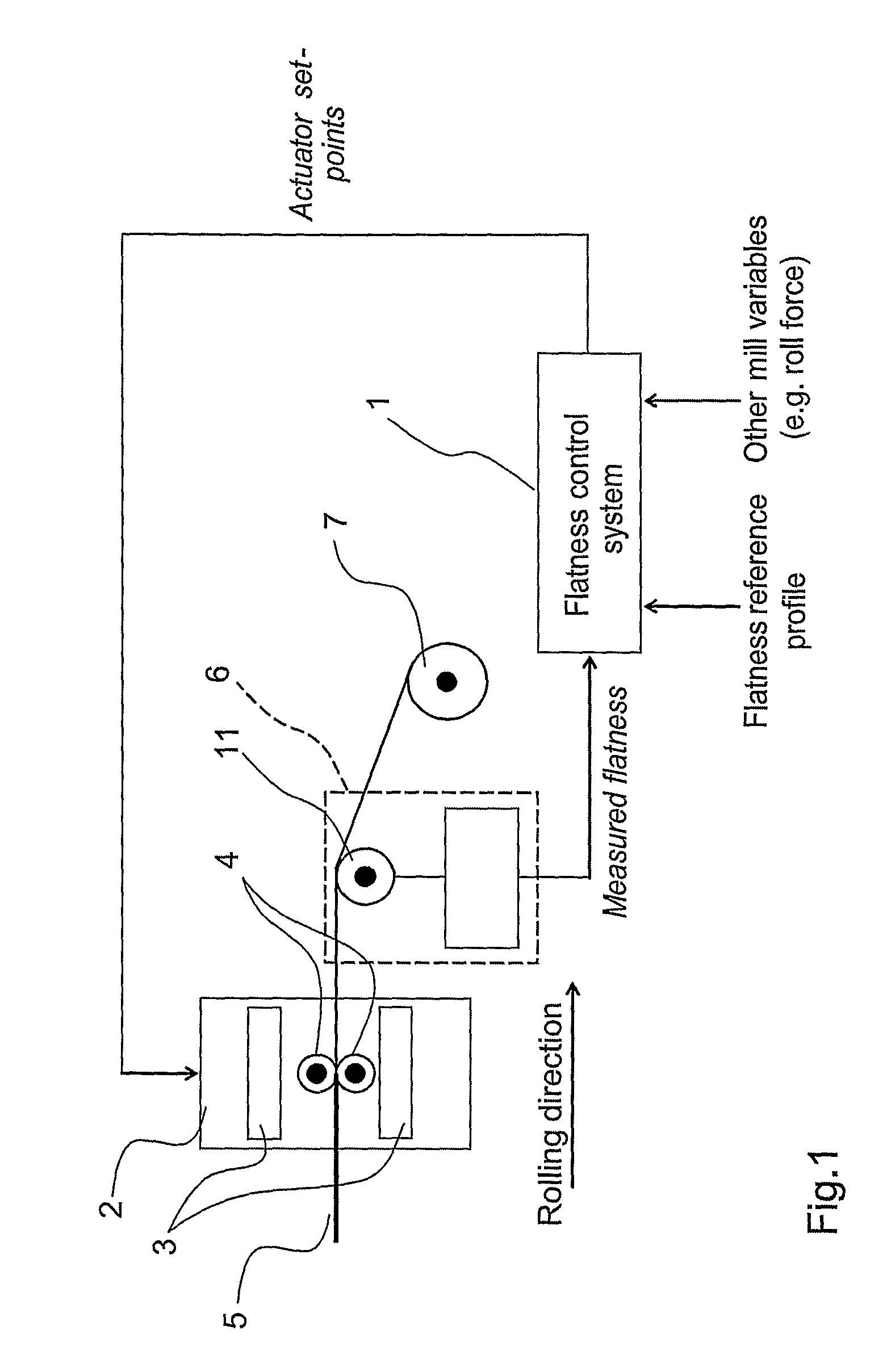

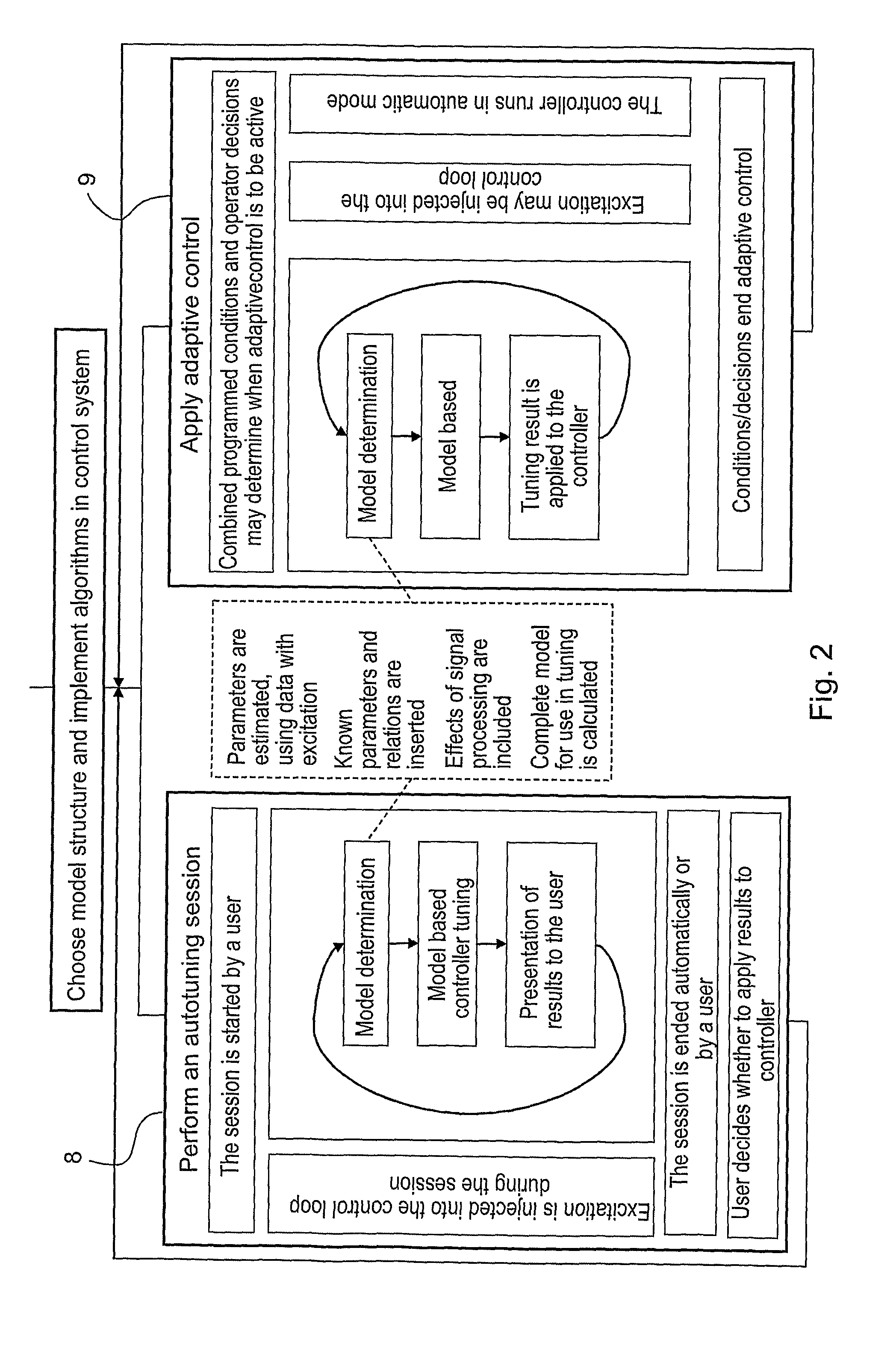

Method and device for tuning and control

ActiveUS20090138102A1Increase productionLess producedMilling machinesProgram controlModel based controllerEngineering

A method and a device for tuning and control of industrial processes having varying material flow rate. An adder is configured to add excitation signals to the controller output signal. A measurement system is configured to measure a property in response to the excitation signals. A model based tuning unit is adapted to estimate the value of at least one parameter with unknown value of a process model structure describing the effect of varying material flow rate, based on the measurements of the property and the output signal from the controller, and to calculate a model that describes the dynamics from controller output to controller input based on the estimated value of the parameter, and to perform model based tuning of the controller based on the model that describes the dynamics from controller output to controller input.

Owner:ABB (SCHWEIZ) AG

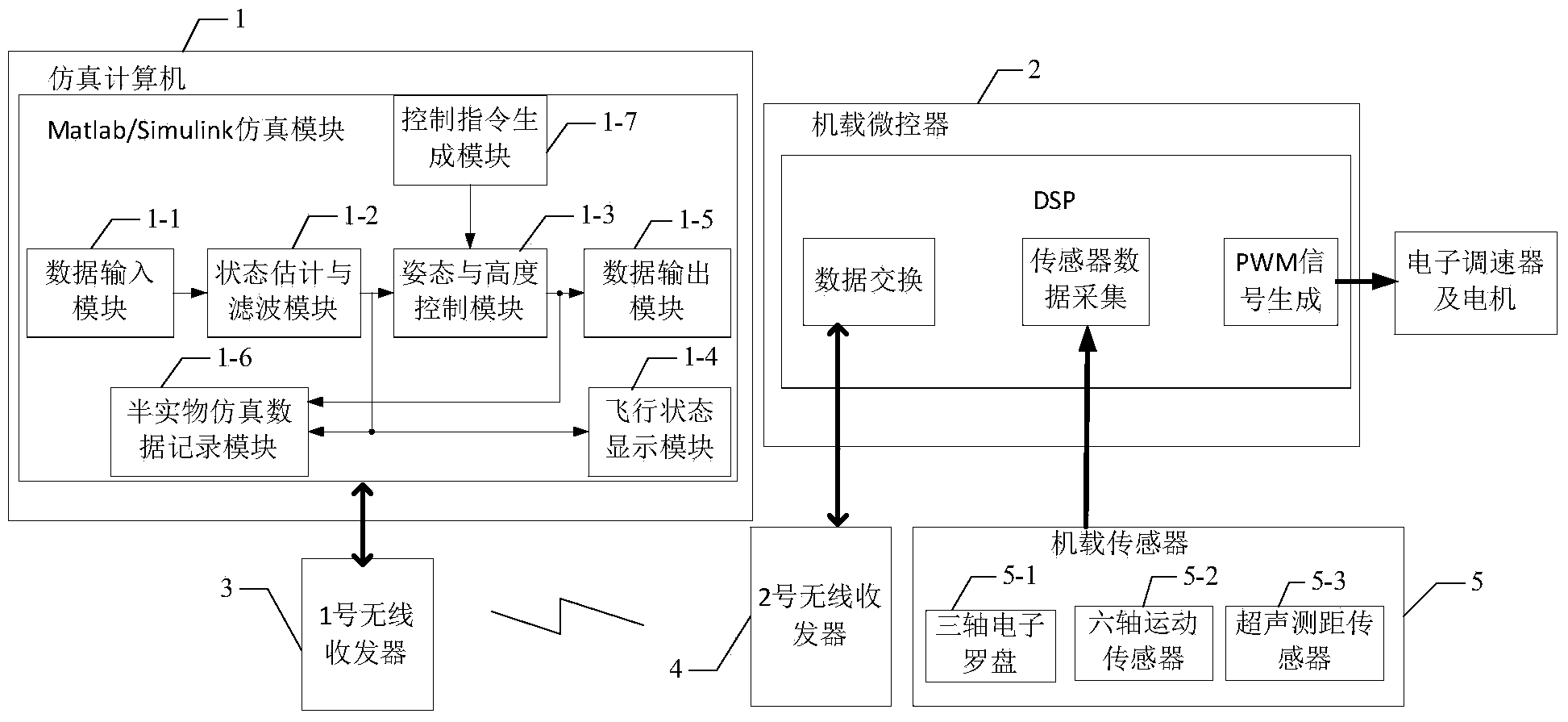

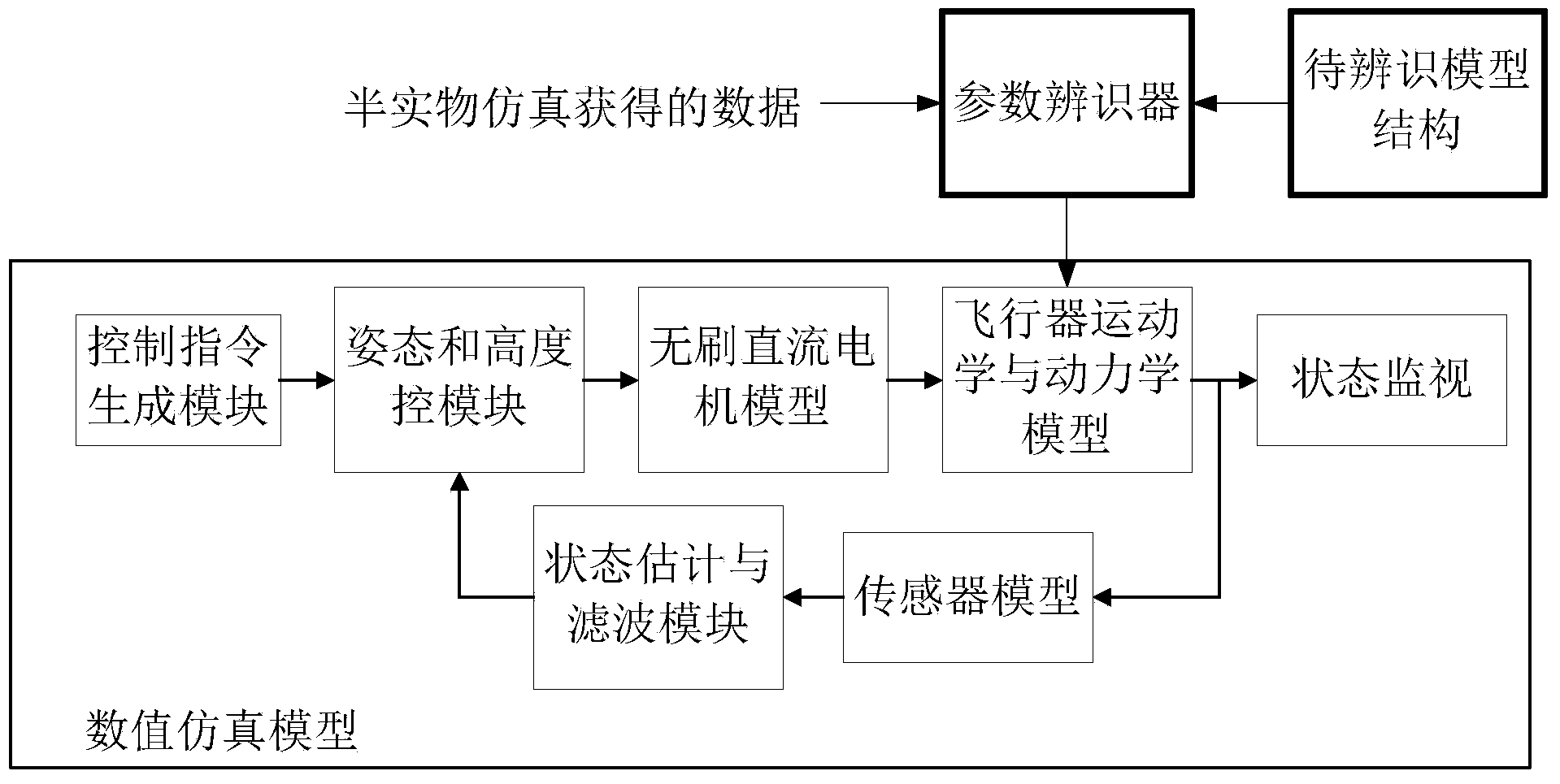

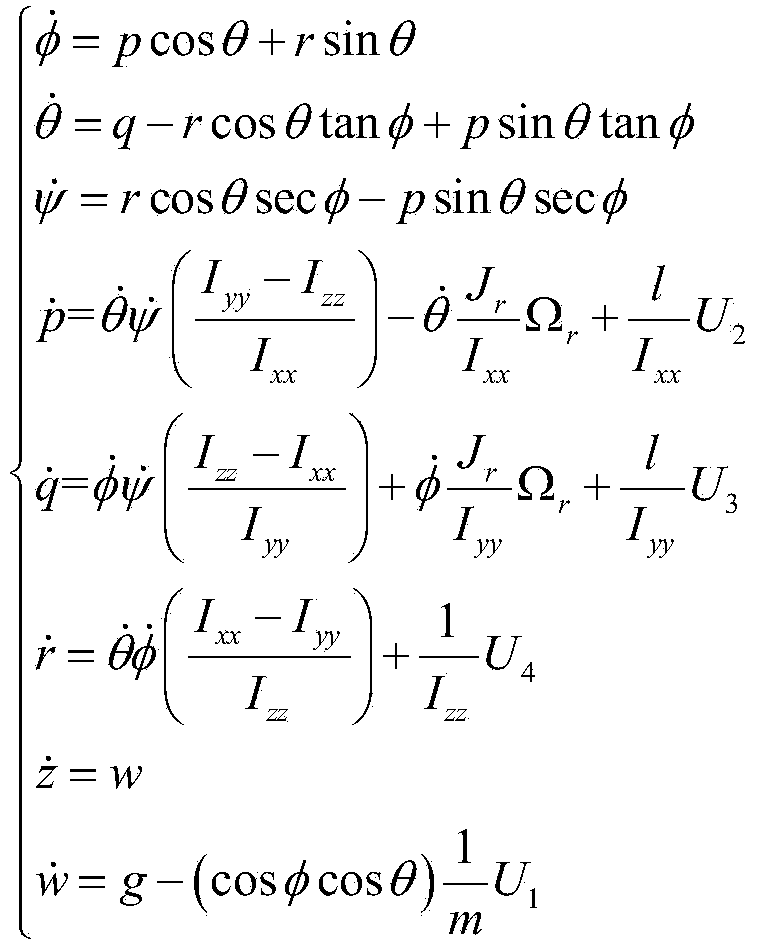

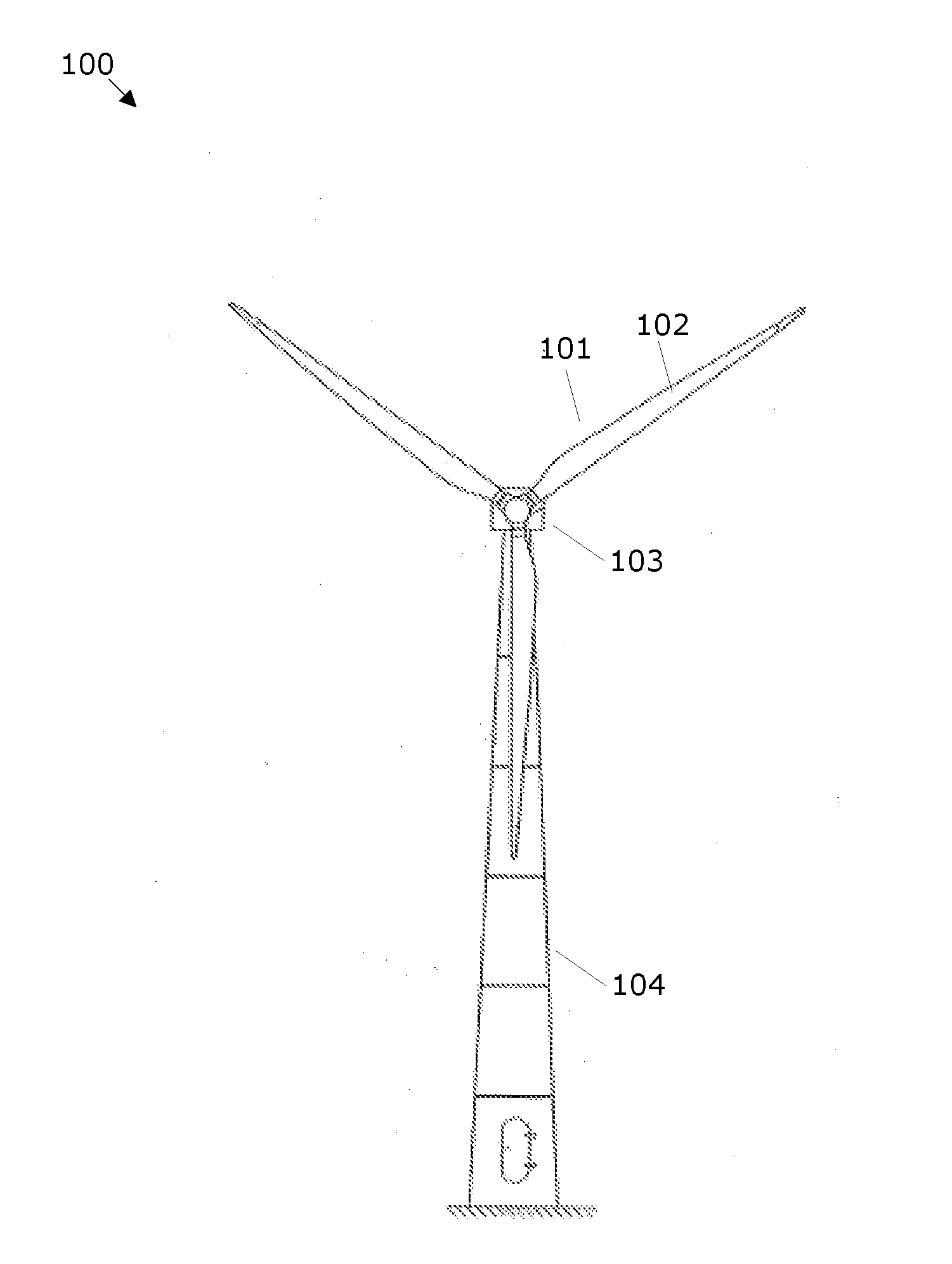

Simulation method for four-rotor aircraft

InactiveCN104133379AShorten the development cycleSave flight experiment costSimulator controlElectric testing/monitoringReal-time simulationFlight vehicle

The invention provides a simulation method for a four-rotor aircraft, and relates to a real-time simulation method of an unmanned aircraft. The simulation method for the four-rotor aircraft solves the problems that an existing semi-physical simulation system is huge in size, complex in connection, low in accuracy due to the fact that virtual state variables exist in simulation, and low in accuracy of a model obtained through modeling applying a controller design method based on the models and a numerical simulation system mechanism, wherein the controller design method based on the models and the numerical simulation system mechanism cannot be applied to modeling easily. According to the simulation method for the four-rotor aircraft, the actual aircraft is regarded as the controlled object and connected to a simulation circuit, and a reference is provided for the numerical simulation models obtained by mechanism modeling in MATLAB / Simulink, so that accuracy of aircraft mechanism modeling can be verified rapidly. A parameter recognition method is adopted so as to guarantee accuracy of objective models in numerical simulation, so that feasible controllers are verified in the numerical simulation and the controllers can be finally effectively applied to actual physical objects. The simulation method for the four-rotor aircraft is specifically applied to the field of four-rotor aircraft simulation.

Owner:HARBIN INST OF TECH

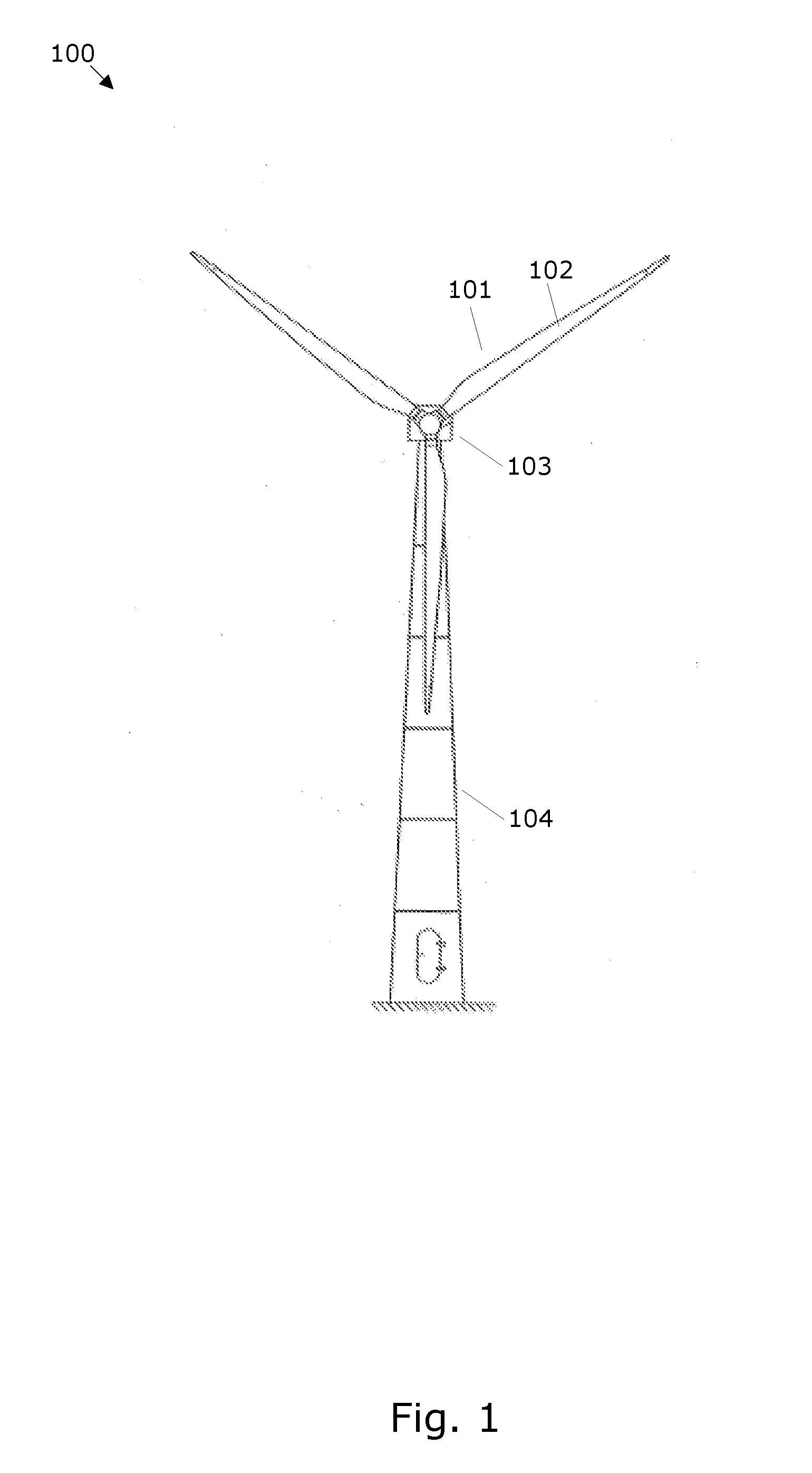

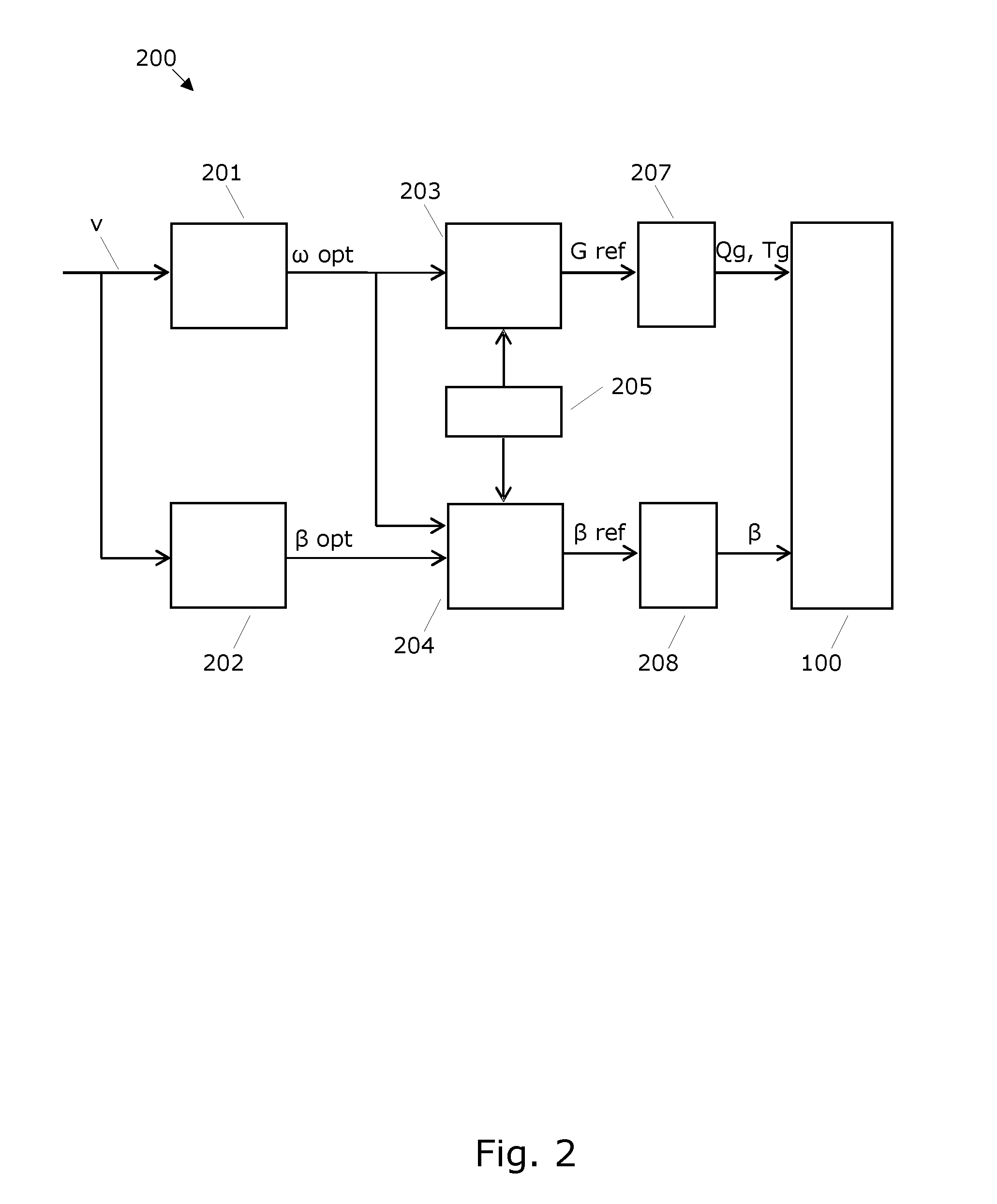

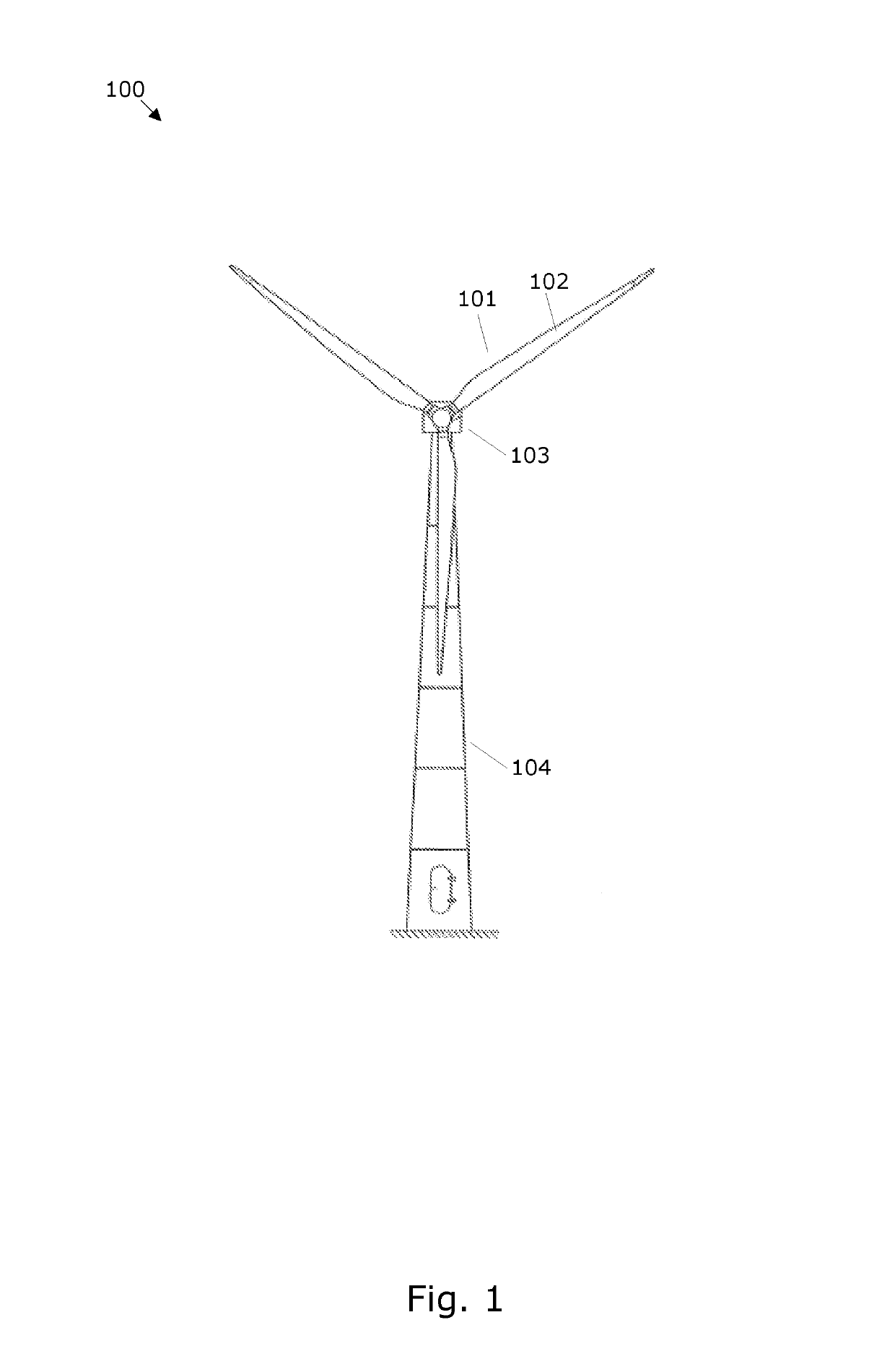

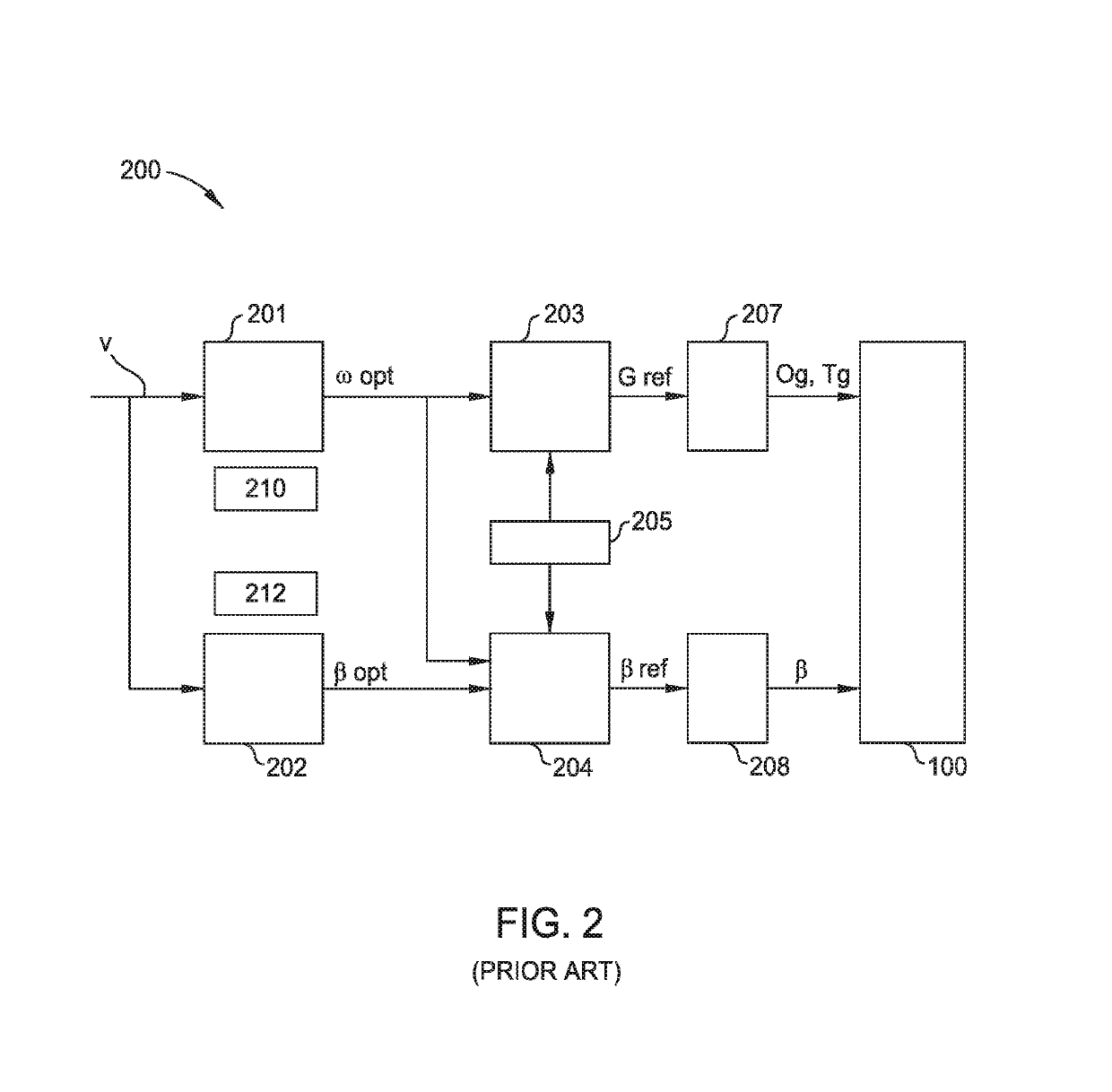

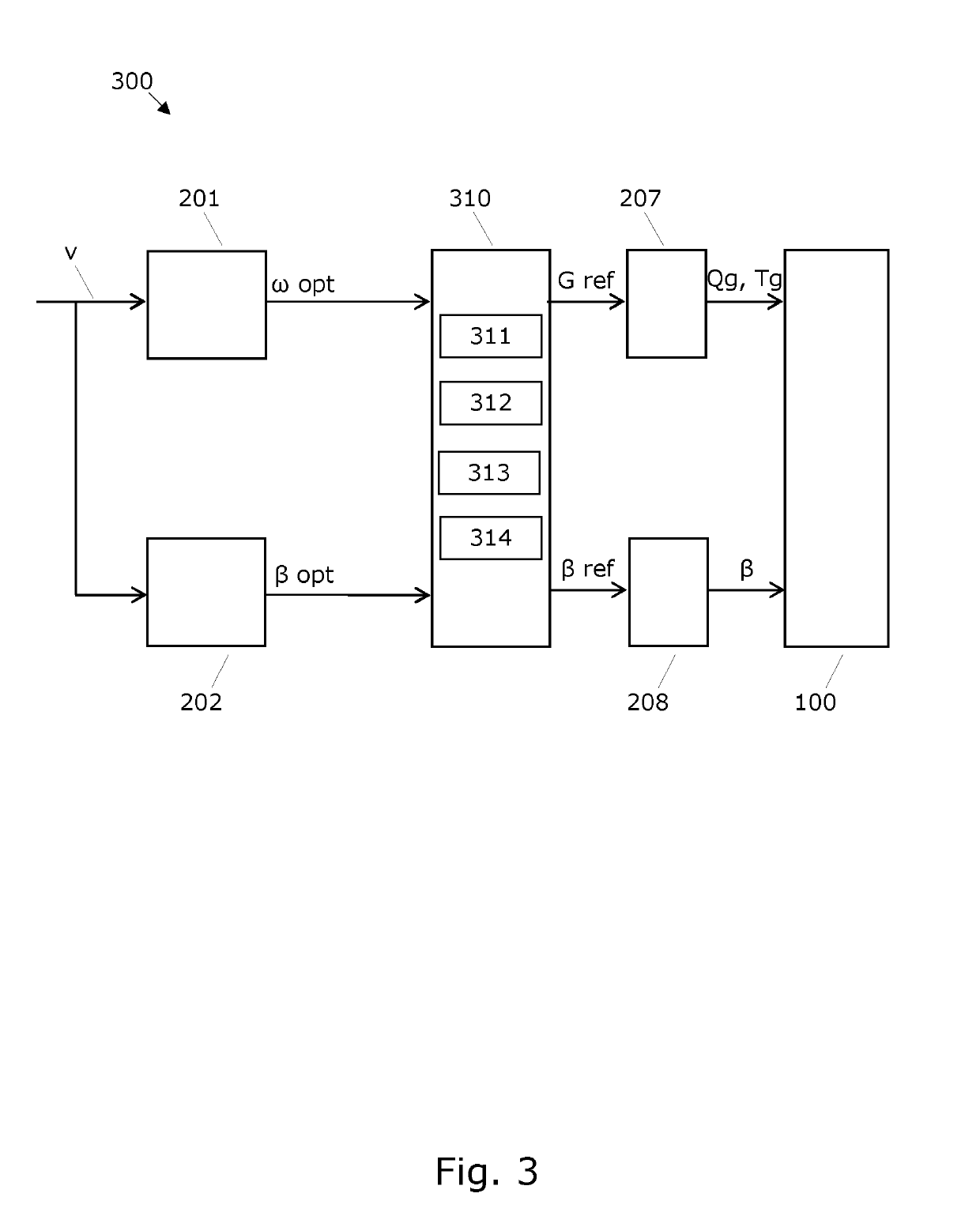

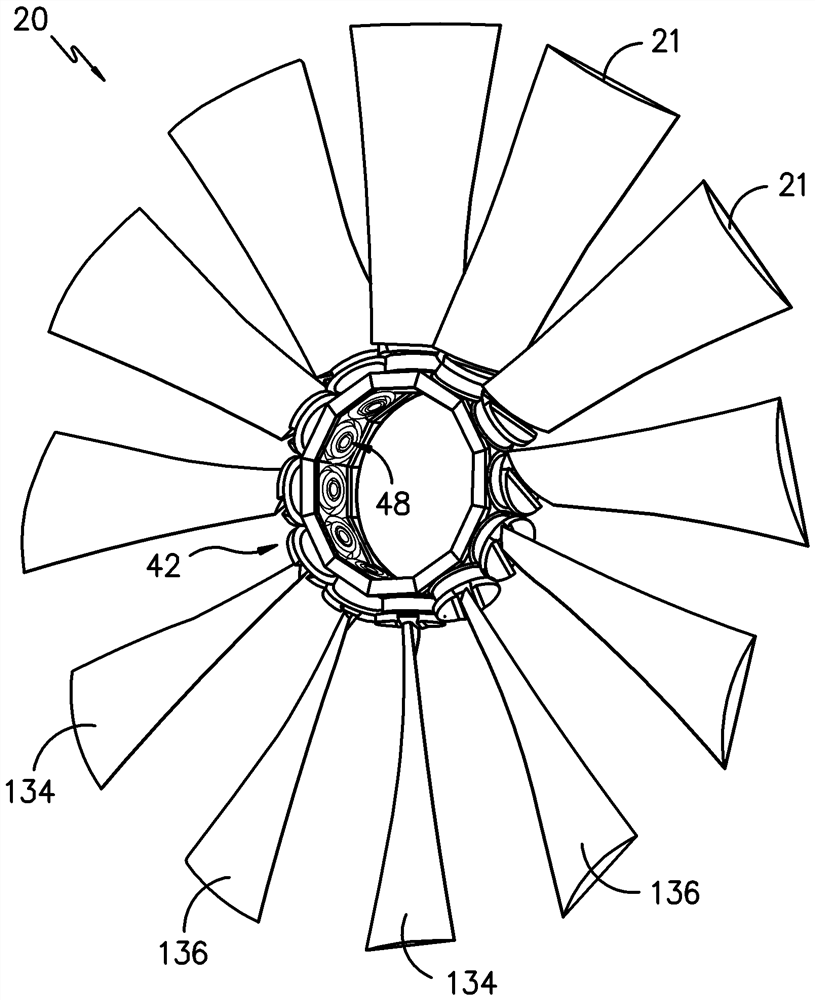

Model based controller for a wind turbine generator

ActiveUS20150369214A1Load minimizationPropellersWind motor controlPhysical modelModel based controller

The invention relates to a controller configured to determine one or more future values of blade control references and / or a generator control references for a wind turbine generator. The first of the future values of the control references are used for control purposes. The future control references are determined from a physical model of a system of the wind turbine generator by solving an optimization problem which includes at least one cost function and at least one constraint.

Owner:VESTAS WIND SYST AS

Model predictive control of a fermentation feed in biofuel production

ActiveUS8634940B2Bioreactor/fermenter combinationsBiological substance pretreatmentsBiofuelModel based controller

System and method for managing fermentation feed in a biofuel production process, comprising a dynamic multivariate predictive model-based controller coupled to a dynamic multivariate predictive model. The model is executable to: receive process information, including water inventory and biomass information, from the biofuel production process; receive a specified objective for the fermentation feed specifying a target biomass concentration; and generate model output comprising target values for a plurality of manipulated variables of the biofuel production process, including target flow rates of water and / or biomass contributing to the fermentation feed in accordance with the specified objective. The controller is operable to dynamically control the biofuel production process by adjusting the plurality of manipulated variables to model-determined target values to stabilize water / biomass balance in the fermentation feed in accordance with the specified objective, including the specified target biomass concentration.

Owner:ROCKWELL AUTOMATION TECH

Method for using a model-based controller for a robotic leg

A model-based neuromechanical controller for a robotic limb having at least one joint includes a finite state machine configured to receive feedback data relating to the state of the robotic limb and to determine the state of the robotic limb, a muscle model processor configured to receive state information from the finite state machine and, using muscle geometry and reflex architecture information and a neuromuscular model, to determine at least one desired joint torque or stiffness command to be sent to the robotic limb, and a joint command processor configured to command the biomimetic torques and stiffnesses determined by the muscle model processor at the robotic limb joint. The feedback data is preferably provided by at least one sensor mounted at each joint of the robotic limb. In a preferred embodiment, the robotic limb is a leg and the finite state machine is synchronized to the leg gait cycle.

Owner:MASSACHUSETTS INST OF TECH

Method and system for actively tuning a valve

InactiveUS20100256888A1Analogue computers for vehiclesTurbine/propulsion fuel valvesReal-time dataMultiple sensor

An embodiment of the present invention has the technical effect of utilizing a model-based system and real time data to adjust a parameter of at least one valve. An embodiment of the present invention may reduce the need of multiple sensors within a fuel system by integrating a model-based controller with real-time or approximately real-time data to adjust a parameter of at least one valve. An embodiment of the present invention may utilize a model-based controller to calculate the fuel flow through the at least one valve, in or near real-time.

Owner:GENERAL ELECTRIC CO

Model predictive control of a fermentation feed in biofuel production

InactiveUS20140134599A1Bioreactor/fermenter combinationsMicrobiological testing/measurementBiofuelModel based controller

System and method for managing fermentation feed in a biofuel production process, comprising a dynamic multivariate predictive model-based controller coupled to a dynamic multivariate predictive model. The model is executable to: receive process information, including water inventory and biomass information, from the biofuel production process; receive a specified objective for the fermentation feed specifying a target biomass concentration; and generate model output comprising target values for a plurality of manipulated variables of the biofuel production process, including target flow rates of water and / or biomass contributing to the fermentation feed in accordance with the specified objective. The controller is operable to dynamically control the biofuel production process by adjusting the plurality of manipulated variables to model-determined target values to stabilize water / biomass balance in the fermentation feed in accordance with the specified objective, including the specified target biomass concentration.

Owner:ROCKWELL AUTOMATION TECH

Control of an expanded drying section of a paper machine

ActiveCN102341544ASavings potentialEasy to understandDryer sectionEnergy industryEnergy balancedModel based controller

The invention relates to a method and to a model-based controller for controlling at least one part of a paper machine, to a paper machine having such a controller, to a computer program for executing the method according to the invention, and to a computer program product on which the computer program according to the invention is stored.; In order to achieve an improved or optimized operation mode of an "expanded drying section" of a paper machine - comprising the "actual" drying section, separated, if applicable, into pre-drying and post-drying sections with a size press located therebetween, a steam and condensate system, an exhaust air heat recovery system, a wet press and the white water - a model that includes the above system components is proposed, with which mass and energy balances for the system components as well as the specific energy consumption of the drying section are calculated, based on values for parameters relevant for the drying process.

Owner:西门子能源全球两合公司

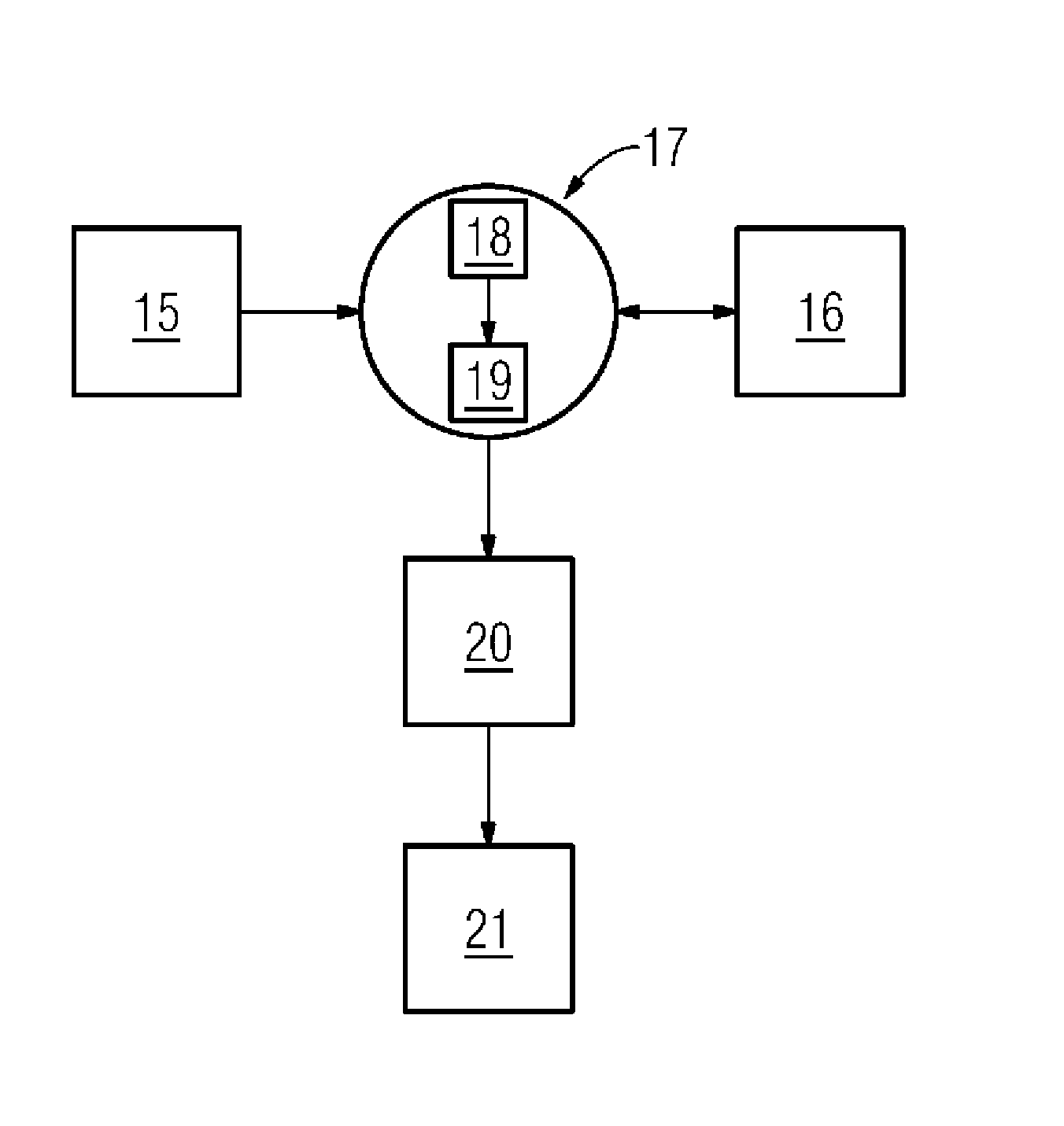

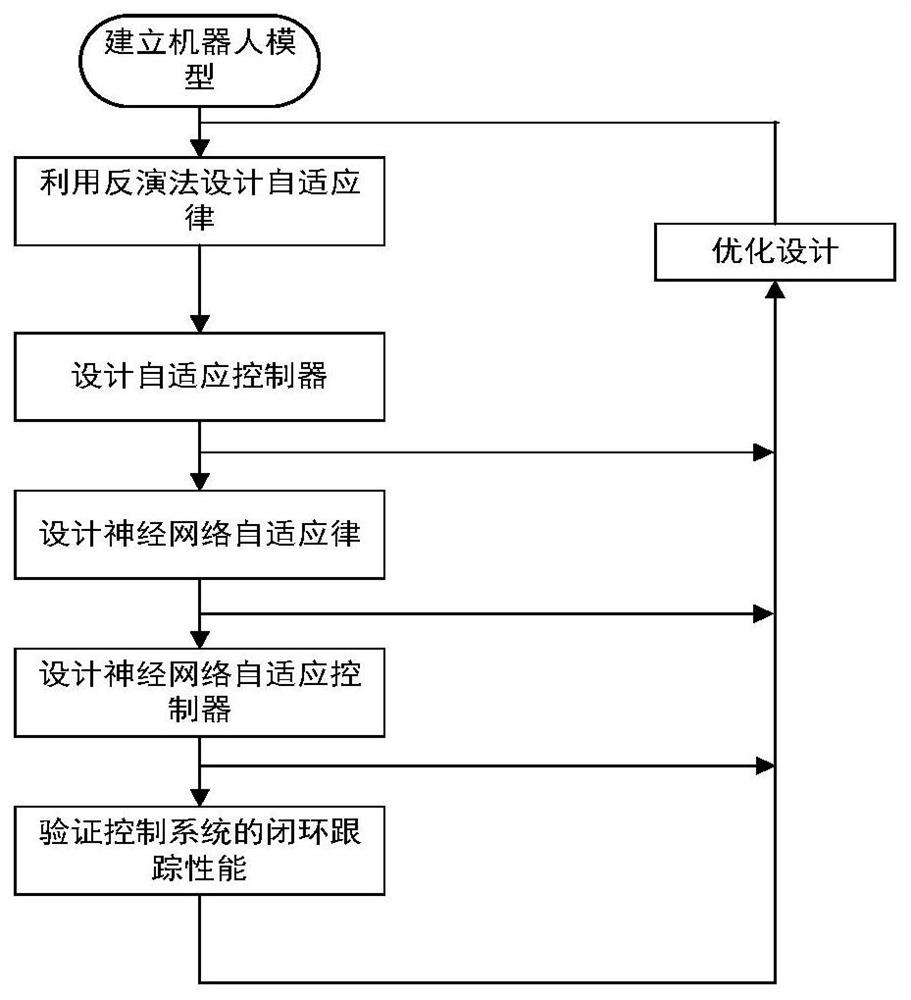

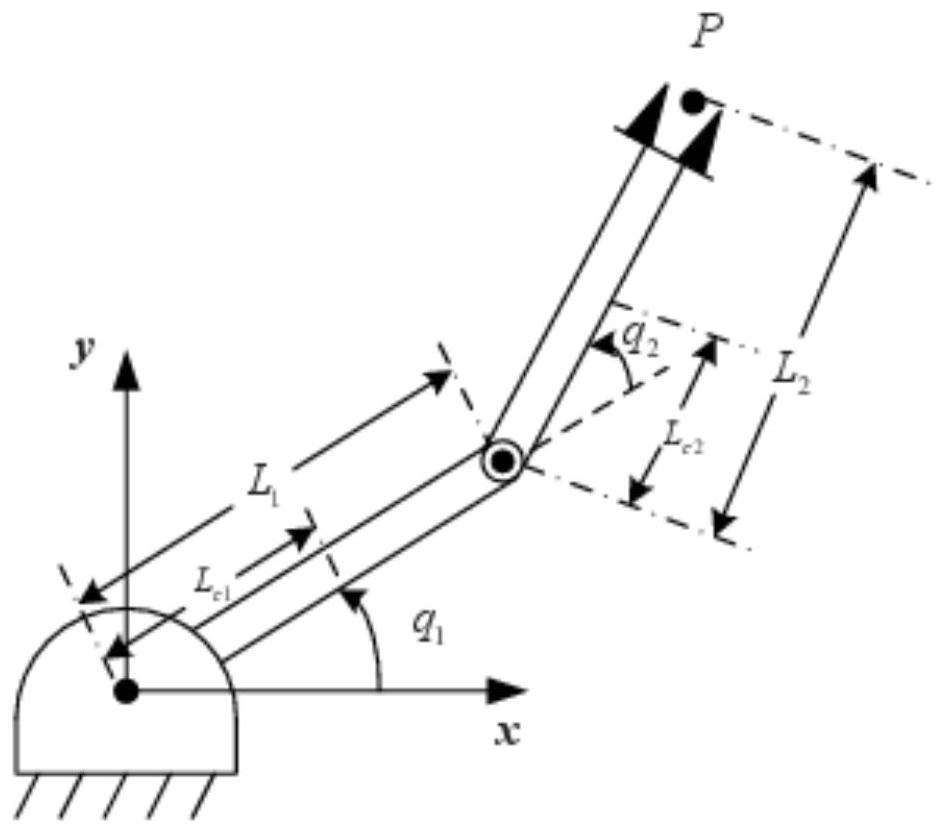

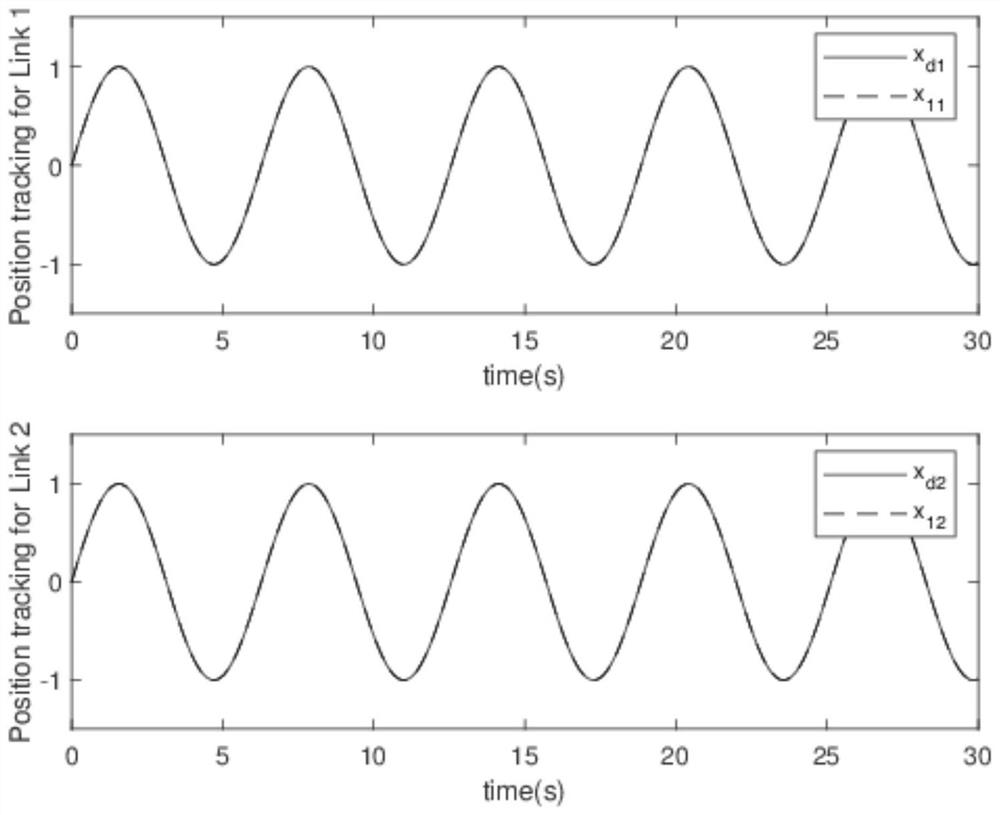

Uncertainty robot adaptive neural network control method based on inversion method

InactiveCN112192573AImprove adaptabilityGuaranteed stabilityProgramme-controlled manipulatorAdaptive controlControl systemModel based controller

The invention provides an uncertainty robot adaptive neural network control method based on an inversion method. The method includes the steps of step 1, establishing a kinetic model of an uncertaintyrobot; step 2, converting the kinetic model of the uncertain robot into a general state space form; step 3, defining a tracking error, and converting the general state space form in the step 2 into astate space form about the error; step 4, designing a model-based controller by using the inversion method; step 5, introducing a Moore-Penrose inversion, and designing a control law tau 0; and step6, designing an adaptive controller by utilizing a neural network under the condition of considering the kinetic model and the uncertainty of external disturbance. According to a neural network adaptive trajectory tracking method and the controller provided, the disturbance generated by an external environment and robot modeling uncertainty are fully considered, so that the method and the controller have more practical significance for improving the adaptive ability of a robot control system to uncertainty factors.

Owner:NANJING UNIV OF POSTS & TELECOMM

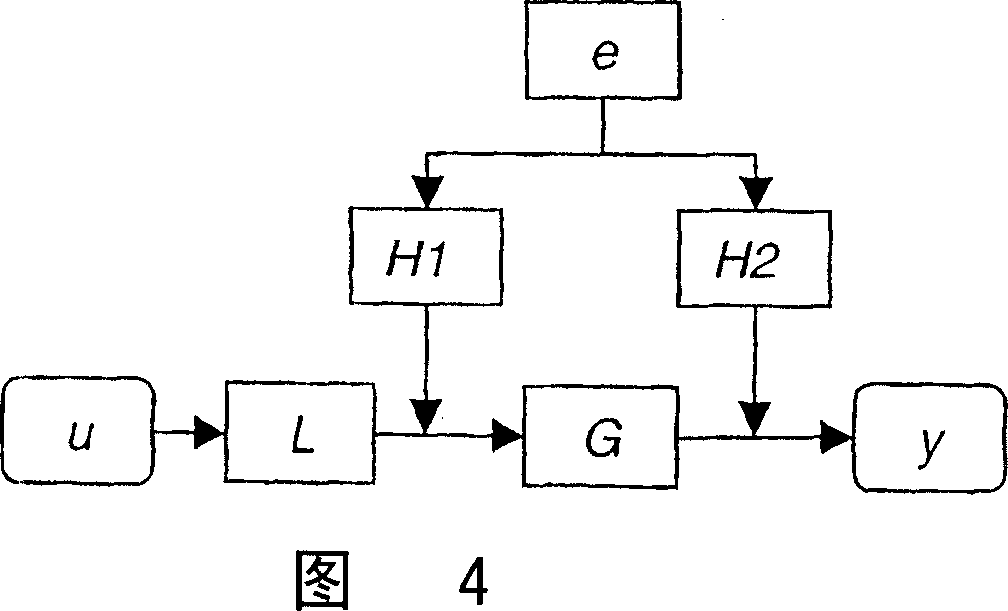

Model-Based Learning Control

ActiveUS20130304236A1Reduce noiseReduce installation costsSimulator controlElevatorsControl systemModel based controller

A method controls an operation of a system. The system is operated by a controller. The controller is model-based controller determined according to a model of the system. The method updates the model, during the operation, based on an extremum seeking, and updates the controller based on the updated model.

Owner:MITSUBISHI ELECTRIC RES LAB INC

Integrated model predictive control of distillation and dehydration sub-processes in a biofuel production process

ActiveUS8521310B2Efficiently manipulatedBioreactor/fermenter combinationsBiological substance pretreatmentsProduction rateDistillation

A system and method are provided for integrated management of a biofuel distillation process and a biofuel dehydration process of a biofuel production process, comprising a dynamic multivariate model-based controller coupled to a dynamic multivariate predictive model. The model is executable to: receive distillation and dehydration process information including biofuel compositions, receive an objective for biofuel production output from the distillation and dehydration processes, e.g., target product composition, production rate, and / or feed rate, and generate model output comprising target values for a plurality of manipulated variables related to the distillation and dehydration processes in accordance with the objective. The controller is operable to dynamically control the biofuel production process by adjusting the plurality of manipulated variables to the model-determined target values in accordance with the objective for biofuel production.

Owner:ROCKWELL AUTOMATION TECH

Method and device for tuning and control

ActiveUS7937165B2Quick and reliable to tuneImproved and stable and robust controlMilling machinesProgram controlModel based controllerExcitation signal

A method and a device for tuning and control of industrial processes having varying material flow rate. An adder is configured to add excitation signals to the controller output signal. A measurement system is configured to measure a property in response to the excitation signals. A model based tuning unit is adapted to estimate the value of at least one parameter with unknown value of a process model structure describing the effect of varying material flow rate, based on the measurements of the property and the output signal from the controller, and to calculate a model that describes the dynamics from controller output to controller input based on the estimated value of the parameter, and to perform model based tuning of the controller based on the model that describes the dynamics from controller output to controller input.

Owner:ABB (SCHWEIZ) AG

Model-based learning control

A method controls an operation of a system. The system is operated by a controller. The controller is model-based controller determined according to a model of the system. The method updates the model, during the operation, based on an extremum seeking, and updates the controller based on the updated model.

Owner:MITSUBISHI ELECTRIC RES LAB INC

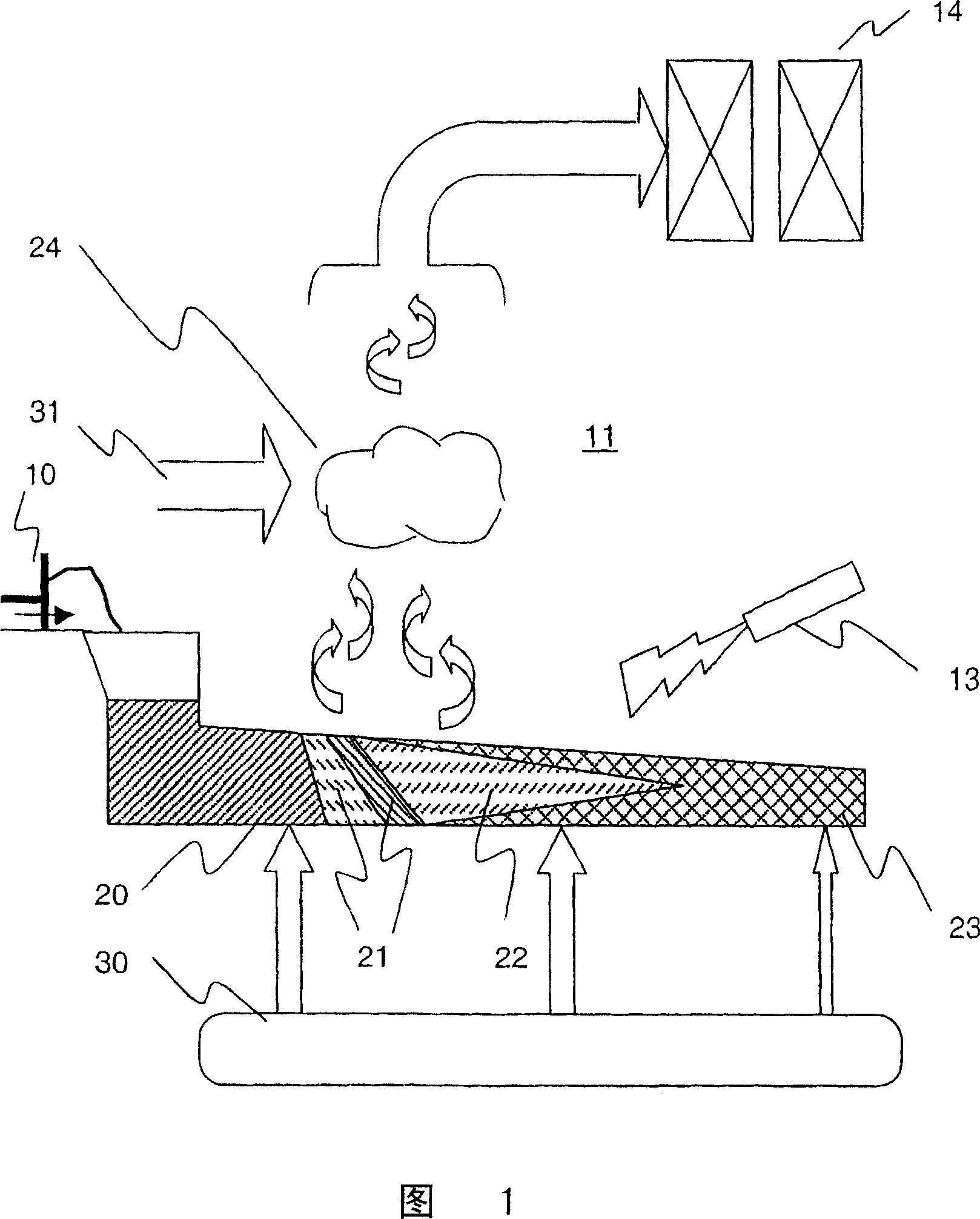

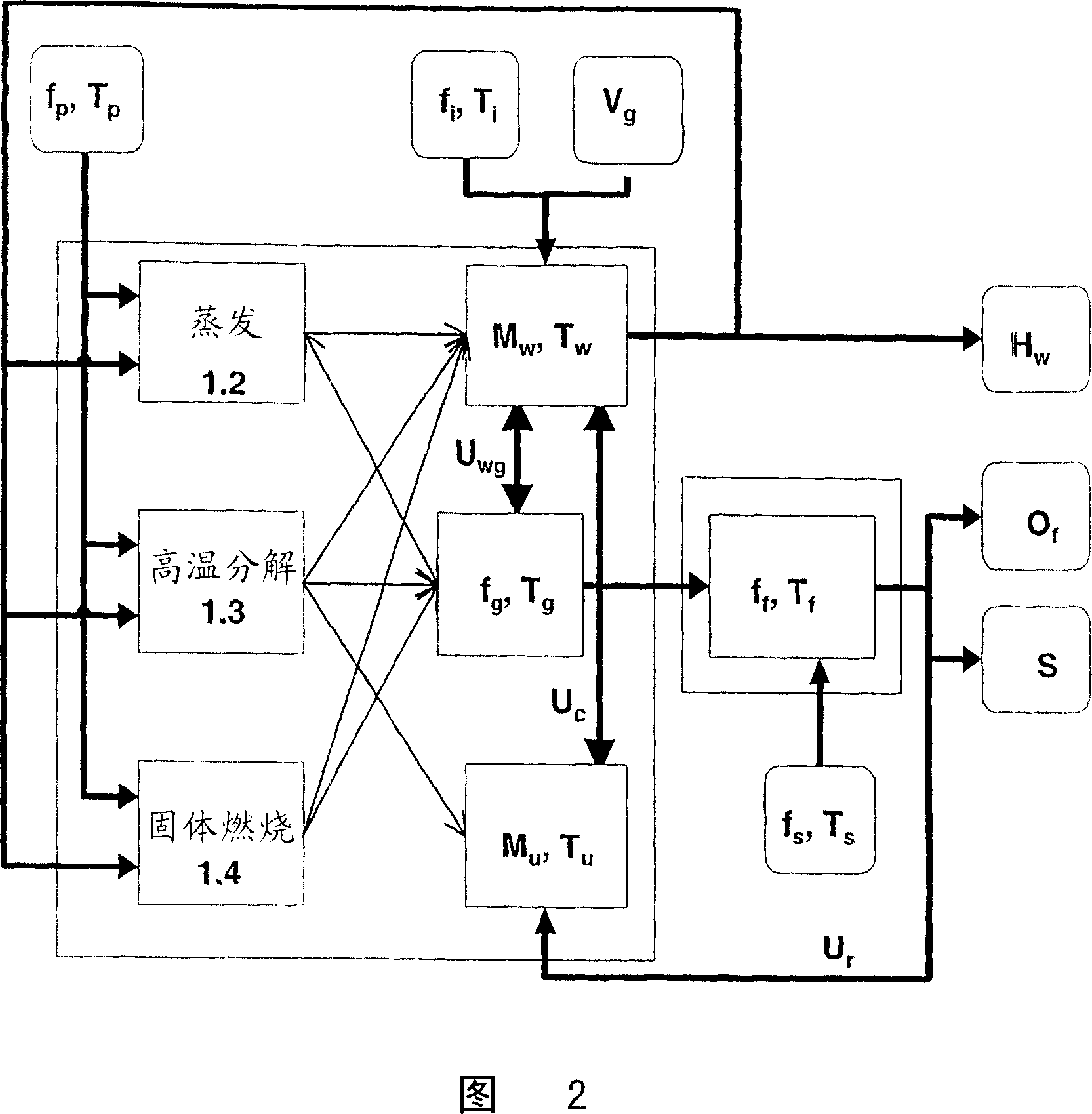

Model and control of a waste combustion process

InactiveCN1947073APrecise regenerationReliable regenerationCombustion signal processingIncinerator apparatusComputation complexityModel based controller

The present invention is concerned with a model of a waste combustion process which is accurate and of limited computational complexity at the same time and thus is suitable for controlling or simulating a waste incineration plant. A pile of waste is represented by two layers, and the heat transfer from a gas combustion phase or flame above the pile is limited to a heat radiation interaction between the flame and upper one of the layers. The resulting model-based controller for a waste incineration grate takes into account a variability of the waste composition via filtered white noise. The controller can assist the operator in maintaining constant process conditions and maximizing the throughput of the plant at constant energy output, or realize a training simulator to educated operators in running a waste to energy plant secure, reliable and efficient.

Owner:ABB RES LTD

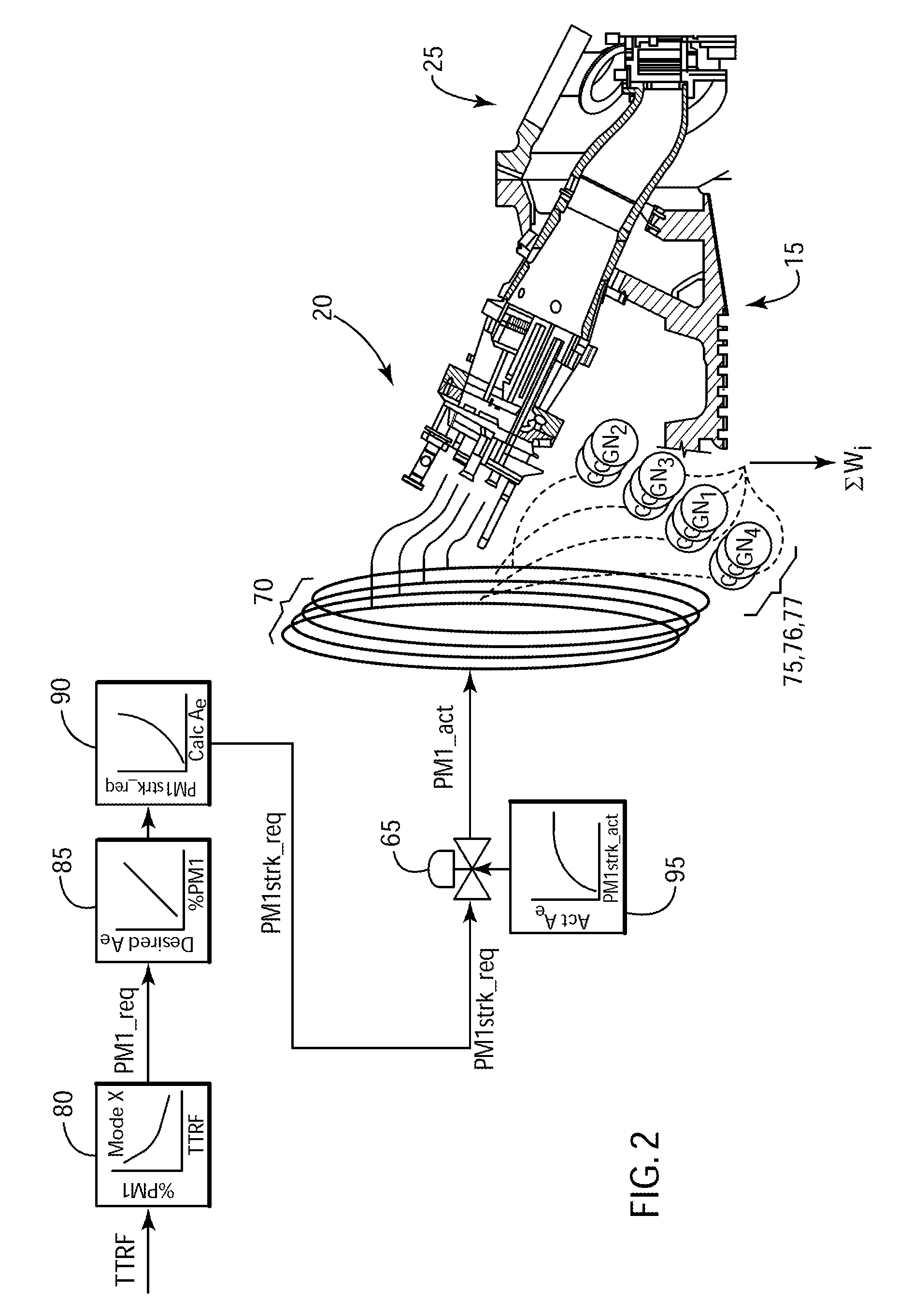

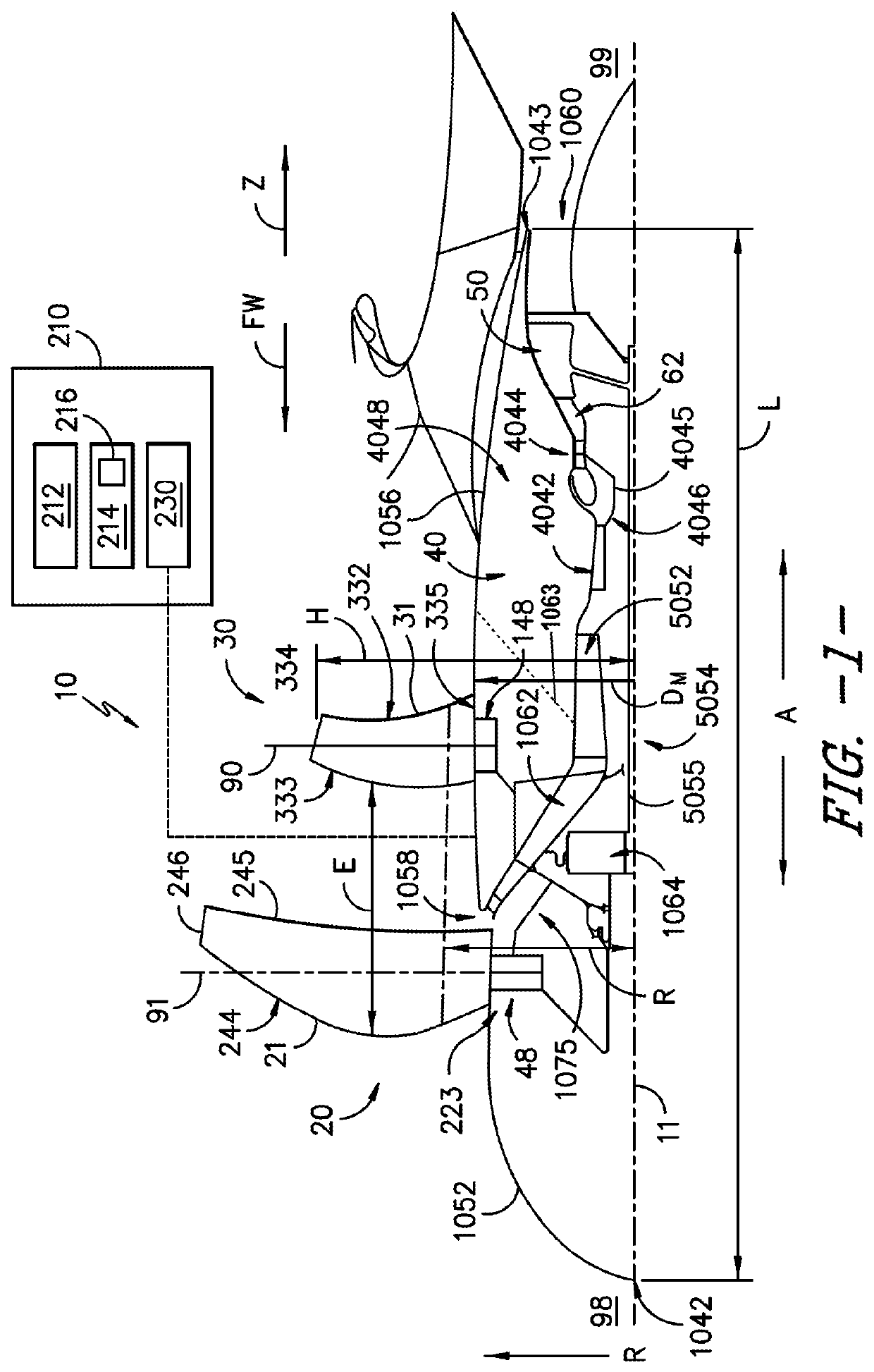

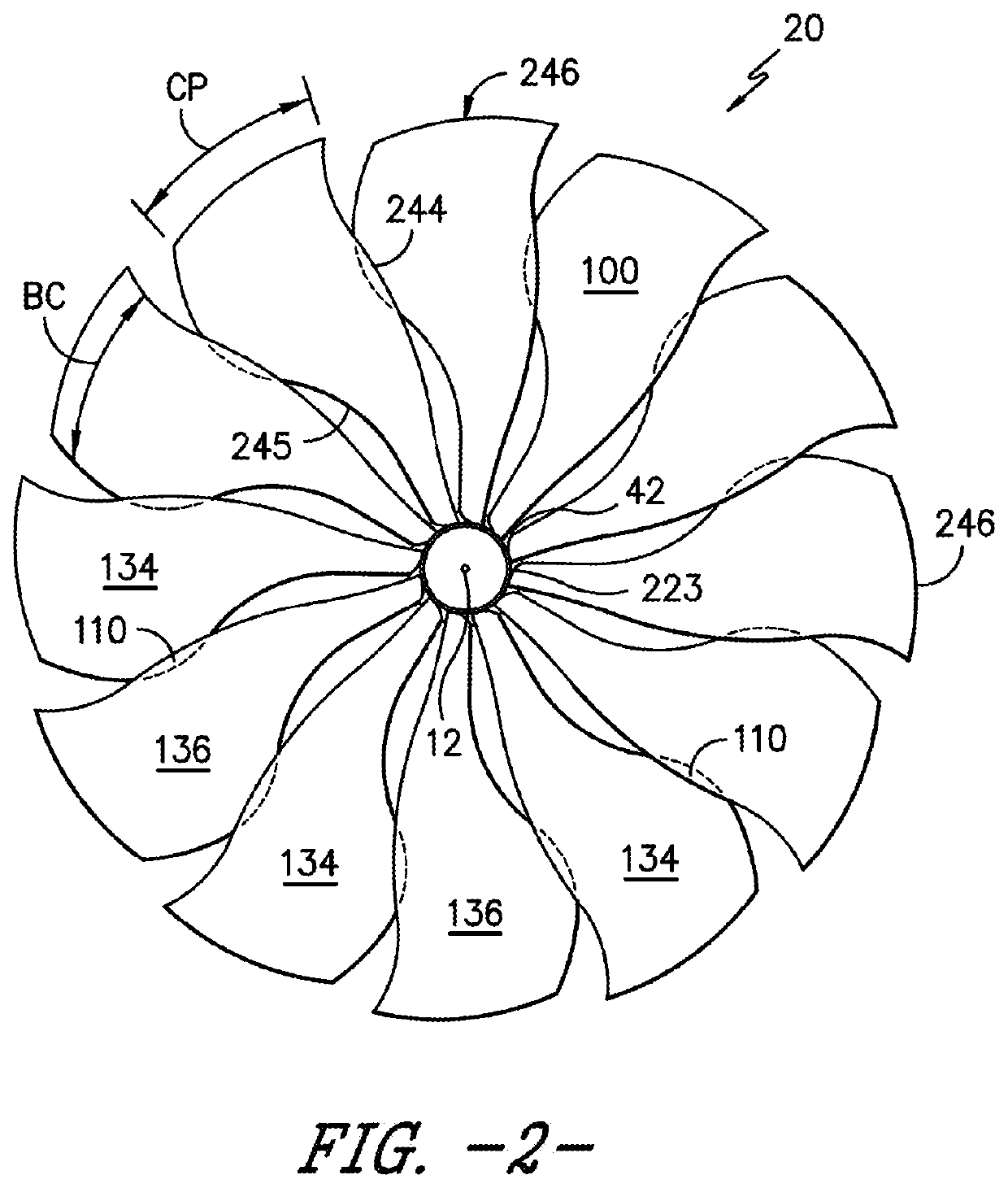

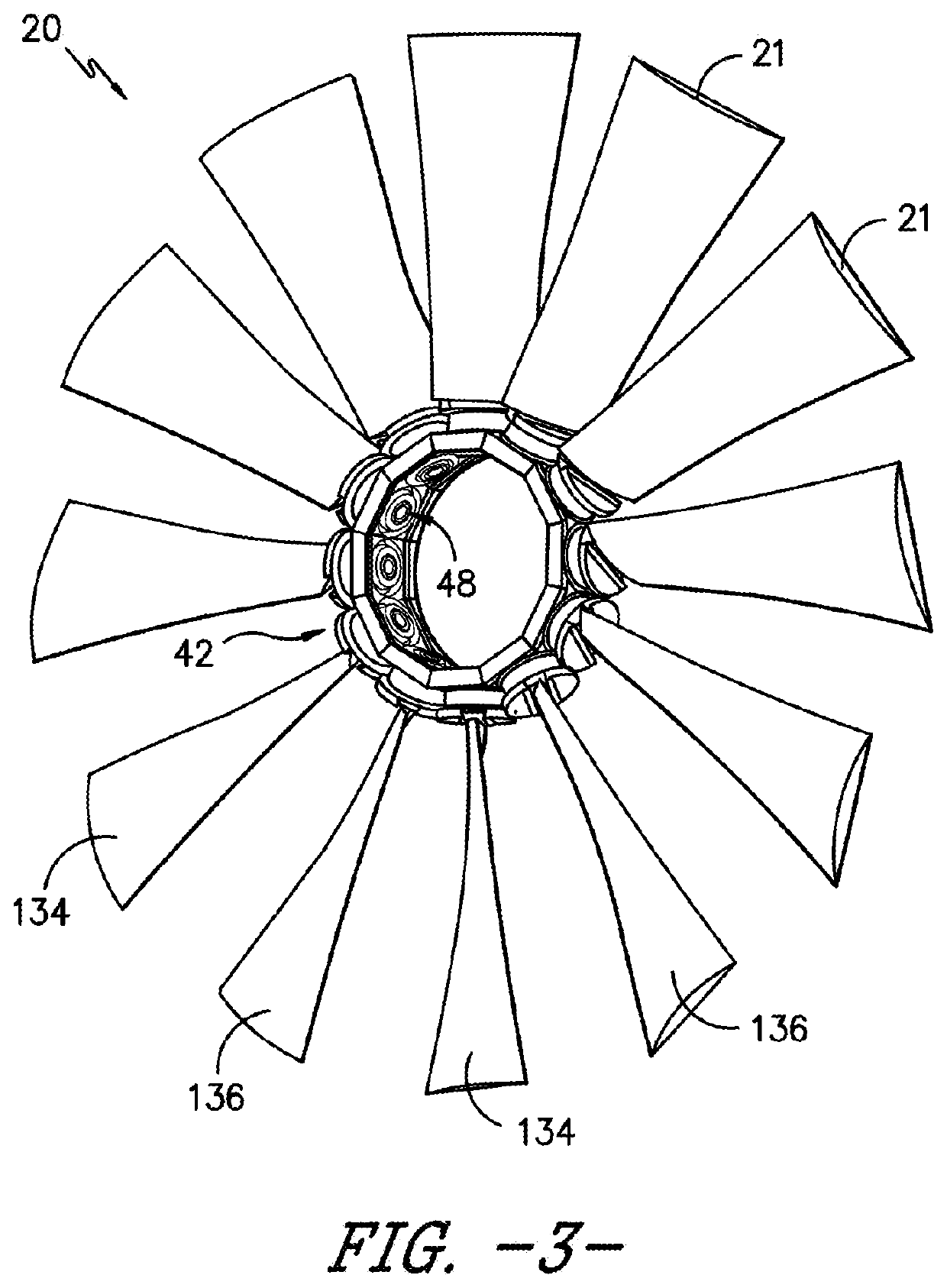

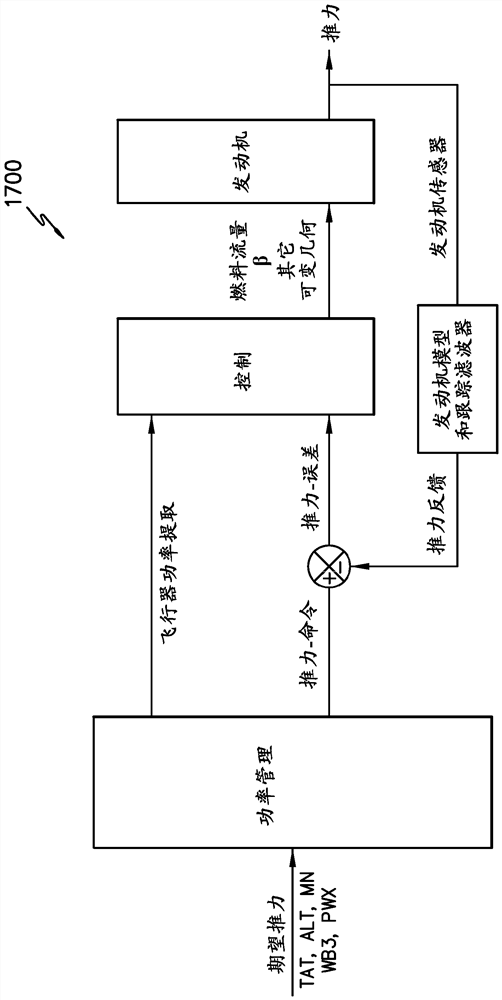

System and method for control for unducted engine

A computing system for an unducted rotor engine with a variable pitch vane assembly in aerodynamic relationship with an unducted rotor assembly, including a sensor-based controller configured to execute a first set of operations and a model-based controller configured to execute a second set of operations. The first set of operations includes obtaining a first signal corresponding to a commanded low spool speed; obtaining a second signal indicative of a pitch angle corresponding to thrust output from the unducted rotor assembly and variable pitch vane assembly; generating a pitch feedback signal corresponding to a commanded adjustment to the pitch angle based at least on one or both of a variable blade pitch angle or a variable vane pitch angle. The second set of operations include obtaining a desired thrust output via a throttle input; determining, at least via a power management block, a commanded thrust output signal; receiving the commanded thrust output signal; and generating an output signal.

Owner:GENERAL ELECTRIC CO

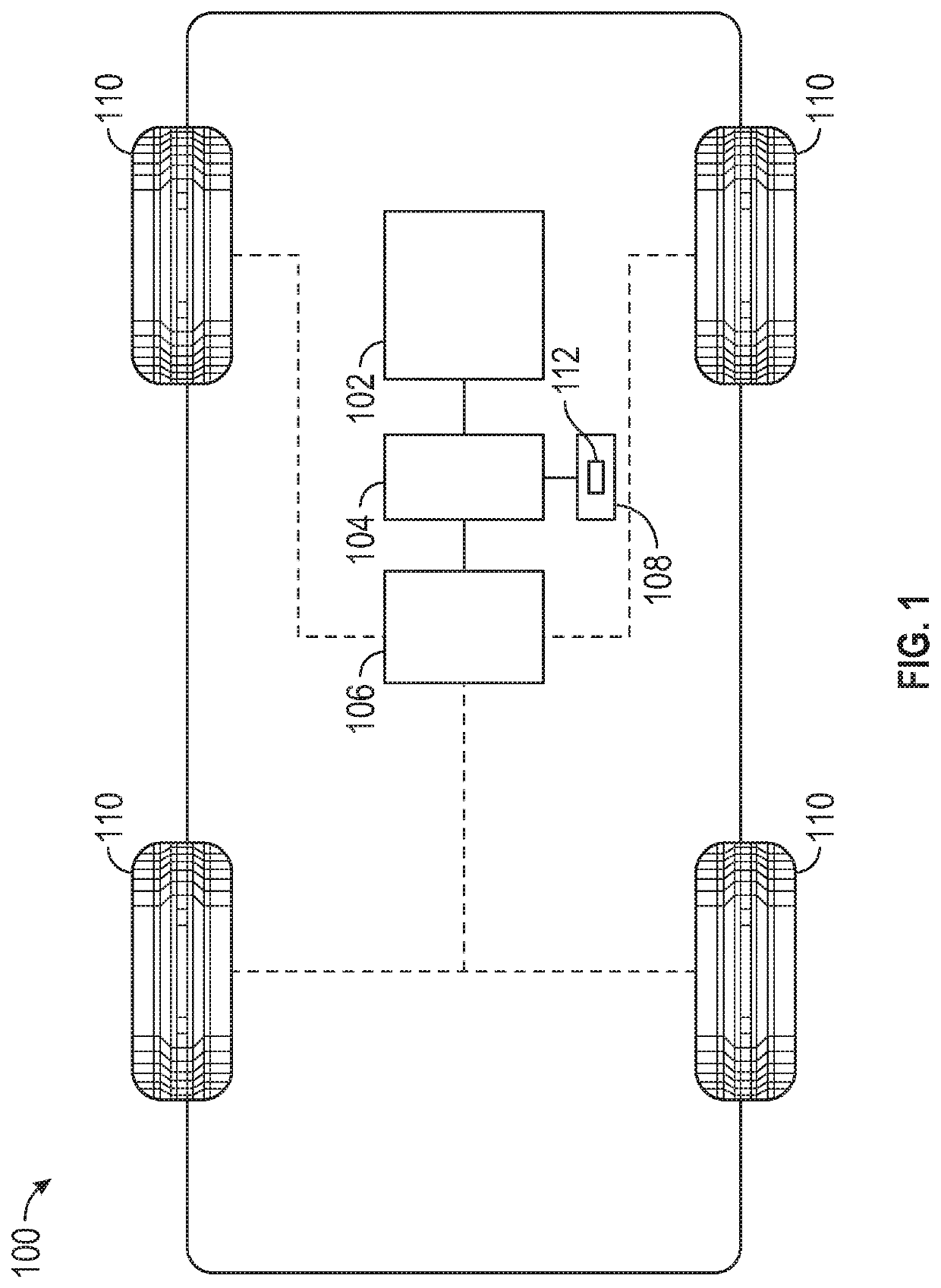

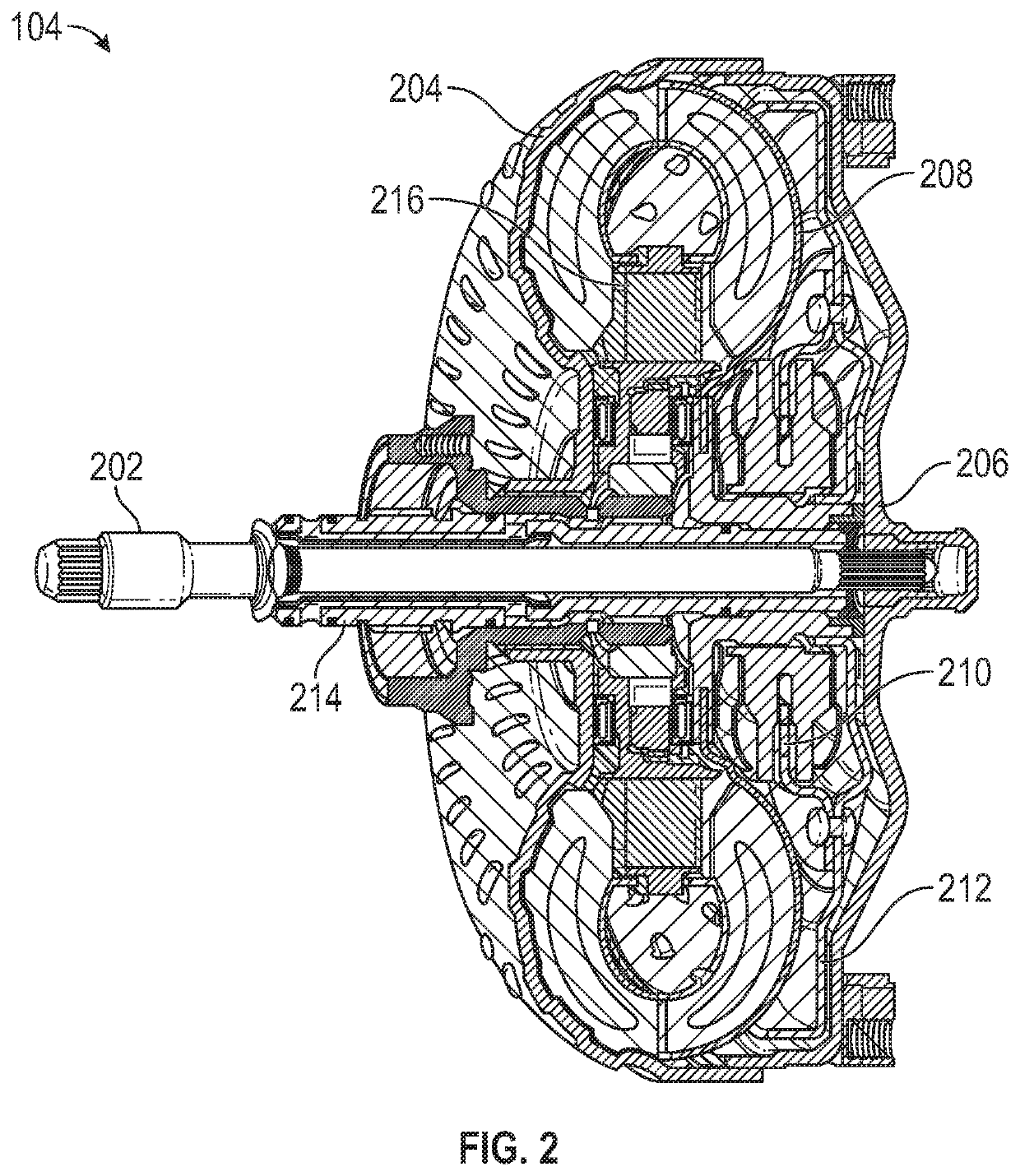

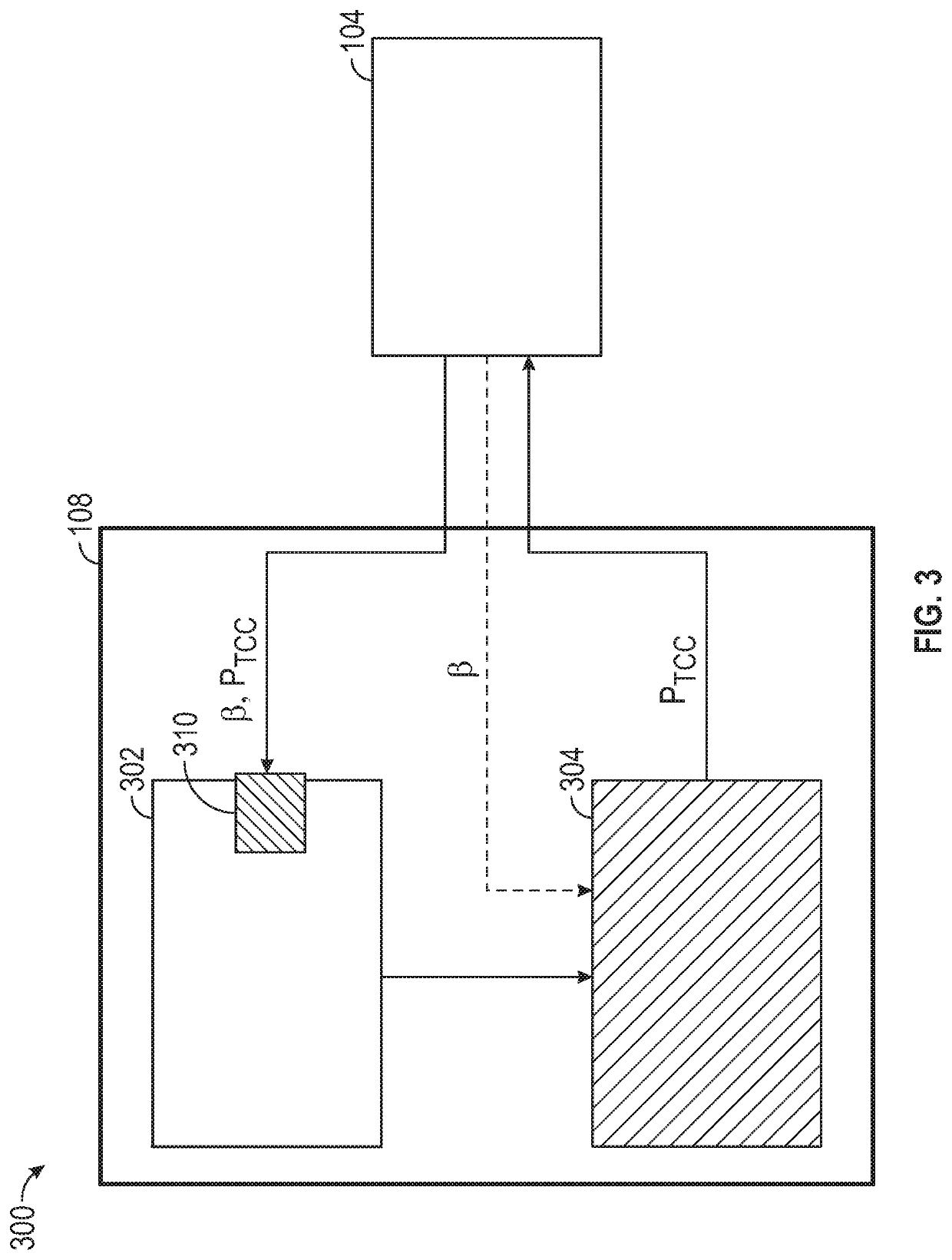

Real time supervised machine learning torque converter model

A vehicle, control system for operating a torque converter of a vehicle and a method of operating a torque converter. The control system includes a machine learning model and a model-based controller. The machine learning model is configured to receive a first set of measurements of operational parameters of the torque converter, and determine fit parameters for a model of the torque converter using the first set of measurements. The model-based controller is configured to receive a second set of measurements of operational parameters of the torque converter, determine a clutch pressure for the torque converter from the second set of measurements and the fit parameters, and apply the determined clutch pressure to the torque converter.

Owner:GM GLOBAL TECH OPERATIONS LLC

Nonlinear model-based controller for premixed charge compression ignition combustion timing in diesel engines

ActiveUS10094306B2Electrical controlInternal combustion piston enginesNonlinear modelModel based controller

Owner:PURDUE RES FOUND INC

Model based controller for a wind turbine generator

ActiveUS10302067B2Load minimizationWind motor controlActive/predictive/anticipative controlPhysical modelModel based controller

Owner:VESTAS WIND SYST AS

Fast plant test for model-based control

InactiveCN101004608ASimulation assignmentSimulation Friendliness CriterionData processing applicationsElectronic circuit testingFrequency spectrumModel based controller

A method and apparatus are provided for designing perturbation signals to excite a number of input variables of a system, in order to test that system for the purpose of obtaining models for the synthesis of a model-based controller. The method begins with providing input parameters of the system. A plurality of binary multi-frequency (BMF) signals are generated based on these input parameters and the frequency spectra of these BMF signals are calculated. One BMF signal is selected out of the set of BMF signals so that the frequency spectrum of the selected BMF signal most closely matches a desired frequency spectrum specified by the input parameters. The selected BMF signal is used as a first perturbation signal for testing the system. The selected BMF signal is also shifted by predetermined amounts of samples to create delayed copies of the original BMF signal to be used as additional perturbation signals.

Owner:AIR PROD & CHEM INC

Model-based controller for auto-ignition optimization in a diesel engine

InactiveCN101278116AElectrical controlInternal combustion piston enginesDiesel combustionModel based controller

A diesel engine (10) operates by alternative diesel combustion. Formation of fuel and charge air mixtures is controlled by processing a particular set of values for certain input data according to a predictor algorithm model (50) to develop data values for predicted time of auto-ignition thetaAI and resulting torque TQAI , and also develop data values for control of fuel and air that will produce the predicted time of auto-ignition thetaAI and resulting torque TQAI. The data values developed by the predictor algorithm and data values for at least some of the input data are processed according to a control algorithm (52) that compensates for any disturbance deltaIMT, deltaEGR introduced into any of the data values for at least some of the input data being processed by the control algorithm.; This causes the systems to be controlled by compensated data values IVC, Mf that produce predicted time thetaAI of auto-ignition and resulting torque TQAI in the presence of any such disturbance deltaIMT, deltaEGR.

Owner:INT ENGINE INTPROP CO LLC

System and method for controlling ductless engine

A computing system is provided for a ductless rotor engine having a variable pitch stator blade assembly in aerodynamic relationship with the ductless rotor assembly. The computing system includes a sensor-based controller configured to perform a first set of operations. The first set of operations includes: obtaining a first signal corresponding to a commanded low axis of rotation speed; obtaining a second signal indicative of a pitch angle corresponding to a thrust output from the unducted rotor assembly and the variable pitch stator blade assembly; generating a pitch feedback signal corresponding to a commanded adjustment of the pitch angle based at least on one or both of the variable blade pitch angle or the variable stator blade pitch angle. The computing system also includes a model-based controller configured to perform a second set of operations. The second set of operations includes: obtaining a desired thrust output via the accelerator input; determining a commanded thrust output signal via at least the power management block; receiving a command thrust output signal; and generating an output signal.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com