Control of an expanded drying section of a paper machine

A drying part, paper machine technology, applied in the direction of paper machine, dryer part, paper making, etc., can solve the problems affecting production cost and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

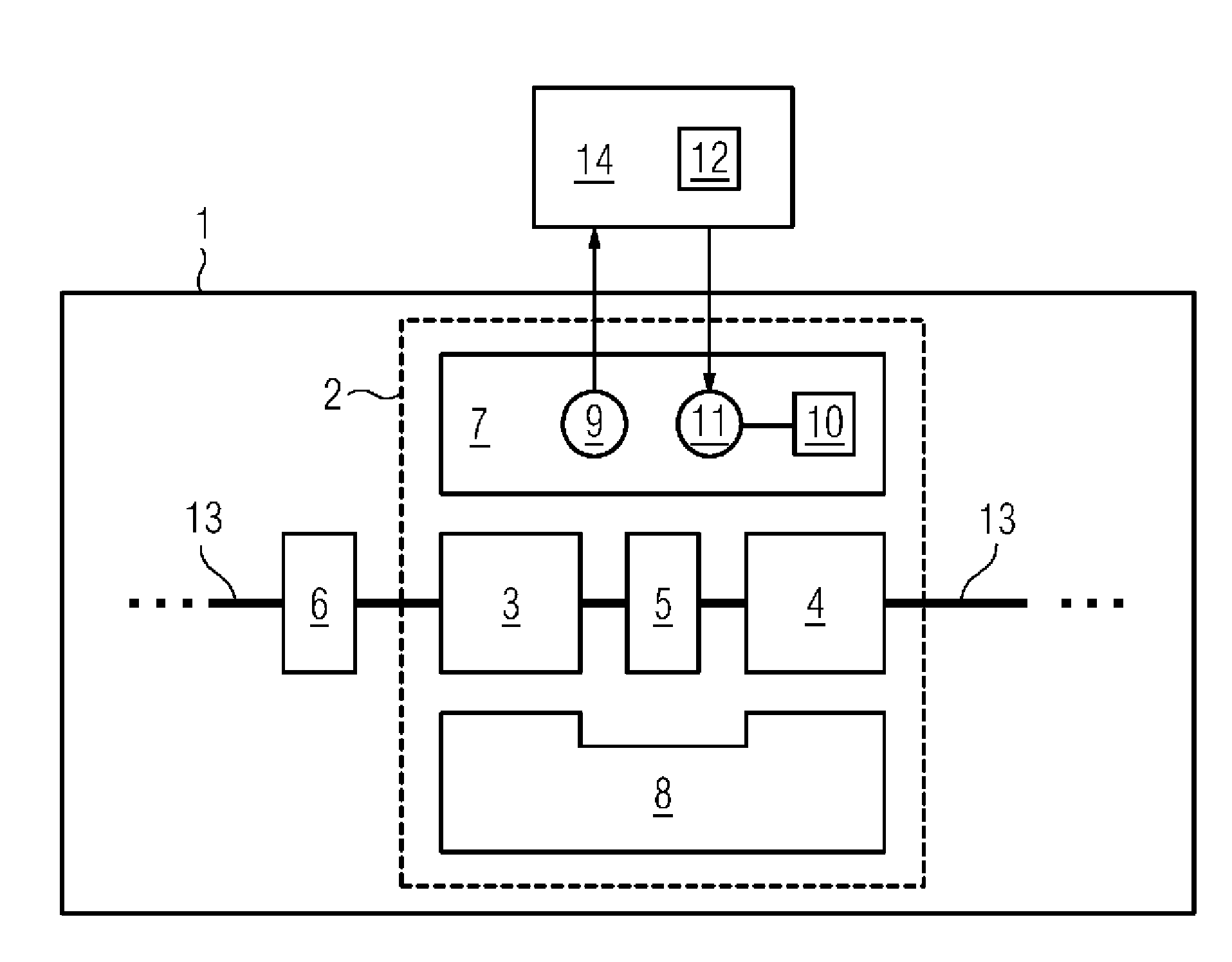

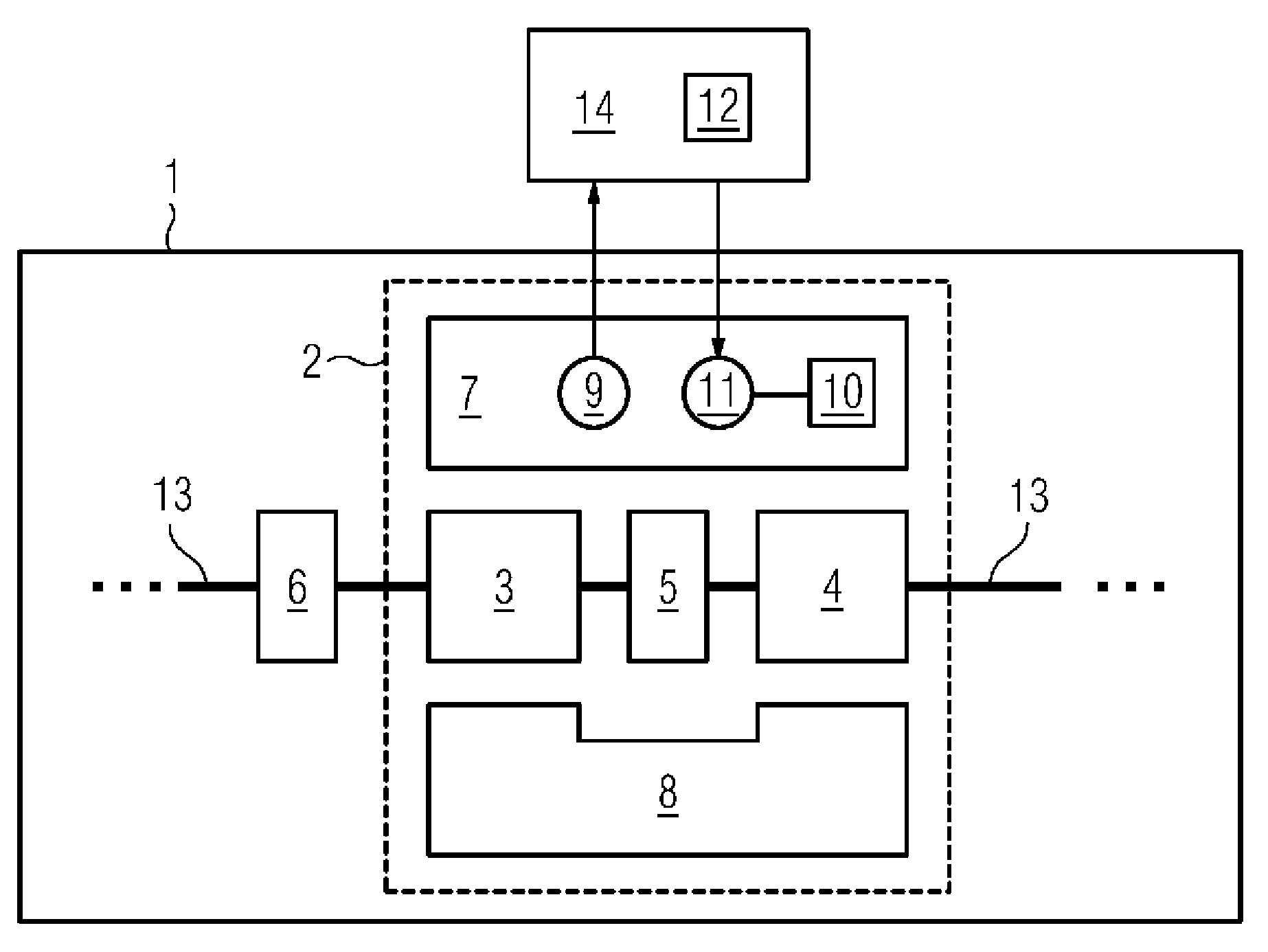

[0077] figure 1 A simplified schematic diagram of a paper machine 1 is shown, the illustration being limited to the plant components that are relevant to the invention. This is firstly the drying section 2 , which has a pre-drying section 3 , a post-drying section 4 and a size press 5 , the effect of the wet press 6 on the drying of the paper web 13 also being simulated together. Furthermore, the heat recovery system 7 and the evaporation and condensation system 8 also belong to the drying section 2 . All plant components can have a plurality of sensors 9 for receiving different measured values (for example parameters calculated in the method according to the invention), of which only one sensor 9 in the heat recovery system 7 is shown in the drawing. The sensor 9 supplies measured values to a controller 14 of the paper machine 1, which has suitable means 12, such as input and output means, working memories, processors, etc., for carrying out the method according to the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com