Method and apparatus for producing a three-dimensional object

A three-dimensional, structural technique, applied in the field of equipment for performing the method, which can solve the problems of very expensive and expensive manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

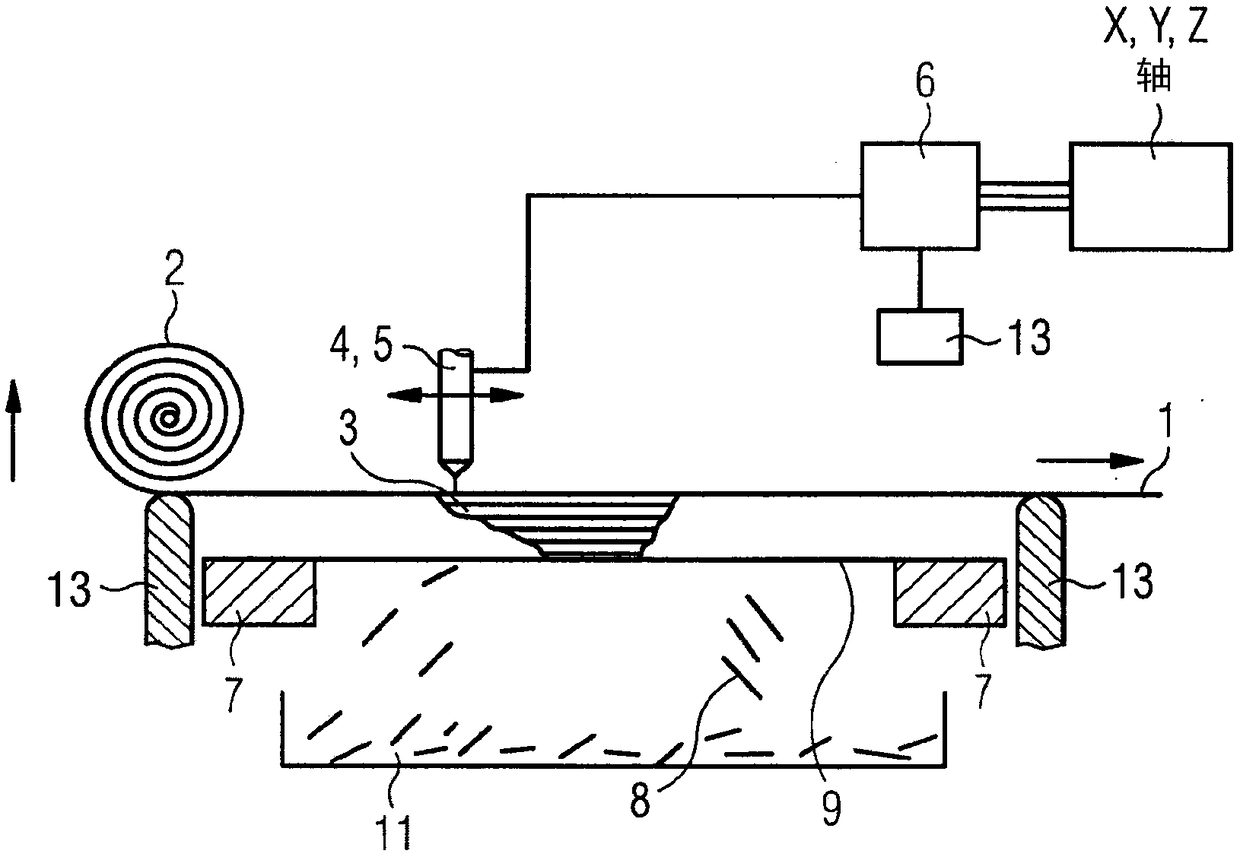

[0047] exist figure 1 An embodiment of a device for producing a three-dimensional workpiece 3 is shown in a side view of . Plate 1 is stocked on roll 2. The sheet metal 1 can be lifted layer by layer by means of the roll guide unit 13 . The lowermost sheet metal layer rests on the carrier frame 7 . Notches, not shown in detail, are cut into the lowermost sheet-metal layer, through which sheet-metal residues 8 of the upper sheet-metal layer can fall. However, the sheet metal residue 8 does not have to be forced to fall downwards, but can also be transported away with the sheet metal remainder after the sheet metal 1 has been lifted. The cutting unit 5 and the melting unit 4 form a single unit, the laser, in this exemplary embodiment. The controller 6 transmits the implementation of the movement to the corresponding unit, that is to say along the X and Y axes—that is, in a plane parallel to the section plane—and the Z axis (orthogonal to the section plane), wherein, in the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com