Foldable guide rail unit

A technology of folding guide rails and guide rails, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of poor flexibility, inability to change, and increased cost of conveyor belts, and achieve improved competitiveness, good fixation, and shear resistance. The effect of strong bending ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

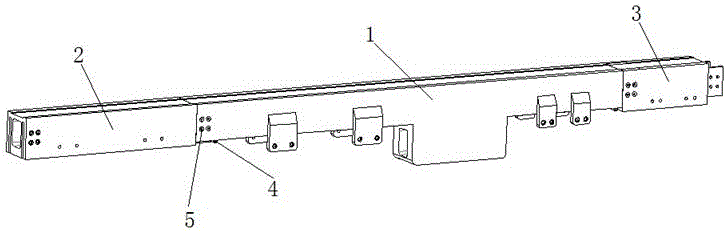

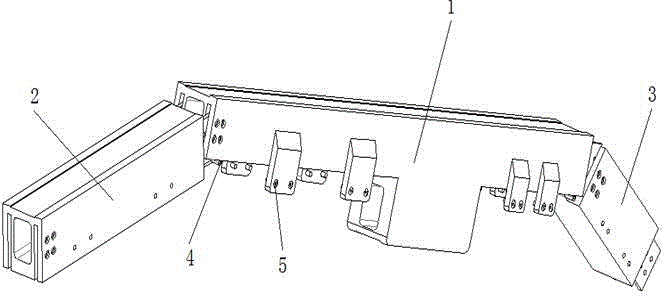

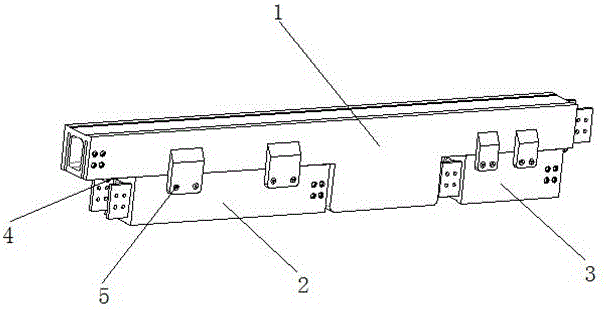

[0019] Such as Figure 1-4 As shown, the present invention includes a main body guide rail 1, a long extension guide rail 2, a short extension guide rail 3, a rotating shaft 4, and a screw 5. The main guide rail 1 includes an upper guide rail 1.1, a lower conveyor belt support structure 1.2, a first slot 1.3, a first insert plate 1.4, a guide rail fixing plate 1.5, and a first conveyor belt groove 1.6, wherein the width of the upper guide rail 1.1 and the lower conveyor belt support structure 1.2 is the same as The height is the same, the upper rail 1.1 is 500mm long, the lower conveyor support structure 1.2 is shorter than the upper rail 1.1 at both ends to accommodate the retracted extension rails (long extension rail 2, short extension rail 3), the upper surface of the upper rail 1.1 and the lower conveyor support structure 1.2 The lower surface is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com