Model-based controller for auto-ignition optimization in a diesel engine

A diesel engine, self-ignition technology, applied in the direction of engine control, electrical control, machine/engine, etc., can solve the problems of engine deflagration, power loss, etc., and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

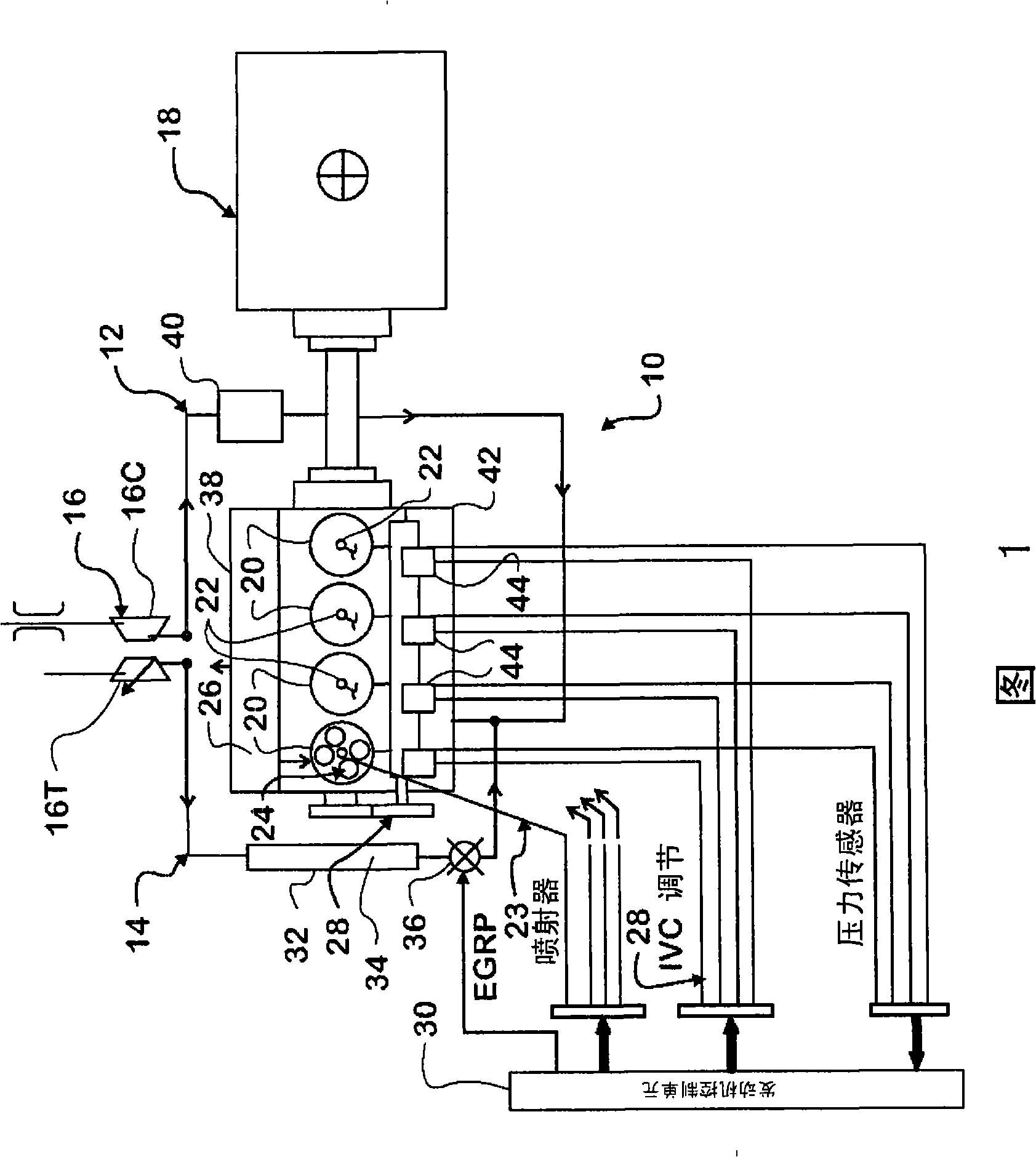

[0039] Figure 1 shows an exemplary internal combustion engine 10 embodying the principles of the present invention. The engine 10 includes an intake system 12 through which charge air for combustion enters the engine, and an exhaust system 14 through which exhaust gas generated by combustion exits the engine. Engine 10 operates on the compression ignition principle and is turbocharged by a turbocharger 16 having a turbine 16T located in exhaust system 14 and a compressor 16C located in intake system 12 . When the engine is used as a motive force for a motor vehicle, such as a truck, engine 10 may be coupled through transmission 18 to driven wheels that propel the vehicle.

[0040] Engine 10 includes a plurality of cylinders 20 (either in an in-line configuration or in a V-configuration) forming combustion chambers into which fuel injectors 22, which are elements of a fuel management system 23, inject fuel to contrast with the 12 incoming charge air mix. Pistons reciprocating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com