Diesel aftertreatment system

A technology for diesel and exhaust gas treatment, used in exhaust gas treatment, separation methods, machines/engines, etc., and can solve problems such as restricted oxidation catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

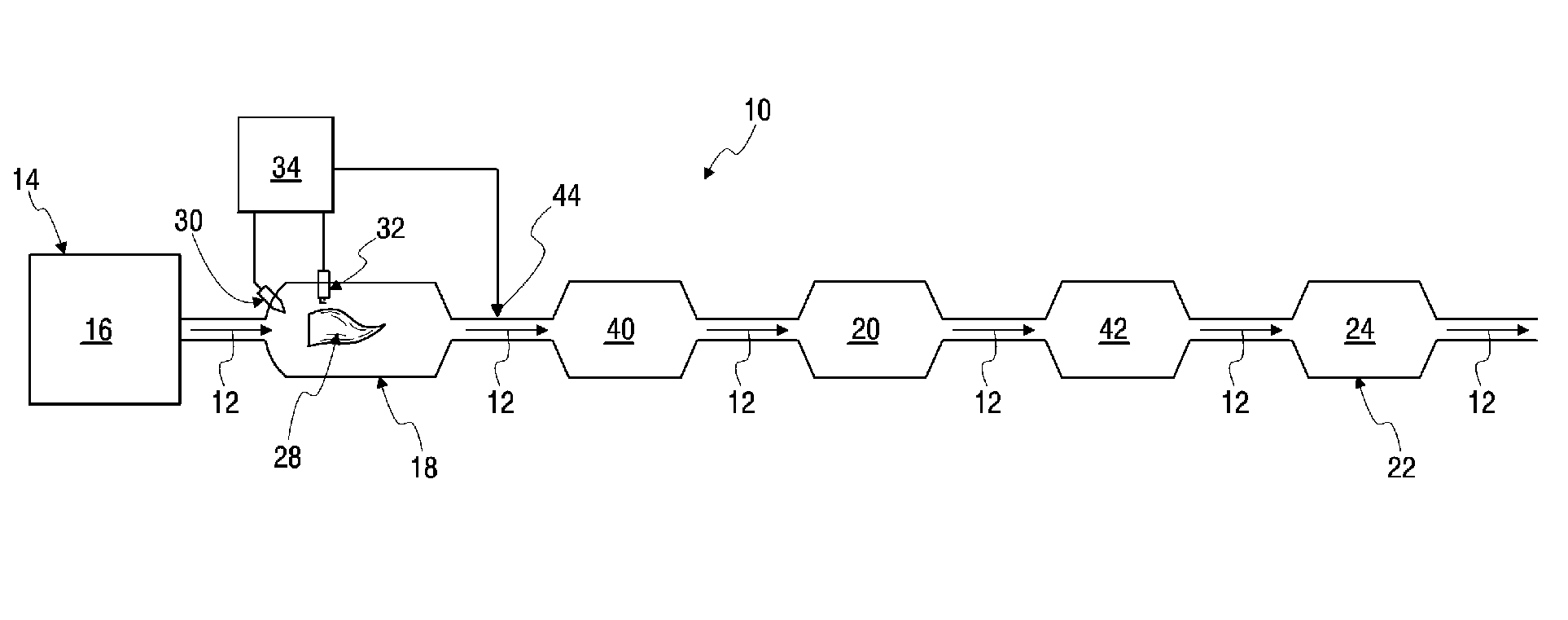

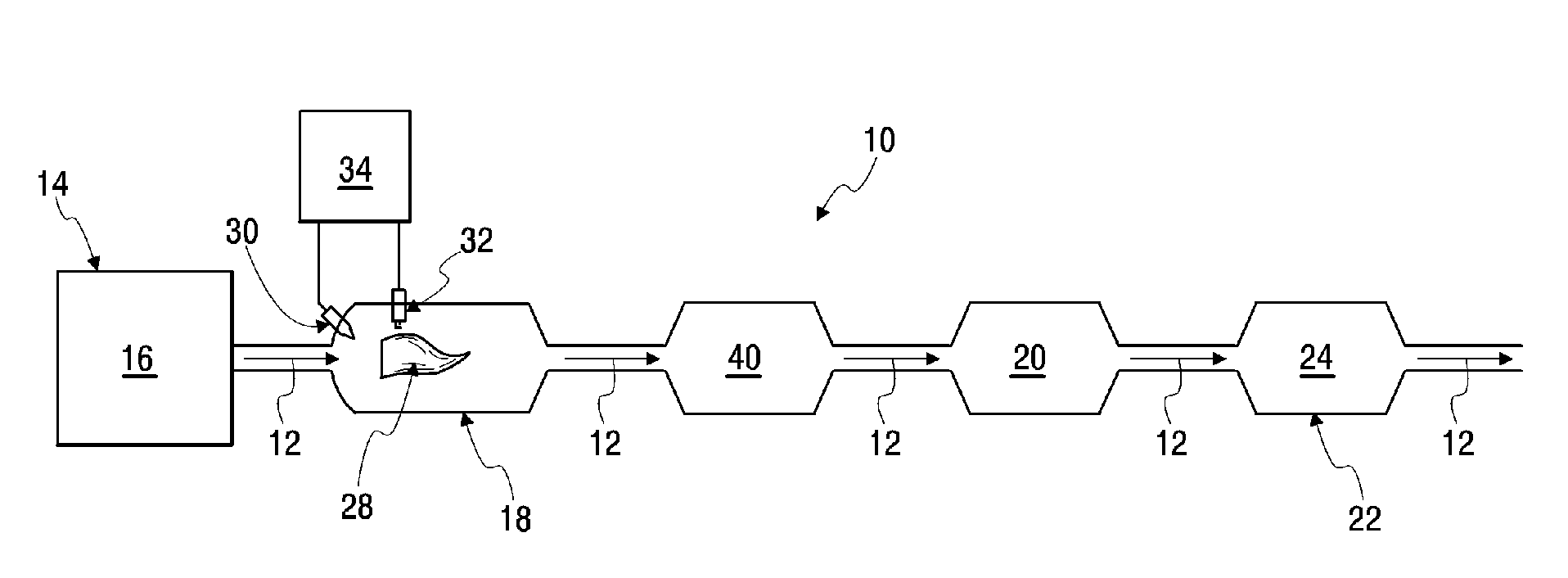

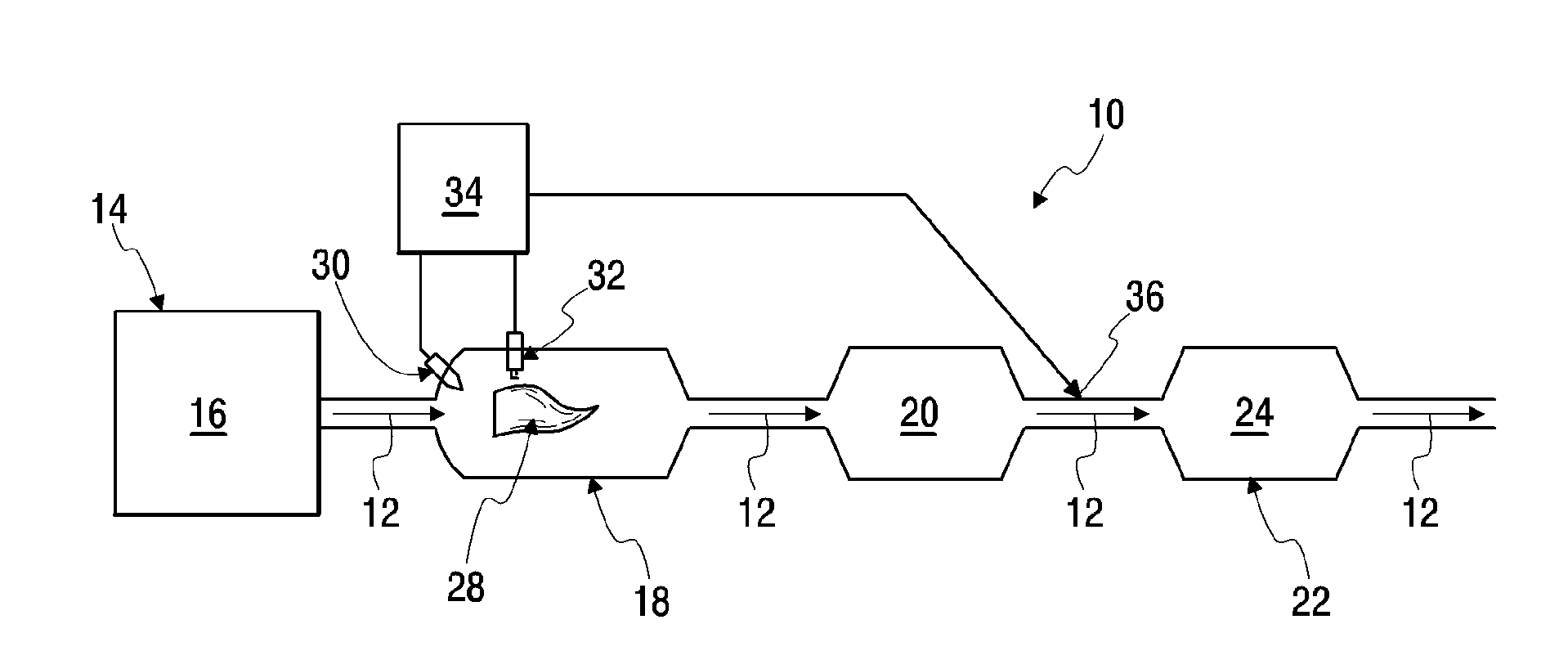

[0027] A diesel exhaust aftertreatment system 10 is provided to treat exhaust gas 12 from a diesel combustion process 14 , such as a diesel compression engine 16 . Exhaust gas 12 typically contains oxides of nitrogen (NO x ), such as nitrogen oxides (NO) and nitrogen dioxide (NO 2 ), particulate matter (PM), hydrocarbons, carbon monoxide (CO) and other combustion by-products.

[0028] The system 10 includes a combustor 18 that selectively supplies elevated temperature exhaust gas 12 to the remainder of the system 10; a diesel particulate filter (DPF) 20 connected downstream of the combustor 18 to receive exhaust gas therefrom. Gas 12; NOx reduction device 22, such as selective catalytic reduction catalyst (SCR) 24, such as figure 1 shown, or lean NO x trap 26, such as figure 2 As shown, it is connected downstream of DPF 20 to receive exhaust gas 12 therefrom. To overcome the low operating temperatures within the exhaust 12 of a lean-burn engine (e.g., a diesel compressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com