Carbon fiber sheet through-wall reinforcement treatment method for cast-in-place floor beam top cracks

A cast-in-situ floor slab and processing method technology, applied in building maintenance, industrial buildings, construction and other directions, can solve the problems of uneven floor, increased floor weight, long operation time, etc., to achieve low maintenance costs, improve integrity, prevent The effect of continuing to expand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

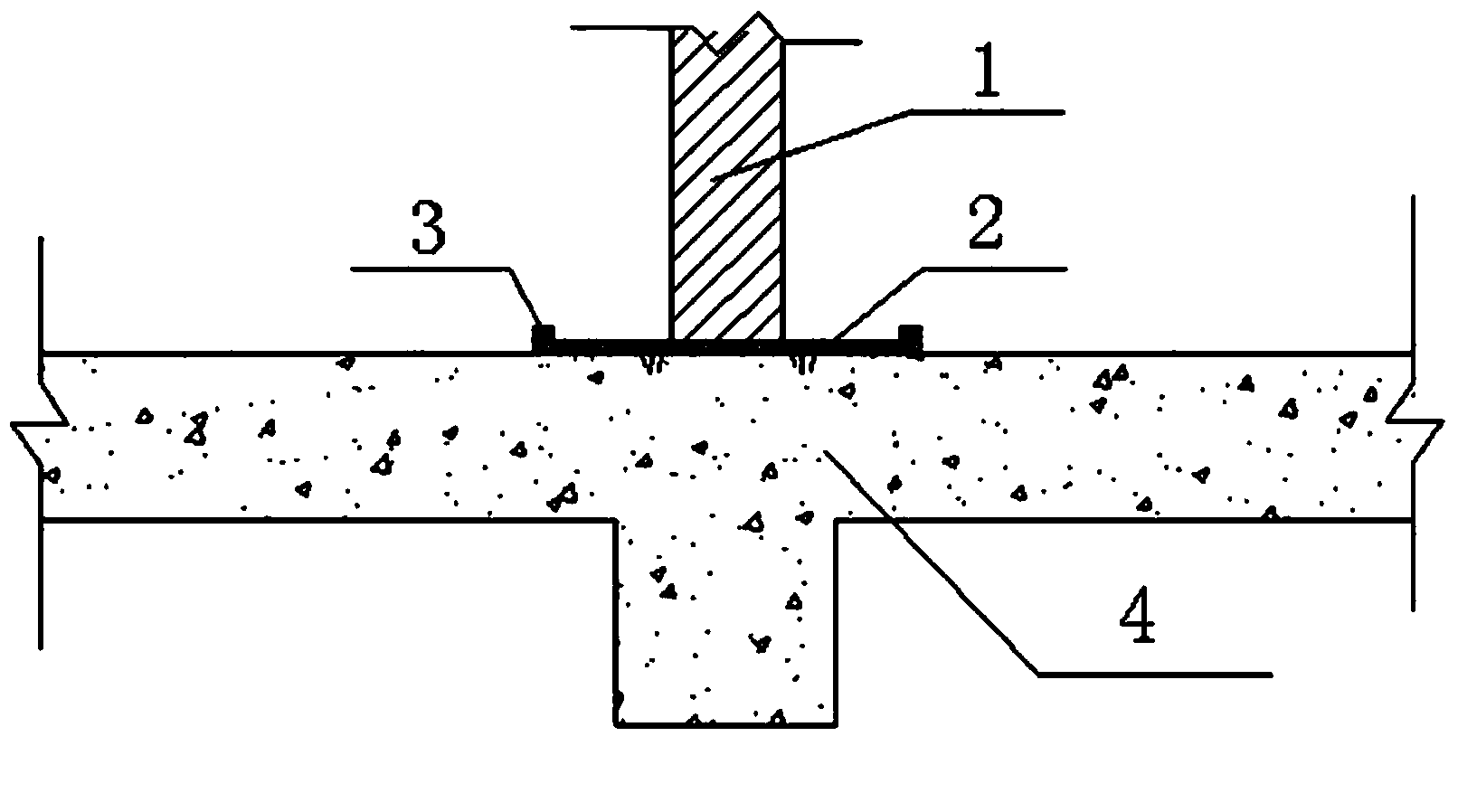

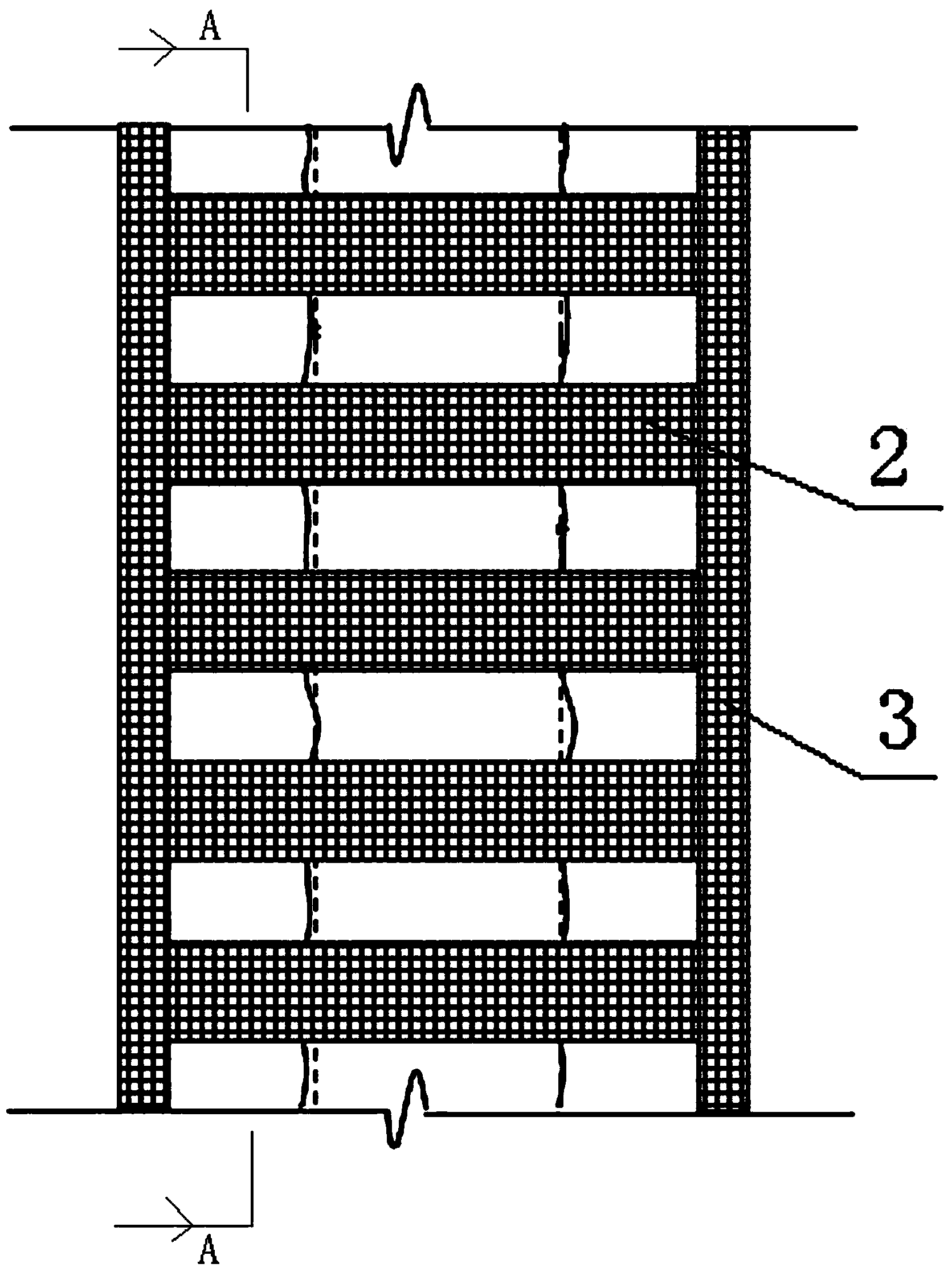

[0024] Such as Figure 1-Figure 3 As shown, a carbon fiber cloth through-wall reinforcement treatment method for cracks on the top of cast-in-place floor slabs includes the following steps:

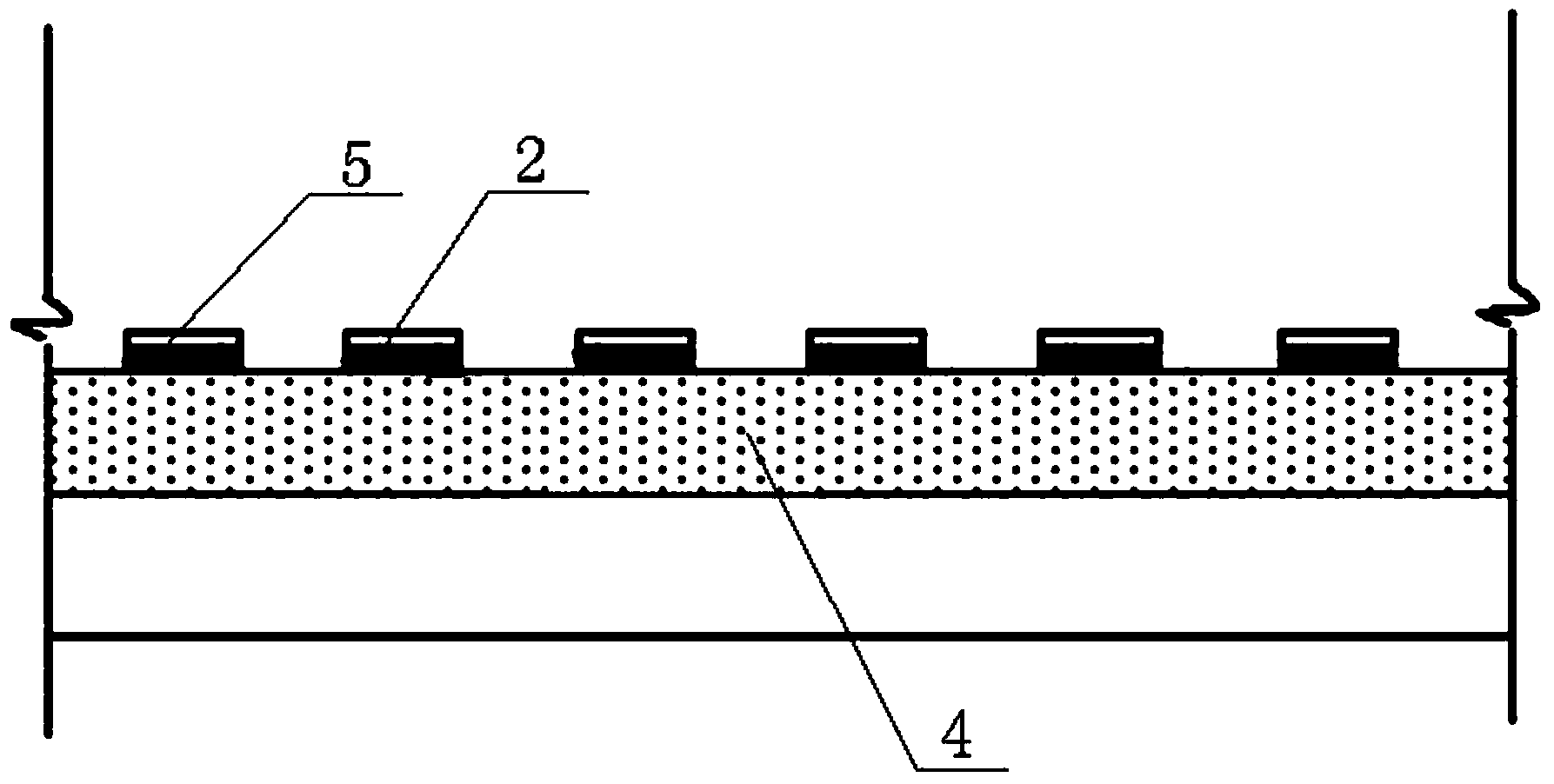

[0025] (1), dig a hole 5 at the bottom of the brick wall 1 on the top of the slab, the height of the hole 5 is 53mm, and the width is 200mm. According to the stress situation of the cast-in-place floor 4, the spacing of the holes is selected, and a hole is generally drawn every 300mm;

[0026] (2) Use epoxy resin grout to pressure grout the cracks. After grouting, use epoxy resin cement to smooth and seal the grouting mouth, and perform surface treatment after sealing;

[0027] (3) Use a grinding wheel to grind and clean the surface of the floor where the carbon fiber cloth is pasted;

[0028] (4) Brush epoxy resin adhesive on the position where the carbon fiber cloth is pasted;

[0029] (5), paste carbon fiber cloth 2 on the epoxy resin adhesive, the width of carbon fiber cloth is 200m...

Embodiment 2

[0033] Such as Figure 1-Figure 3 As shown, a carbon fiber cloth through-wall reinforcement treatment method for cracks on the top of cast-in-place floor slabs includes the following steps:

[0034] (1) Hole 5 is cut at the bottom of brick wall 1 on the top of the slab. The height of hole 5 is 53mm and the width is 200mm. According to the force of cast-in-place floor 4, the distance between holes is selected, and a hole is usually cut every 300mm;

[0035] (2) Use epoxy resin grout to pressure grout the cracks. After grouting, use epoxy resin cement to smooth and seal the grouting mouth, and perform surface treatment after sealing;

[0036] (3) Use a grinding wheel to grind and clean the surface of the floor where the carbon fiber cloth is pasted;

[0037] (4) Brush epoxy resin adhesive on the position where the carbon fiber cloth is pasted;

[0038] (5) Paste the carbon fiber cloth 2 on the epoxy resin adhesive, the width of the carbon fiber cloth is 200mm, and the thicknes...

Embodiment 3

[0042] Such as Figure 1-Figure 3 As shown, a carbon fiber cloth through-wall reinforcement treatment method for cracks on the top of cast-in-place floor slabs includes the following steps:

[0043] (1) Hole 5 is cut at the bottom of brick wall 1 on the top of the slab. The height of hole 5 is 53mm and the width is 200mm. According to the force of cast-in-place floor 4, the distance between holes is selected, and a hole is usually cut every 300mm;

[0044] (2) Use epoxy resin grout to pressure grout the cracks. After grouting, use epoxy resin cement to smooth and seal the grouting mouth, and perform surface treatment after sealing;

[0045] (3) Use a grinding wheel to grind and clean the surface of the floor where the carbon fiber cloth is pasted;

[0046] (4) Brush epoxy resin adhesive on the position where the carbon fiber cloth is pasted;

[0047] (5) Paste the carbon fiber cloth 2 on the epoxy resin adhesive, the width of the carbon fiber cloth is 200mm, and the thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com