Reticular native bamboo framework and light aggregate concrete composite floor

A technology of lightweight aggregate concrete and composite floor slabs, which can be applied to floors, building components, buildings, etc., can solve problems such as self-weight, and achieve the effects of large bearing capacity, energy saving and emission reduction, and good seismic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

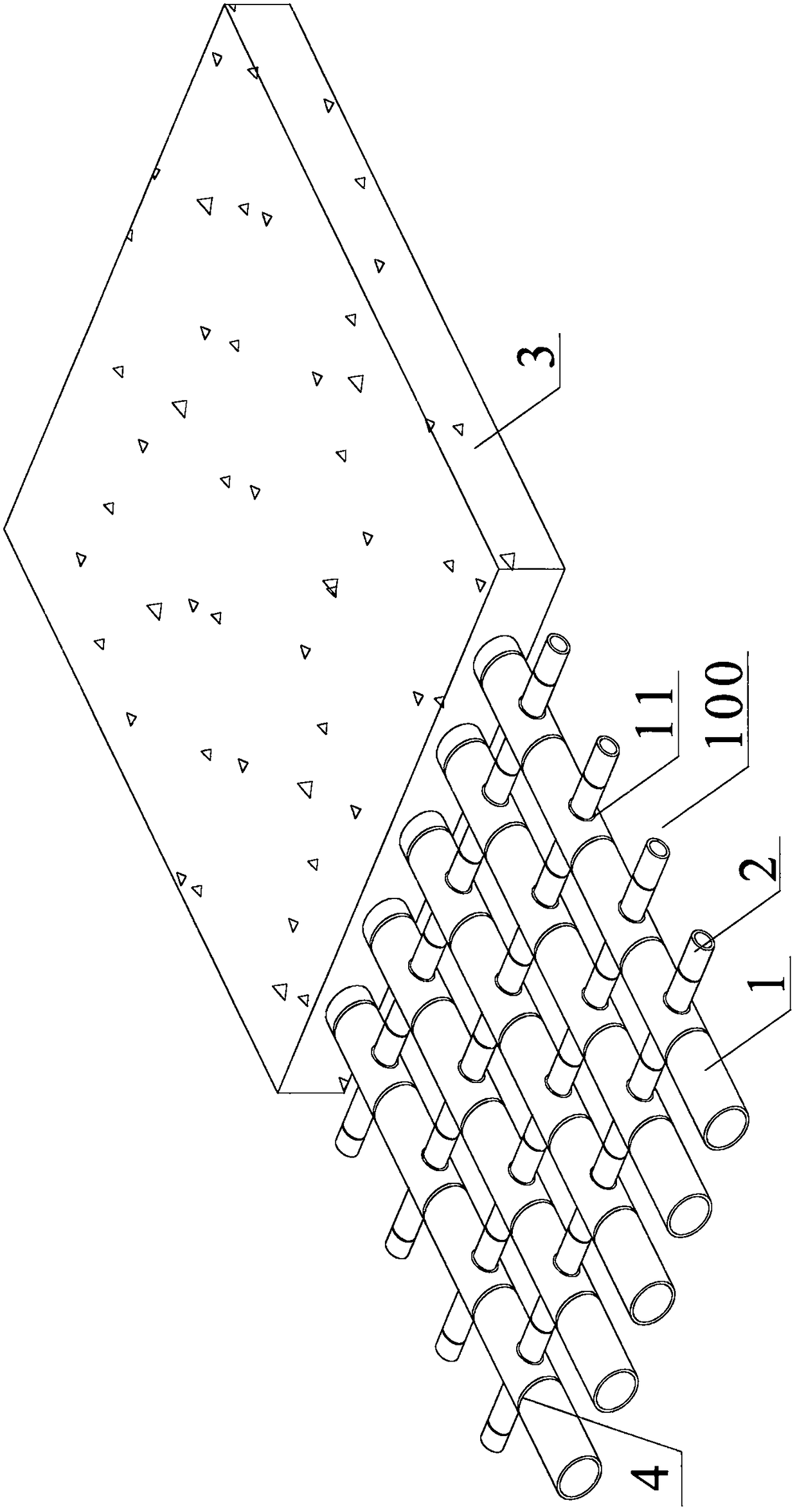

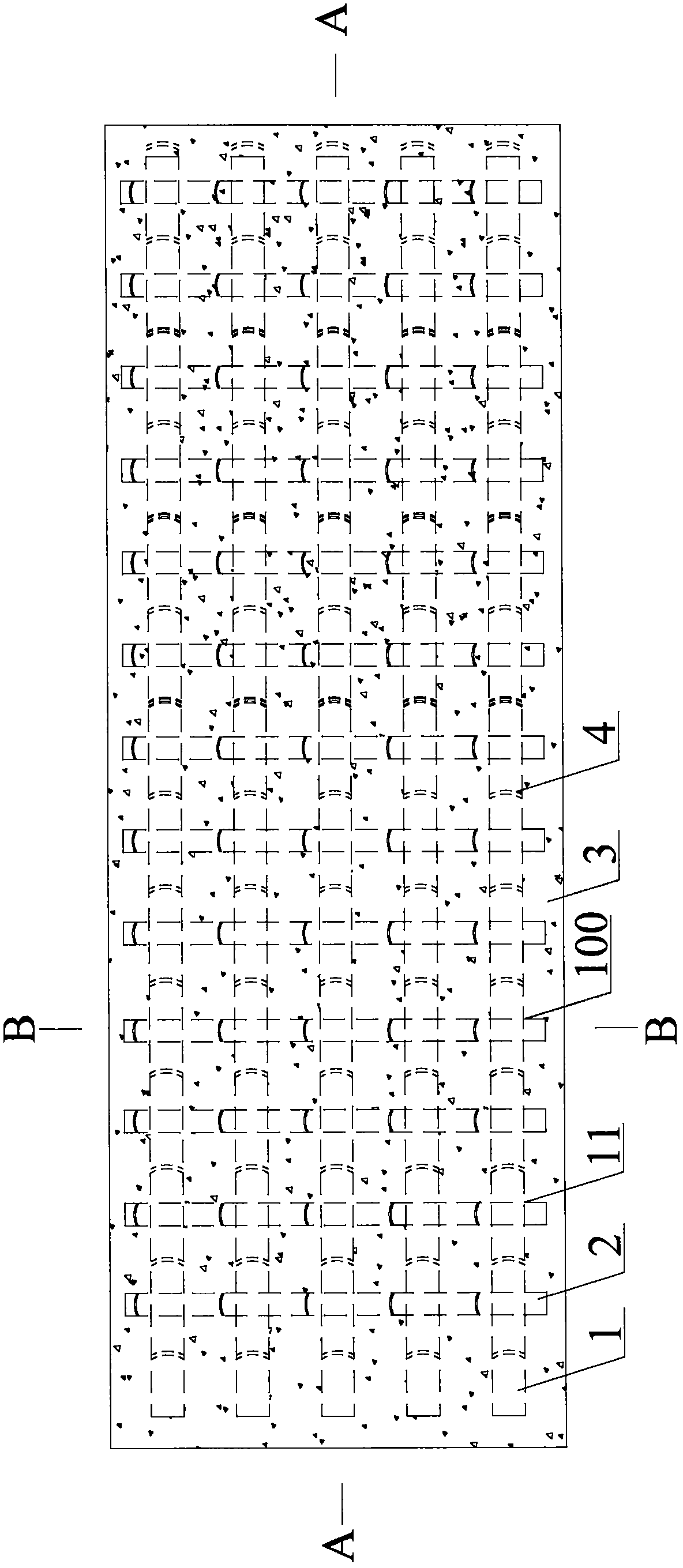

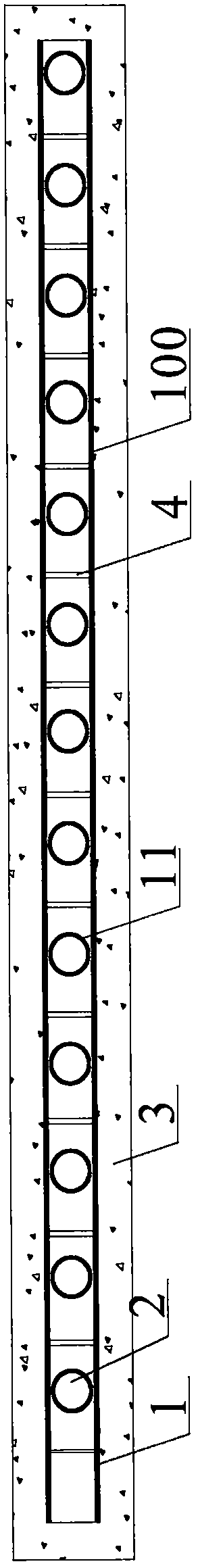

[0024] Such as Figure 1 to Figure 4 As shown, the present invention provides a kind of reticular raw bamboo skeleton-lightweight aggregate concrete composite floor, comprising vertical raw bamboo 1, horizontal raw bamboo 2, lightweight aggregate concrete 3 and is characterized in that, more than two contain natural The equal-length vertical primary bamboos 1 of the bamboo joints 4 are arranged in parallel at intervals, and the longitudinal primary bamboos 1 are evenly opened with two or more through holes 11 along the longitudinal axis, and more than two horizontal primary bamboos 2 closely pass through the through holes 11 and intersect with the vertical primary bamboos 1. Arranged in parallel, the outer wall of the horizontal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com