Foamed lightweight concrete backfilling bridge pier structure

A foam lightweight, concrete technology, applied in filling and other directions, can solve the problems of high vertical load pressure, vertical deformation of bridge piers, vertical differential settlement, etc., to reduce self-weight, reduce corrosion, low elasticity and good shock absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

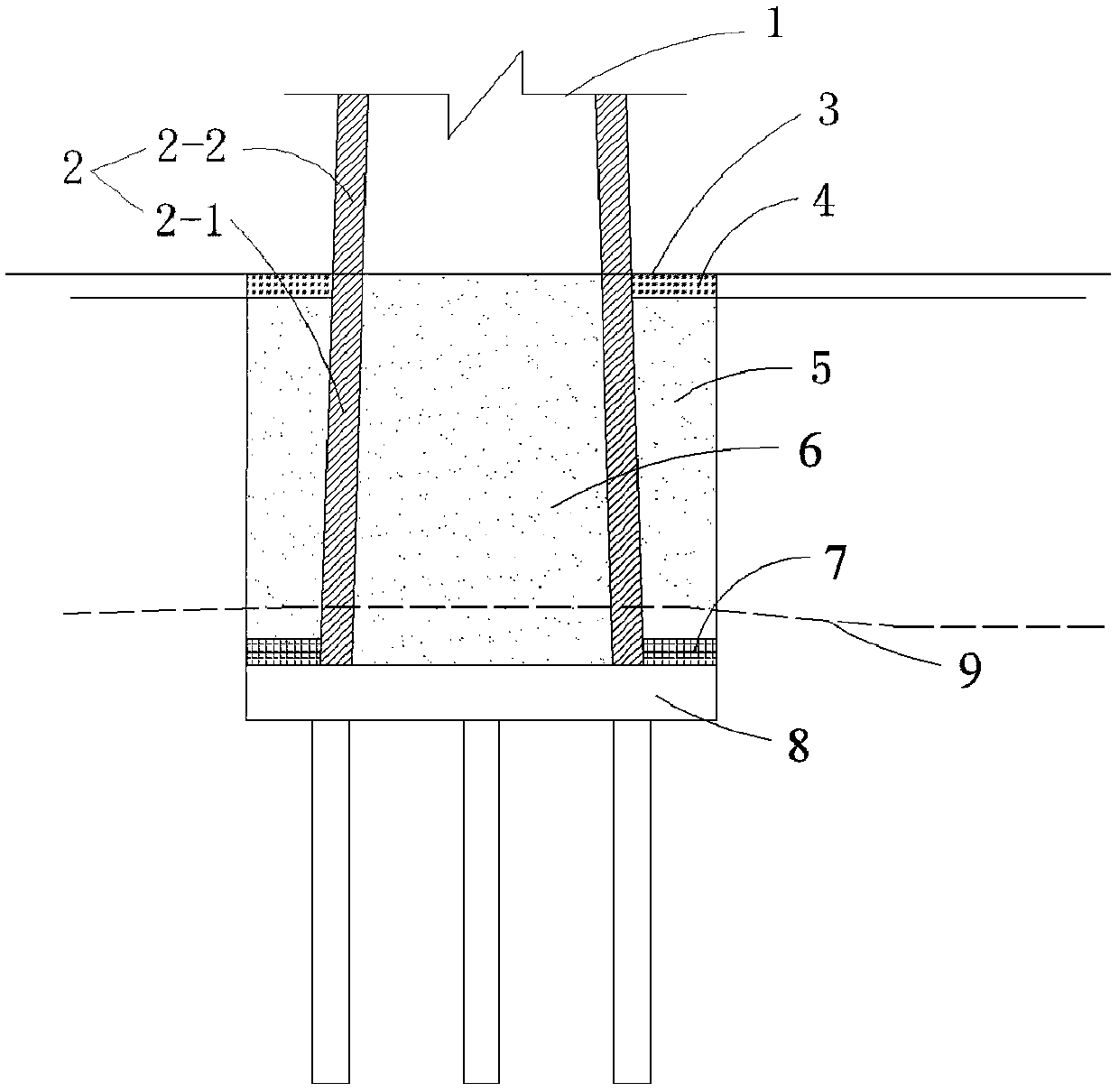

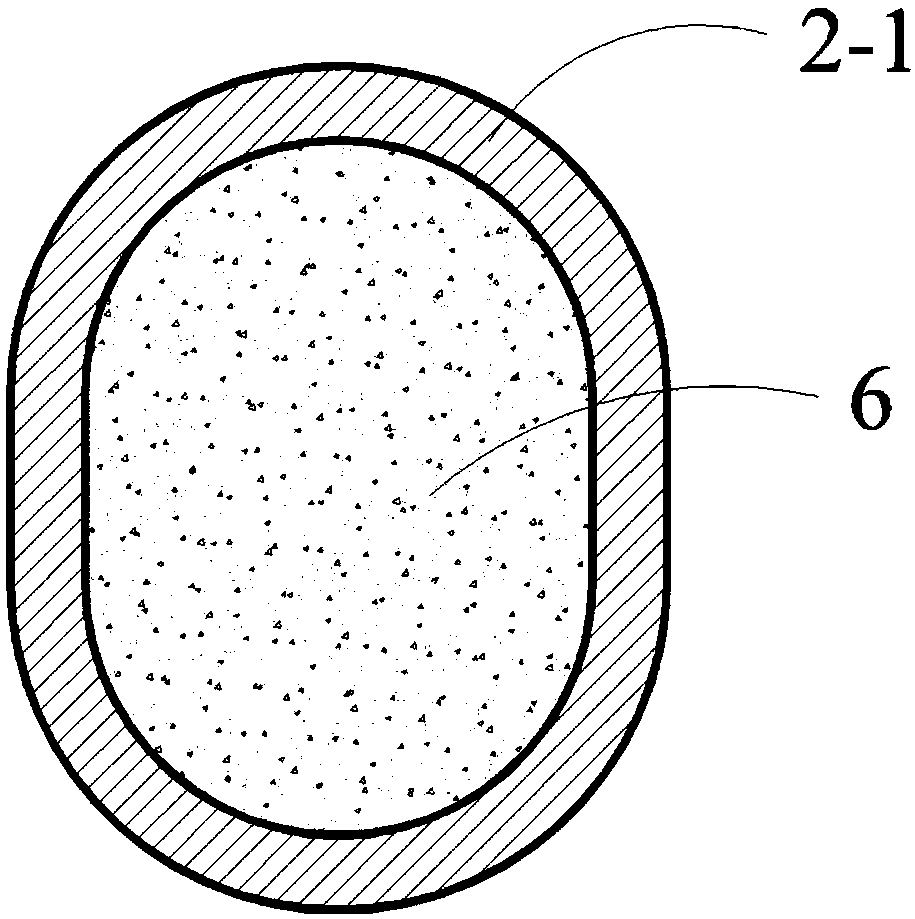

[0027] see figure 1 As shown, a foam lightweight concrete backfill pier structure includes the original pier cap 8 arranged underground and the pier assembly 2 arranged on the top of the original pier cap 8; the pier assembly 2 includes the above-ground pier 2-2 and the underground pier 2 -1, the above-ground pier 2-2 is integrally formed with the underground pier 2-1; the pier assembly 2 is a columnar hollow structure with a diameter at the bottom greater than that at the top, the underground pier 2-1 is filled with foam lightweight concrete layer B6, and the underground pier 2- 1. There is a circle of auxiliary load-bearing mechanism on the outside. The auxiliary load-bearing mechanism includes a superstructure 4, a foam lightweight concrete layer A5 and a gravel layer 7 arranged in sequence from top to bottom. The gravel layer 7 is laid on the top of the bearing platform 8, underground Both the inner wall and the outer wall of pier 2-1 are provided with a waterproof layer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com