Prefabricated reinforced concrete shear wall and construction method

A reinforced concrete and shear wall technology, applied in walls, building components, buildings, etc., can solve problems such as poor connection of vertical steel bars, difficulty in ensuring the quality of joint parts, and unfavorable seismic resistance of structures, so as to solve the problems of stress and construction problems, good connection effect, good mechanical properties and seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

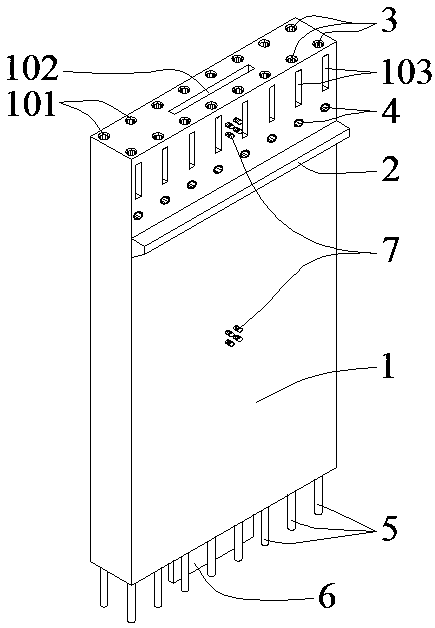

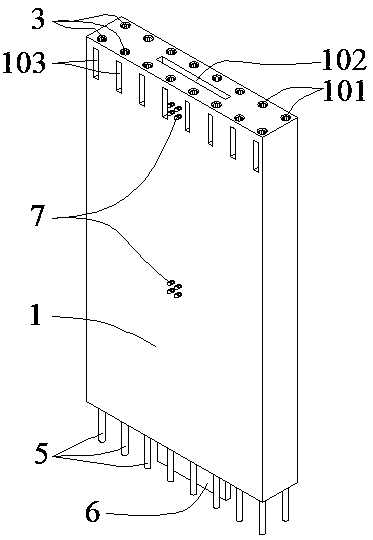

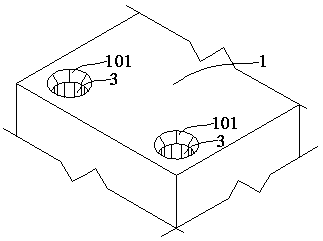

[0019] like Figure 1-Figure 3 As shown, a prefabricated reinforced concrete shear wall consists of wall panels (1), corbels (2), sleeves (3), sleeves (4), insert bars (5), steel plates (6) and anchor bolts (7) composition; the corbel (2) is located on the side of the wallboard (1), and the top surface of the corbel (2) is not less than 600 mm from the top surface of the wallboard (1); the sleeve (3) is embedded in the wallboard ( 1), the top surface of the sleeve (3) is 10mm away from the top surface of the wallboard (1), the upper part of the sleeve (3) is the horn hole (101) of the wallboard (1), and the sleeve (3) has two rows ;The casing (4) is pre-buried on the side of the wallboard (1), the casing (4) and the corbel (2) are on the same side of the wallboard (1), and the position of the casing (4) is higher than the corbel The position of (2), the distance from the top surface of the corbel (2) to the center of the casing (4) is determined according to the thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com