Disassembled and assembled type fire hose protecting bridge

A fire hose, combined technology, applied in fire rescue and other directions, can solve the problems of weak expandable functions, insufficient splicing firmness, low product reliability, etc., to reduce the number of mold openings, high firmness, and investment. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

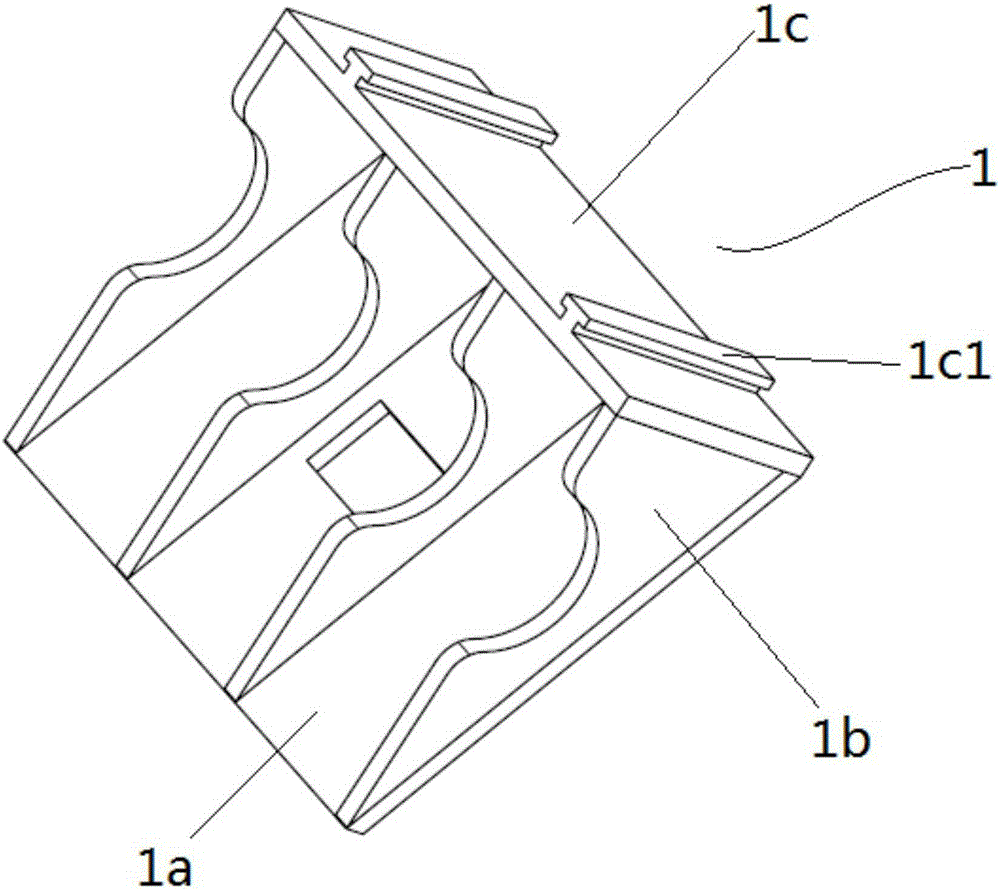

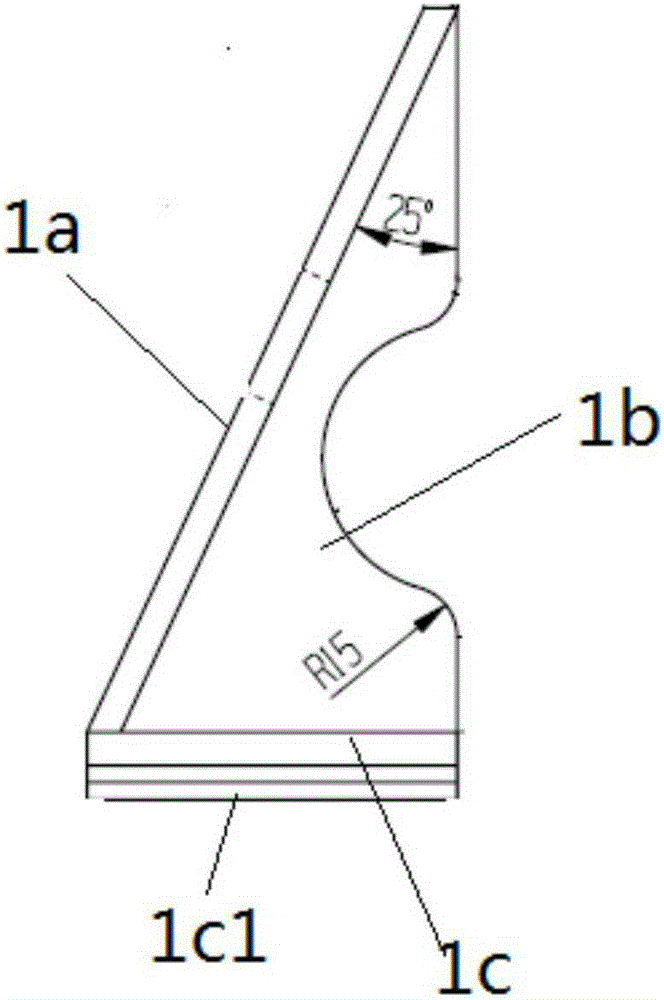

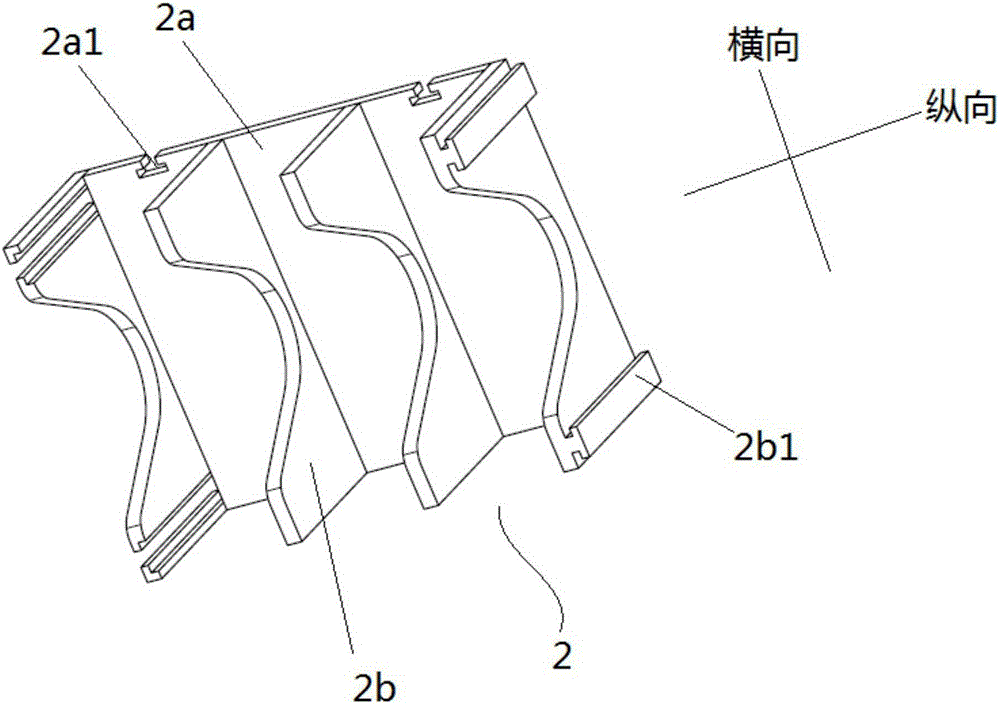

[0025] see Figure 1-Figure 7 , a split and combined fire hose protection bridge, characterized in that: the direction of the hose is set to be longitudinal, and the direction perpendicular to it is horizontal; the fire protection hose protection bridge includes a side bridge protection unit 1, a middle bridge protection unit Unit 2; the side bridge protection unit 1 includes a side pressure plate 1a, at least two side ribs 1b, and a side assembly plate 1c, and the side ribs 1b are arranged on the side bearing along the transverse direction The lower part of the pressure plate 1a is vertically connected with it, and the side mounting plate 1c is arranged longitudinally and connected with the side pressure plate 1a and the side rib plate 1b at the same time, the side pressure plate 1a, the side rib plate 1b, The side mounting plate 1c forms a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com