Patents

Literature

93results about How to "Reduce heat treatment process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High resistivity silicon wafer and method for manufacturing the same

ActiveUS20100224968A1Avoid it happening againHigh mechanical strengthPolycrystalline material growthSemiconductor/solid-state device manufacturingDopantCzochralski method

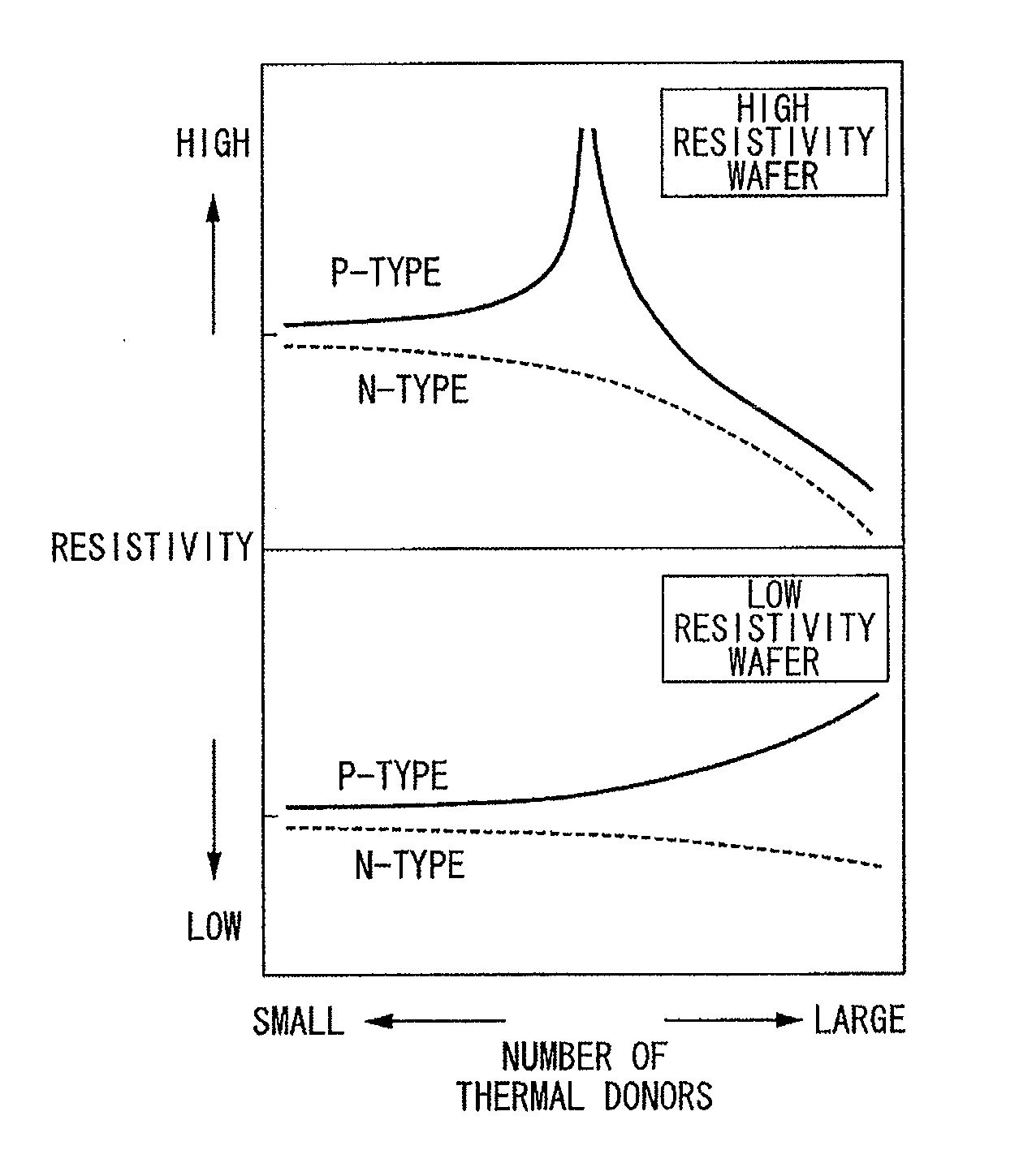

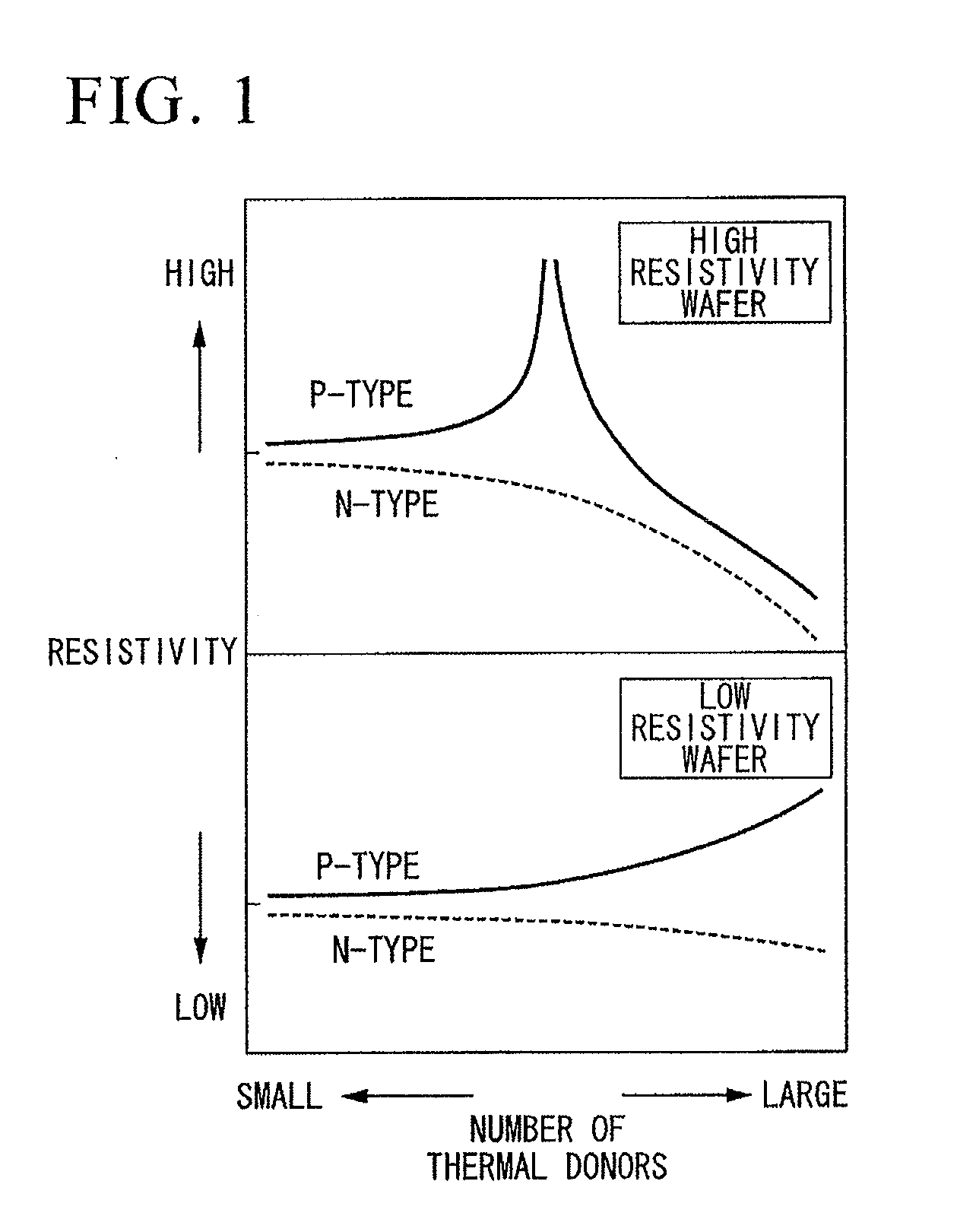

This method for manufacturing a high resistivity silicon wafer includes pulling a single crystal such that the single crystal has a p-type dopant concentration at which a wafer surface resistivity becomes in a range of 0.1 to 10 kΩcm, an oxygen concentration Oi of 5.0×1017 to 20×1017 atoms / cm3 (ASTM F-121, 1979), and either one of a nitrogen concentration of 1.0×1013 to 10×1013 atoms / cm3 (ASTM F-121, 1979) and a carbon concentration of 0.5×1016 to 10×1016 atoms / cm3 or 0.5×1016 to 50×1016 atoms / cm3 (ASTM F-123, 1981) by using a Czochralski method, processing the single crystal into wafers by slicing the single crystal, and subjecting the wafer to an oxygen out-diffusion heat treatment process in a non-oxidizing atmosphere. A peak position of a resistivity serving as a boundary between a p-type region of a wafer surface side and a p / n conversion region of an inner side of a thickness direction is adjusted by the nitrogen concentration or the carbon concentration such that the peak position is set to a boundary depth in a range of 10 to 70 μm from the wafer surface.

Owner:SUMCO CORP

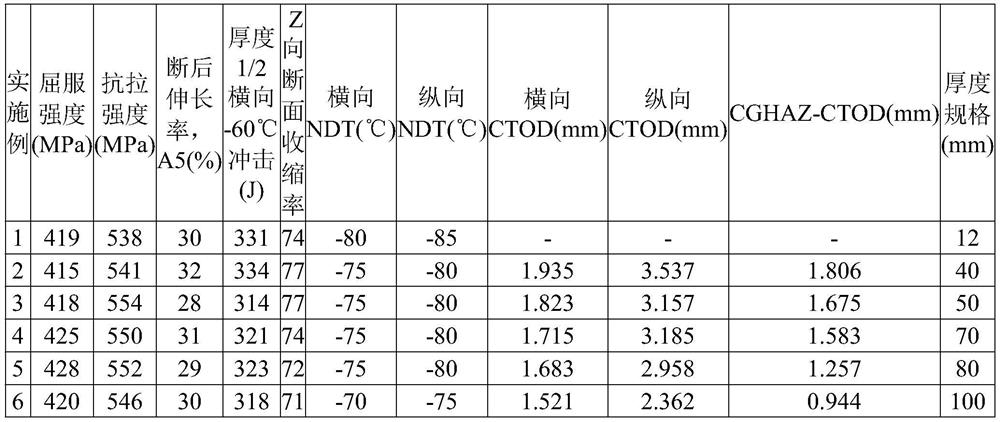

Method for manufacturing low-carbon 9Ni steel thick plate

InactiveCN101215668ASimple production processImprove low temperature toughnessFurnace typesHeat treatment furnacesSteelmakingManganese

The invention relates to a method for preparing a low carbon 9 nickel steel thick plate, the steps are that: steelmaking, the components which are weighted by weight percentages are that carbon is 0.02-0.04 percent, silicon is 0.2-0.3 percent, manganese is 0.4-0.7 percent, sulfur is equal or less than 0.005 percent, phosphorus is equal or less than 0.01 percent, nickel is 8.9-9.5 percent, the allowance is ferrum and impurities, and the components are made into steel. Red charge: molten steel is cast and is stood for 5 minutes and is red charged into a heating furnace. Hot rolling: module ingots are rolled in two stages. On-line heat treatment: when finish rolling temperature is in a dual-phase region, quenching after rolling and tempering heat treatment are used, when the finish rolling temperature is in an austenite region, the quenching after rolling, quenching after solid solution and the tempering heat treatment are used or the quenching after rolling, the quenching after solid solution, dual-phase region quenching and the tempering heat treatment or the quenching after keeping temperature in the dual-phase region for 10-20 minutes are used, and then water-cooling is done after tempering whose temperature is kept for 1 hour in 580 DEG C. The invention has the advantages of short technological process, low producing cost, and high low-temperature flexibility and other mechanical properties of 9 nickel steel.

Owner:NORTHEASTERN UNIV

Method for preparing copper-coated aluminium composite material

InactiveCN102103906AReduce heat treatment processWell combinedSingle bars/rods/wires/strips conductorsMetal/alloy conductorsAluminum compositesSoldering

The invention relates to a method for preparing a copper-coated aluminium composite material. The method comprises the following steps: spinning the head of a copper tube which is utilized as a raw material to form a cone, turning the head of the aluminium bar which is utilized as a raw material to form a cone, mechanically polishing the aluminium bar and then sleeving the aluminium bar with the copper tube to form an extrusion billet; coating a colloidal graphite lubricating film on the exterior of the extrusion billet and carrying out copper and aluminium soldering and sealing on the tail of the extrusion billet; ensuring the container temperature of a hot hydrostatic extruder to be 350-450 DEG C, the temperature of an extruding die to be 150-350 DEG C, the temperature of the copper tube forming the extrusion billet to be 350-450 DEG C and the temperature of the aluminium bar to be 150-250 DEG C; and feeding the extrusion billet into the container, filling extrusion media and then carrying out hydrostatic extrusion, thus obtaining the copper-coated aluminium composite material, wherein the internal diameter of the copper tube is the same as the external diameter of the aluminium bar; and the extrusion ratio is 4-100. The method has the following beneficial effects: the copper-coated aluminium composite material prepared by the method has high copper / aluminium interface bond strength and good bending and forming performance; the frequency of annealing needed in the preparation process is low and the annealing temperature is low; and the production procedure is simplified and the production cost is lowered.

Owner:厦门火炬特种金属材料有限公司

Composite vegetable juice

The present invention relates to one kind of health beverage prepared with several kinds of vegetable and fruit. The composite vegetable and fruit juice of the present invention is produced through processing vegetables and fruits into concentrated juices; mixing juices of carrot, celery, Chinese cabbage, cabbage, rape, apple, orange, red tangerine, etc in certain weight proportion; blending, filtering, preheating, deairing, homogenizing and high pressure instantaneous sterilizing. The beverage of the present invention has rich nutrients, good flavor and scent of vegetable and fruit and good taste.

Owner:CHONGQING SHANGSHUFANG BEVERAGE & FOOD

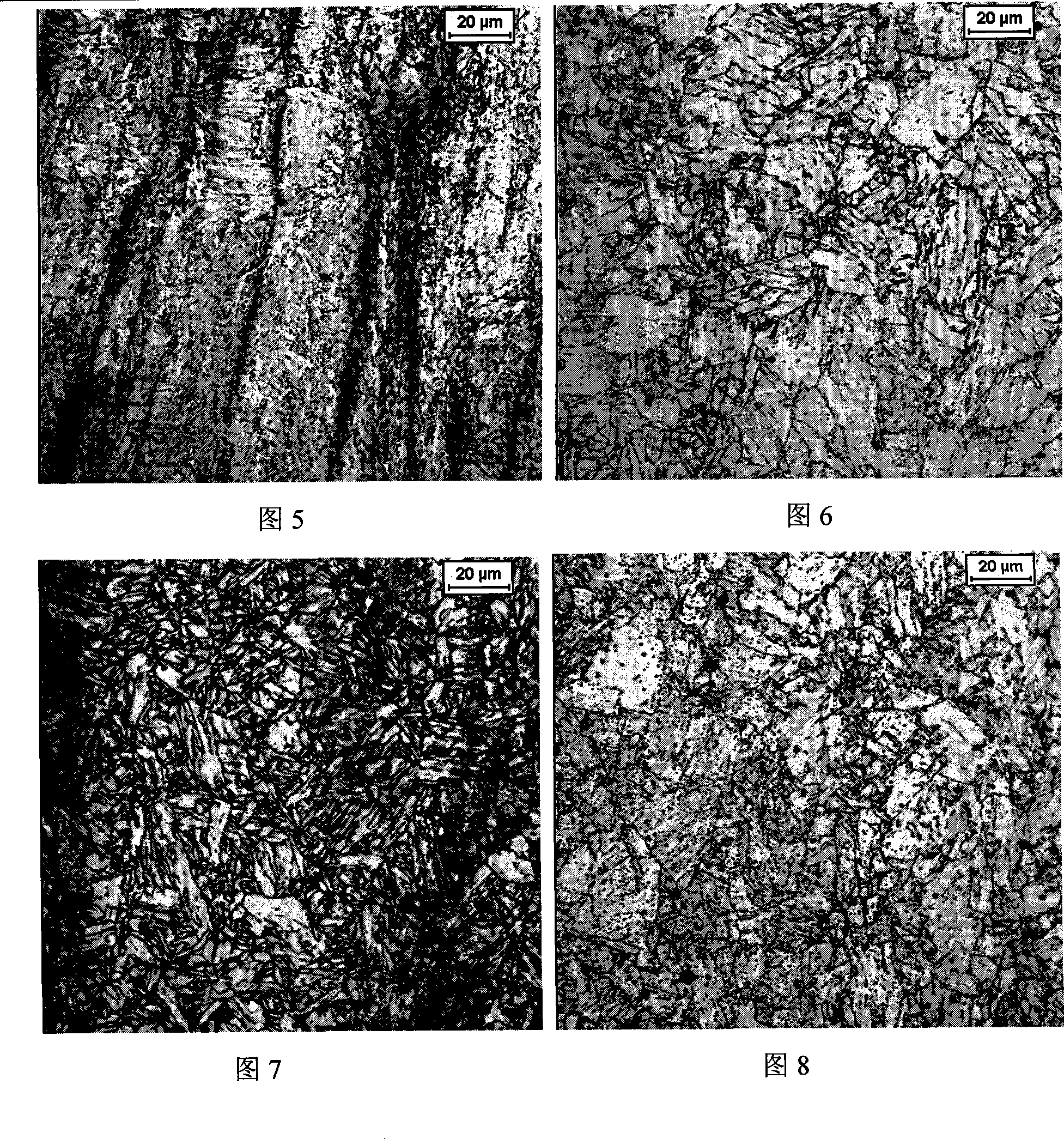

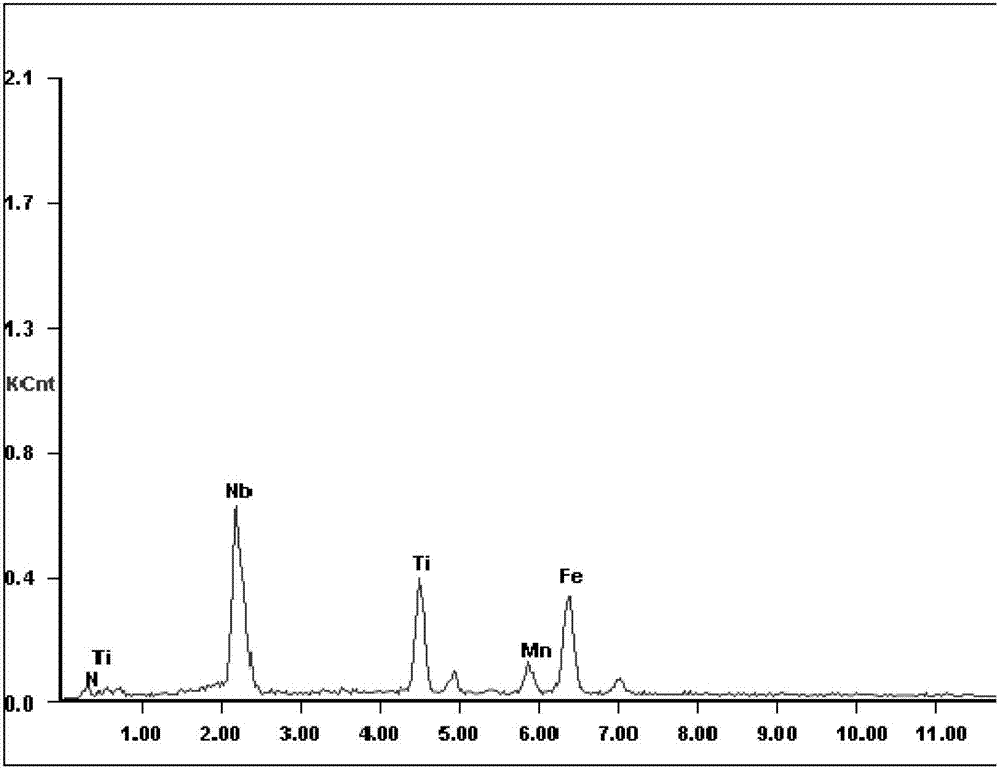

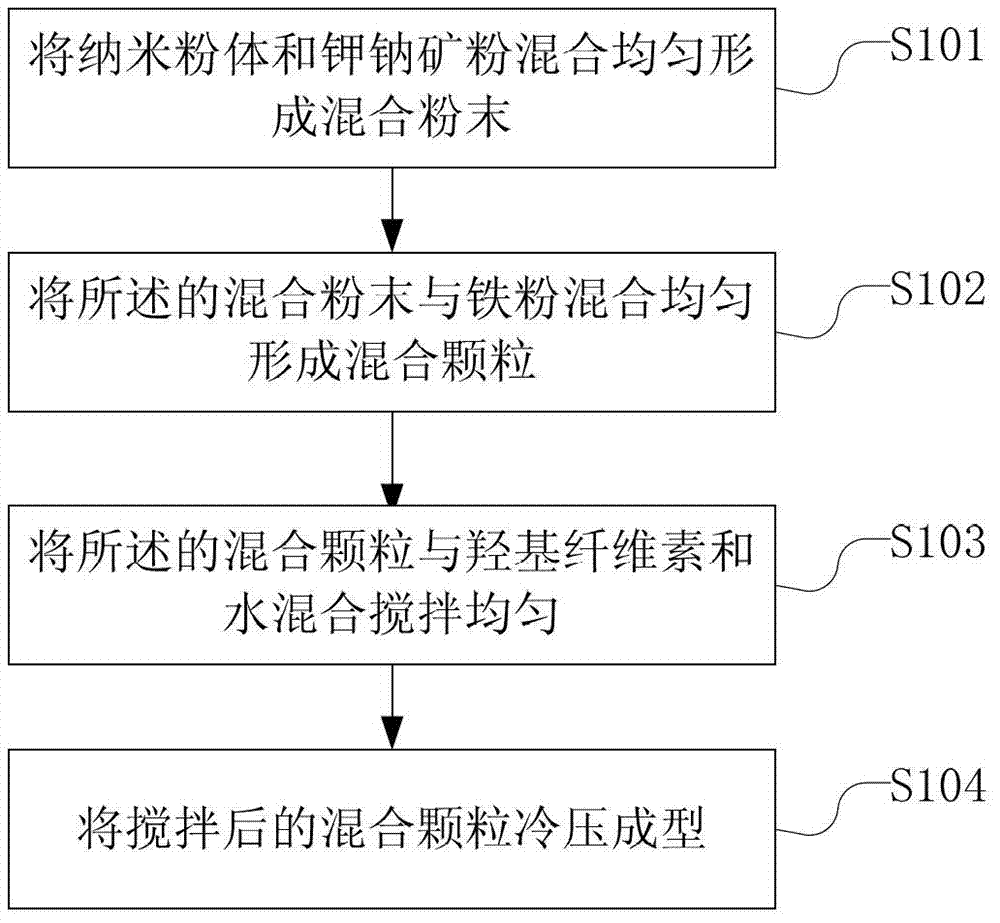

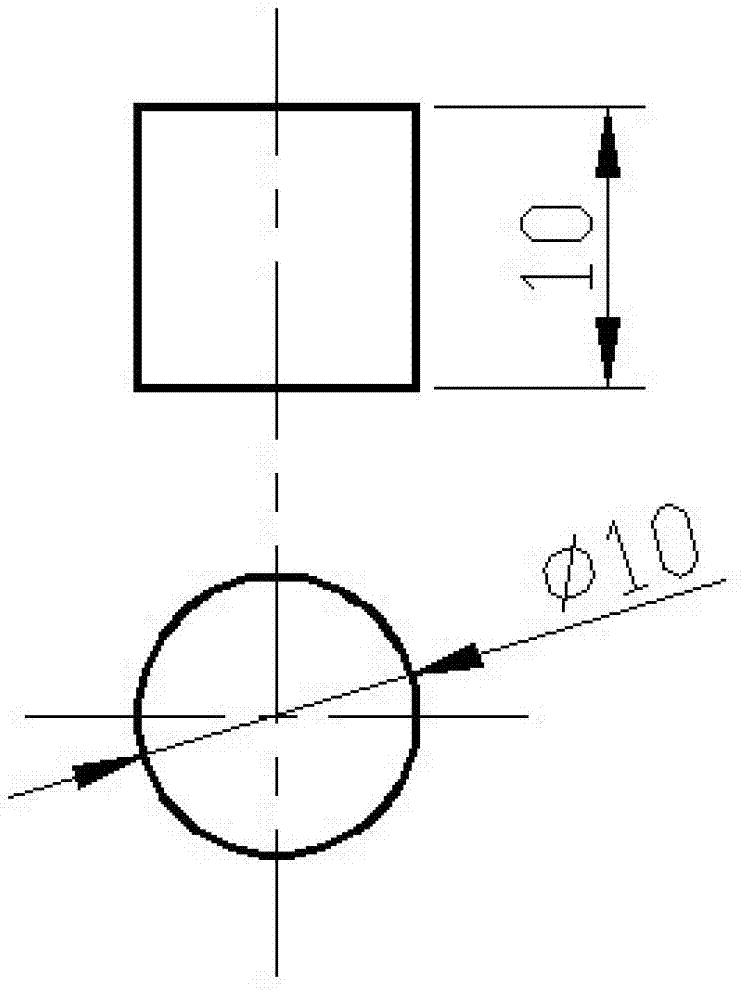

Nano-material interalloy modifier and preparation method thereof, and alloy preparation method

InactiveCN102732740AResistant to oxidation and polymerizationNot easy to decomposeMagnesiumIron powder

The present invention relates to a nano-material interalloy modifier and a preparation method thereof, and an alloy preparation method. The nano-material interalloy modifier comprises the following components, by mass, 5-15% of nano-powder, 1-3% of magnesium powder, 30-40% of sodium potassium ore powder, 40-50% of iron powder, 3-8% of hydroxypropyl cellulose, and 2-4% of water. The nano-material interalloy modifier is not easily oxidized and polymerized during processes of mixing and preparation, has a sufficient strength, is not easily decomposed during using and transportation, and can be rapidly molten when the nano-material interalloy modifier is added to a liquid steel, hot iron, or a nonferrous alloy liquid.

Owner:BEIJING JATR NEW MATERIAL TECH

Preparation method for high-toughness 3.5Ni steel plate

The invention provides a preparation method for a high-toughness 3.5Ni steel plate in order to reduce the production cost and belongs to the field of alloy steel manufacture. The preparation method comprises the steps that (1) hot rolling is conducted, a casting blank is put into a heating furnace with the temperature of 1150 DEG C-1200 DEG C for heat preservation for 1-2 h, the casting blank comprises, by weight, 0.04%-0.07% of C, 0.10%-0.25% of Si, 0.60%-0.90% of Mn, 0-0.005% of S, 0-0.008% of P, 0 or 3.3%-3.8% of Ni, 0-0.60% of Cr, 0-0.04% of Mo, 0.02%-0.05% of Alt and the balance Fe and impurities; two-stage rolling is adopted for hot rolling, and the total compression ratio of the steel plate is the thickness of the casting blank / the thickness of a finished product>=5.00; and (2) direct hot rolling is conducted, the rolled steel plate is quenched directly or after the relaxation for 10-20 s to below 300 DEG C through ultra fast cooling at the speed of larger than or equal to 20 DEG C / s, then the plate is put into a heating furnace with the temperature of 570 DEG C-620 DEG C for heat preservation, after that, the product is obtained after the steel plate is cooled through water or air to the room temperature. According to the preparation method, direct quenching and tempering processes are adopted, so that the process flow of hot treatment is shortened, and the cost is lowered; in addition, the austenite grain size is refined by controlling the rolling process, and the low-temperature toughness and other mechanical properties of 3.5Ni steel are significantly improved.

Owner:NORTHEASTERN UNIV

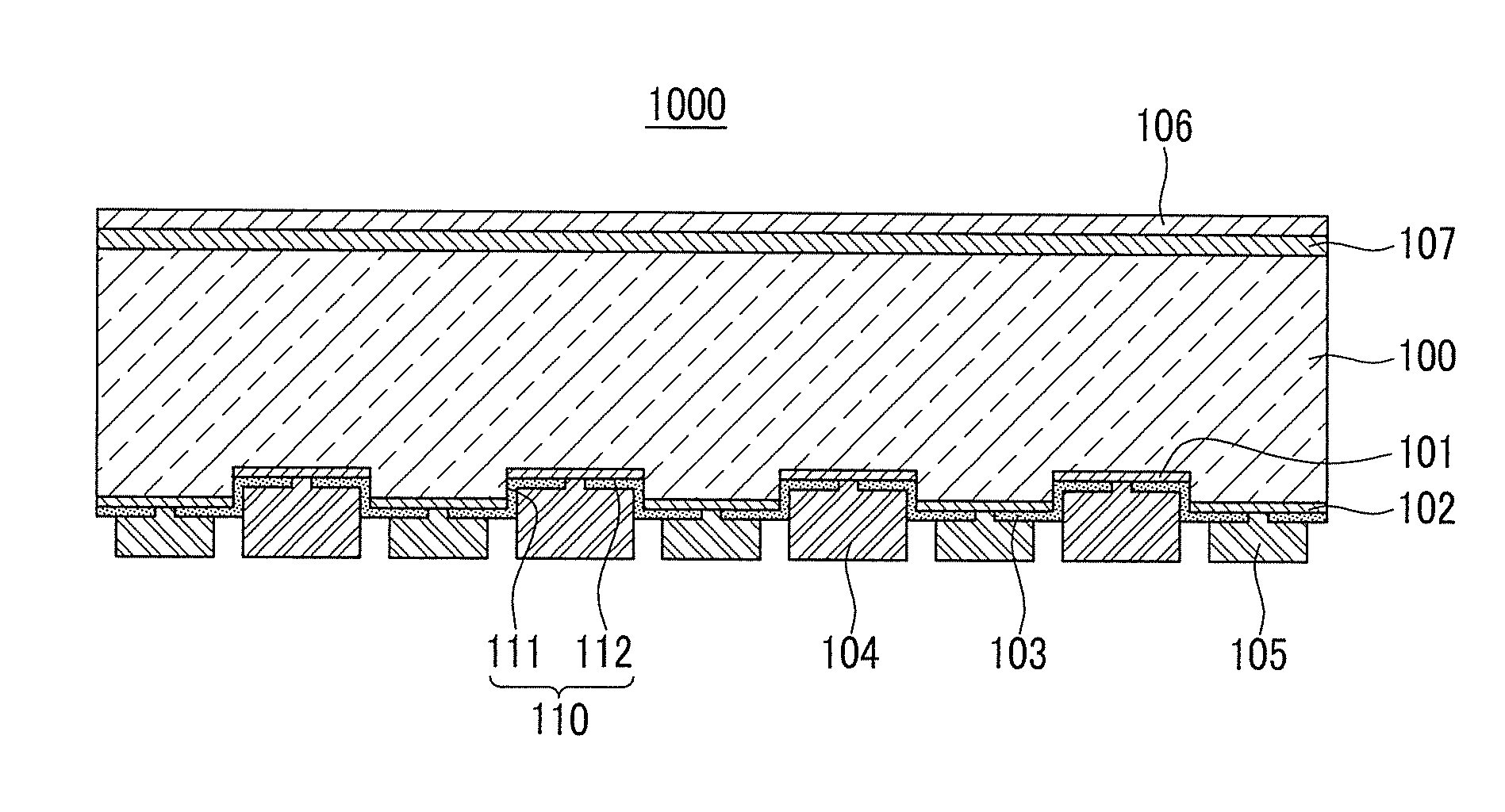

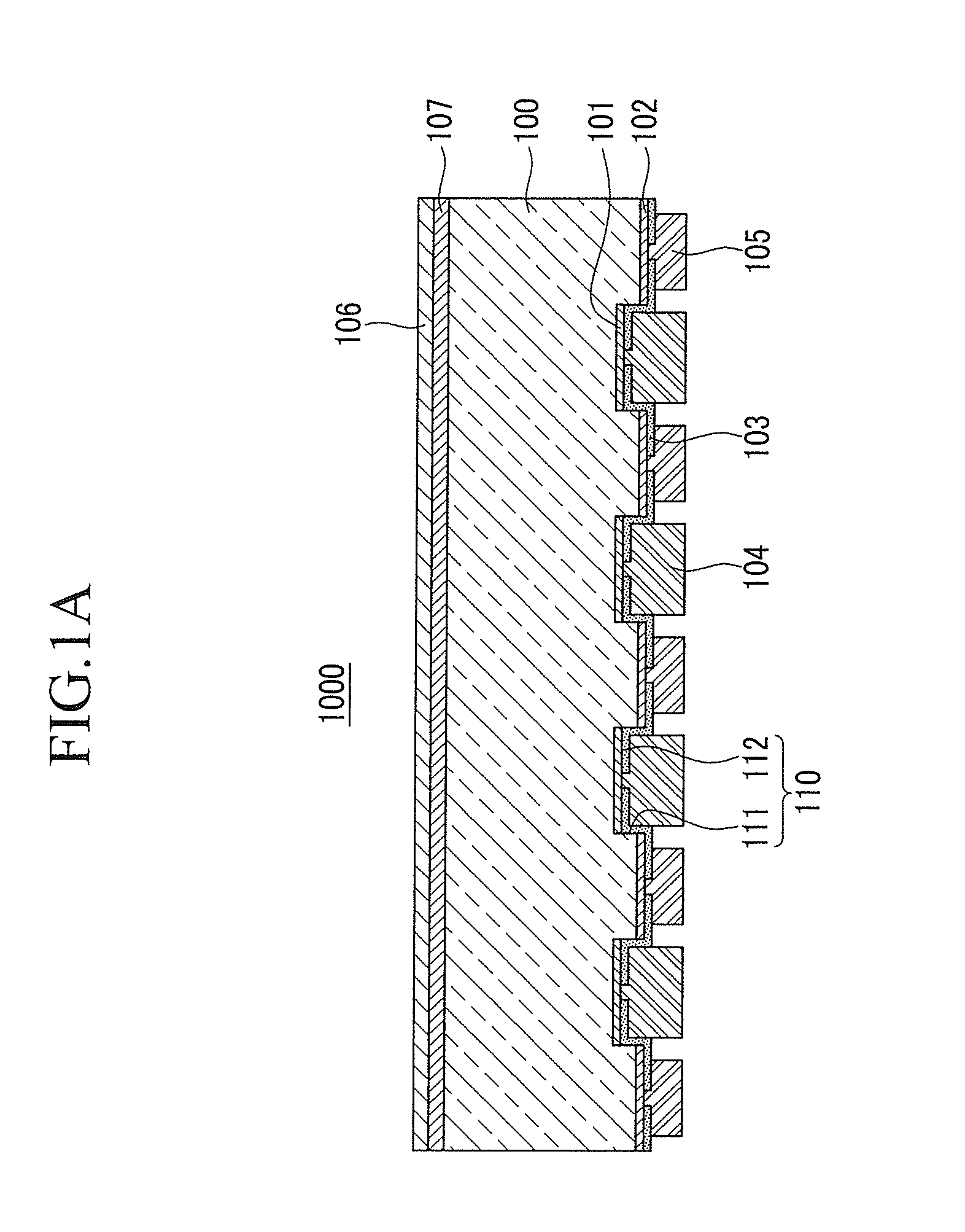

Solar cell and manufacturing method thereof

InactiveUS20130112252A1Simple processReduce processing costsFinal product manufactureSemiconductor/solid-state device manufacturingElectrical conductorSolar cell

A solar cell including a first conductive type semiconductor substrate; a first conductive type first semiconductor layer on a back surface of the semiconductor substrate; a second conductive type second semiconductor layer on the back surface of the semiconductor substrate at a height different from the first semiconductor layer, the second semiconductor layer being separated from the first semiconductor layer; and a passivation layer on the back surface of the semiconductor substrate. The passivation layer covers at least a portion of the first semiconductor layer and at least a portion of the second semiconductor layer. The passivation layer includes impurities.

Owner:SAMSUNG SDI CO LTD

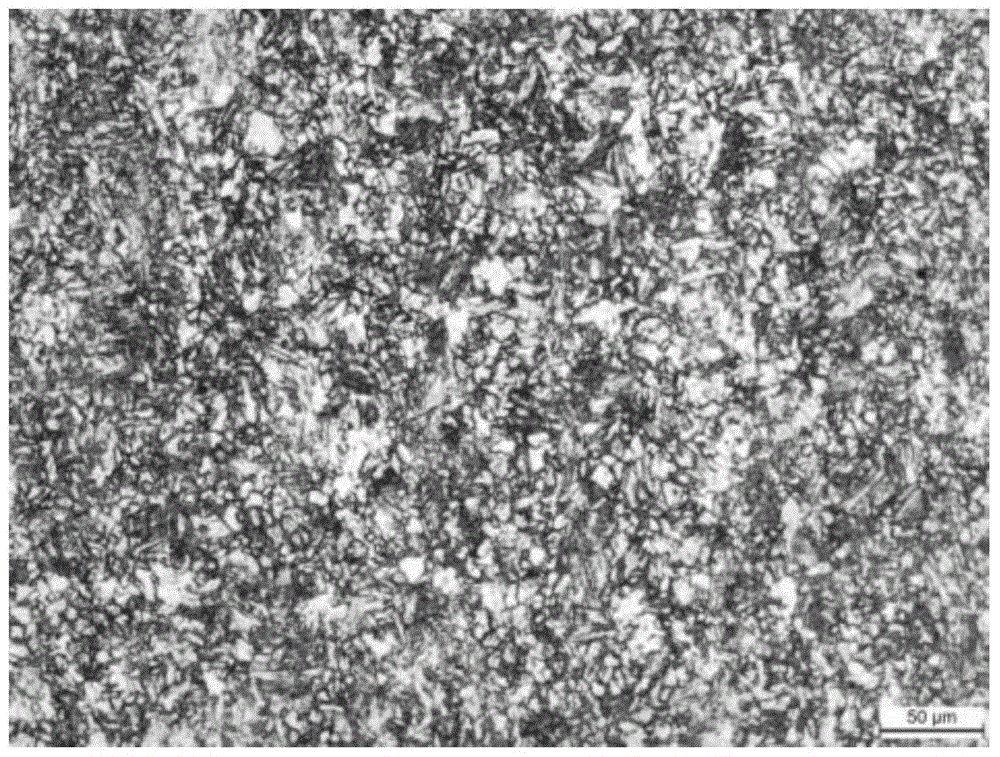

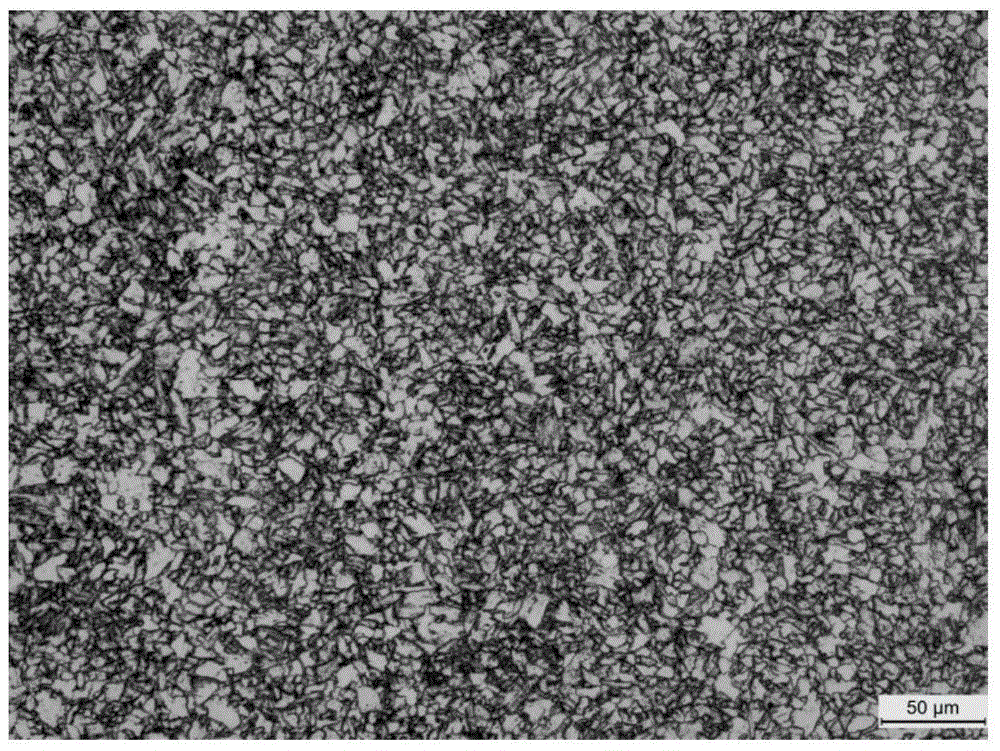

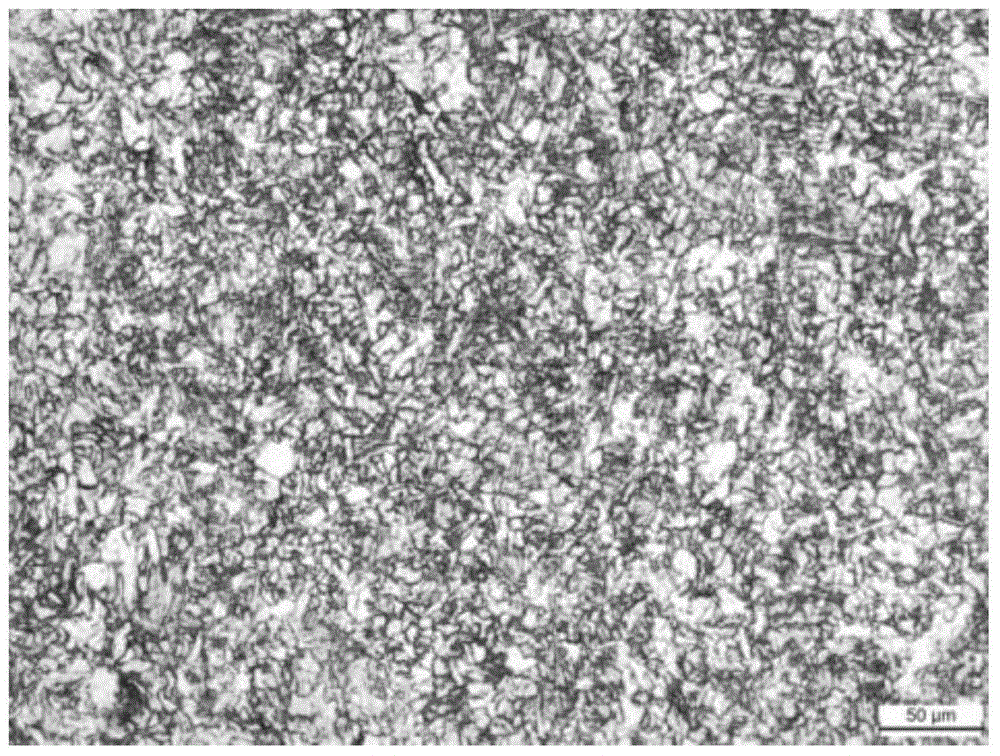

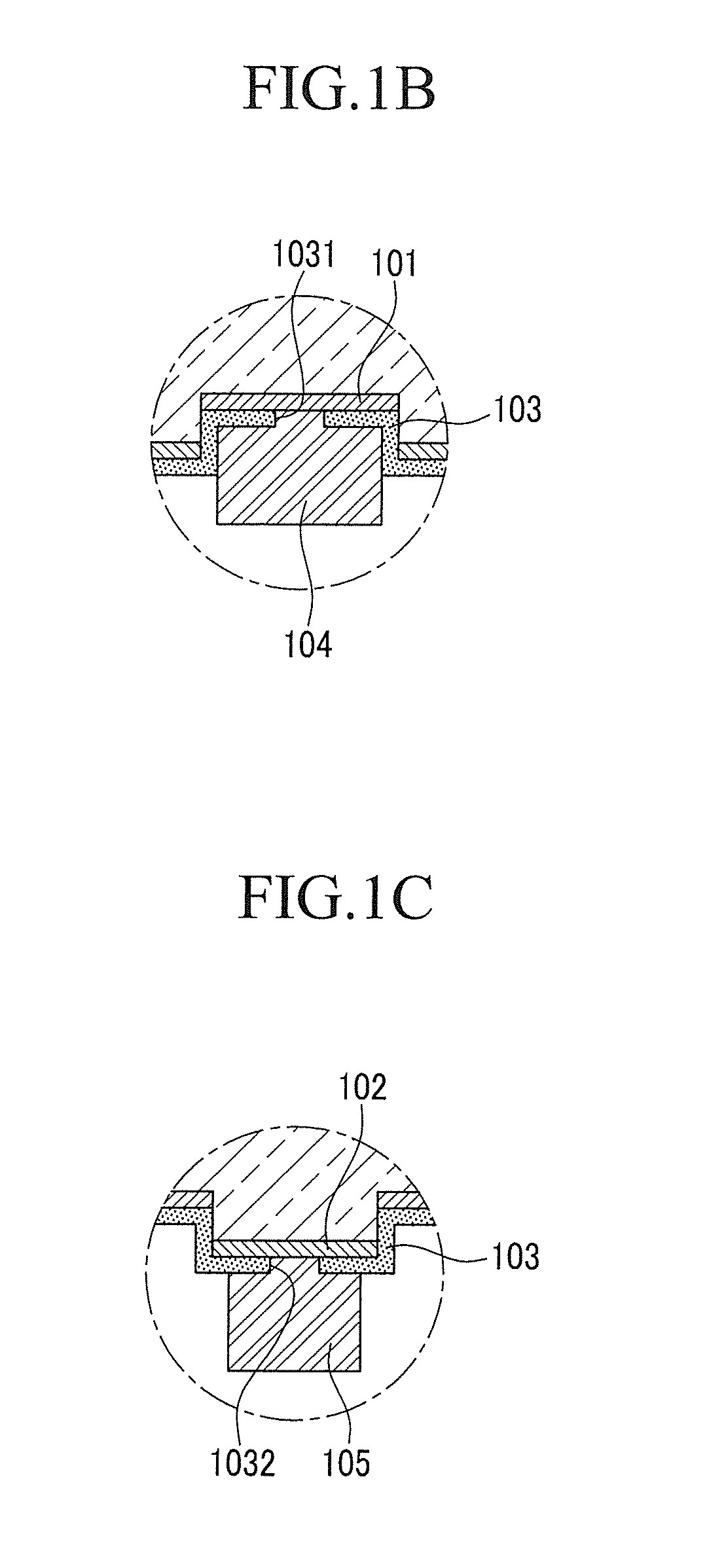

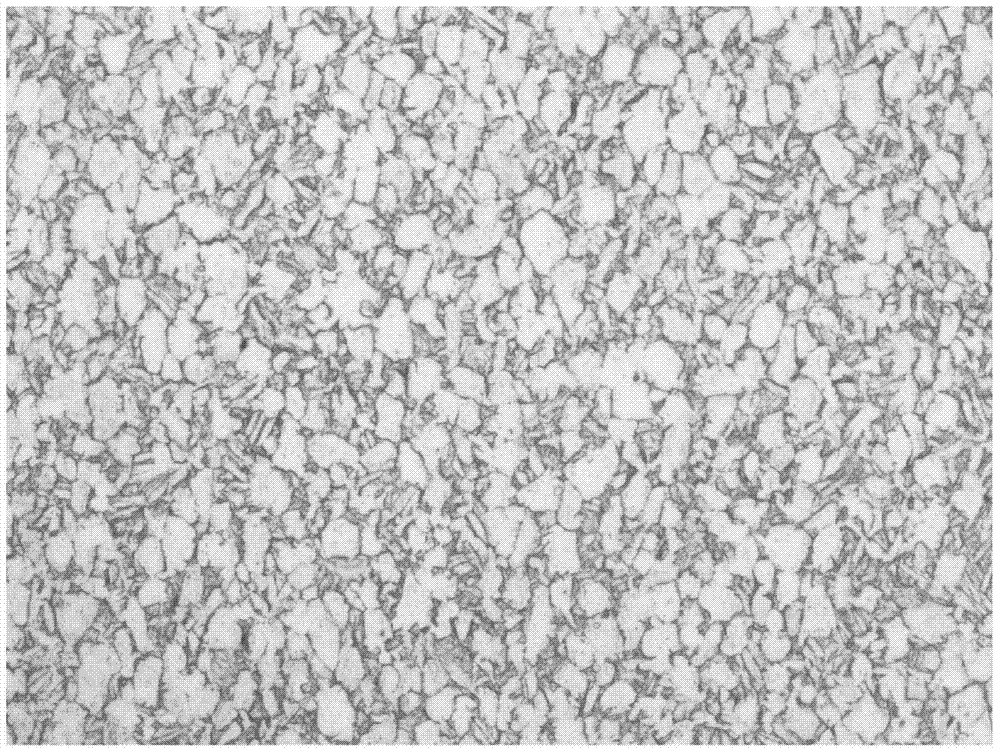

Spheroidizing annealing process for medium carbon steel plate in bell furnace

InactiveCN101307378AReduce heat treatment processReduce consumptionElectrical resistance and conductanceTube furnace

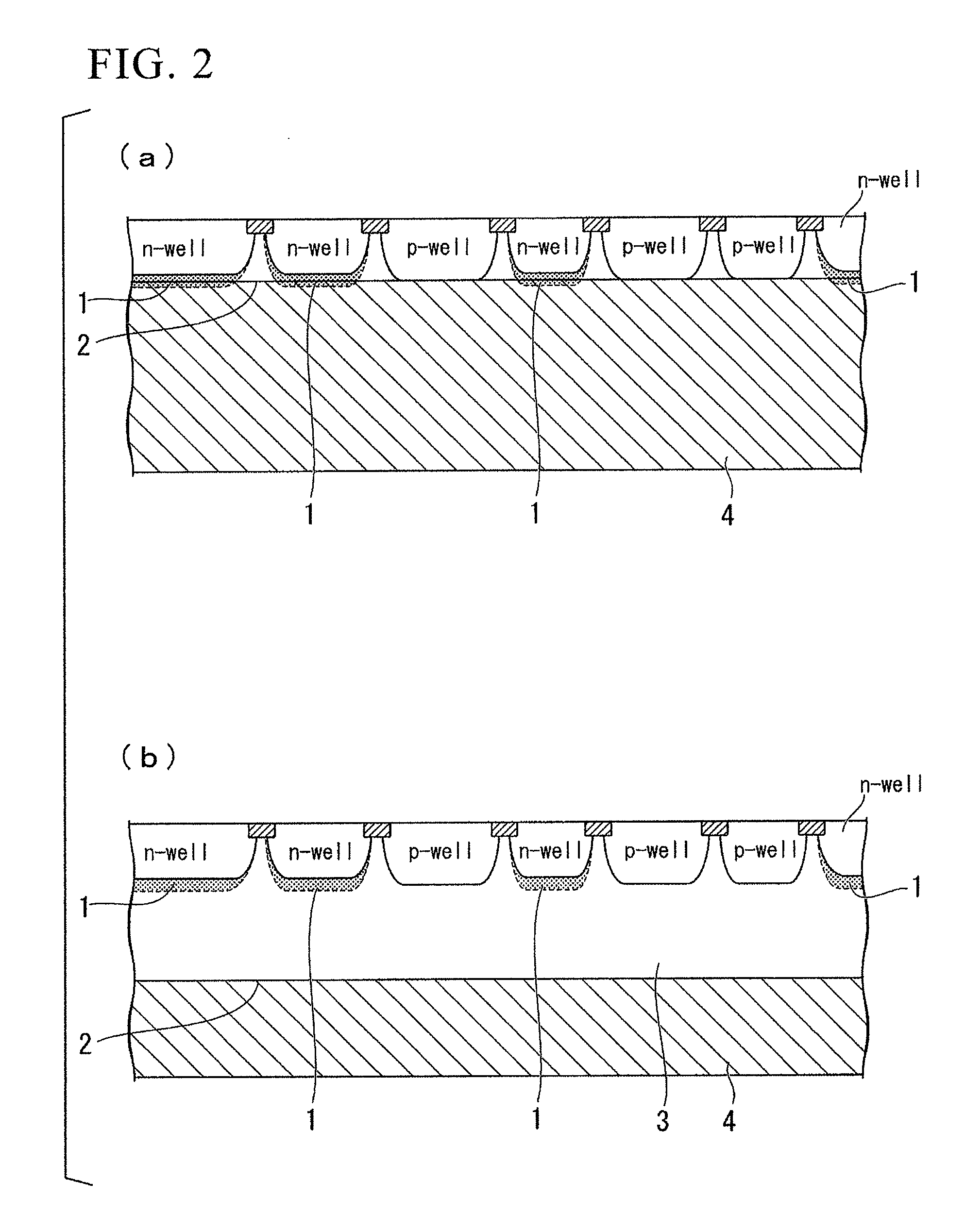

The invention relates to a medium carbon steel plate bell-type furnace spheroidizing annealing method, which orderly comprises the following steps that: (1) a hot-rolled blank steel coil is subject to the cutting and acid cleaning; (2) the longitudinal rolling is adopted, and the rolling deformation is between 28 and 41 percent; (3) the single sheet stack annealing is adopted, and a steel plate is loaded into an electric heating bell-type furnace; wherein, a. a plate temperature thermocouple is adopted to control the temperature, and at least two armored thermocouples are inserted; b. the heating in the furnace adopts two-section type furnace platform and furnace mantle resistance bands; c. protective gas in the furnace platform and the furnace mantle is nitrogen; d. after the steel sheet is loaded into the furnace, a safety cover and a heating mantle are fastened to electrify and increase the temperature for 60 to 70 hours, the heat preservation is performed for 4 to 6h when the temperature is increased to between 690 and 720 DEG C, and the surface temperature of the steel plate is less than or equal to 720 DEG C during the heat preservation; e. then the heating mantle is hoisted away to cool naturally, and the steel plate is taken out of the furnace when the temperature of the core of the steel plate is cooled to be below 250 DEG C. The medium carbon steel plate bell-type furnace spheroidizing annealing method adopts one-time annealing, and the spheroidizing qualification rate of metallurgical structures is apparently improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Hot-rolled wire rod for manufacturing high-strength steel strand of strong and smart grid and production method of hot-rolled wire rod

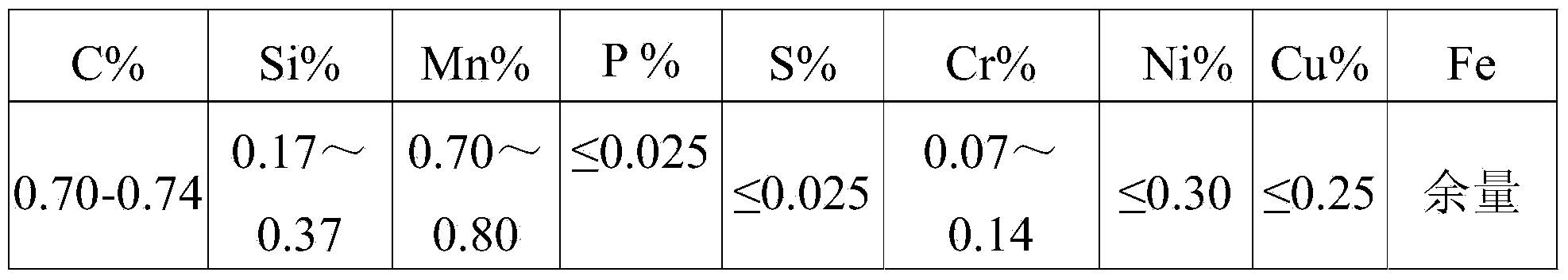

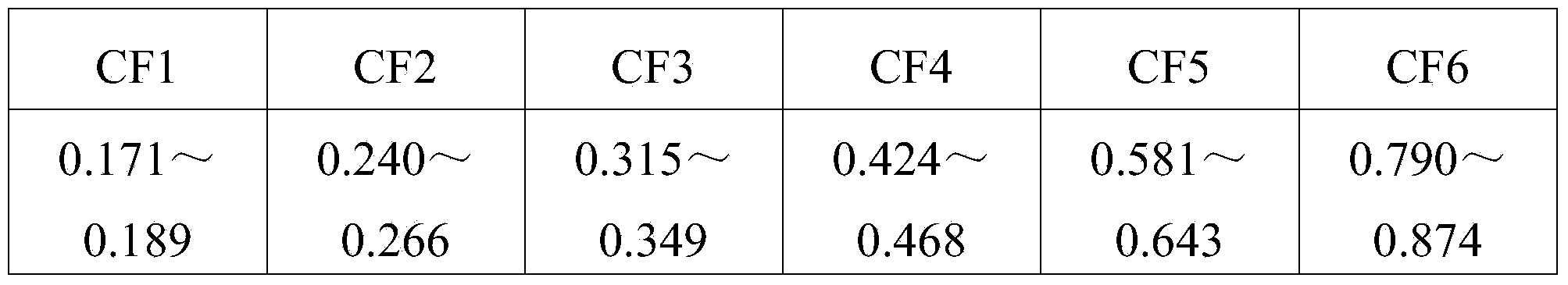

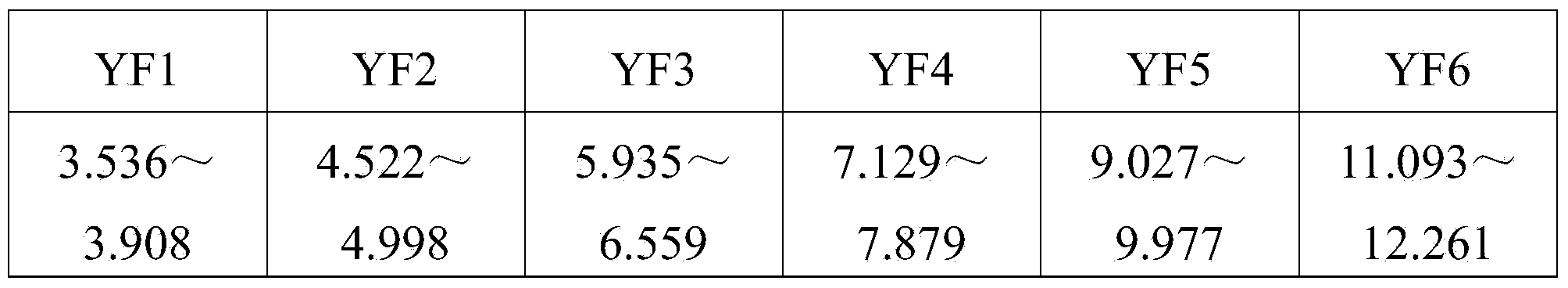

ActiveCN104233097ACompact configurationReasonable configurationMetal rolling arrangementsWire rodChemical composition

The invention discloses a hot-rolled wire rod for manufacturing a high-strength steel strand of a strong and smart grid and a production method of the hot-rolled wire rod, and relates to a hot-rolled wire rod for manufacturing a high-strength steel strand of a grid. Chemical composition of the hot-rolled wire rod is composed of the following substances in percentage by weight (%): 0.70-0.74% of C, 0.17-0.37% of Si, 0.70-0.80% of Mn, 0.07-0.14% of Cr, less than or equal to 0.025% of P, less than or equal to 0.025% of S, less than or equal to 0.30% of Ni, less than or equal to 0.25% of Cu and the balance of Fe. According to the phi6.5mm hot-rolled wire rod produced by the method disclosed by the invention, tensile strength is 1120-1200Mpa, area reduction is 40-50% and percentage of elongation is more than or equal to 18%. The hot-rolled wire rod disclosed by the invention has the advantages that process equipment and parameter setting are reasonable, longstanding problems are solved and product quality is improved; the wire rod is drawn into a steel wire to enhance strength, and a loading bearing capacity of a steel strand processed from the steel wire is greatly improved; and the hot-rolled wire rod is easy to draw, and capable of avoiding an intermediate heat treatment process and saving energy.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Method for producing high-strength titanium alloy seamless tube

The invention relates to and aims at providing a method for producing a high-strength titanium alloy seamless tube and belongs to the field of metallurgy. The method for producing the high-strength titanium alloy seamless tube sequentially comprises the following steps: heating a round billet, perforating, sizing, carrying out hydraulic drawing and temperature correcting, and the like, thereby obtaining the titanium alloy seamless tube finally. The method for producing the high-strength titanium alloy seamless tube has the advantages that deformation at the medium temperature of 750-850 DEG C is increased to directly obtain the titanium alloy tube meeting performance requirements, a heat treatment process is eliminated, and the aims of simplifying working procedures, optimizing a technology, reducing cost, shortening a production cycle, improving production efficiency and improving product quality are achieved. The titanium alloy tube produced by the method has the advantages of thin gas permeable layer, high outer diameter and wall thickness dimensional accuracy, few inner and outer surface defects, high yield and the like. The method provides a new choice for production of the titanium alloy tube and has broad application prospects.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

High-toughness quantitative-reduction ship plate marine steel and preparation method thereof

The invention discloses high-toughness quantitative-reduction ship plate marine steel. A steel plate comprises the following chemical components by weight percent: 0.04%-0.14% of C, 0.15%-0.45% of Si,0.90%-1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.010%-0.040% of Nb, 0-0.20% of Cr, 0-0.030% of V, 0.005%-0.020% of Ti, 0.015%-0.050% of Als, less than or equal to 30 ppm of N, less than or equal to 30 ppm of O, less than or equal to 2 ppm of H, and the balance Fe and inevitable impurities, wherein Als is acid-soluble aluminum; a welding crack sensitivityindex (Pcm) of the steel plate is less than or equal to 0.22%; and a carbon equivalent value (CEV) is less than or equal to 0.39%. The steel plate is not liable to be broken and damaged, and has goodstrength and toughness, welding performance and crack arrest performance.

Owner:SD STEEL RIZHAO CO LTD

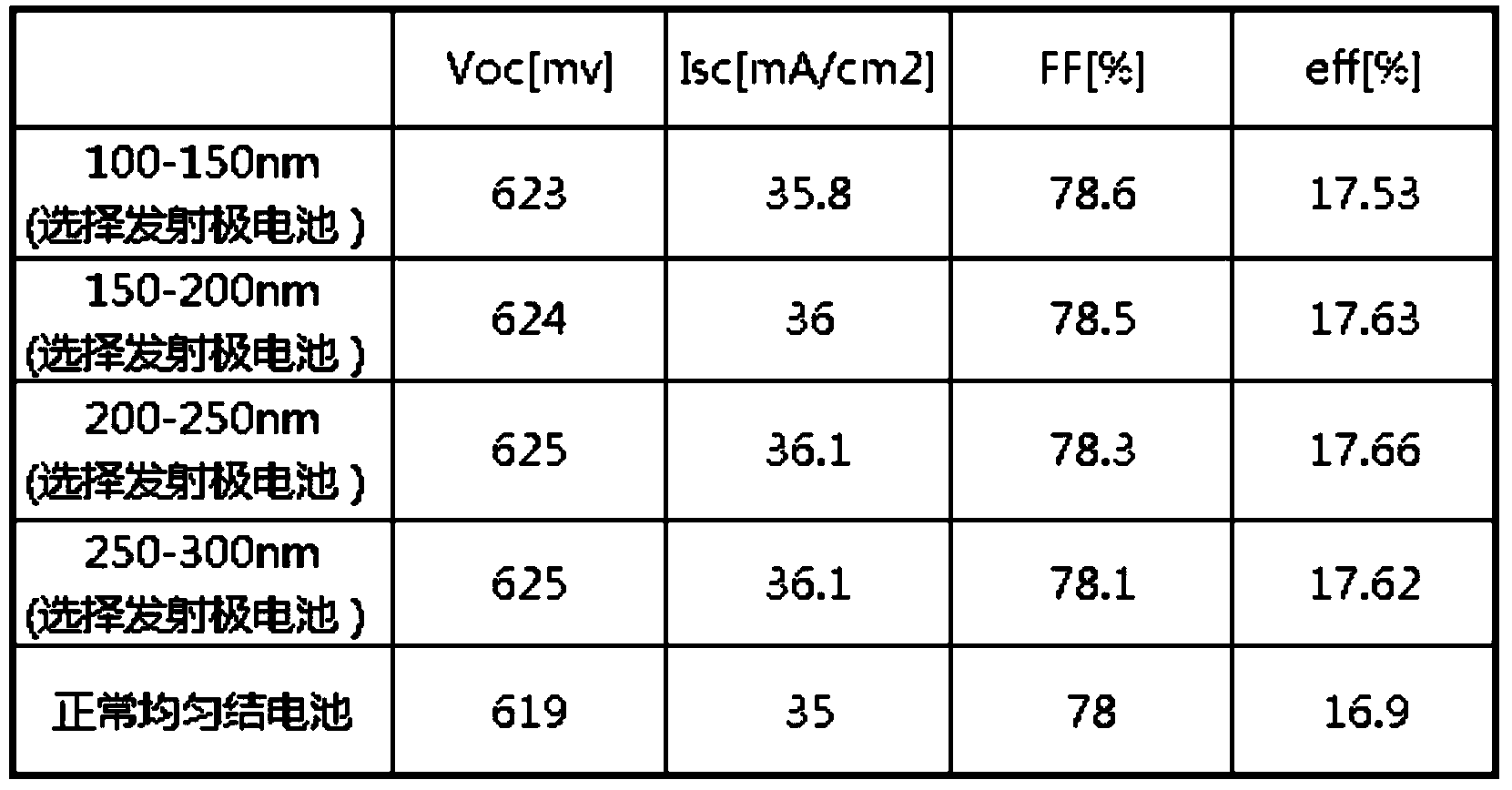

Preparation method for polycrystal/monocrystal-like solar cell selective emitting electrode structure

InactiveCN103531657AImprove conversion efficiencyReduce heat treatment processFinal product manufacturePhotovoltaic energy generationOptoelectronicsSolar cell

The invention discloses a preparation method for a polycrystal / monocrystal-like solar cell selective emitting electrode structure. The preparation method for the polycrystal / monocrystal-like solar cell selective emitting electrode structure comprises the following steps: (1) chemically removing a surface energy affected layer; (2) carrying out heavy doping by the one-time diffusion technology to form a PN junction; (3) growing or forming a dielectric layer or a mask layer on the surface of a silicon wafer; (4) corroding the dielectric layer of a non-electrode grid line area with a chemical corrosion method, and keeping the mask layer under an electrode grid line area; (5) etching a pyramid matte structure of 100-300nm in the non-electrode grid line area by reactive ion etching (RIE), and meanwhile, forming a shallow doped area in one time; and (6) removing a surface affected layer formed by RIE and a lower mask layer under the electrode grid line area with a wet chemistry method to obtain the selective emitting electrode structure. According to the preparation method for the polycrystal / monocrystal-like solar cell selective emitting electrode structure, which is disclosed by the invention, the light doping and the heavy doping required by the selective emitting electrode polycrystal / monocrystal-like solar cell and a low-reflectivity nanoscale surface texture can be finished by one-time diffusion combined with the RIE technology, the process path is simplified, the conversion efficiency is high, and the preparation method for the polycrystal / monocrystal-like solar cell selective emitting electrode structure is suitable for industrial volume production.

Owner:CHINA SUNERGY CO LTD

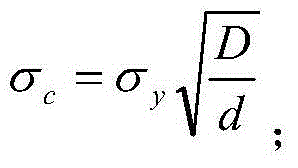

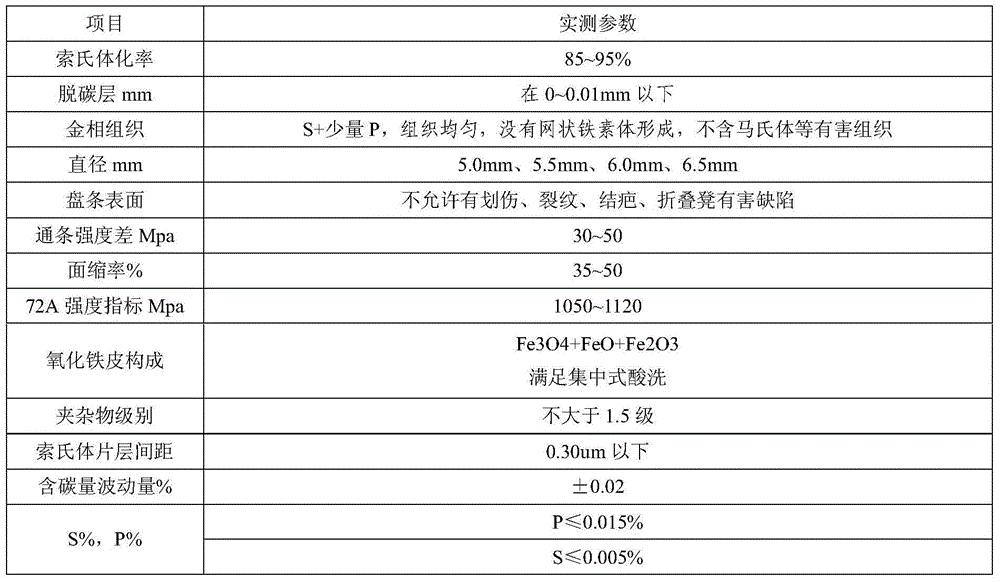

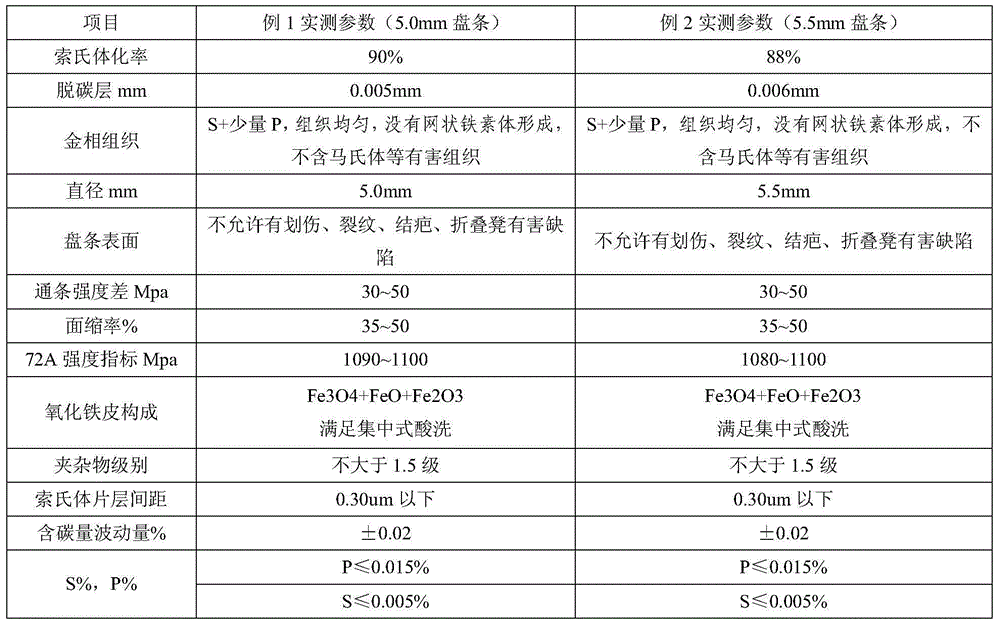

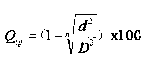

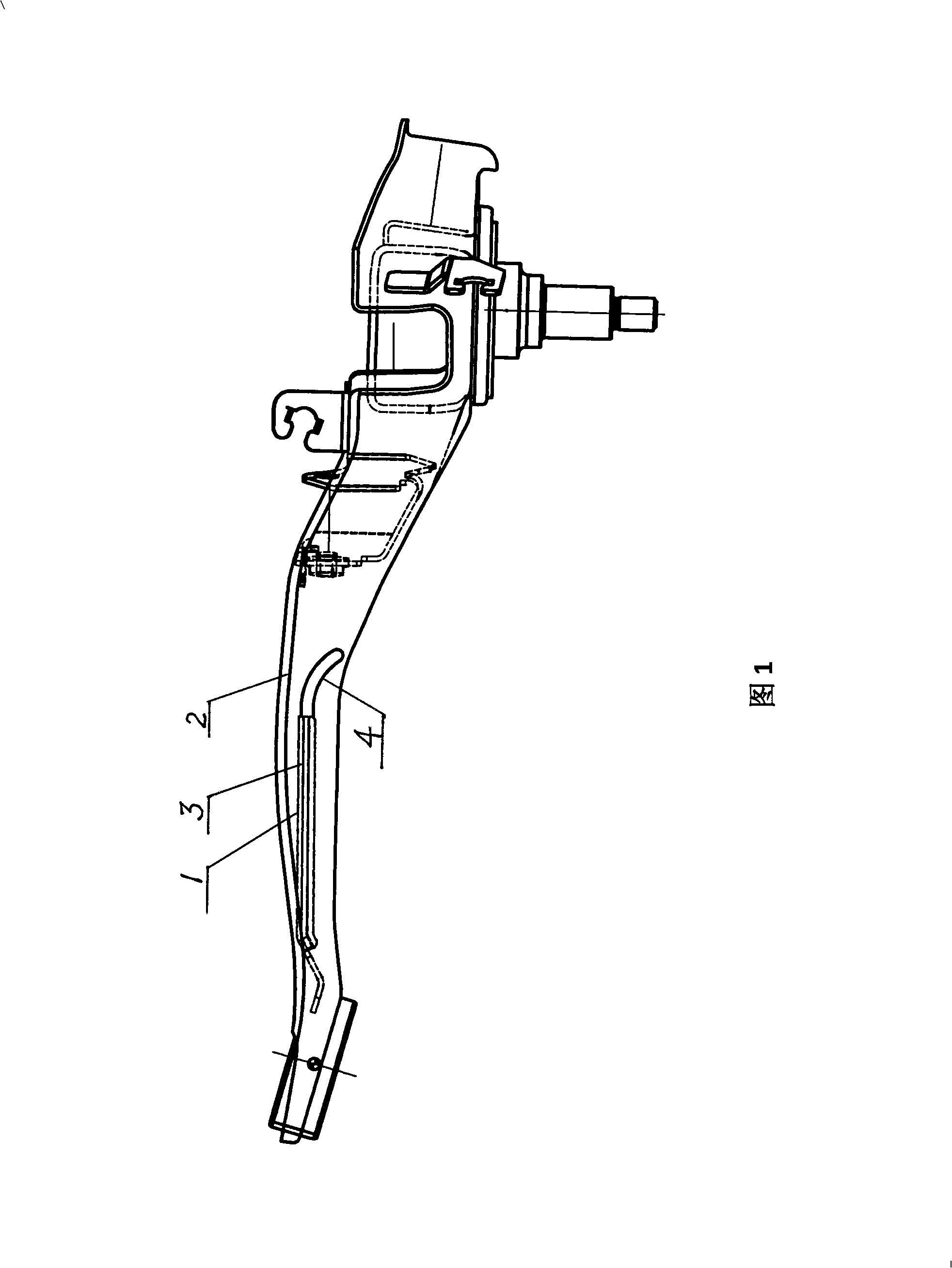

Method for producing significant-purpose steel wire for manufacturing rope

The invention relates to a method for producing a significant-purpose steel wire for manufacturing a rope. The method comprises the following production processes: coiling, performing acid pickling rusting, pulling a half-finished product, performing EDC coiling, pulling a finished product steel wire, and inspecting the steel wire, and comprises the following production steps: (1) after the half-finished product is pulled, performing EDC coiling, soaking a coiled strip in an austenite state into water and cooling rapidly, thereby obtaining austenite texture, wherein the austenite rate is 85-95%; and (2) according to a Linhof equation as shown in the specification, enabling the strength of the finished product steel wire and the strength of a raw material are in a linear relationship, wherein the pull resistance sigma c of the EDC coiled strip is 1050-1120Mpa. The method has the advantages that the experiment shows that the significant-purpose steel wire which is pulled by using the method and is used for manufacturing the rope can meet relevant requirements in the national standard (YB / T5343-2009). The technical indexes of the product completely meet the national standard and use requirements.

Owner:ANGANG STEEL WIRE ROPE

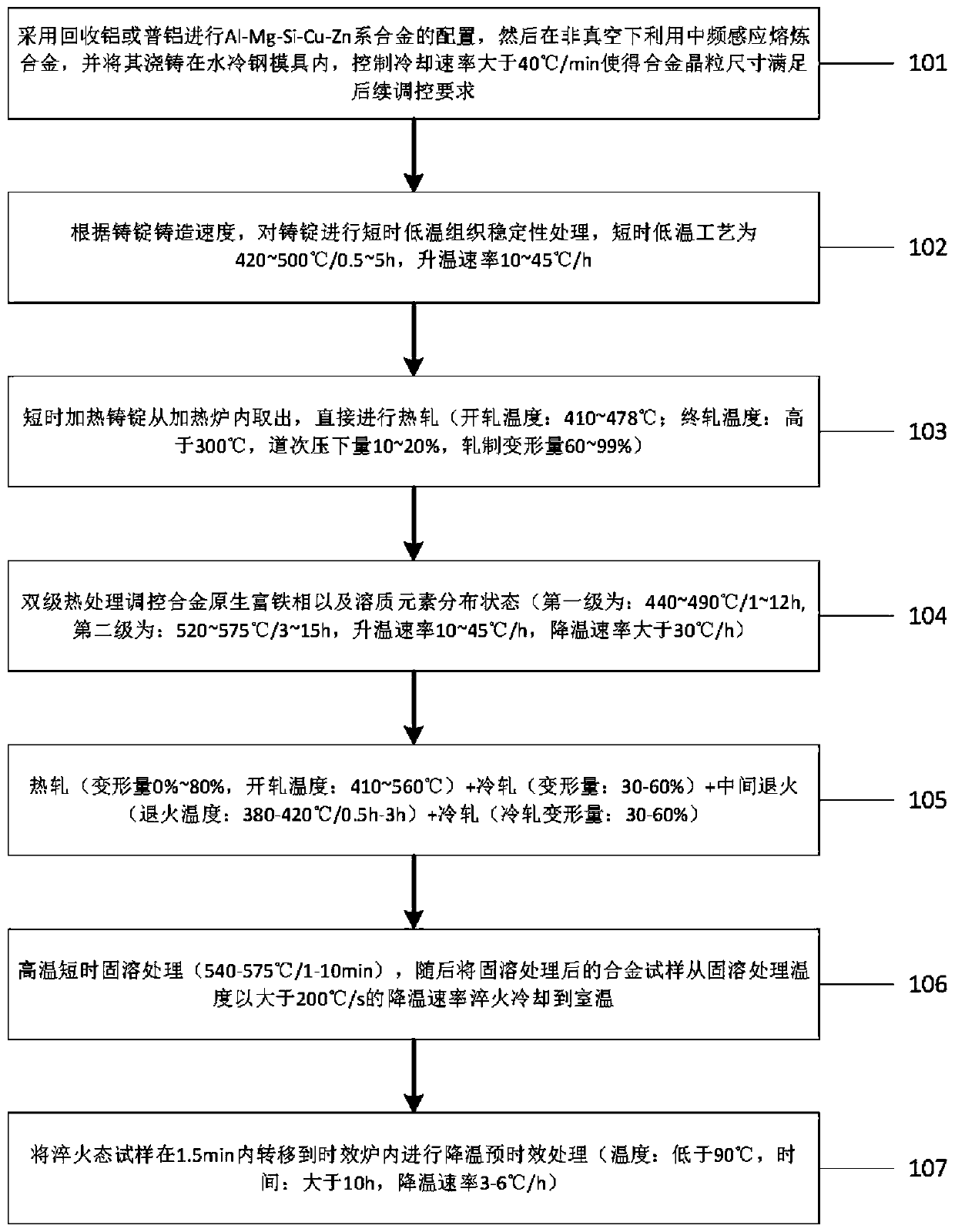

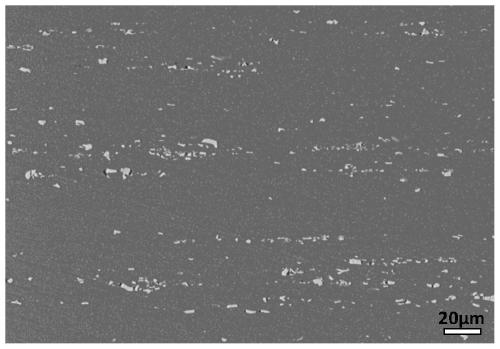

Progress regulation method of automotive high-formability aluminum alloy heterogeneous structure

InactiveCN111057980AReduce manufacturing costImproved press formabilitySolution treatmentTest sample

The invention discloses a progress regulation method of an automotive high-formability aluminum alloy heterogeneous structure, and belongs to the technical field of aluminium alloy. The progress regulation method comprises the following steps of configuring the automotive high-formability Al-Mg-Si-Cu-Zn alloy, smelting the alloy through medium-frequency induction in non-vacuum, and casting the alloy in a cold cooling steel die for cooling; performing short-time low-temperature structure stability treatment; taking out an ingot heated in short time from a heating furnace, and directly performing hot rolling treatment; performing two-stage thermal treatment to regulate the distribution state of alloy primary iron-rich phase and a solute element; performing hot rolling, cold rolling, intermediate annealing and cold rolling treatment in sequence; performing high-temperature short-time solid-solution treatment, and then carrying out quench cooling on the alloy test sample subjected to solid-solution treatment from the solid-solution treatment temperature to room temperature; and transferring a quenched test sample in an ageing furnace for cooling and preliminary ageing treatment. The treatment method can effectively control the crystal grain in the alloy and the size and the distribution of a precipitating phase, and the heterogeneous structure having remarkable prompting effects onthe alloy formability is formed.

Owner:UNIV OF SCI & TECH BEIJING +2

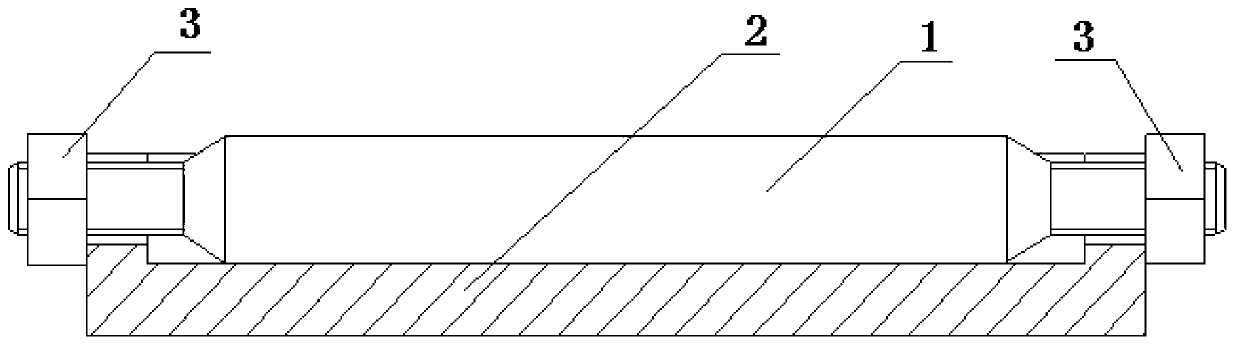

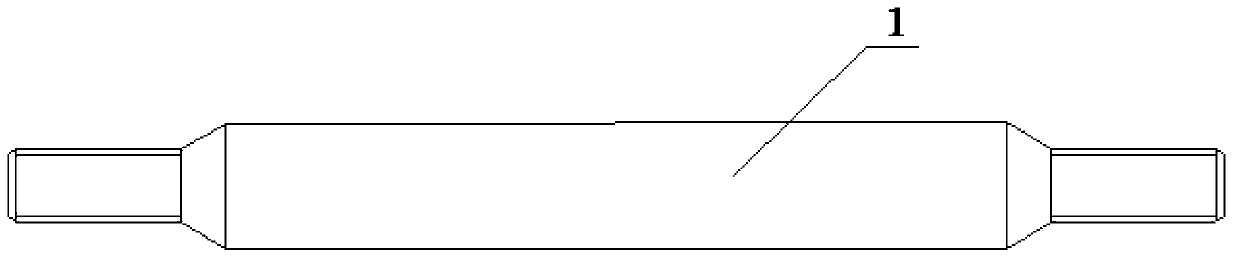

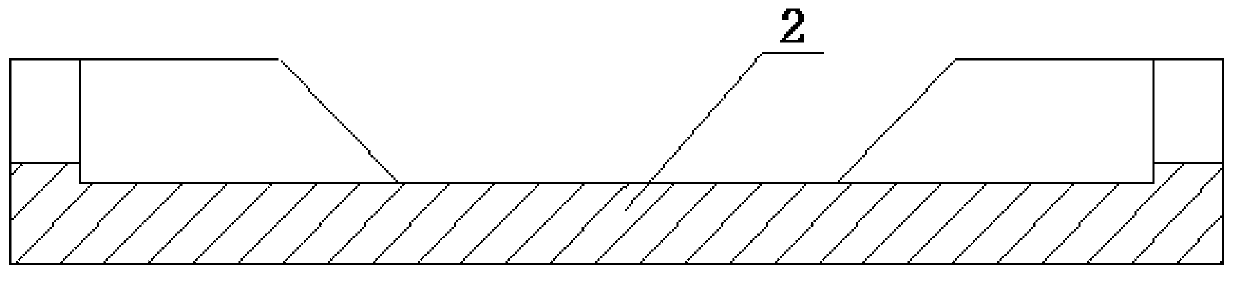

Prestressed quench hardening and grinding composite processing method

ActiveCN103213049AAvoid investmentReduce processing stepsGrinding machinesPre stressRoom temperature

The invention provides a prestressed quench hardening and grinding composite processing method, belongs to the technical field of material surface mechanical processing and particularly relates to the prestressed quench hardening and grinding composite processing method for integrating grinding, quenching and residual stress control. The processing method comprises the following steps that a workpiece to be ground is arranged in a prestress loading device, when the workpiece is installed in place, the pretensioning stress is applied on the workpiece, at the moment, and the two parts are combined into an assembly body; the assembly body is placed in a grinding mechanism, the grinding position in the grinding mechanism realizes the loading, the clamping and the fixation of the assembly body, and after the loading, the clamping and the fixation are completed, the grinding mechanism carries out dry grinding processing on the workpiece in the assembly body without applying grinding liquid; after the grinding processing is finished, the air cooling is carried out until the temperature of the workpiece is reduced to the room temperature; and when the temperature of the workpiece reaches the room temperature, the pretensioning stress is unloaded, the workpiece is taken out from the prestress loading device, and the prestressed quench hardening and grinding processing of the workpiece is completed.

Owner:NORTHEASTERN UNIV

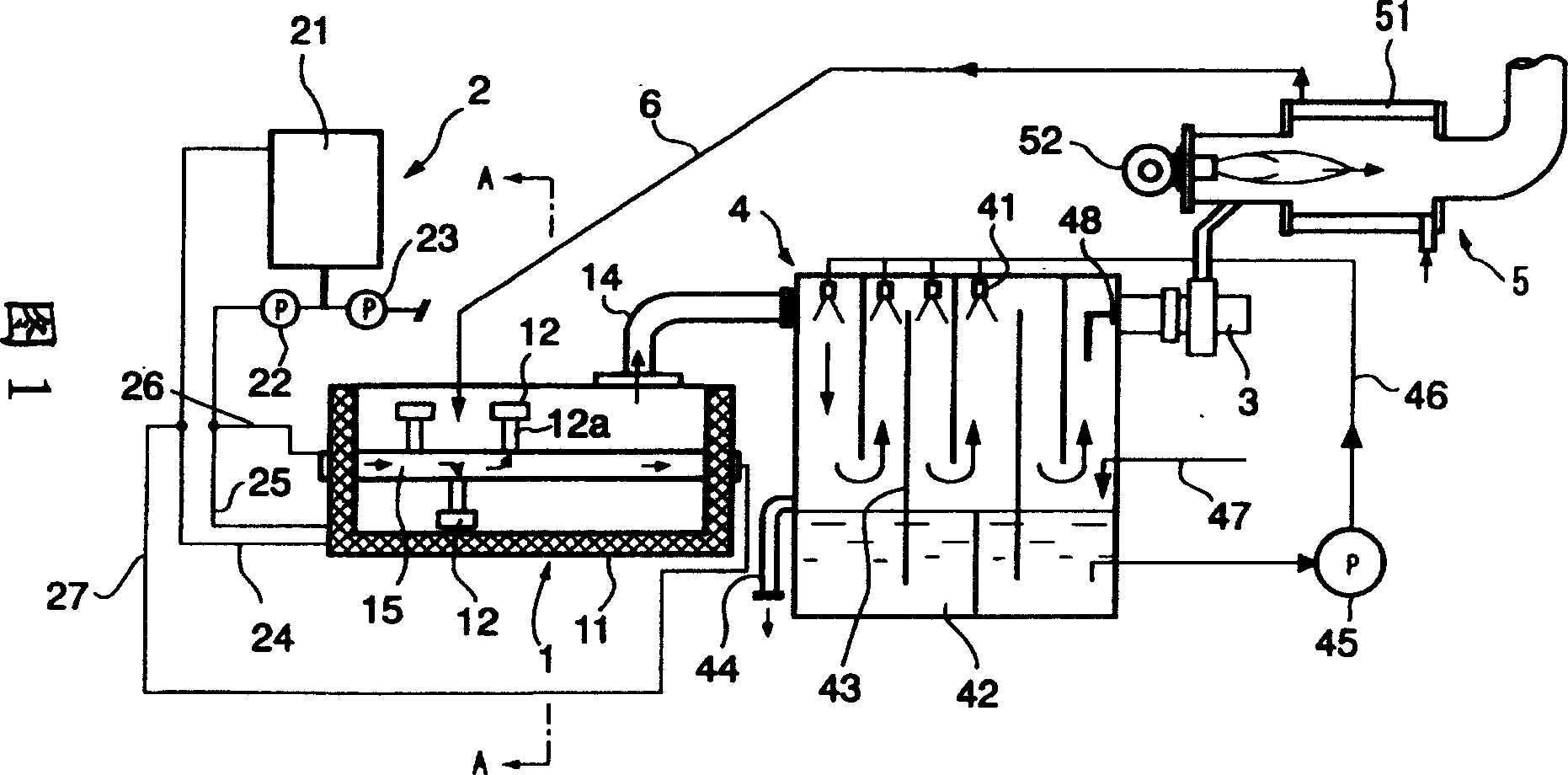

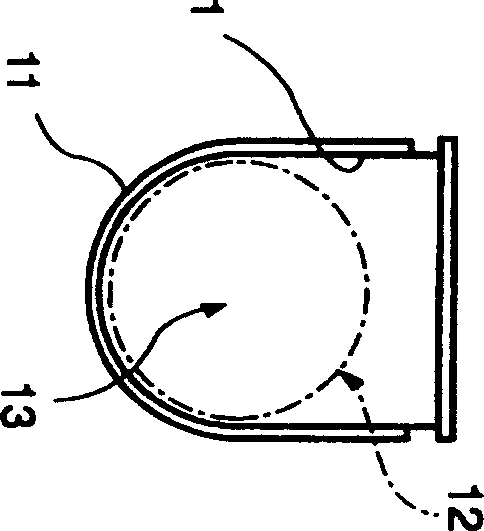

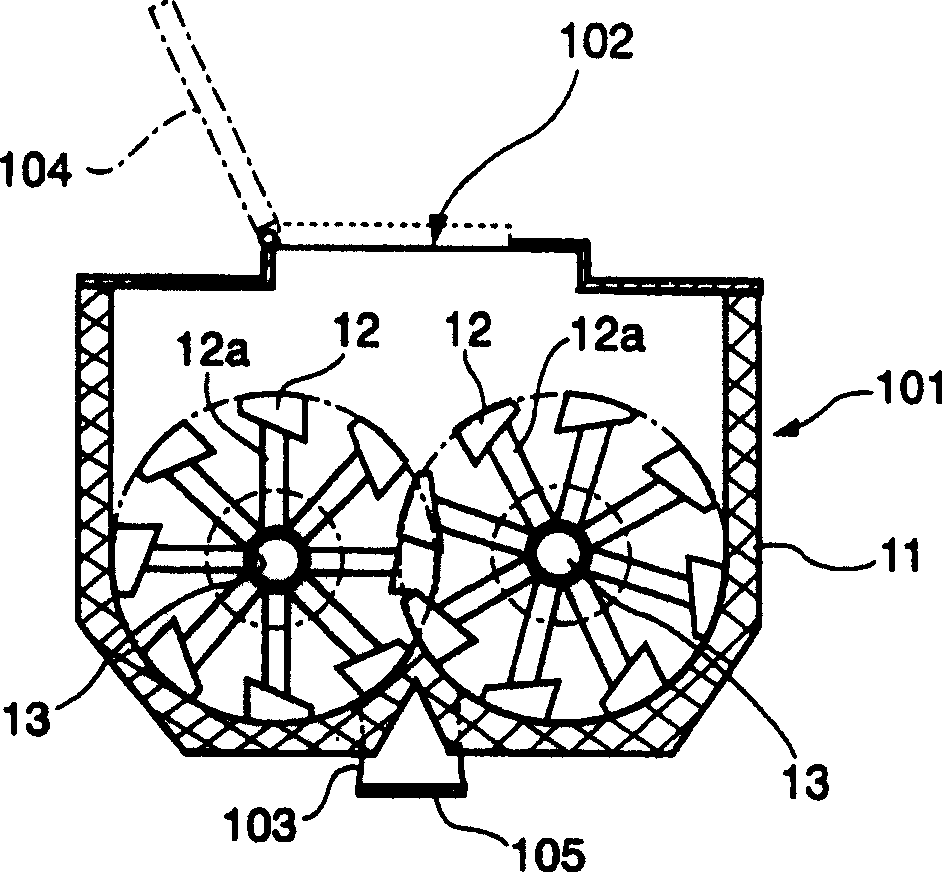

Heating method and apparatus for processing biological organic refuse

InactiveCN1572384AUniform heating temperatureIncrease heat transfer areaSludge treatment by de-watering/drying/thickeningFood processingDecompositionHeating temperature

In the heating method, the following two heating-methods are selectively applied to a to-be-treated matter by switching set temperatures in conformity with the kind and properties of animals and vegetables contained in the treated matter. That is, in one heating method for oxidative-decomposition treatment, the heating temperature is controlled to 25-130[deg.]C, and in the other heating method, the heating temperature is controlled to 25-250[deg.]C to conduct oxidative-decomposition treatment and low temperature thermal decomposition treatment in combination.

Owner:KANKYO KOGAKU KENKYUSHOKK

Casting method of bi-metal for plunger pump rotor

InactiveCN107716902AThe joint surface is completeLittle oxidationMetallic material coating processesMetal bindingMachining

The invention provides a casting method of bi-metal for a plunger pump rotor and belongs to the technical field of bi-metal casting. The casting method comprises the following steps: machining a steelsubstrate; pretreating the steel substrate; carrying out a heat-treatment annealing process on the steel substrate; carrying out Ni-Cu-P multi-component nickel plating on the inner surface of the steel substrate; preheating the steel substrate; smelting a lead-tin bronze alloy; casting the lead-tin bronze alloy; and machining the plunger pump rotor. A bi-metal binding surface obtained by adoptingthe casting method provided by the invention has the advantages that not only do the properties reach the standards, but also the equipment investment is low, the process operation is simple and convenient, and the workpiece cost is reduced; the casting method is suitable for extensive popularization and application, and has broad prospects; and compared with a powder metallurgy method, the casting method has the advantages that the performance is superior, the heat treatment procedure is eliminated, the time is saved, and the cost is reduced.

Owner:安徽恒利增材制造科技有限公司

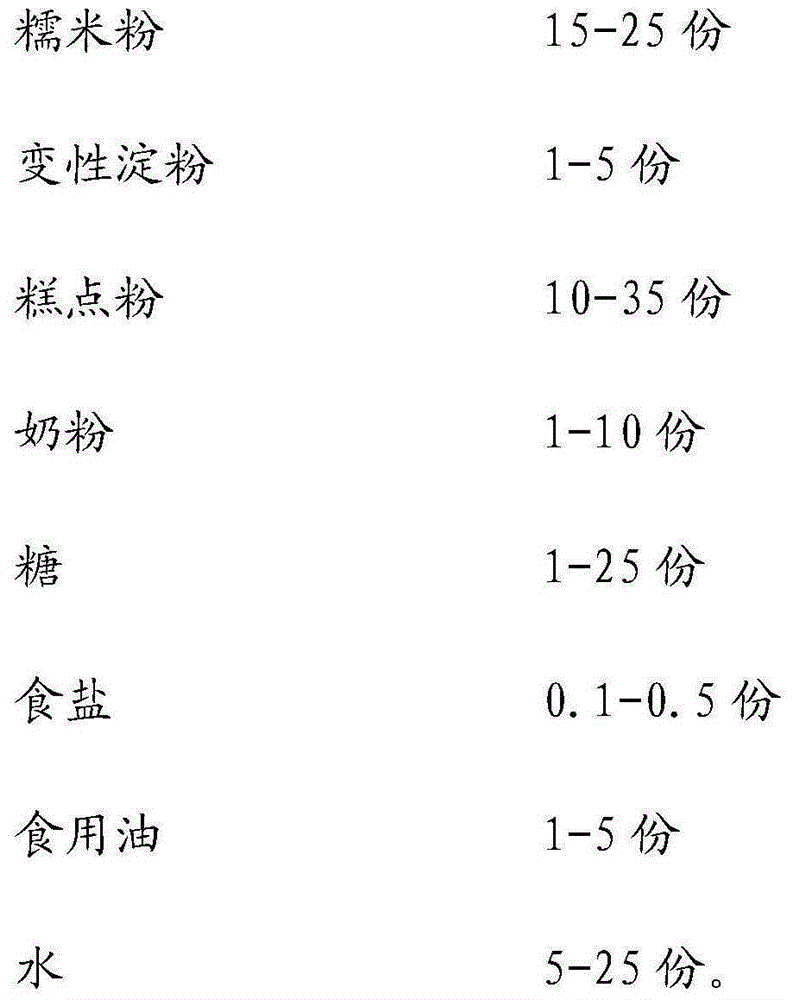

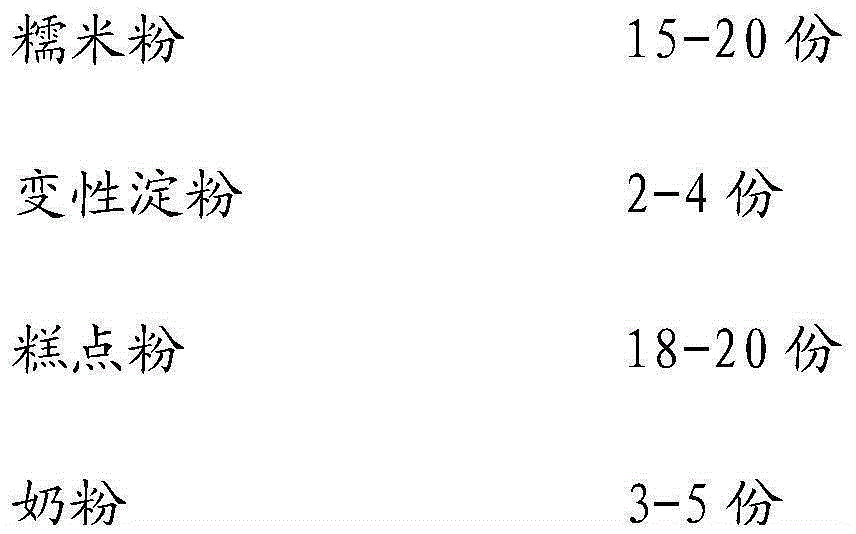

Stuffed rice cake and preparation method thereof

InactiveCN105124426ASolve technical problems that cannot be stuffedRich tasteFood preparationPreservativeHigh pressure

The invention discloses stuffed rice cake and a preparation method thereof. The stuffed rice cake is prepared from rice cake wrapper and stuffing which is stuffed in the rice cake wrapper, wherein the rice cake wrapper is prepared from the following components in parts by weight: 15-25 parts of glutinous rice flour, 1-5 parts of modified starch, 10-35 parts of cake flour, 1-10 parts of milk powder, 1-25 parts of sugar, 0.1-0.5 part of edible salt, 1-5 parts of edible oil and 5-25 parts of water. According to the stuffed rice cake, the technical problem that stuffing cannot be stuffed in rice cake in the prior art can be solved. Furthermore, the production efficiency is greatly improved since the stuffed rice cake can be creatively mechanically produced in batches. The prepared stuffed rice cake is rich in taste and color, does not contain preservative, is prepared by means of high-temperature high-pressure sterilization, and can be preserved for 2 months at normal temperature.

Owner:GUANGZHOU RESTAURANT GRP LIKOUFU FOOD

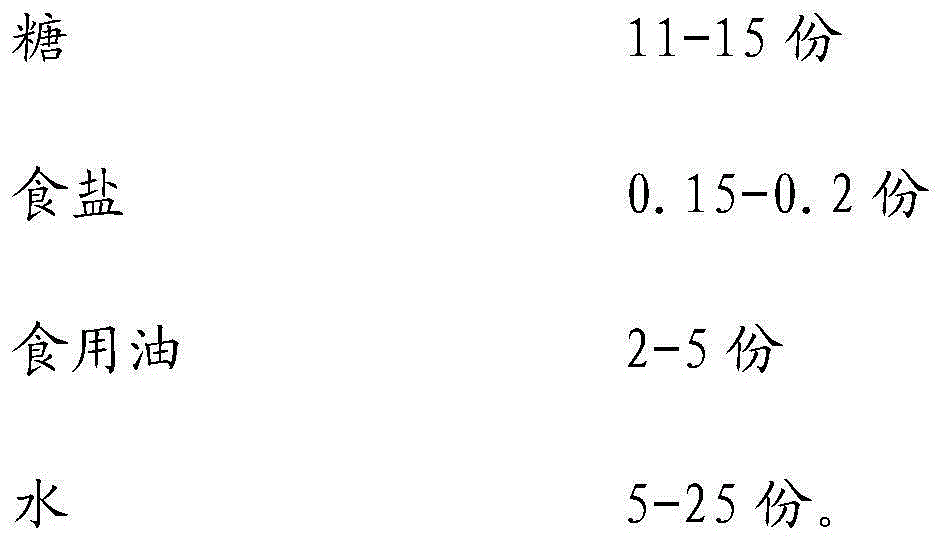

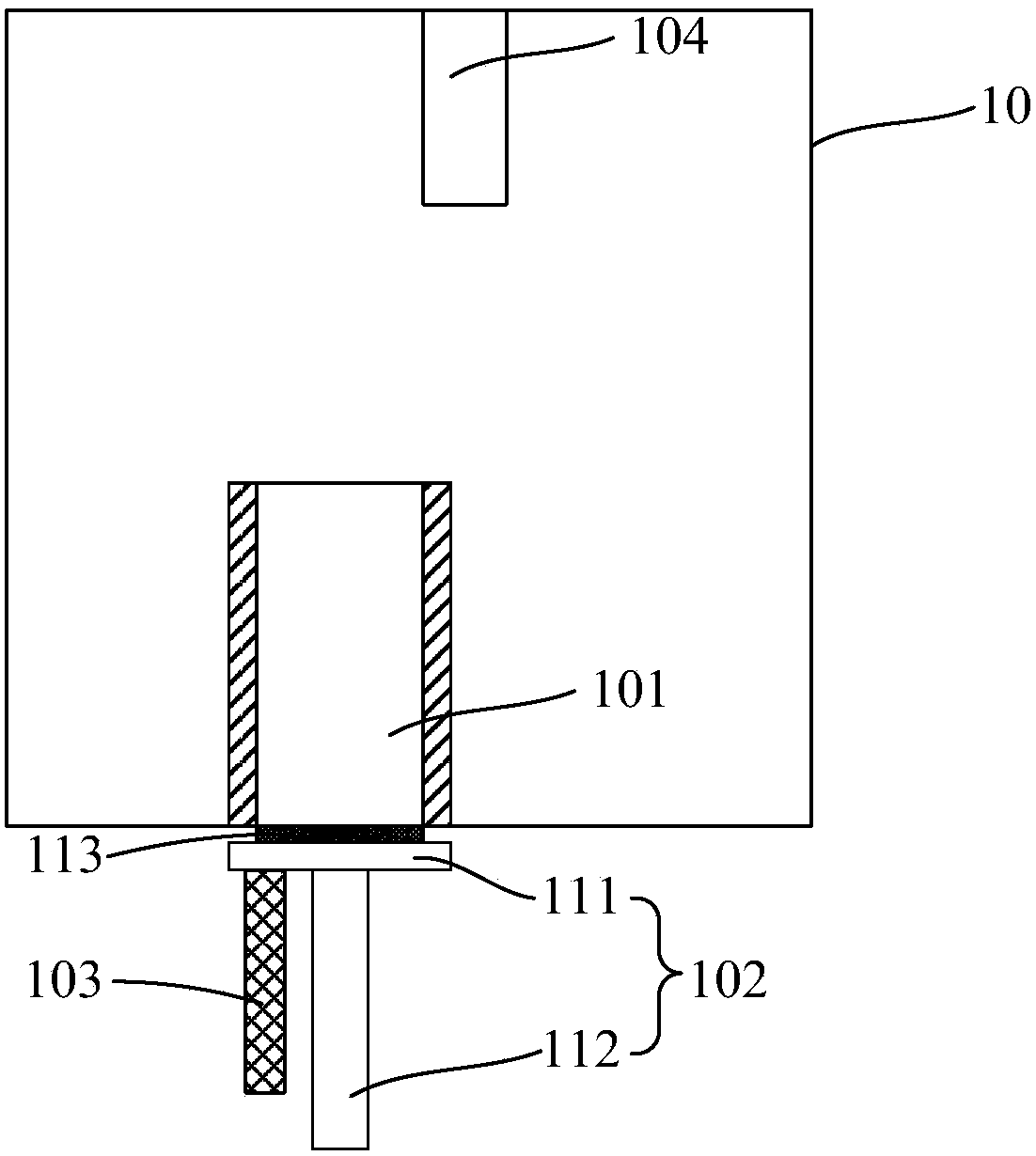

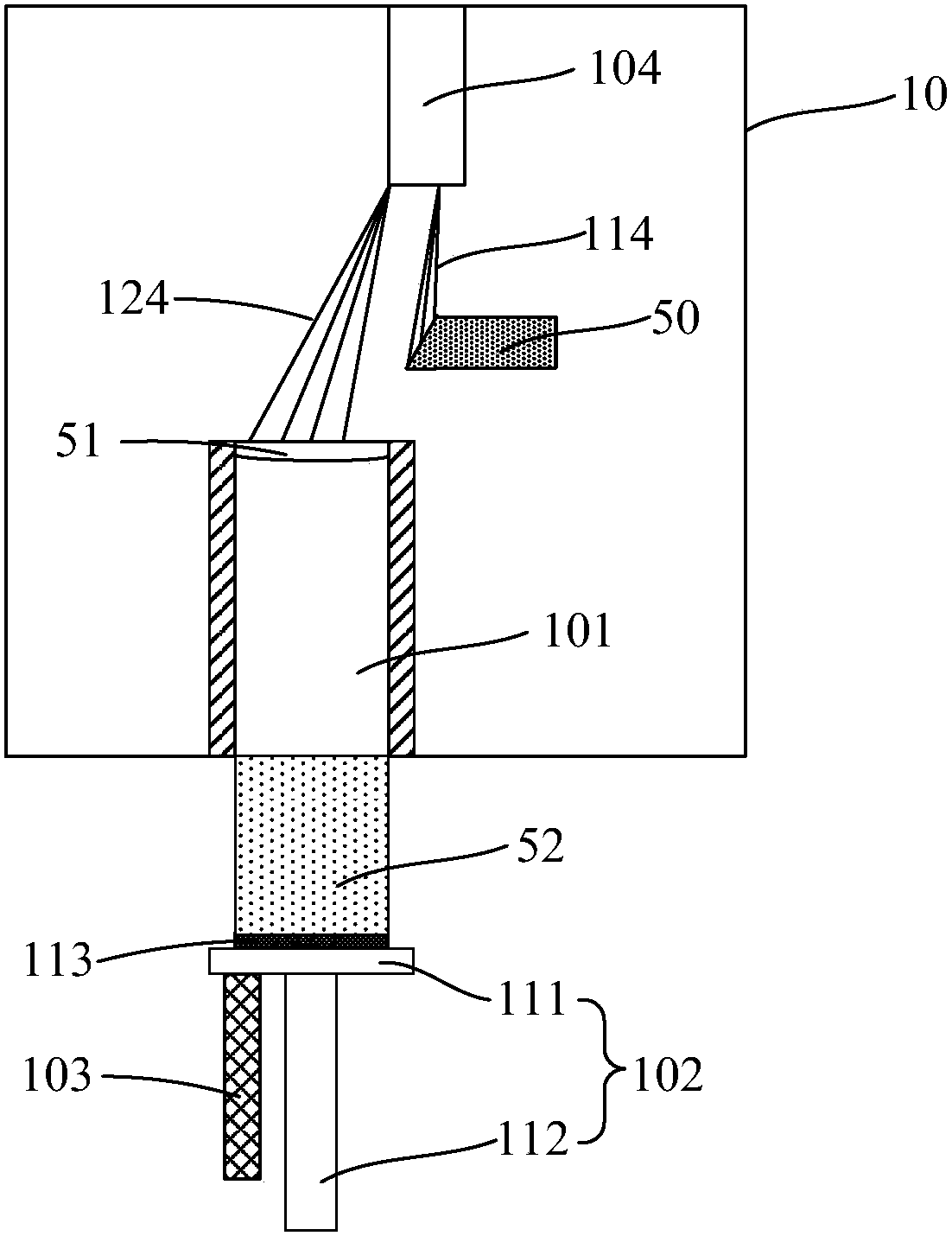

Smelting equipment and smelting method

The invention relates to smelting equipment and a smelting method. Specifically, the smelting equipment includes: a crystallizer; an ingot pulling mechanism, which is connected to the bottom of the crystallizer; a vibrating mechanism, which is suitable for vibration of the ingot pulling mechanism. The equipment and method provided by the invention simplify the metal grain refinement process whilereducing the grain size of the ingot, make the later TMP (plastic deformation and recrystallization process) operation simple, and also reduce the heat treatment procedure and equipment investment, thereby substantially lowering the production cost.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

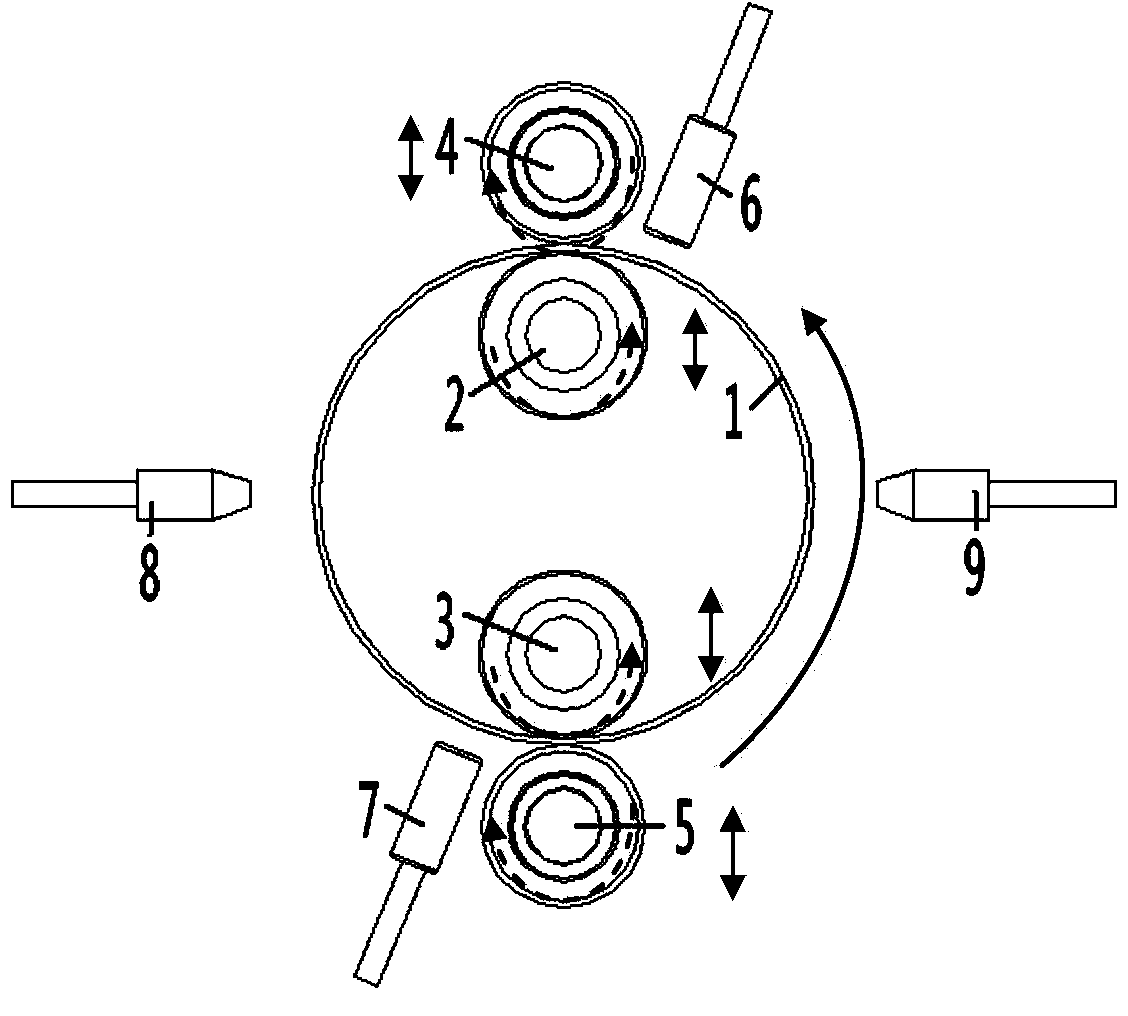

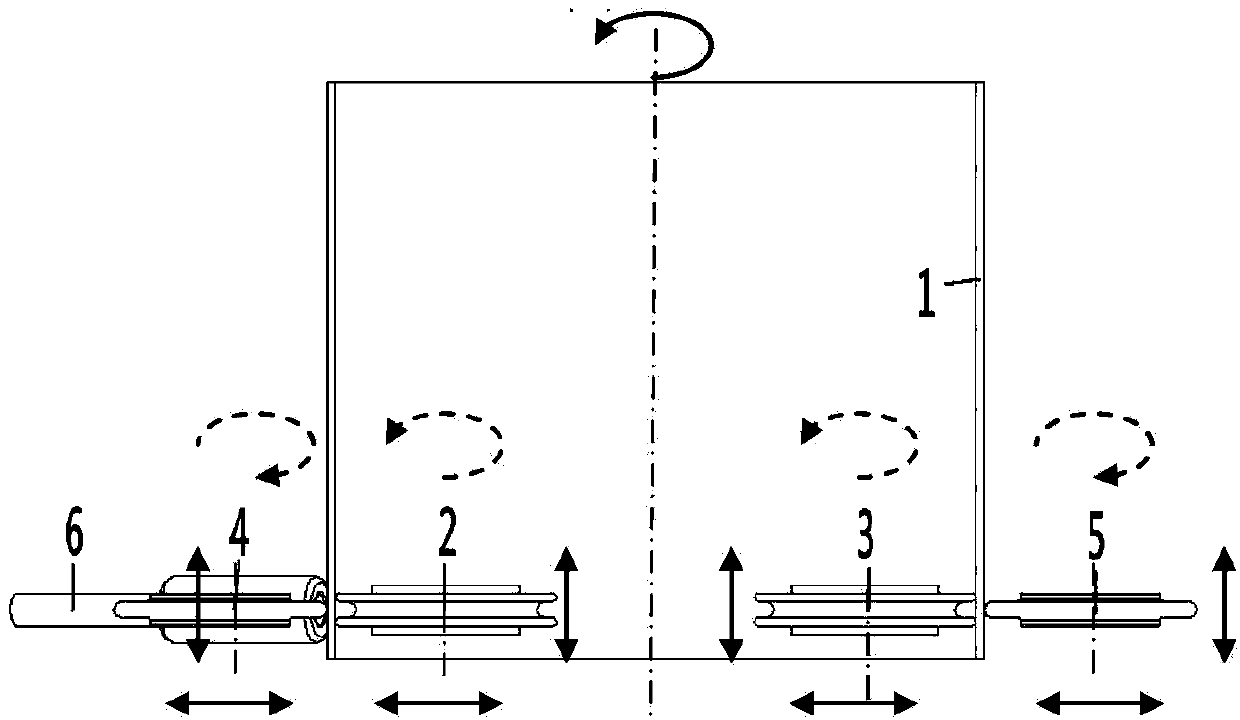

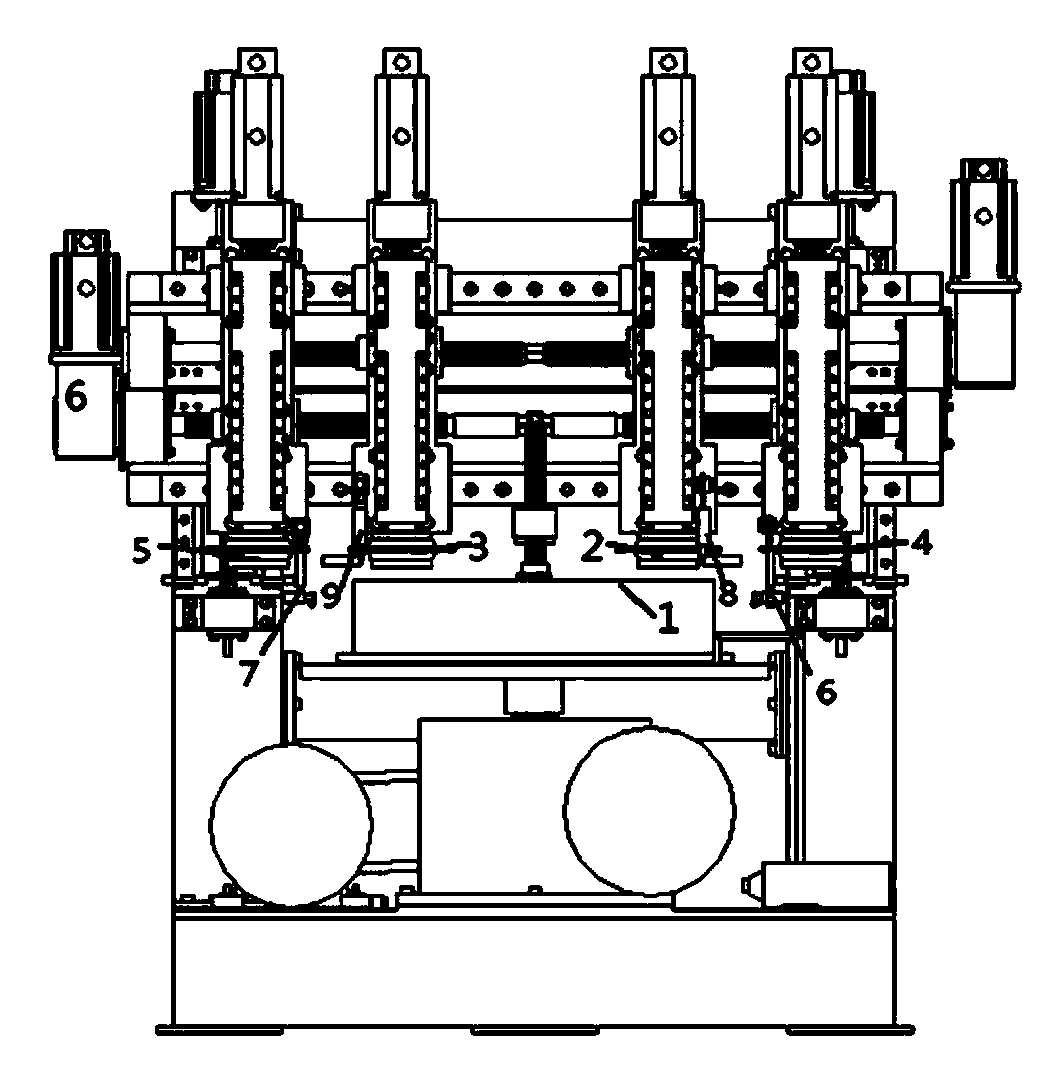

Opposite roller spinning and deformation heat treatment combined manufacturing process for large bellows

The invention provides an opposite roller spinning and deformation heat treatment combined manufacturing process for large bellows. The deformation heat treatment mode is used in an opposite roller spinning process, and novel internally and externally rotated roller sets provided with one or more corrugation shapes are used for spinning corrugation sequentially under the condition of local heating. The manufacturing process can process the bellows with large diameter, large wall thickness and high strength and has the characteristics of high processing capability and high adaptability.

Owner:XI AN JIAOTONG UNIV

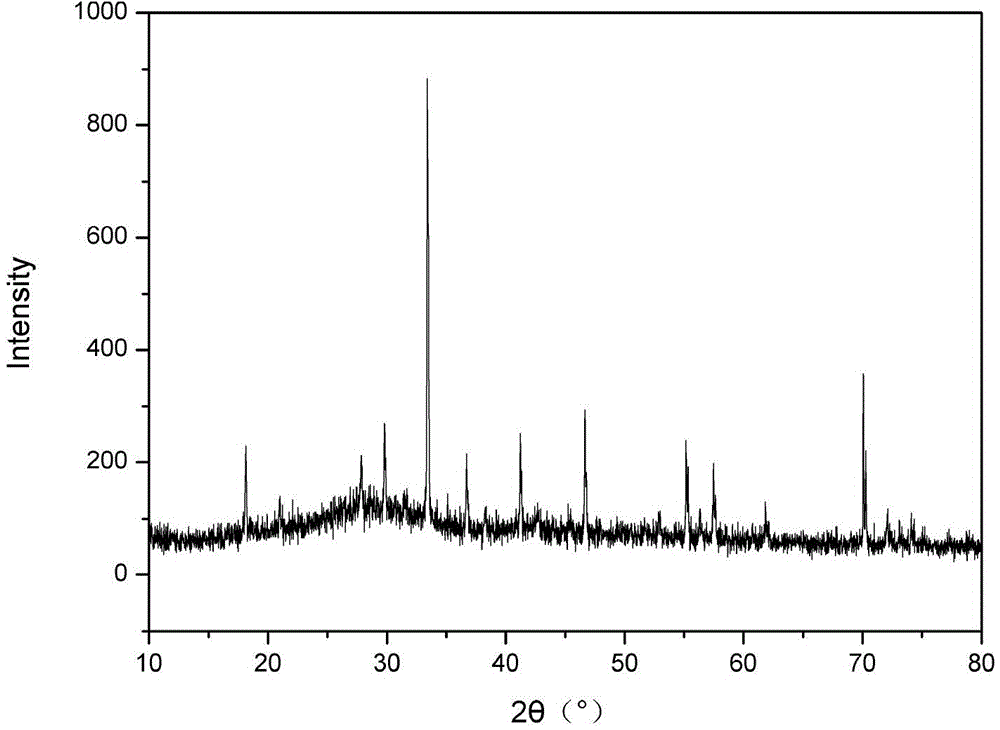

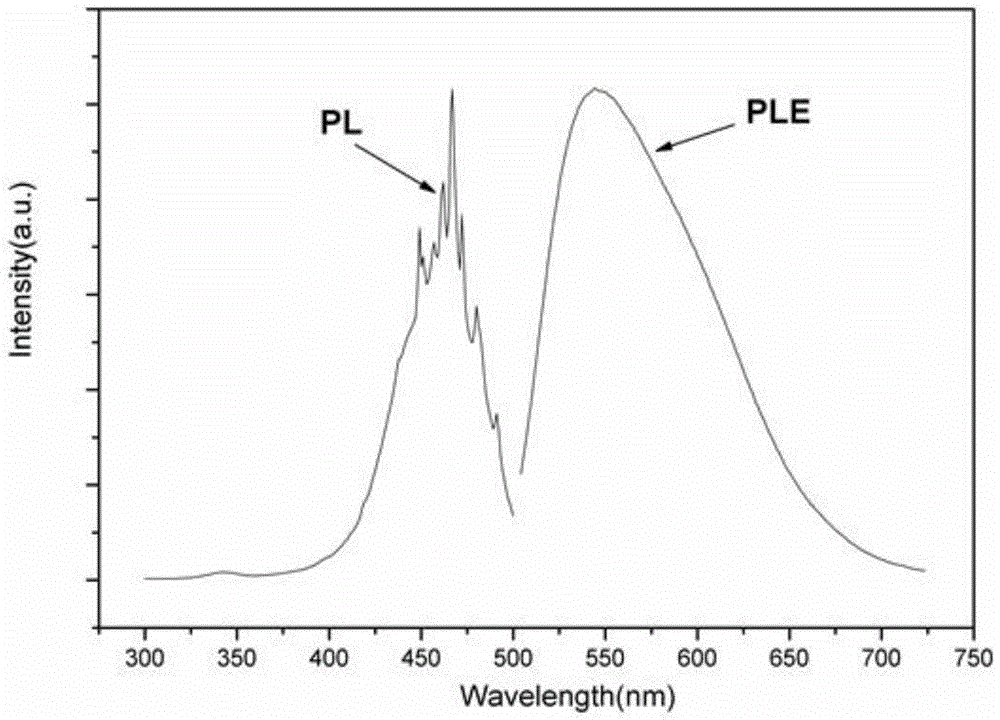

Transparent Ce:YAG microcrystalline glass and application of transparent Ce:YAG microcrystalline glass in white LED

The invention discloses transparent Ce:YAG microcrystalline glass and application of the transparent Ce:YAG microcrystalline glass in a white LED. The microcrystalline glass is self-crystallized, and is prepared from the following active materials in percentage by mole: 19-30mol% of SiO2, 15-30mol% of Al2O3, 5-20mol% of Y2O3, 40-60mol% of PbO, 0.5-5mol% of CeF3 and 2-10mol% of B2O3, wherein the sum of the mole percentage of the components is 100 percent. The Ce:YAG microcrystalline glass disclosed by the invention meets the requirements that the glass melting temperature is low, a preparation method is simple, the raw materials are readily available, the production cycle is short, the batch production is easily realized, and the glass is stable in physicochemical properties, high in uniformity, long in service life and high in heat conductivity; and moreover, the Ce:YAG microcrystalline glass emits bright yellow light under blue light excitation of 465nm, the yellow light and blue light are combined to generate strong white light, and the microcrystalline glass can be used for preparing the white LED.

Owner:WENZHOU UNIVERSITY

Steel wire for aerial cable steel core with spanning degree not smaller than 3500m and production method thereof

InactiveCN103014508AImprove initial strengthReduce harmSuperimposed coating processAerial cableSimple component

The invention discloses a steel wire for an aerial cable steel core with a spanning degree not smaller than 3500m and a production method thereof. The steel wire comprises the following components in percentage by weight in terms of content: 0.79-0.84% of C, 0.70-0.90% of Mn, 0.15-0.30% of Si, not more than 0.01% of P, not more than 0.01% of S, 0.28-0.35% of Cr, and 0.015-0.035% of V. The production method comprises the steps of: selecting a wire rod with the diameter being 9-11mm and the tensile strength not lower than 1180MPa; carrying out acid washing and phosphating treatment on the wire rod; drawing the wire rod; and galvanizing the drawn wire rod to obtain a steel wire for later use. According to the galvanized steel wire with phi being 2.70-4.60mm, produced according to the invention, the wire rod is directly drawn without undergoing lead hardening treatment, so that the pollution to the environment is reduced, thermal treatment procedures such as the lead hardening and the like as well as corresponding equipment maintenance works are reduced; and in addition, under the condition of simple components, the steel wire is at least 1900MPa in tensile strength, at least 1600MPa in 1% elongation stress and at least 20 in torsion number.

Owner:武钢集团有限公司

Copper-steel double-metal composite casting method for plunger pump rotor

InactiveCN107790679AThe joint surface is completeLittle oxidationHot-dipping/immersion processesMachiningTin bronze

The invention discloses a copper-steel double-metal composite casting method for a plunger pump rotor and belongs to the technical field of double-metal casting. The method includes steps of machiningof a steel base body, pretreatment of the steel base body, performing of a heat treatment annealing technology on the steel base body, Ni-Cu-P multi-element nickel plating treatment of the inner surface of the steel base body, flux treatment, preheating of the steel base body, smelting of a lead tin bronze alloy, performing of a hot dipping technology, casting and machining, and the plunger pumprotor is prepared. The performance of the double-metal combined surface obtained in the casting manner reaches the standards, the equipment input is low, the technologies are simple and convenient tooperate, the workpiece cost is reduced, and the method is suitable for wide popularization and application and has the broad prospect. Compared with the powder metallurgy method, the method has the advantages as follows: the performance is more excellent, the heat treatment procedure is omitted, the time is saved, and the cost is reduced.

Owner:安徽恒利增材制造科技有限公司

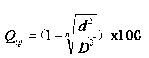

Welding process for rear overhang rack

InactiveCN101293468AEliminate welding residual stressReduce heat treatment processPivoted suspension armsWelding residual stressWeld line

The invention relates to a welding technique of a back suspension fork of an automobile; a reinforced plate is connected with a dragging arm; the invention is characterized in that the head part of a welding line is welded with a smooth arc and then is transited to the bottom side of the dragging arm; the welding technique of the invention has the advantages of removing the heat treatment after the welding and eliminating welding residual stress of the welding joint of the reinforced plate, thereby simplifying the technique during manufacture, being easy to control the quality, improving the fatigue strength of a product and reducing the manufacturing cost.

Owner:SHANGHAI ZHONGLI AUTO PARTS

Chinese toon sauce and preparation method thereof

The invention discloses a Chinese toon sauce and a preparation method thereof. The Chinese toon sauce is prepared from the following raw materials in parts by weight: 10-20 parts of Chinese toon sprouts, 80-90 parts of Chinese toon old leaves, 25-30 parts of peanut oil, 5-7 parts of table salt, 4-8 parts of cane sugar, 0.5-1 part of gourmet powder, 3-6 parts of pepper powder, 2-4 parts of vinegar, 1-2 parts of scallions, 2-4 parts of ginger, and 1-2 parts of garlic. The preparation method comprises the following steps of selecting materials, performing thorough cleaning, performing cutting into sections, performing decoction, performing uniform mixing, performing bottling, performing curing, performing sterilization and performing cooling. According to the Chinese toon sauce and the preparation method thereof disclosed by the invention, the Chinese toon old leaves and the Chinese toon sprouts are in an appropriate compounding ratio, so that the purpose that the old leaves and the sprouts have complementary advantages is realized; the curing process and the sterilizing process of the Chinese toon raw materials are integrated, and the heat treatment working procedure of the Chinese toon is effectively omitted, so that the unique aroma components of the Chinese toon are maintained, and besides, the nutrient loss is reduced; and heat effect is reduced, so that the thermal-sensitive nutrient components of the raw materials and ingredients can also be effectively maintained. The Chinese toon sauce not only is rich in fragrance, but also is complete in shape, moderate in texture and good in appearance.

Owner:XUCHANG UNIV

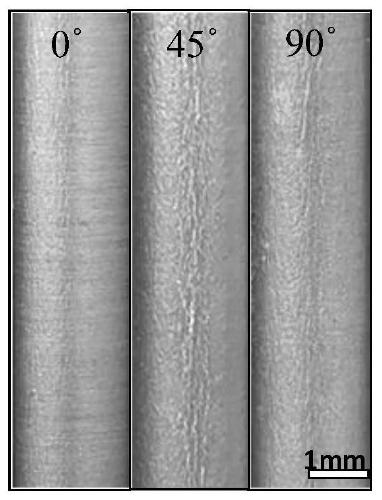

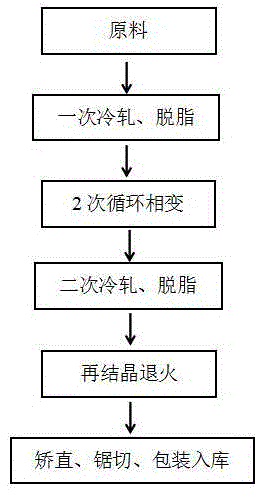

Machining method capable of controlling commercial pure titanium plate cold rolling texture

The invention relates to a machining method capable of controlling commercial pure titanium plate cold rolling texture and belongs to the technical field of preparation of a titanium alloy material. The method is used for weakening or even eliminating anisotropy of cold rolling industrial pure titanium plates. According to the invention, TA1, TA2 titanium plates with thickness of 4-8mm are adopted as raw material, are subjected to treatment including primary cold rolling, degreasing, two times of cyclic phase change, two times of cold rolling, degreasing, annealing and the like, and the obtained thin titanium plate reserves [110] || ND phase change fiber texture subjected to two times of alpha-beta-alpha cyclic phase change, so that the anisotropy of the plate is remarkably weakened or even eliminated. The thin titanium plate prepared by adopting the method overcomes the defect of the prior art that weakening of the anisotropy is not ideal by recrystallization annealing, and a thin titanium plate product is good in surface quality, simple in machining process, low in production cost and suitable for industrial production.

Owner:XIANGTAN UNIV

100 mm-120 mm Q460D extra-thick high-strength steel and preparation method thereof

ActiveCN113249641AReduce production pressureImprove efficiencyFurnace typesHeat treatment furnacesChemical compositionDehydrogenation

The invention relates to 100 mm-120 mm Q460D extra-thick high-strength steel which comprises the following chemical components including, by mass, 0.10% to 0.13% of C, 0.30% to 0.50% of Si, 1.40% to 1.60% of Mn, less than or equal to 0.0070% of P, less than or equal to 0.0020% of S, 0.020% to 0.050% of Nb, 0.008% to 0.020% of Ti, 0.020% to 0.040% of Al, 0.10% to 0.20% of Cu, 0.10% to 0.20% of Cr, 0.10% to 0.20% of Ni and the balance Fe and inevitable impurity elements. The production process flow comprises the following steps of converter smelting, LF refining, RH vacuum degassing, Ca treatment, continuous casting, casting blank dehydrogenation treatment, heating, normalizing rolling, air cooling, steel plate stacking and slow cooling and unstacking. The yield strength of a steel plate ranges from 430 MPa to 470 MPa, the tensile strength ranges from 550 MPa to 570 MPa, the ductility is larger than or equal to 20%, and the Charpy impact energy at the 1 / 4 position and the 1 / 2 position of the thickness of -20 DEG C is larger than or equal to 200 J. The flaw detection result meets the ASTM A 578C level requirement, and the surface of the steel plate has no defect.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

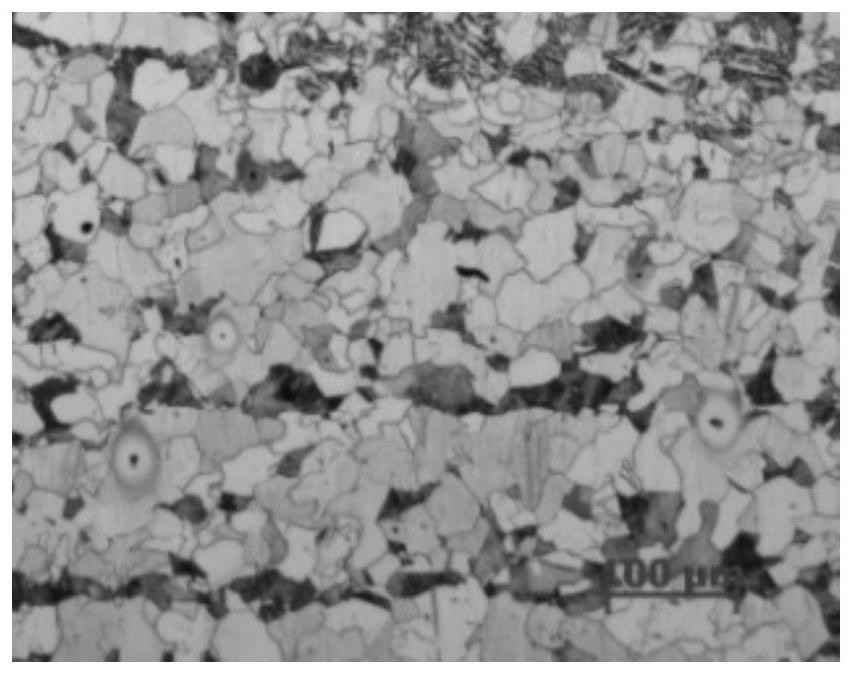

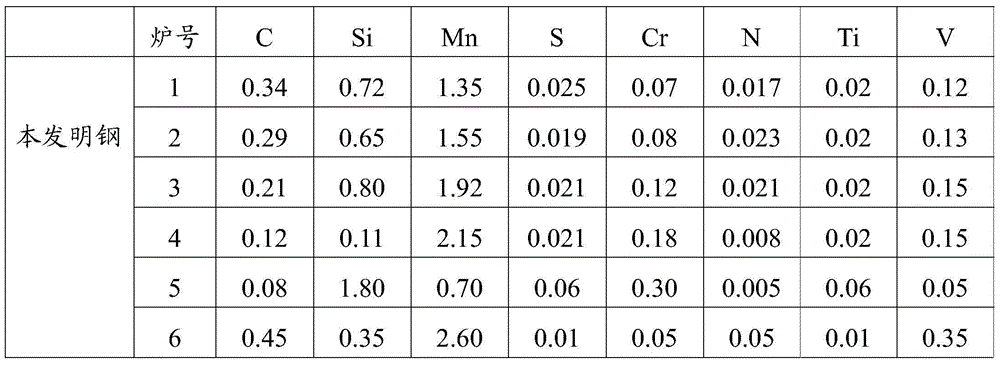

Ball stud steel of automobile steering system and manufacturing method thereof

InactiveCN105821348AGuaranteed mechanical propertiesConforming to cold deformation processCompound (substance)Ultimate tensile strength

The invention relates to ball stud steel of an automobile steering system and a manufacturing method thereof. the steel product contains the following chemical components (by weight): 0.08-0.45% of C, 0.35-1.80% of Si, 0.7-2.6% of Mn, 0.01-0.06% of S, P being less than or equal to 0.025%, 0.05-0.30% of Cr, 0.05-0.35% of V, 0.010-0.060% of Ti, 0.005-0.050% of N and the rest of Fe and unavoidable impurities. The steel has moderate strength, good plasticity and good machinability, and can be used in manufacturing ball studs for an automobile steering system of above 900 MPa. In addition, production technology is simple and environmentally friendly, the hot-rolled steel product requires no annealing or quenching-and-tempering heat treatment, energy conservation and emission reduction can be effectively achieved, and manufacturing cost of workpieces can be reduced.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

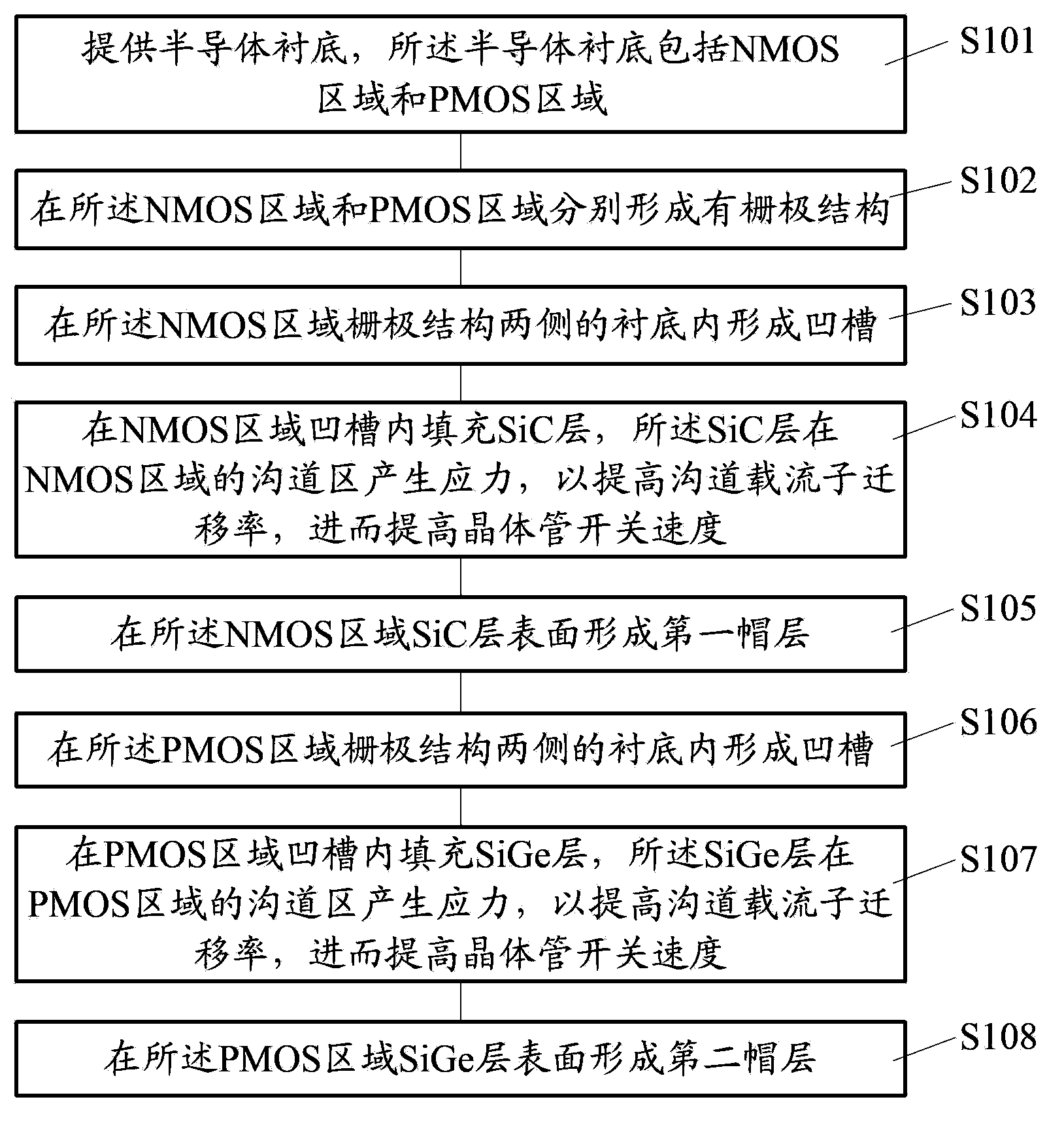

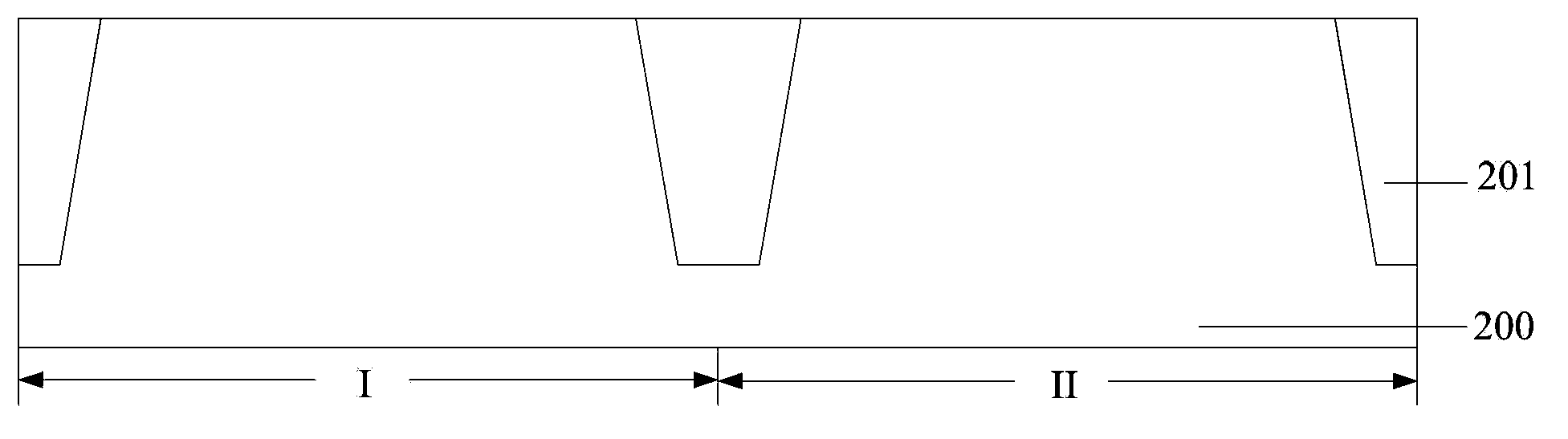

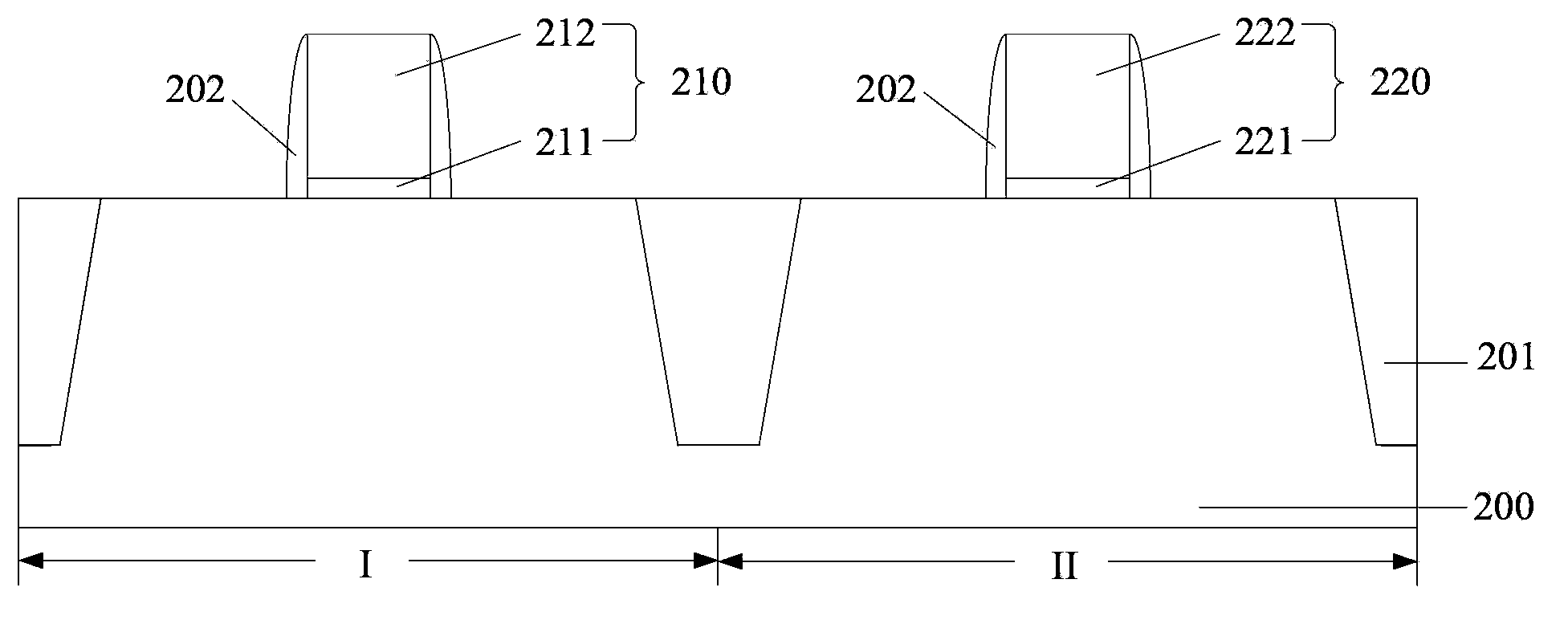

Method for forming CMOS (Complementary Metal-Oxide-Semiconductor) transistor

ActiveCN104253090AReduce heat treatment processPrevent proliferationSemiconductor/solid-state device manufacturingCMOSEngineering

The invention discloses a method for forming a CMOS (Complementary Metal-Oxide-Semiconductor) transistor. The method comprises the following steps: providing a semiconductor substrate; forming gate structures on the first region and the second region of the semiconductor substrate; forming first grooves in the semiconductor substrate on both sides of the gate structure in the first region; filling the first grooves with first stress layers; forming second grooves in the semiconductor substrate on both sides of the gate structure in the second region; filling the second grooves with second stress layers, wherein the stress types of the second stress layers are opposite to those of the first stress layers; and forming first cap layers on the surfaces of the first stress layers, and meanwhile forming second cap layers on the surfaces of the second stress layers. Through adoption of the forming method disclosed by the invention, thermal budget in the forming process of the CMOS transistor is reduced, and the reliability and electrical performance of the CMOS transistor are enhanced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com