Method for producing high-strength titanium alloy seamless tube

A titanium alloy and seamless tube technology, applied in the field of metallurgy, can solve the problems of complex cold-rolled titanium tube process, low yield of hot-rolled titanium tube, and poor internal and external surface quality, so as to save the heat treatment process and have fewer internal and external surface defects , the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

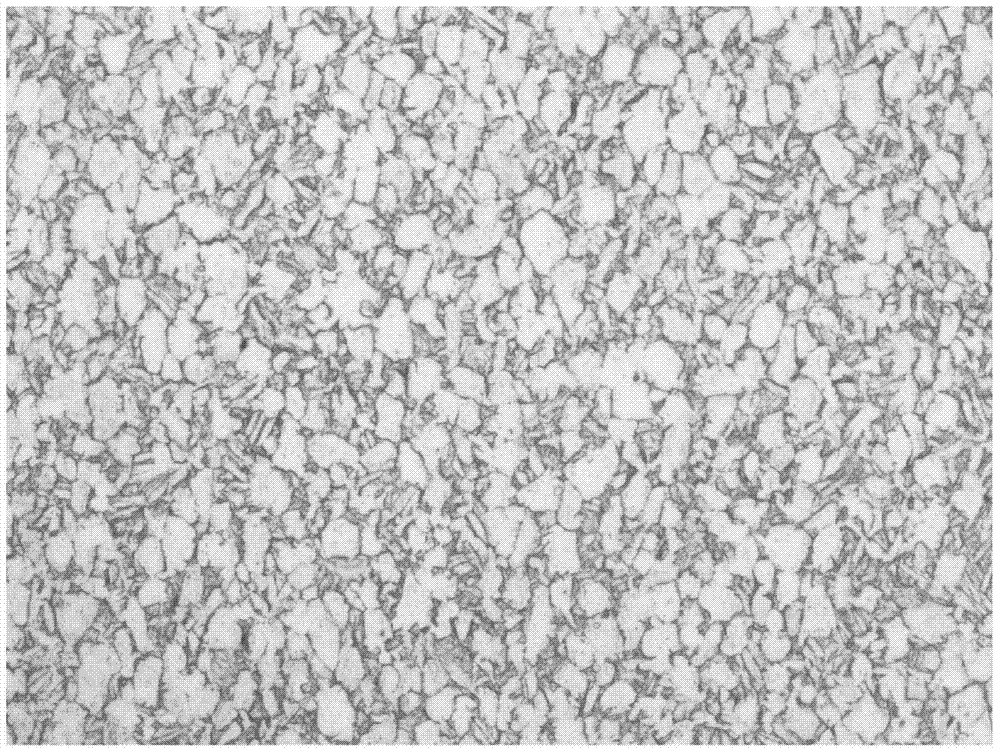

Image

Examples

Embodiment 1

[0039] The production process of 88.9*6.45 TC4 titanium alloy pipe is as follows: forging machine processing φ95 round billet → drilling centering hole → heating in inclined bottom furnace → piercing into 98*7.5 capillary pipe → sizing to 89*7.5 smooth pipe → tape Warm straightening → warm fine drawing to 88.9*6.45 → warm straightening → pickling → finished product.

[0040] The φ95 round billet is heated in an inclined-bottom furnace at 920°C for 2 hours. At this time, the thickness of the air-permeable layer of the round billet is less than 0.25 mm. The capillary temperature after piercing is 1040°C, the temperature before sizing is 810°C~830°C, the temperature after sizing is 770°C~800°C, after fine drawing at 800°C~830°C, it is straightened at 580°C~600°C, pickled Using 8% hydrofluoric acid + 19% nitric acid + water.

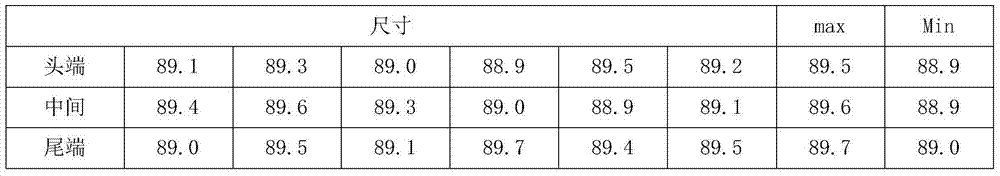

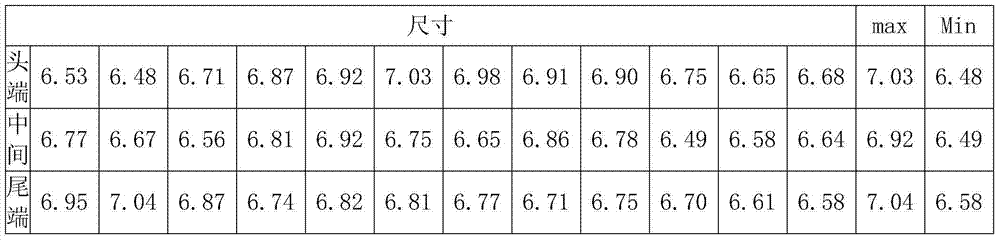

[0041] The outer diameter of the TC4 titanium alloy tube in Example 1 is shown in Table 1.

[0042] The outer diameter size (mm) of the TC4 titanium alloy...

Embodiment 2

[0052] Production of 73*5.51 TC4 titanium alloy tubes, process flow: forging machine processing φ85 round billet → drilling centering hole → heating in inclined bottom furnace → piercing into 87*6.5 capillary tube → sizing to 73*6.5 bare tube → temperature Straightening → fine drawing with temperature to 73*5.51 → straightening with temperature → pickling → finished product.

[0053] The φ85 round billet is heated in an inclined-bottom furnace at 910°C for 100 minutes. At this time, the thickness of the air-permeable layer of the round billet is less than 0.25 mm. The capillary temperature after piercing is 1050°C, the temperature before sizing is 815°C~835°C, the temperature after sizing is 775°C~805°C, after fine drawing at 800°C~830°C, it is straightened at 580°C~600°C, pickled Using 7% hydrofluoric acid + 18% nitric acid + water.

[0054] The outer diameter tolerance of the TC4 titanium alloy tube produced in Example 2 is in the range of 0-+1%, and the wall thickness tole...

Embodiment 3

[0058] Production of 114*6.88 TC4 titanium alloy tubes, process flow: forging machine processing φ115 round billet → drilling centering hole → heating in inclined bottom furnace → piercing into 118*8 capillary tube → sizing to 114*8 bare tube → temperature Straightening → fine drawing with temperature to 114*6.88 → straightening with temperature → pickling → finished product.

[0059] The φ115 round billet is heated in an inclined-bottom furnace at 940°C for 4 hours. At this time, the thickness of the air-permeable layer of the round billet is less than 0.25mm. The capillary temperature after piercing is 1055°C, the temperature before sizing is 820°C~840°C, the temperature after sizing is 780°C~810°C, after fine drawing at 800°C~830°C, it is straightened at 580°C~600°C, pickled Using 8.5% hydrofluoric acid + 20% nitric acid + water.

[0060] The outer diameter tolerance of the TC4 titanium alloy tube produced in Example 3 is in the range of 0-+1%, and the wall thickness toler...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com