Steel wire for aerial cable steel core with spanning degree not smaller than 3500m and production method thereof

A technology for overhead cables and steel cores, applied in the field of steel wires for steel cores of ultra-high-strength overhead cables, which can solve the problems of steel toughness damage, work hardening with V content, etc., and achieve the goal of reducing damage, reducing pollution, and reducing heat treatment processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Production of G4A 7 / 3.60 (1×7-10.08mm) galvanized steel strand:

[0030] The composition and weight percentage of the produced wire rod are C: 0.80%, Si: 0.22%, Mn: 0.75%, Cr: 0.35%, V: 0.035%, S: 0.01%, P: 0.0098%, and the rest is Fe and unavoidable impurities;

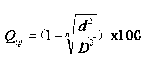

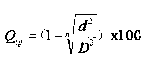

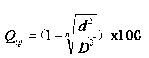

[0031] The diameter D of the wire rod is 11mm, the initial tensile strength is 1195MPa, the reduction of area is 34%, the grain size is 8 grades, the sorbite content is 90%, the diameter d of the steel wire is 3.60mm, and the steel wire is galvanized. The speed v is 36m / min, and the number of pressing passes n is 10 times.

[0032] Its production steps:

[0033] 1) Produce a wire rod with a diameter D of 11.0mm and an initial tensile strength of 1195MPa;

[0034] 2) Carry out conventional pickling and phosphating treatment, and the phosphating film layer on the surface of the wire rod after phosphating treatment is uniform;

[0035] 3) Pulling, the number of drawing passes n is 10 times, the ave...

Embodiment 2

[0041] Embodiment 2: Production of G4A φ3.60mm galvanized steel wire:

[0042] The composition and weight percentage of the produced wire rod are C: 0.81%, Si: 0.24%, Mn: 0.82%, Cr: 0.30%, V: 0.030%, S: 0.008%, P: 0.009%, and the rest is Fe and unavoidable impurities;

[0043] The diameter D of the wire rod is 10.0mm, the initial tensile strength is 1205MPa, the reduction of area is 32%, the grain size is 8 grades, the sorbite content is 90%, the diameter d of the steel wire is 3.60mm, and the steel wire is galvanized. The running speed v is 36m / min, and the number of pressing passes n is 9 times.

[0044] Its production steps:

[0045] 1) Produce a wire rod with a diameter D of 10.0mm and an initial tensile strength of 1205MPa;

[0046] 2) Carry out conventional pickling and phosphating treatment, and the phosphating film layer on the surface of the wire rod after phosphating treatment is uniform;

[0047] 3) Pulling, the number of drawing passes n is 9 times, the average...

Embodiment 3

[0052] Example 3: Production of G4A 37 / 3.14 (1×37-22mm) galvanized steel strand:

[0053] The composition and weight percentage of the produced wire rod are C: 0.81%, Si: 0.25%, Mn: 0.80%, Cr: 0.32%, V: 0.025, S: 0.00951%, P: 0.0097%, and the rest are Fe and unavoidable impurities;

[0054] The diameter D of the wire rod is 10.0mm, the initial tensile strength is 1200MPa, the reduction of area is 33%, the grain size is 8 grades, the sorbite content is 90%, the diameter d of the steel wire is 3.14mm, and the steel wire is galvanized. The running speed v is 38m / min, and the number of pressing passes n is 10 times.

[0055] Its production steps:

[0056] 1) Produce a wire rod with a diameter of 10.0mm and an initial tensile strength of 1200MPa;

[0057] 2) Carry out conventional pickling and phosphating treatment, and the phosphating film layer on the surface of the wire rod after phosphating treatment is uniform;

[0058] 3) Drawing is carried out, the drawing pass n is 10 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com