Method for manufacturing low-carbon 9Ni steel thick plate

A manufacturing method and post-rolling technology, applied in the field of steel rolling process, can solve the problems of not realizing localization, not finding the patent authorization of 9Ni steel wide and thick plate production technology and material design, etc., so as to shorten the heat treatment process, improve the low temperature toughness and Other mechanical properties, without loss of material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

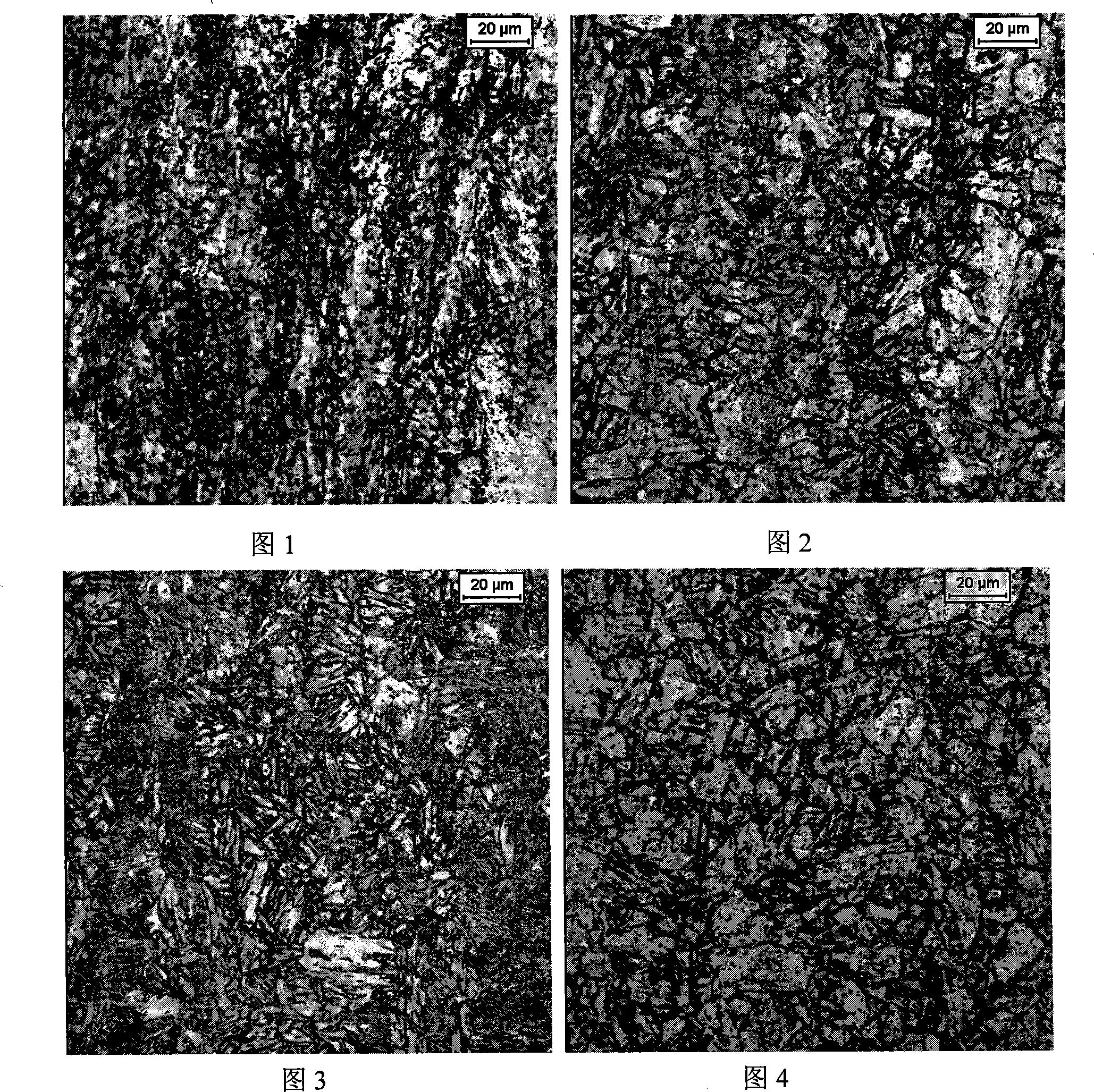

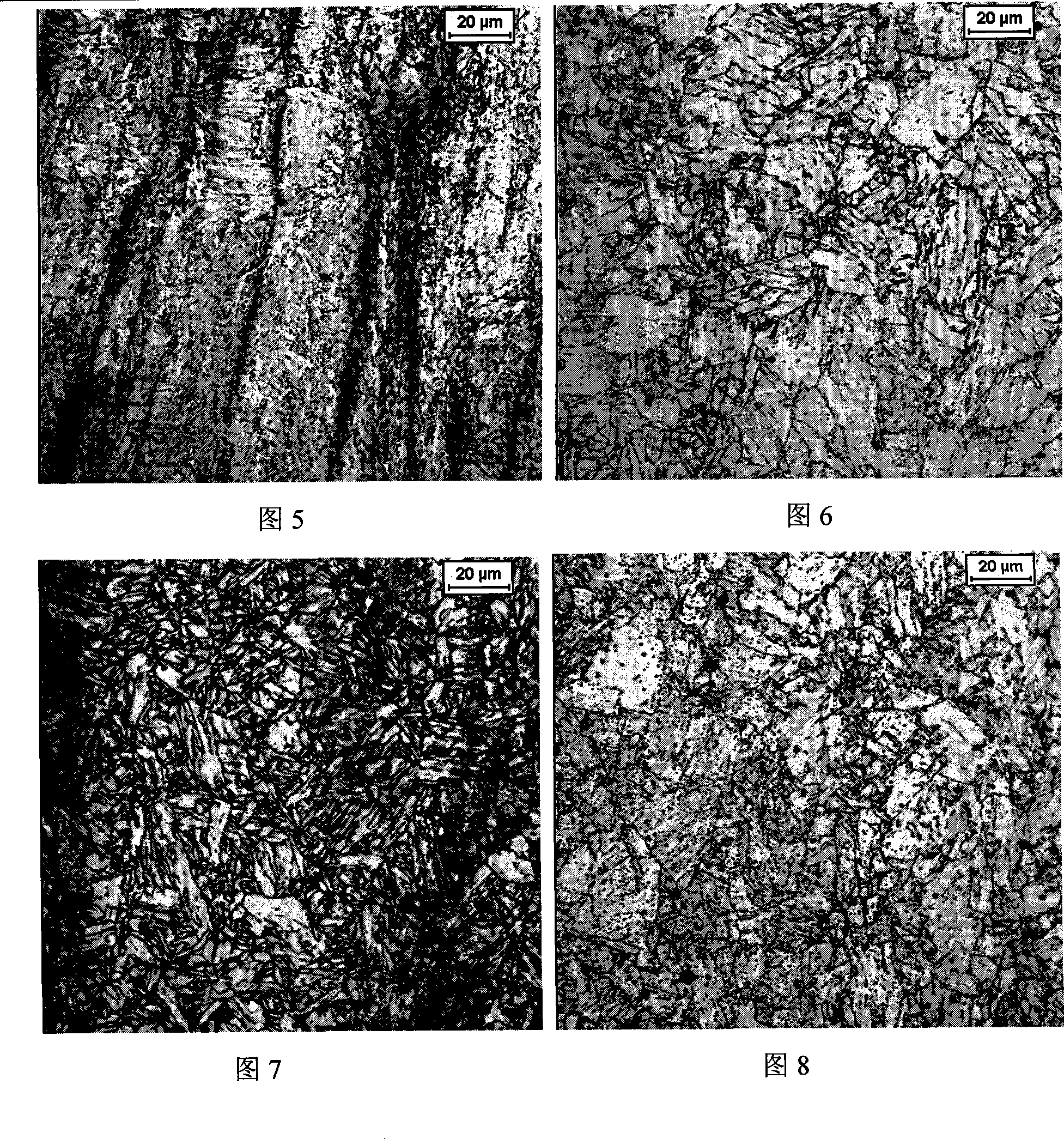

Image

Examples

example 1

[0026] The design composition of 9Ni steel by weight percentage is: C 0.021%, Si 0.247%, Mn0.62%, S0.002%, P0.01%, Ni8.97%, and the balance is Fe and impurities.

[0027] The production process includes steelmaking, red delivery, hot charging, hot rolling, and on-line heat treatment, specifically:

[0028] Use a 50Kg vacuum induction furnace to make steel, and pour it into a pouring system composed of two refractory molds with an inner cavity of 100×100×170mm. After calming down for 5 minutes, the steel is sent to a heating furnace with a temperature of 1200°C. After the temperature is uniform , Immediately smash the mold and take out the steel ingot for hot rolling. Roll from a thickness of 100mm to a finished product with a thickness of 16mm. Rough rolling is carried out in austenite complete recrystallization rolling. The starting temperature of rolling is controlled at 1090°C, and the finishing temperature of rough rolling is 1050°C. system, the starting rolling temperatu...

example 2

[0033] The design composition of 9Ni steel by weight percentage is: C 0.037%, Si 0.28%, Mn 0.67%, S 0.002%, P 0.01%, Ni 9.01%, and the balance is Fe and impurities.

[0034] The production process includes steelmaking, red delivery, hot charging, hot rolling, and on-line heat treatment, specifically:

[0035] Use a 50Kg vacuum induction furnace to make steel, and pour it into a pouring system composed of two refractory molds with an inner cavity of 100×100×170mm. After calming down for 5 minutes, the steel is sent to a heating furnace with a temperature of 1200°C. After the temperature is uniform , Immediately smash the mold and take out the steel ingot for hot rolling. Roll the rough billet with a thickness of 100mm into a finished product with a thickness of 16mm. Rough rolling is carried out in austenite complete recrystallization rolling. For rolling in the recrystallization zone, the starting rolling temperature is controlled at 760°C, and the final rolling temperature i...

example 3

[0039] The design composition of 9Ni steel by weight percentage is: C 0.025%, Si 0.246%, Mn0.429%, S0.003%, P0.01%, Ni9.3%, and the balance is Fe and impurities.

[0040] The production process includes steelmaking, red delivery, hot charging, hot rolling, and on-line heat treatment, specifically:

[0041] Use a 50Kg vacuum induction furnace to make steel, and pour it into a pouring system composed of two refractory molds with an inner cavity of 100×100×170mm. After calming down for 5 minutes, the steel is sent to a heating furnace with a temperature of 1200°C. After the temperature is uniform , Immediately smash the mold and take out the steel ingot for hot rolling. Roll from a rough billet with a thickness of 100mm to a finished product with a thickness of 16mm. Rough rolling is carried out in austenite complete recrystallization rolling. For rolling in the recrystallization zone, the starting rolling temperature is controlled at 780°C, and the final rolling temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com