Prestressed quench hardening and grinding composite processing method

A compound processing and prestressing technology, which is applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the problems of large residual tensile stress on the surface of the workpiece, the decline of the surface quality of the part, the increase of equipment, personnel, and venues, etc., to achieve Improve resource utilization and labor productivity, reduce workpiece deformation, and reduce the effect of heat treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] A prestressed hardened grinding compound processing method, comprising the steps of:

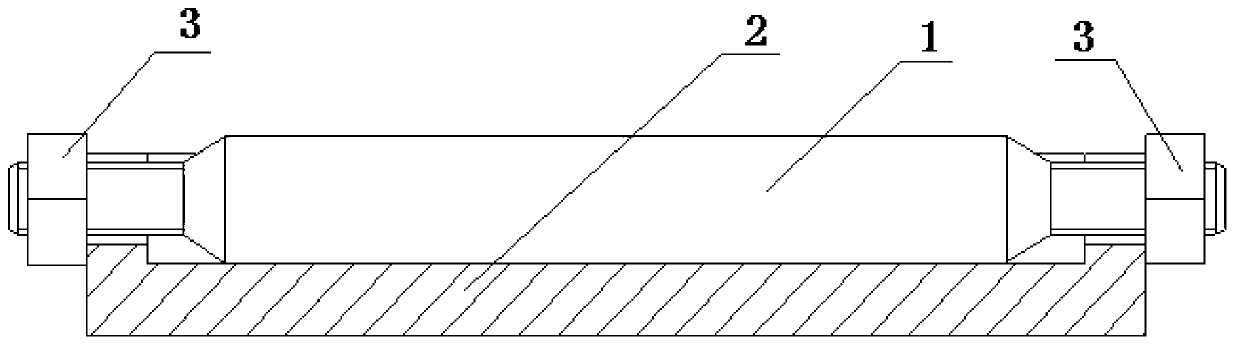

[0023] Step 1: Install the workpiece 1 to be ground into the prestress loading device 2, and when the workpiece 1 is installed in place, apply pre-tension stress to the workpiece 1, and the two form an assembly at this time;

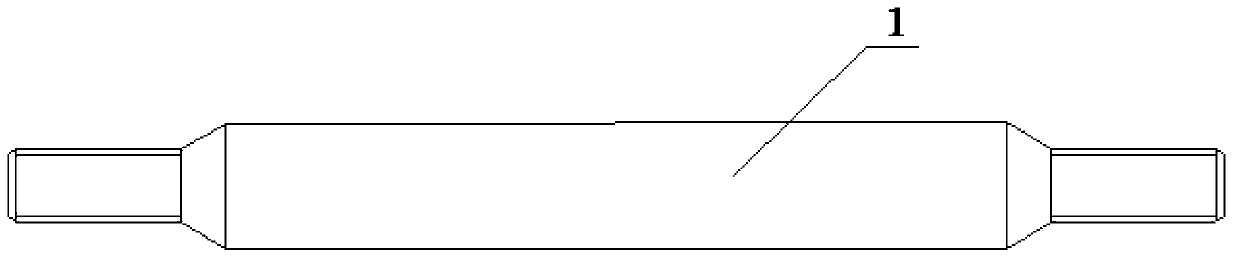

[0024] In this embodiment, workpiece 1 is as figure 2 As shown, its size is 140mm×9mm×14mm, of which the grinding section is 90mm, and M8 threads are processed at both ends of the workpiece 1, the thread length is 20mm, and the length of the thread and the grinding section is 5mm. Gradual transition connection, the material of workpiece 1 is 45# steel;

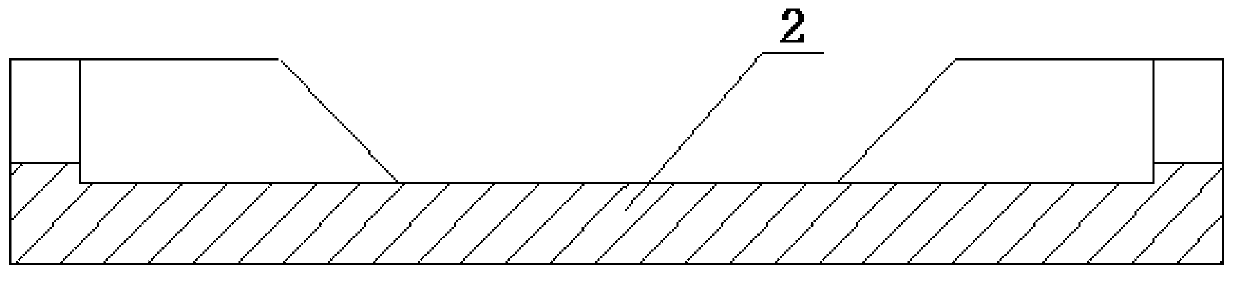

[0025] Such as image 3 The prestress loading device 2 shown has a size of 122mm×32mm×20mm, and the width of the place where the workpiece 1 is placed is 10mm. Suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com