Adiabatic methanation process and device for preparing synthetic natural gas

A technology for synthesizing natural gas and methanation, applied in the field of adiabatic methanation processes and devices, can solve the problems of decreased heat utilization efficiency, harsh operating conditions, and reduced high-grade heat recovery, so as to reduce purification investment and operating costs, and avoid metal powder. The effect of reducing corrosion and improving the quality of synthetic natural gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

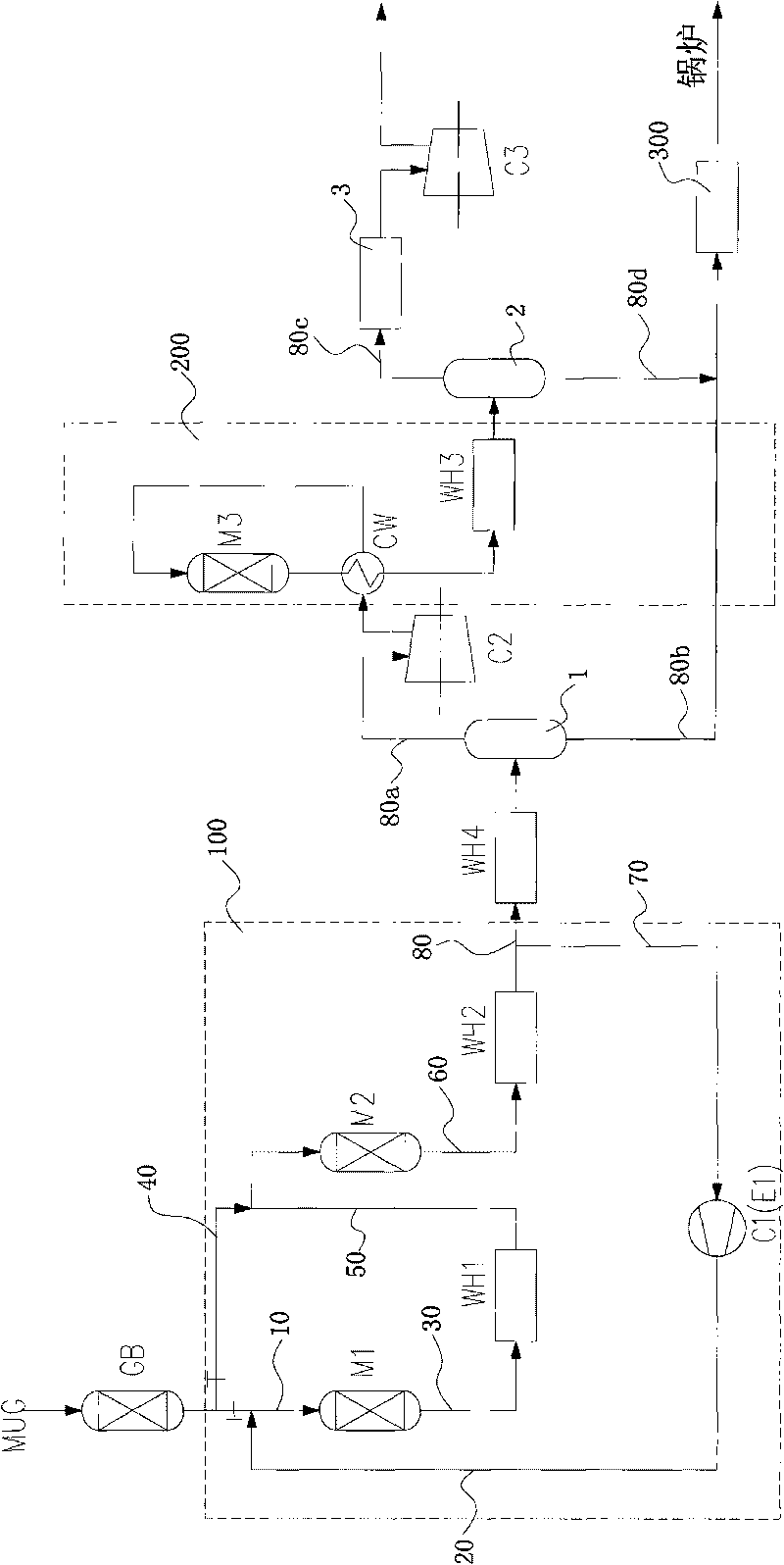

Embodiment 1

[0075] see figure 1 , an adiabatic methanation unit for producing synthetic natural gas, including a guard bed GB, a methanation unit 100 , a methanation refining unit 200 , a methanation heat recovery steam generation unit, and a condensate treatment unit 300 . The methanation unit includes the first adiabatic methanation reactor M1, the first adiabatic methanation reactor M2, the first heat recovery system WH1, the second heat recovery system WH2, the first cycle compressor C1; the methanation heat recovery steam production unit It includes the fourth heat recovery system WH4, the first gas-liquid separation tank 1, the second cycle compressor C2, the condenser CW, the second gas-liquid separation tank 2, the dryer 3, and the third cycle compressor C3. The methanation refining unit 200 includes a third adiabatic methanation reactor M3 and a third heat recovery system WH3.

[0076] The crude gas is regulated by transformation (H 2 -CO 2) / (CO+CO 2 ) is slightly greater tha...

Embodiment 2

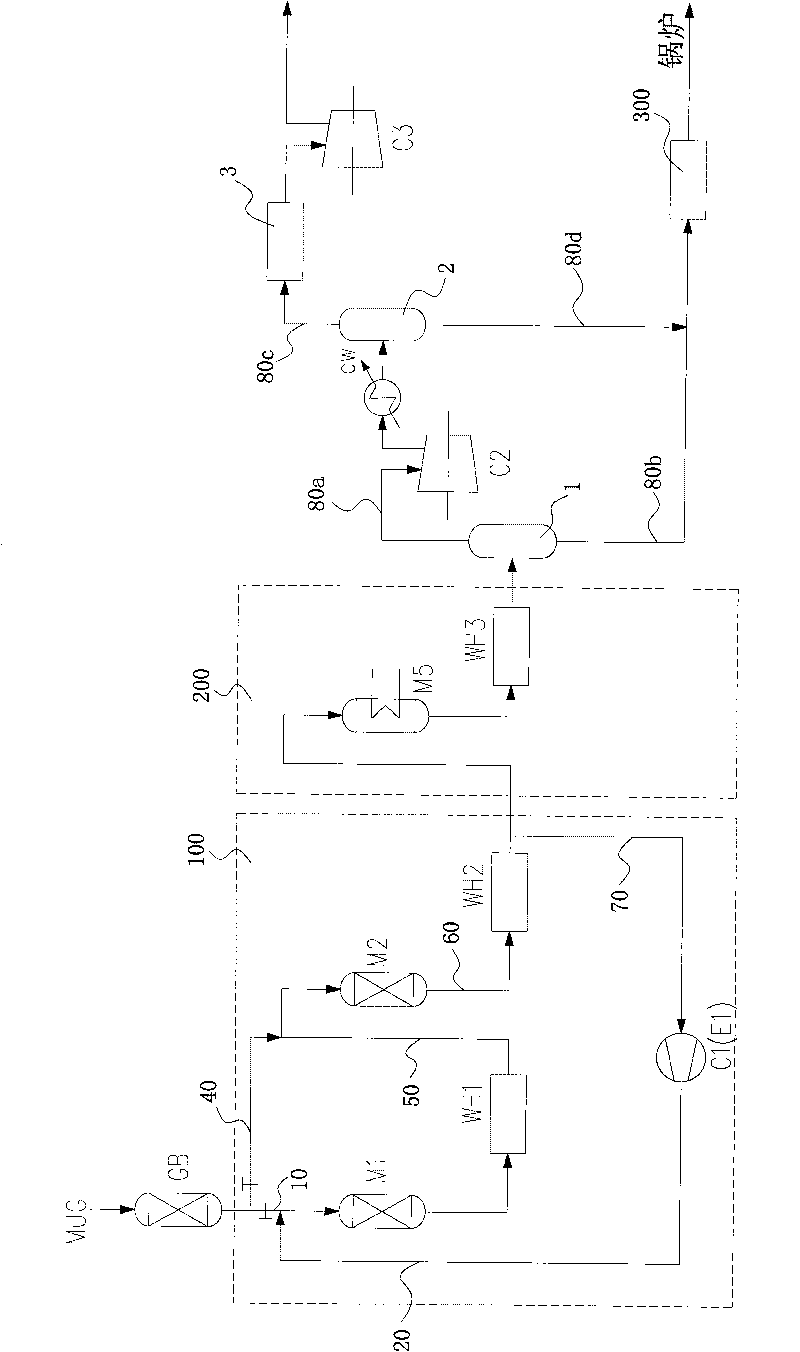

[0087] see figure 2 , an adiabatic methanation unit for producing synthetic natural gas, including a guard bed GB, a methanation unit 100 , a methanation refining unit 200 , a methanation heat recovery steam generation unit and a condensate treatment unit 300 . The methanation unit includes the first adiabatic methanation reactor M1, the first adiabatic methanation reactor M2, the first heat recovery system WH1, the second heat recovery system WH2, the first cycle compressor C1; the methanation heat recovery steam production unit It includes a first gas-liquid separation tank 1, a second circulation compressor C2, a condenser CW, a second gas-liquid separation tank 2, a dryer 3, and a third circulation compressor C3. The methanation refining unit 200 includes an isothermal methanation reactor M5 and a third heat recovery system WH3.

[0088] The fresh synthesis gas coming out of the outlet of the guard bed GB is divided into two paths, the first part of the fresh synthesis g...

Embodiment 3

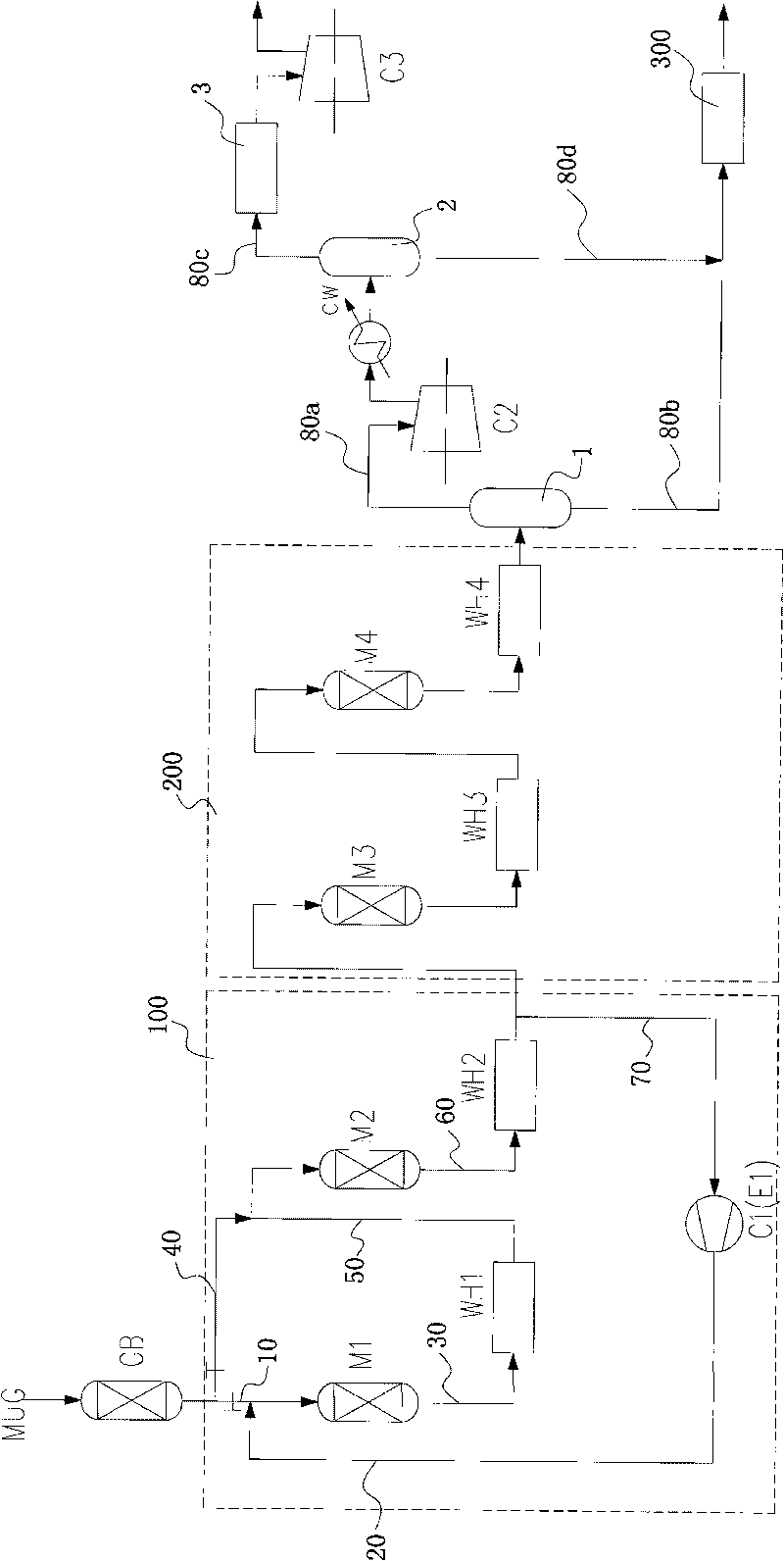

[0098] see image 3 , an adiabatic methanation unit for producing synthetic natural gas, including a guard bed GB, a methanation unit 100, a methanation refining unit 200, a methanation heat recovery steam generation unit, and a condensate treatment unit 300. The methanation unit includes a first adiabatic methanation unit Reactor M1, the first adiabatic methanation reactor M2, the first heat recovery system WH1, the second heat recovery system WH2, the first cycle compressor C1; the methanation heat recovery steam production device includes the first gas-liquid separation tank 1, Second cycle compressor C2, condenser CW, second gas-liquid separation tank 2, drier 3, third cycle compressor C3. The methanation refining unit 200 includes a third adiabatic methanation reactor M3, a fourth adiabatic methanation reactor Reactor M4, third heat recovery unit WH3, fourth heat recovery unit WH4.

[0099] The fresh synthesis gas coming out of the outlet of the guard bed GB is divided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com