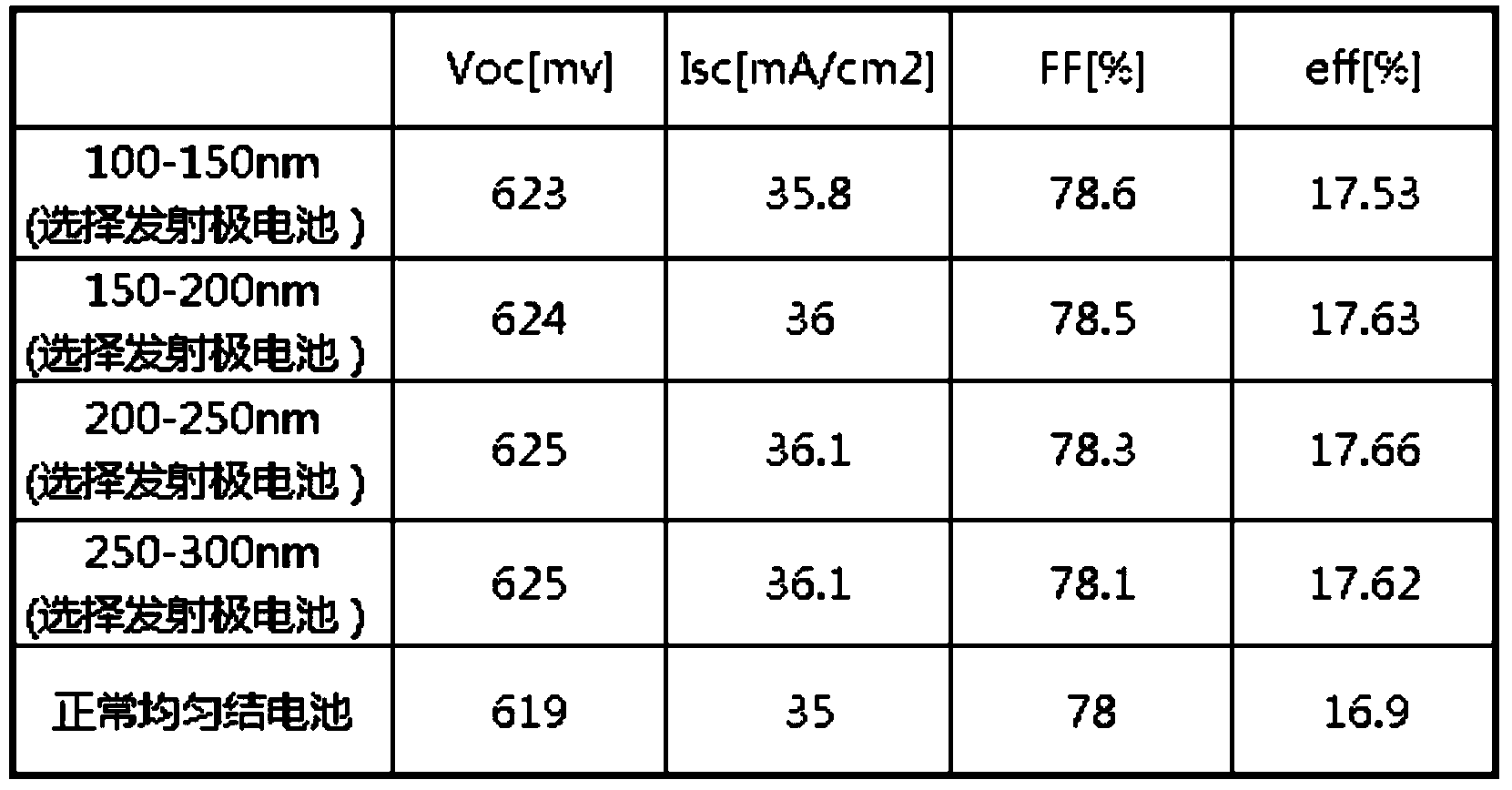

Preparation method for polycrystal/monocrystal-like solar cell selective emitting electrode structure

A solar cell and monocrystalline silicon-like technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as complex process steps, high cost, internal damage to silicon wafers, and large energy consumption, and achieve simplified process paths and conversion High efficiency, reducing the effect of high temperature treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Step 1: the removal of the surface energy damage layer, the step is to put the polysilicon wafer in a sodium hydroxide solution with a mass concentration of 20% at 85-90 ° C for 80-100 seconds, and then wash it by bubbling in deionized water for 200 seconds, and then Heat and wash in 1# and 2# cleaning solution for 360s respectively. Or other conventional corrosion and cleaning methods are also available.

[0012] Step 2: The heavy doping step is to use the conventional tubular diffusion method on the cleaned and dried silicon wafer at a temperature of 850-950°C, using phosphorus oxychloride as the phosphorus diffusion source, and simultaneously injecting a volume ratio of 14:1 nitrogen and oxygen mixed gas, the diffusion time is 10-30min, the diffusion resistance is 10-30Ω / □, and then soaked in HF acid solution with 1-5% mass concentration at room temperature for 20-200s to remove silicon Surface PSG.

[0013] Step 3: growing or forming a dielectric layer or a mask l...

Embodiment 2

[0021] Step 1 and Step 2 are the same as above.

[0022] Step 3: said growing or forming a dielectric layer or a mask layer on the surface of the silicon wafer, such as using MOCVD to deposit a ZnO film, the step is to deposit a 50-300nm thick ZnO film on the surface of the silicon wafer by metal organic chemical vapor deposition. The zinc-containing DPM complex Zn(DPM)2 was used as the precursor of zinc, and the deposition time was 15-100min in the pressure range of 10-50 Torr and the temperature range of 400-600 °C.

[0023] Step 4: The step of retaining the mask layer under the electrode grid line area by the screen printing slurry etching method is: using screen printing to print a layer of corrosive slurry with a concentration of 10-25% ammonium bifluoride on the ZnO thin layer, Stand still for 400-1000s, so that the slurry fully etches away the ZnO thin layer in the non-electrode grid line area, and keep the ZnO under the electrode grid line area as a mask layer.

[002...

Embodiment 3

[0027] Step 1 and Step 2 are the same as above.

[0028] Step 3: growing or forming a dielectric layer or a mask layer on the surface of the silicon wafer, such as growing a SiNx mask layer on the surface of the silicon wafer by using PECVD technology, the step is to grow a 200-300nm SiNx mask layer on the surface of the silicon wafer by using PECVD technology film layer. SiH 4 The flow rate is 600-700sccm, NH 3 The flow rate is 1400-1500sccm, the working pressure is 0.1-0.3mbar, the process temperature is 300-500℃, the discharge frequency is 2450MHz, the discharge power is 2000-3500w, and the discharge time is 450-900s.

[0029] Step 4: Using inkjet printing technology, spray corrosive slurry with a concentration of 10-25% ammonium bifluoride on the non-electrode grid line area, and let it stand for 500-1200s, so that the slurry can fully corrode the SiNx thin film in the non-electrode grid line area. Layer, keep the SiNx under the electrode grid line area as a mask layer;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com