Smelting equipment and smelting method

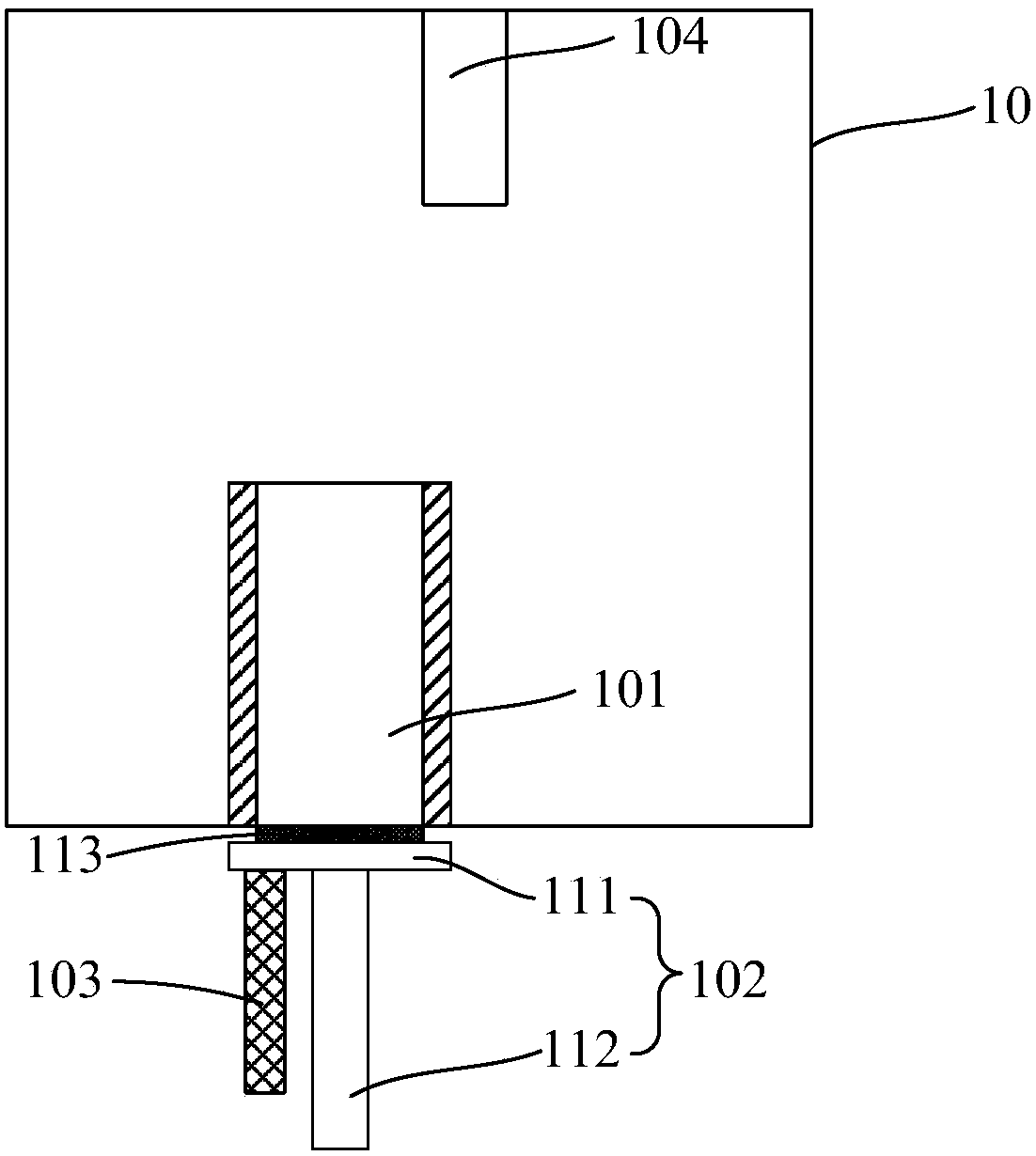

A smelting equipment and smelting furnace technology, which is applied in lighting and heating equipment, crucible furnaces, furnaces, etc., to reduce production costs, simplify metal grain refinement procedures, and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

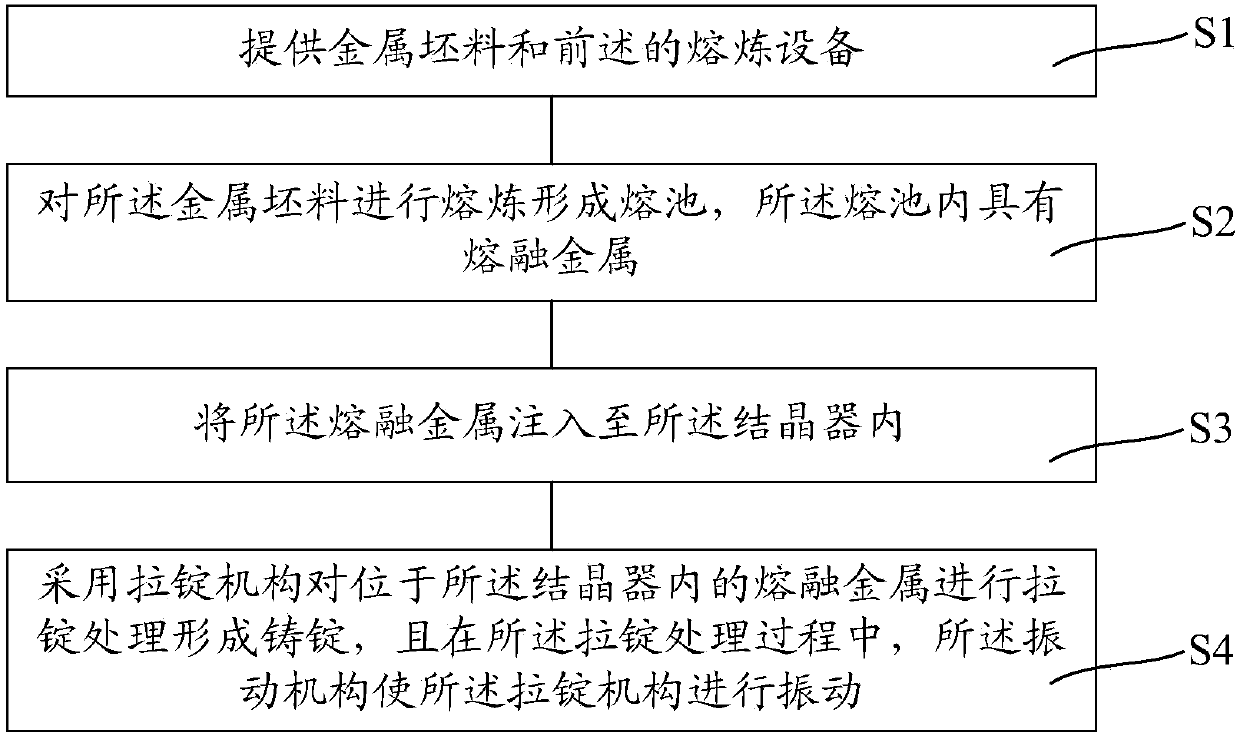

Method used

Image

Examples

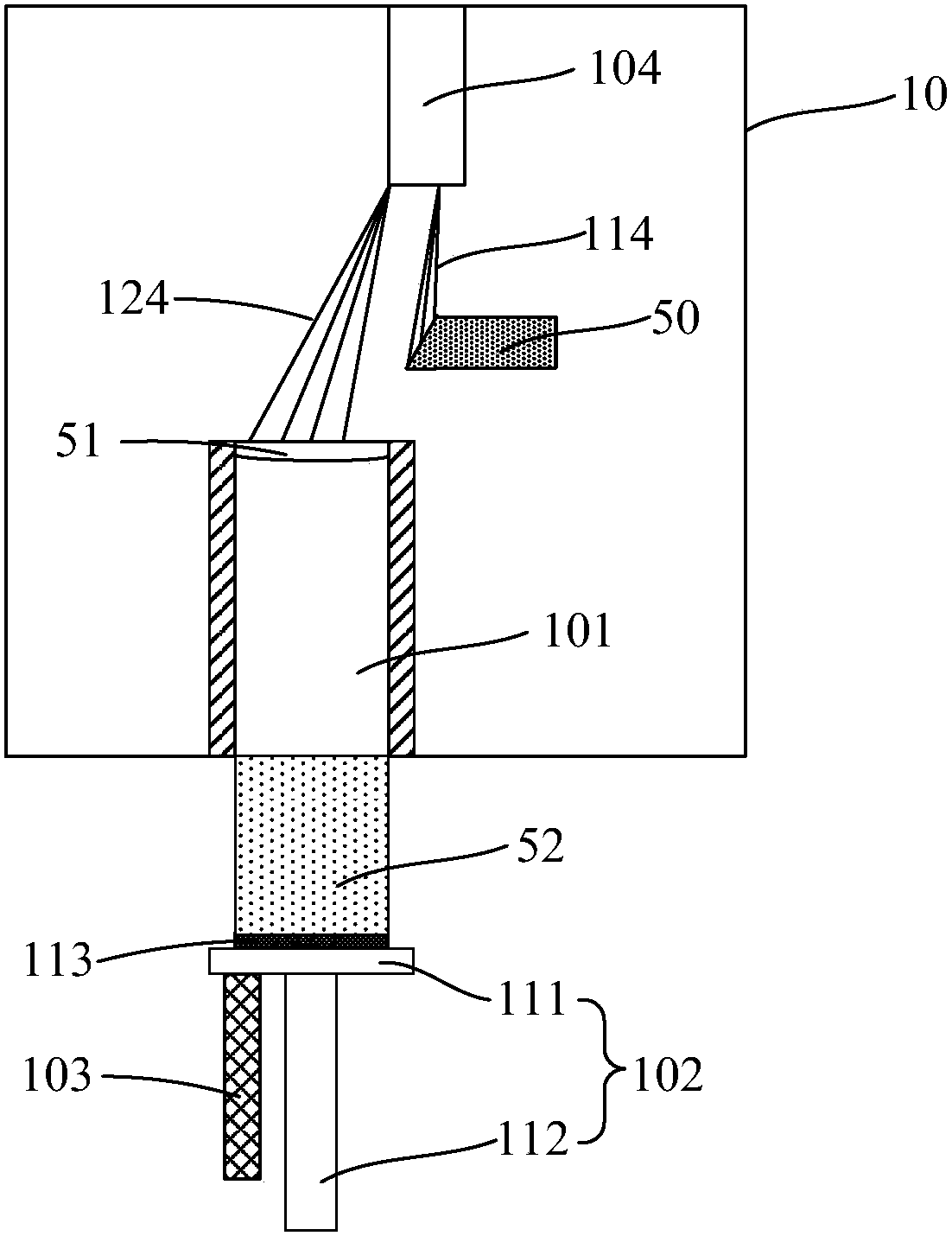

Embodiment Construction

[0033] According to the background technology, the quality of the ingot produced by smelting in the prior art needs to be further improved.

[0034] The crystal grains of the ingot produced by smelting in the prior art are relatively coarse, so that the strength, hardness, toughness and plasticity of the ingot need to be further improved.

[0035] After analysis, metals are usually polycrystals composed of many crystal grains. The grain size can be characterized by the number of crystal grains per unit volume. In a certain volume of crystals, the more grains there are, the finer the metal grains will be. Generally speaking, the finer the grain of the metal part, the better the plasticity and toughness of the metal.

[0036] The method of improving the mechanical properties of metal materials by refining grains is called fine grain strengthening. Generally, the fine-grain strengthening method of an ingot is that after the ingot is produced by smelting, the ingot is subjected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com