High-toughness quantitative-reduction ship plate marine steel and preparation method thereof

A high-toughness, industrial steel technology, applied in the steel field, can solve the problems of limited production specifications, limited production thickness specifications, and difficult production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

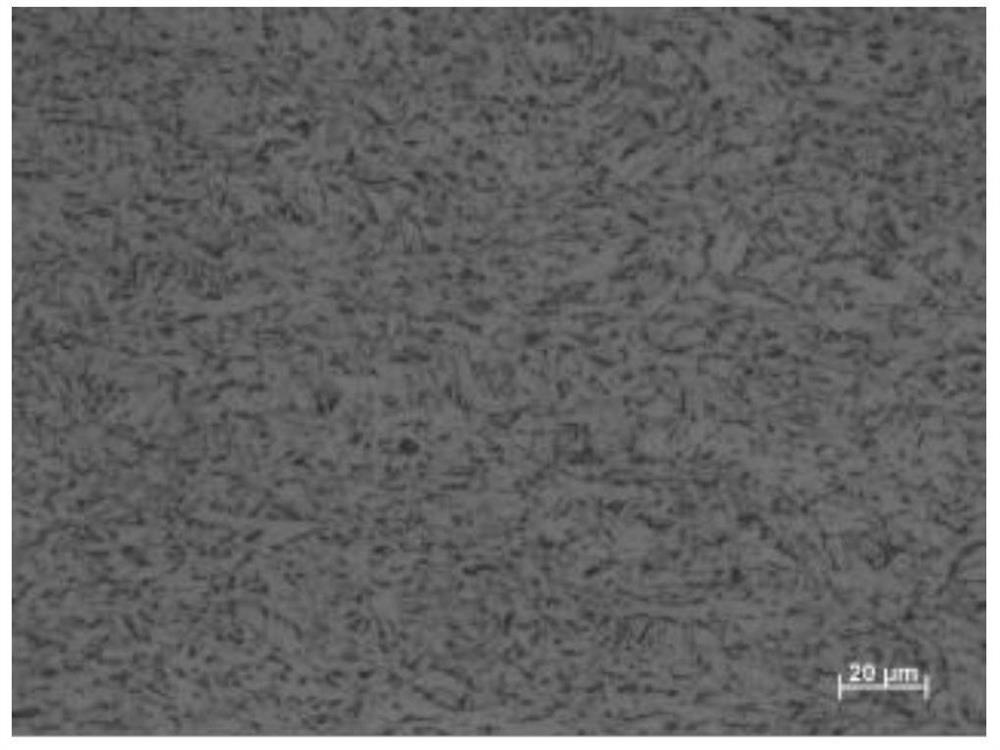

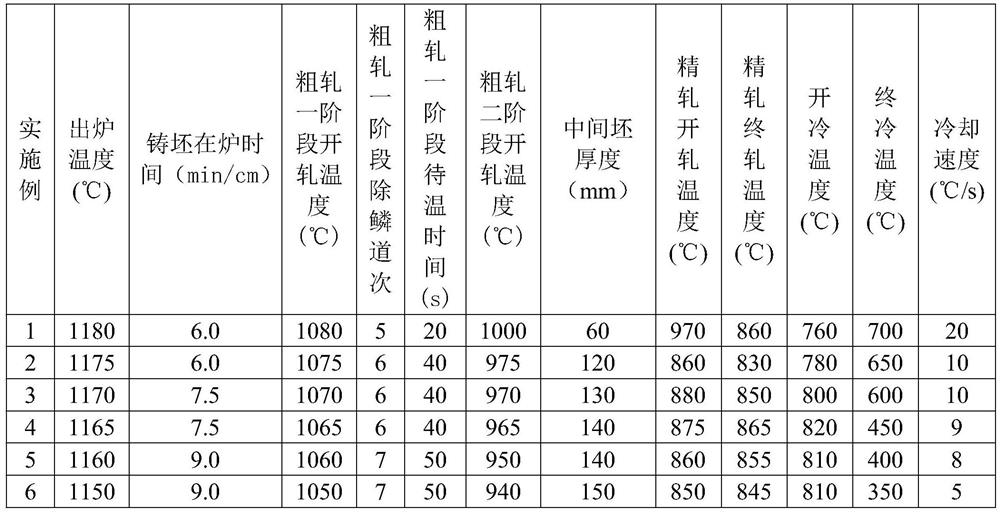

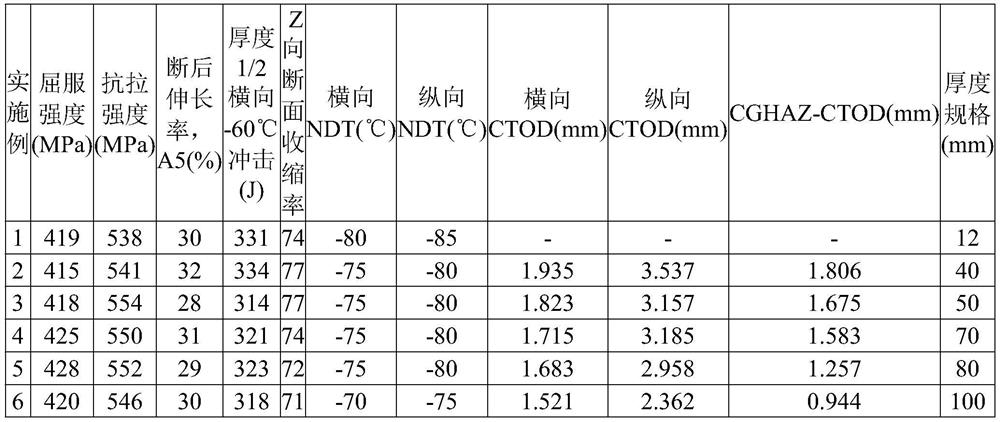

[0052] The chemical composition of the high-toughness reduction ship plate marine steel involved in the present invention is smelted in a converter according to the chemical composition shown in Table 1 and poured into a continuous casting slab or ingot, and the continuous casting slab or ingot is opened in the heating furnace Medium heating, rolling by medium and heavy plate rolling mill. See Table 2 for main process parameters such as slab discharge temperature, final rolling temperature, and final cooling temperature. The corresponding steel plate tensile strength, impact energy, crack arrest performance, thickness specifications, etc. are listed in Table 3, it can be seen that the steel of the present invention has excellent strength and toughness, and excellent crack arrest performance. figure 1 The microstructure photos of the steel of Example 6 are shown, showing that the microstructures are polygonal ferrite, acicular ferrite and fine pearlite.

[0053] Table 1 below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com