Preparation method for high-toughness 3.5Ni steel plate

A high-toughness, steel plate technology, applied in the field of alloy steel manufacturing, can solve the problem of high impact test temperature, achieve the effect of improving low-temperature toughness and strength, reducing production costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

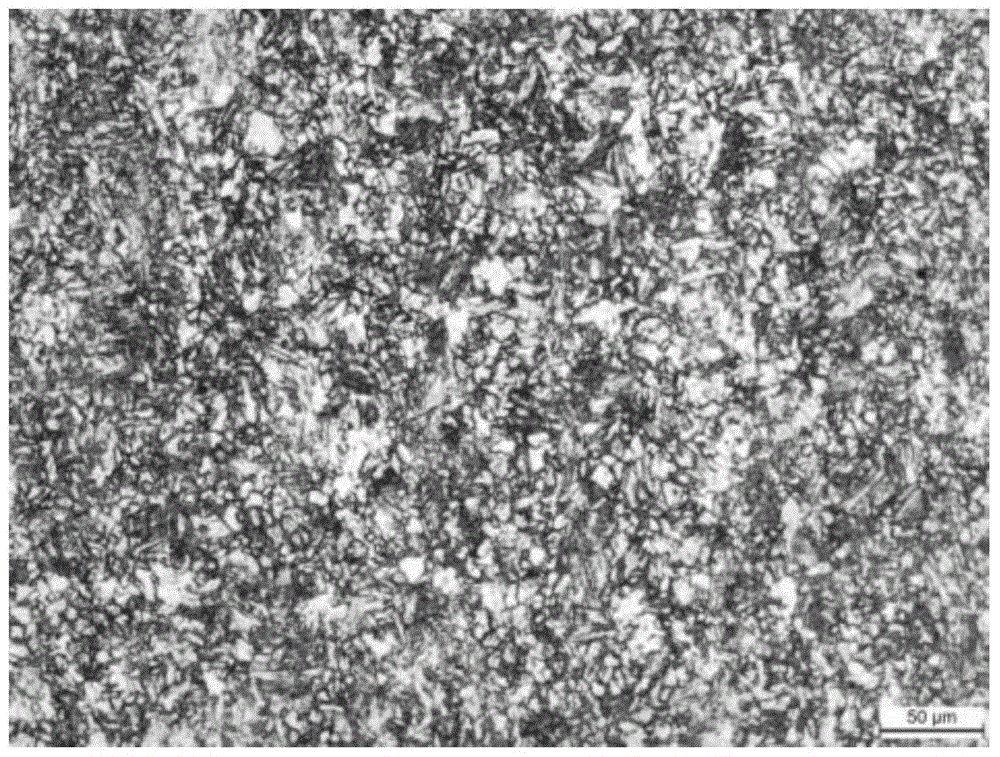

Embodiment 1

[0025] The composition of 3.5Ni steel by weight percentage is: C0.065%, Si0.21%, Mn0.62%, S0.002%, P0.005%, Ni3.72%, Al0.031%, and the balance is Fe and impurities;

[0026] The steps of the steel preparation method include steelmaking, billet opening, two-stage controlled rolling, and on-line heat treatment, specifically:

[0027] Use a 50Kg vacuum induction furnace to make steel. After the pouring is completed, the ingot is kept in a heating furnace at a temperature of 1200°C for 1 hour, and then hot-rolled to form a 100mm thick billet. The billet is placed in the heating furnace and heated to 1200°C. keep warm for 2 hours;

[0028] The rolling is controlled in two stages, and a total of seven rolling passes have been passed, of which the first four passes are rough rolling, and the last three passes are finish rolling; the rough rolling is rolled in the austenite complete recrystallization zone, and the rolling temperature is 1100°C , the finishing temperature of rough ro...

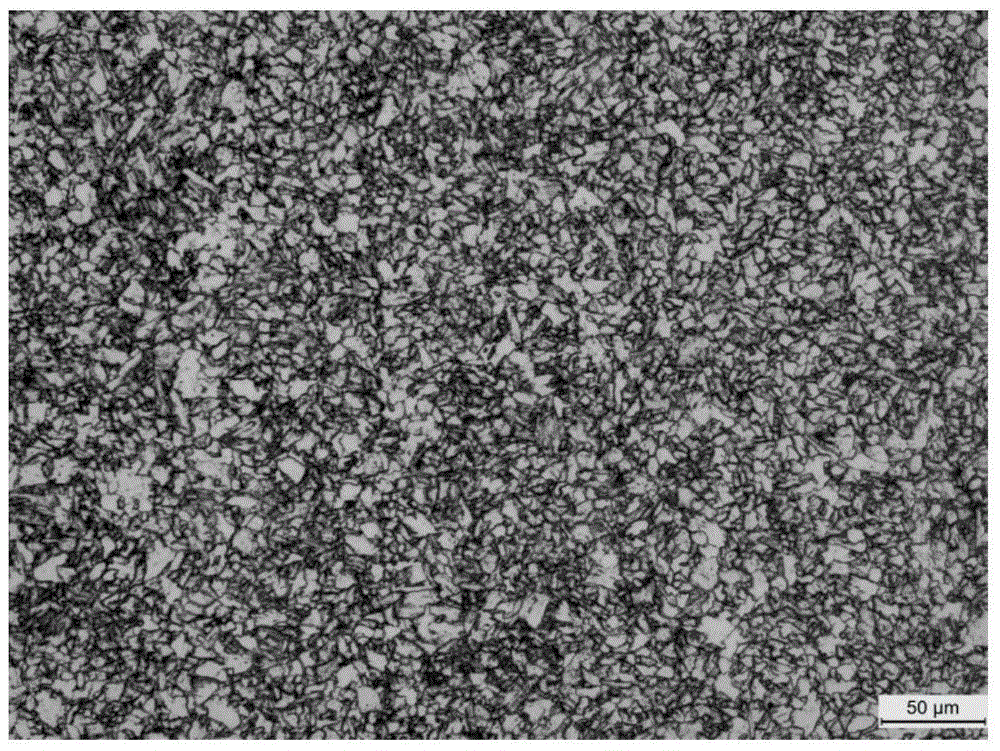

Embodiment 2

[0039] The composition of 3.5Ni steel is designed by weight percentage: C0.055%, Si0.17%, Mn0.68%, S0.002%, P0.005%, Ni3.46%, Al0.023%, the balance For Fe and impurities;

[0040] The steps of the steel preparation method include steelmaking, billet opening, two-stage controlled rolling, and on-line heat treatment, specifically:

[0041] Use a 50Kg vacuum induction furnace to make steel. After the pouring is completed, the ingot is kept in a heating furnace at a temperature of 1150°C for 2 hours, and then hot-rolled to form a 100mm thick billet. Put the billet into the heating furnace and heat it to 1150°C. keep warm for 2 hours;

[0042] The rolling is controlled in two stages, and a total of six rolling passes have been passed, of which the first three passes are rough rolling, and the last three passes are finish rolling; the rough rolling is rolled in the austenite complete recrystallization zone, and the rolling temperature is 1120°C , the finishing temperature of rough...

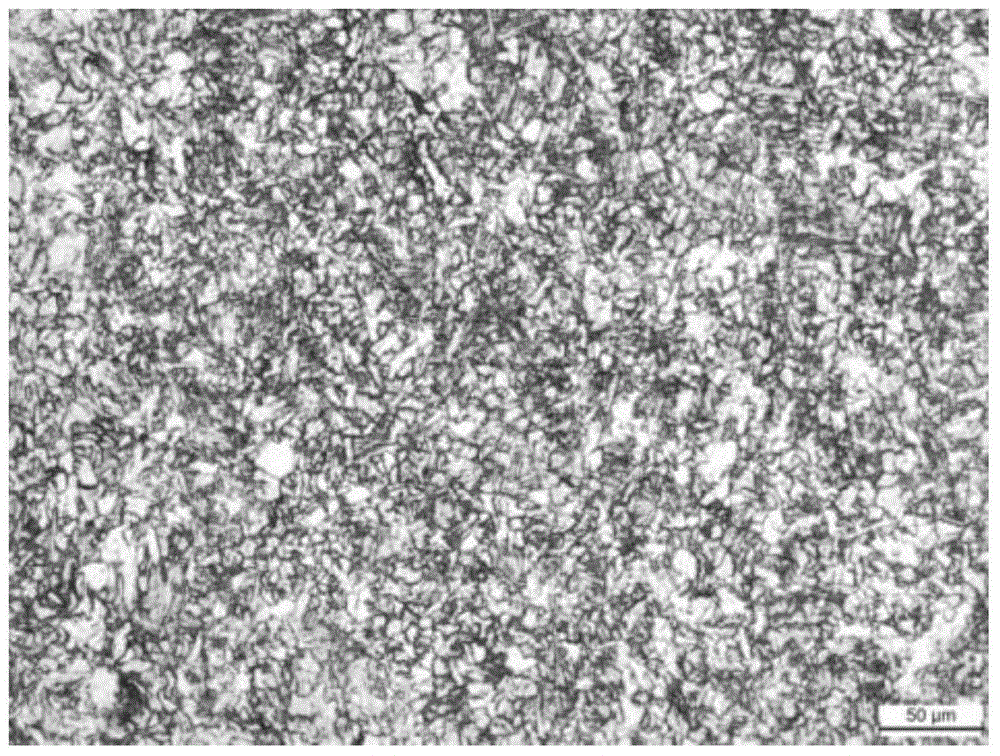

Embodiment 3

[0046] The composition of 3.5Ni steel by weight percentage is: C0.043%, Si0.13%, Mn0.86%, S0.004%, P0.007%, Ni3.3%, Cr0.59%, Mo0.037% , Al0.039%, the balance is Fe and impurities;

[0047] The steps of the steel preparation method include steelmaking, billet opening, two-stage controlled rolling, and on-line heat treatment, specifically:

[0048] Use a 50Kg vacuum induction furnace to make steel. After the pouring is completed, the ingot is kept in a heating furnace at a temperature of 1150°C for 2 hours, and then hot-rolled to form a 100mm thick billet. Put the billet into the heating furnace and heat it to 1150°C. keep warm for 2 hours;

[0049] The rolling is controlled in two stages, and a total of seven rolling passes have been passed, of which the first four passes are rough rolling, and the last three passes are finish rolling; the rough rolling is rolled in the austenite complete recrystallization zone, and the rolling temperature is 1120°C , the rough rolling end te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com