Spheroidizing annealing process for medium carbon steel plate in bell furnace

A steel plate cover and steel plate technology, which is applied to the field of spheroidizing furnace annealing of medium carbon steel plates, namely No. 45 steel, can solve the problems of difficult to achieve pre-annealing process, low spheroidization qualification rate, difficulty in spheroidization, etc., and shorten the delivery time. Cycle time, improve mechanical properties, reduce the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Pickling steel blank

[0033] At room temperature, wash off the scale of the hot-rolled billet on the surface of the steel plate with an external dimension of 5.6×1535×1250mm with hydrochloric acid in a tank-type pickling tank;

[0034] (2) Longitudinal rolling billet

[0035] The pickled steel billet is rolled by a four-roller 2300mm reversible cold rolling mill for 7-15 passes, and longitudinally rolled into a steel plate with an external dimension of 4.0×1200×2000mm, with a deformation of 28%. The upper roll: 0.03mm, bottom roller: 0mm;

[0036] (3) Annealing by stacking sheets

[0037] Put the cold-rolled steel plate into the hearth of the electric heating bell furnace, the furnace load is 40t, and then buckle the inner and outer covers;

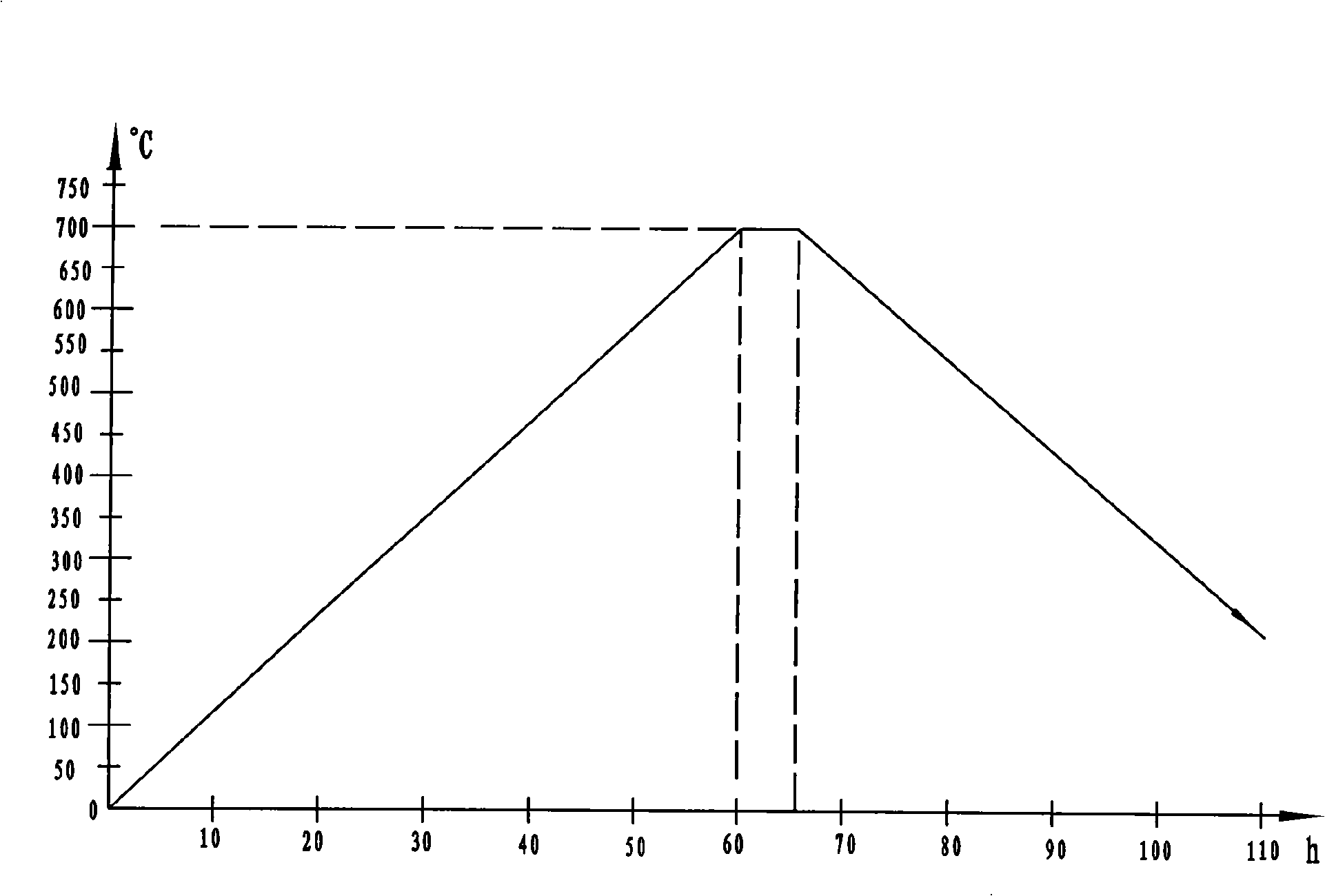

[0038] a. The plate temperature thermocouple is used to control the temperature. There are three thermocouples inserted into the electric heating mantle furnace. The principle of temperature measurement is the same. From th...

Embodiment 2

[0047] (1) Pickling steel blank

[0048] At room temperature, use a tank-type pickling tank to wash off the scale of the hot-rolled blank on the surface of the steel plate with an overall size of 6.0×1440×1250mm with hydrochloric acid;

[0049] (2) Longitudinal rolling billet

[0050] The pickled steel slabs are rolled by a four-roller 2300mm reversible cold rolling mill for 7-15 passes.

[0051] Longitudinal rolling into a steel plate with an external dimension of 4.0×1200×2000mm, with a deformation of 33%, upper roll: 0.03mm, lower roll: 0mm;

[0052] (3) Annealing by stacking sheets

[0053]The steel plate after cold-rolling is packed into the hearth of electric heating bell-type furnace, and furnace charge is 60t, covers furnace cover then; a adopts plate temperature thermocouple to control temperature, and method is identical with embodiment one;

[0054] b. The heating in the bell-type furnace adopts two-stage furnace base and hood resistance belt heating. The output ...

Embodiment 3

[0060] (1) Pickling steel blank

[0061] At room temperature, wash off the oxide skin of the steel plate blank with an external dimension of 8.5×1265×1250mm with hydrochloric acid in a tank-type pickling tank;

[0062] (2) Longitudinal rolling billet

[0063] The pickled steel plate blank is rolled by a four-roller 2300mm reversible cold rolling mill for 7-15 passes, and longitudinally rolled into a steel plate with an external dimension of 5.0×1200×2000mm, with a deformation of 41%. The upper roll: 0.03mm, bottom roller: 0mm;

[0064] (3) Annealing by stacking sheets

[0065] Put the cold-rolled steel plate into the hearth of the electric heating mantle furnace, the furnace load is 80t, and then cover the mantle;

[0066] A adopts plate temperature thermocouple to control temperature, and method is identical with embodiment one;

[0067] The heating in the bell-type furnace adopts two-stage furnace platform and furnace cover resistance belt heating, the output power of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com