Machining method capable of controlling commercial pure titanium plate cold rolling texture

A technology of industrial pure titanium and a processing method, applied in the field of titanium alloy material preparation, can solve the problems of reducing the anisotropy of cold-rolled titanium coils, weakening the anisotropic effect of titanium coils, weakening the anisotropy of titanium coils, etc. Achieve the effect of good follow-up processing and forming performance, reducing heat treatment process and weakening anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

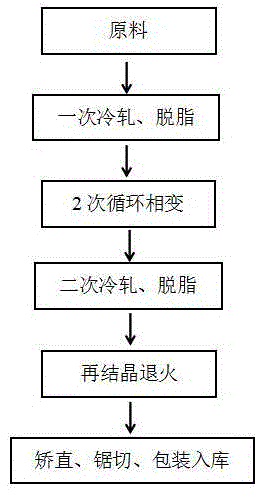

[0028] The specific implementation steps are as follows:

[0029] (1) After hot rolling and annealing, the TA2 titanium plate with a thickness of 4mm and a width of 1250mm is subjected to cold rolling deformation on a multi-roll cold rolling mill, with a rolling deformation of 75% and a rolling speed of 25m / min; the thickness is obtained 1.0mm, width of 1250mm blooming slab, and conventional degreasing treatment for the blooming slab;

[0030] (2) Put the first-rolled slab coil with a thickness of 1.0mm, a width of 1250mm, and a titanium coil thickness of 162mm in a furnace at a temperature of 950°C for 81 minutes, then take it out of the furnace and air-cool it, and cycle twice;

[0031] (3) The TA2 titanium plate with a thickness of 1.0mm and a width of 1250mm after cyclic phase transformation is subjected to cold rolling deformation on a multi-roll cold rolling mill, the rolling deformation is 20%, and the rolling speed is 35m / min; the thickness is obtained Thin titanium p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com