100 mm-120 mm Q460D extra-thick high-strength steel and preparation method thereof

A high-strength steel and manufacturing method technology, applied in the field of iron and steel metallurgy, can solve problems such as large internal stress of steel plates, affecting use and welding, and achieve the effects of reducing production capacity pressure, saving heat treatment costs, and stabilizing production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

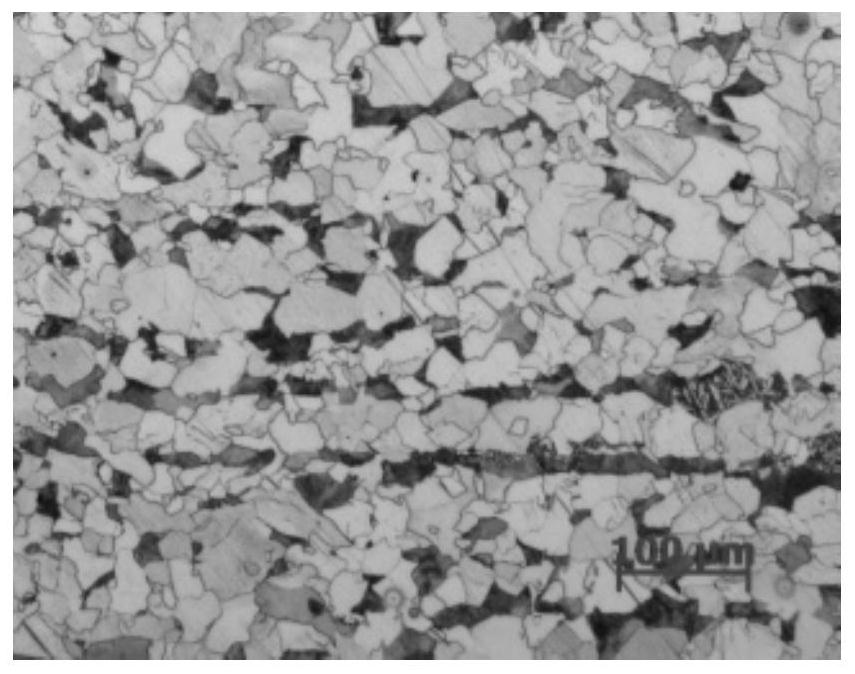

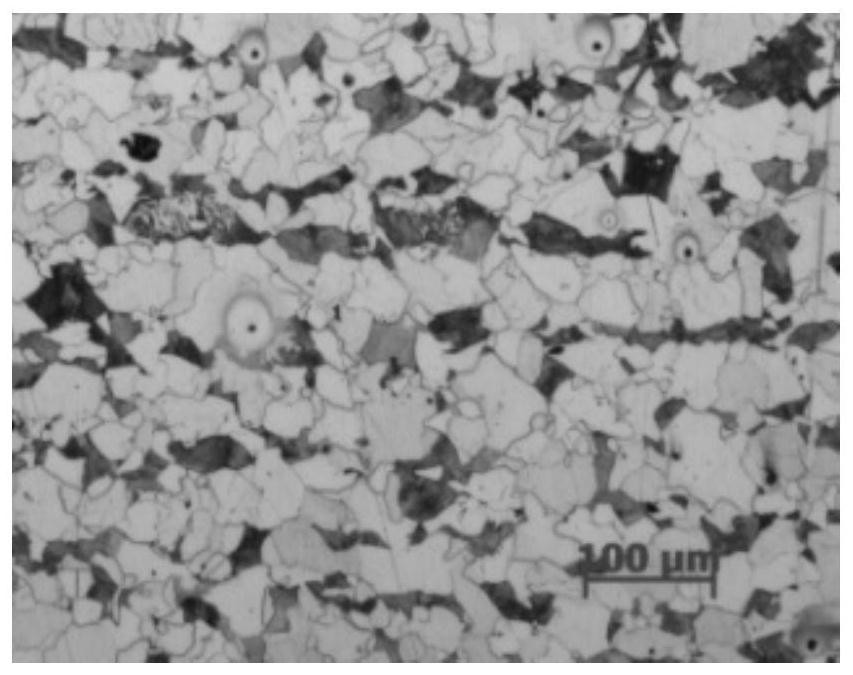

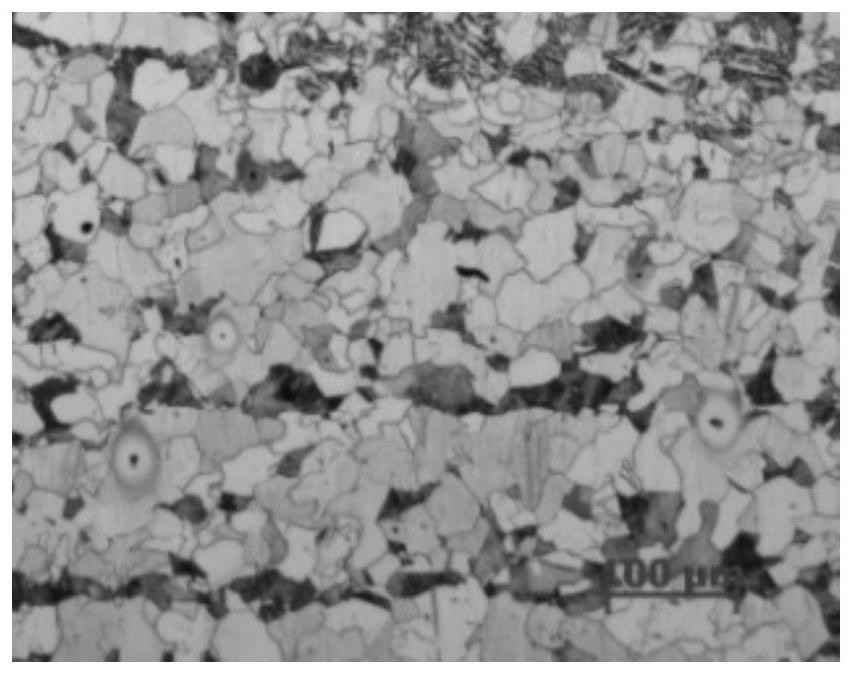

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings, embodiments and comparative examples.

[0041] The production process of the 100-120mm Q460D extra-thick high-strength steel of the present invention is: converter -> LF refining -> RH vacuum degassing -> Ca treatment -> continuous casting -> billet dehydrogenation treatment -> heating -> normalizing rolling Manufacturing -> air cooling -> slow cooling of steel plate stacking -> unstacking.

[0042] A kind of normalizing rolled Q460D extra-thick high-strength steel and its preparation method of Examples 1-4 of the present invention and Comparative Example 1, only in the normalizing rolling process, the process of Comparative Example 1 is different from that of Examples 1-4, The rest are consistent, as follows:

[0043] (1) Smelting: use a 150-ton converter for smelting, then send it to an LF furnace for refining and RH vacuum degassing treatment, and perform C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com