Welding process for rear overhang rack

A welding process and rear suspension technology, which is applied to suspensions, vehicle parts, cantilevers mounted on pivots, etc., can solve the problems of difficult heat treatment of drag arm components, ignoring welding heat-affected zones, ignoring stress concentration points, etc. , to achieve the effect of easy control of quality, reduction of heat treatment process, and elimination of welding residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

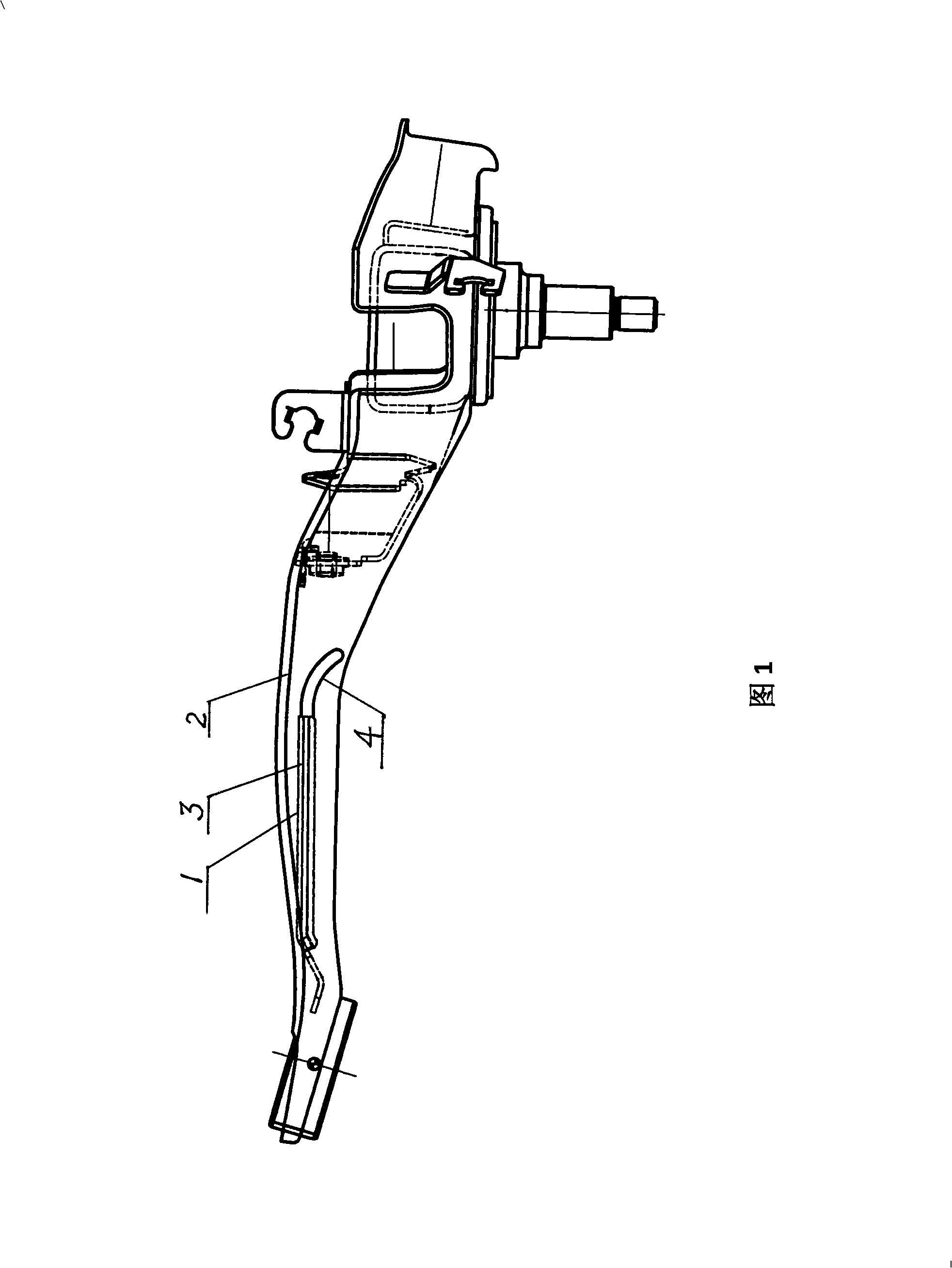

[0021] As shown in Figure 1, it is a schematic diagram of the welding structure of a rear suspension of an automobile. The welding process of the rear suspension of an automobile is as follows: the reinforcing plate 1 is welded with the trailing arm 2, and then welded at the joint of the weld 3 Transition to the bottom edge of the drag arm 2 with a smooth arc 4, the length of the arc 4 is 43mm, the radius of the arc is 35mm, the weld width is 7mm, and all welding parameters are the same as the original welding.

[0022] The welded rear suspension of the automobile did not break after reaching the required number of fatigue times during the suspension fatigue test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com