Nano-material interalloy modifier and preparation method thereof, and alloy preparation method

An intermediate alloy and nano-material technology, which is applied in the fields of metallurgy, steel and non-ferrous metal alloys, can solve the problems of loss of effect, large loss of argon blowing tube, inability to crystallize to core dispersion strengthening, etc., so as not to be easily oxidized and aggregated, and reduce production Cost, effect of grain size refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

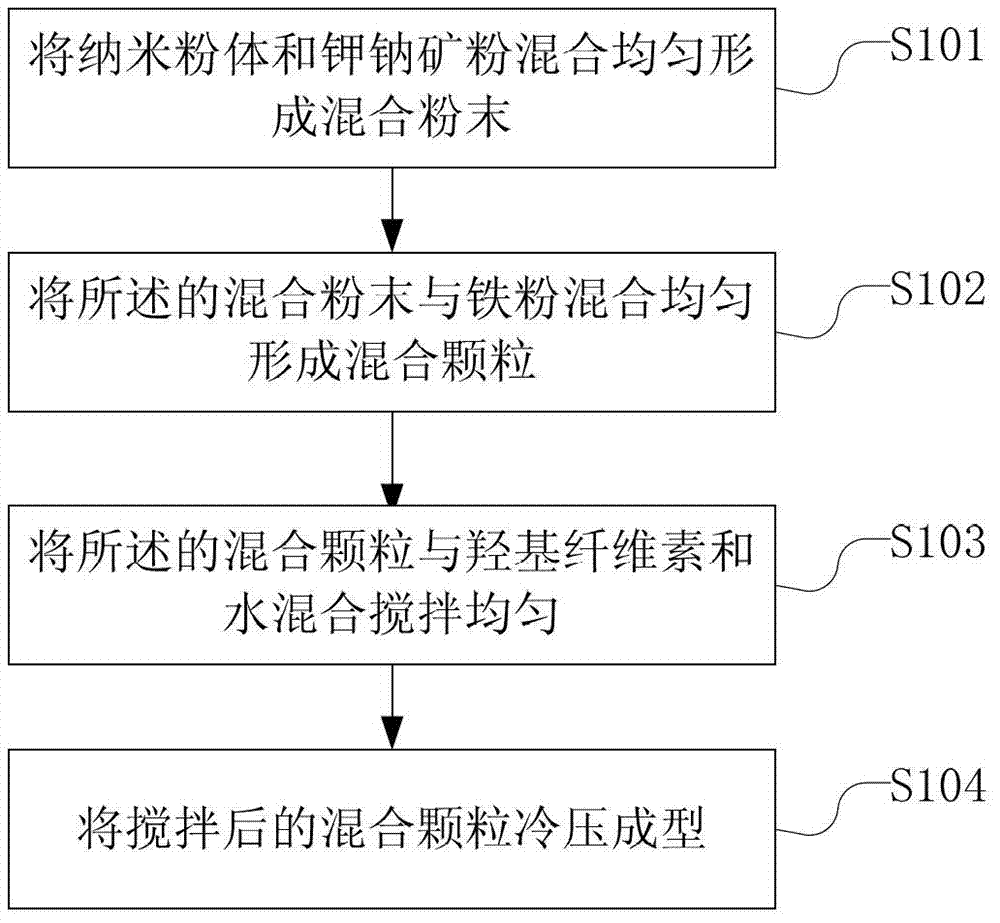

[0035] figure 1 It is a flow chart of a method for preparing a nanomaterial master alloy modifier provided by an embodiment of the present invention, such as figure 1 As shown, the described method comprises the following steps:

[0036] S101, uniformly mixing the nanometer powder and potassium sodium ore powder to form a mixed powder.

[0037] In the embodiment of the present invention, in view of the inherent characteristics of nano-powders, in the process of preparing nano-powder master alloys, the oxidation, polymerization and pyrolysis of nano-powder materials should be avoided as much as possible. The raw material of the powder (preferably aluminum-coated), so that the nano-powder material will not be excessively oxidized and aggregated during the mixing and preparation process.

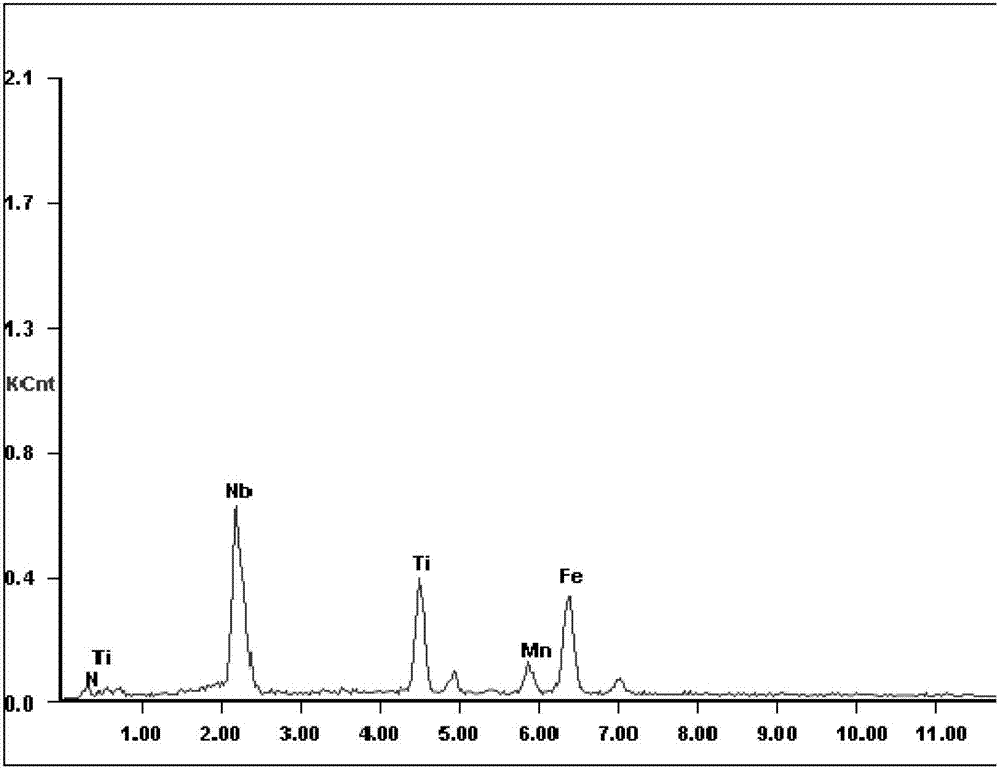

[0038] The configuration of the TiN nano-master alloy modification agent is used as an example for illustration below. In other embodiments of the present invention, the nano-powder can be Ti...

Embodiment 2

[0052] Figure 4 It is a flow chart of an alloy preparation method provided by an embodiment of the present invention, such as Figure 4 As shown, the alloy preparation method comprises the following steps:

[0053] S401, nano-material master alloy modifier for slag removal and pre-deoxidation treatment;

[0054] In the embodiment of the present invention, the nanomaterial master alloy modifier can be the nanomaterial master alloy modifier generated in the embodiment, before the nanomaterial master alloy modifier is added to molten steel, molten iron or non-ferrous alloy liquid, the nanomaterial must be The master alloy modifier should be fully pre-deoxidized, and the residue must be removed.

[0055] S402, adding the nano-material master alloy modifying agent into the smelting furnace to be released according to 0.02%~0.04% of the weight of molten steel, molten iron or non-ferrous alloy liquid, or flowing out of molten steel, molten iron or non-ferrous alloy liquid 1 / 3 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com