Heating method and apparatus for processing biological organic refuse

A technology of organic waste and heating method, which is applied in the direction of heating device, removal of solid waste, mixer with rotating stirring device, etc. Major and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

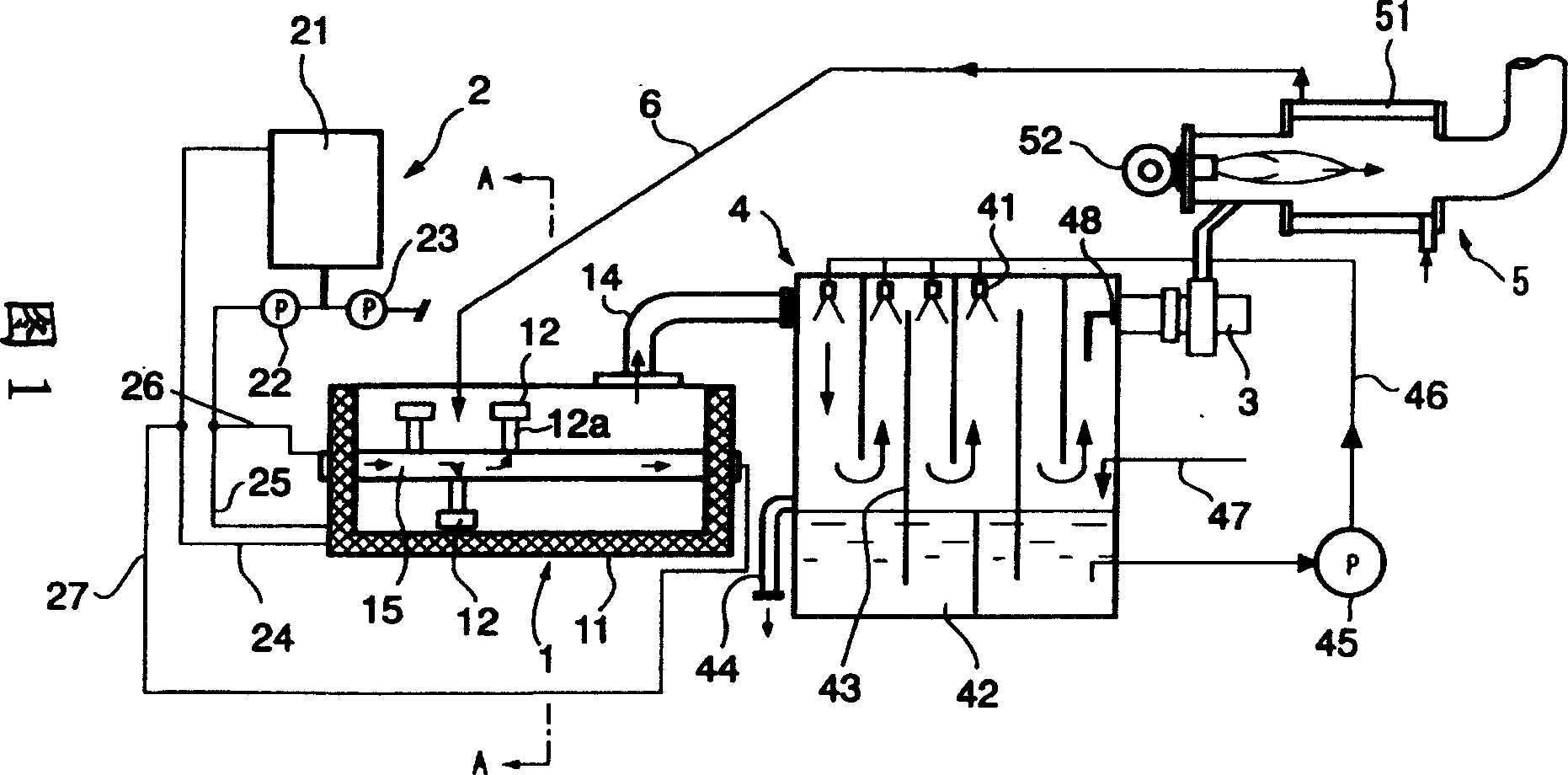

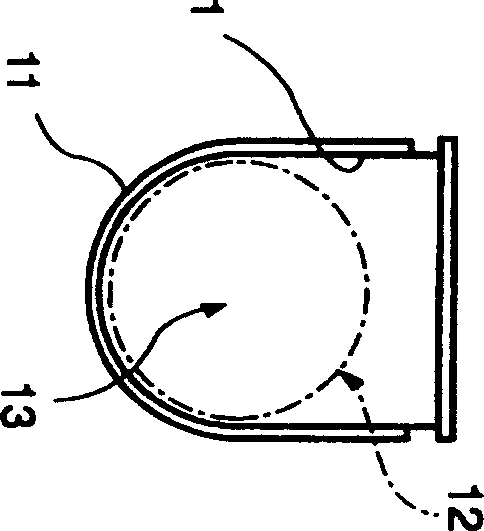

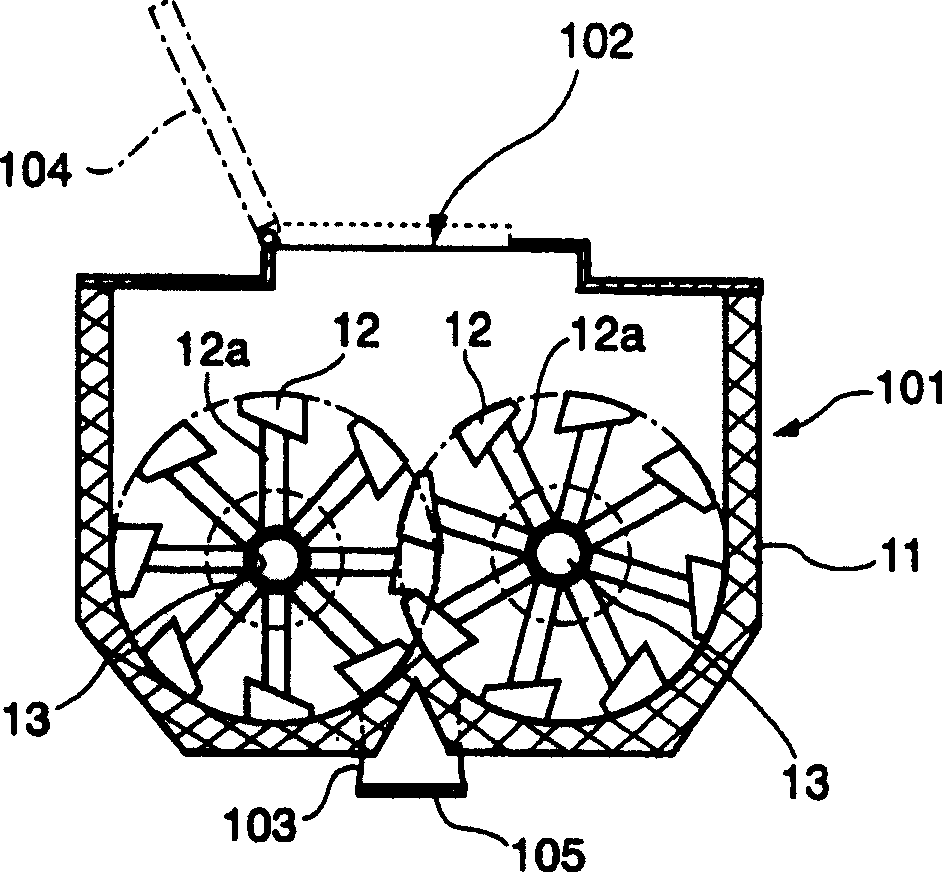

[0029] Next, an example of a suitable processing device for carrying out the method of the present invention will be specifically described with reference to the drawings. 1 is an explanatory diagram showing the outline of an embodiment of a single-tank type heat treatment apparatus employing the method of the present invention, figure 2 It is the A-A direction sectional view of the single treatment tank of Fig. 1, image 3 It is a side sectional view of an example of a treatment tank in the form of a combination of two tanks, Figure 4 is with image 3 The treatment tank of the same form as the combination of the two tanks is provided with image 3 Plan sectional views of examples of different heat transfer blades, Figure 5 It is a graph for comparing the heating temperature, the moisture content of the object to be treated, and the humidity in the tank between direct heating and indirect heating.

[0030] In Fig. 1, 1 is a single-trough type horizontal treatment tank wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com