An eccentric planet axis mechanism with tunable centre-to-centre distance and its regulation means

An adjustment method and planetary shaft technology, which is applied to mechanical equipment, transmission parts, gear transmissions, etc., can solve problems such as low work efficiency, complicated eccentric planetary shaft process, and high production costs, so as to improve work efficiency and reduce storage volume , Reduce the effect of processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

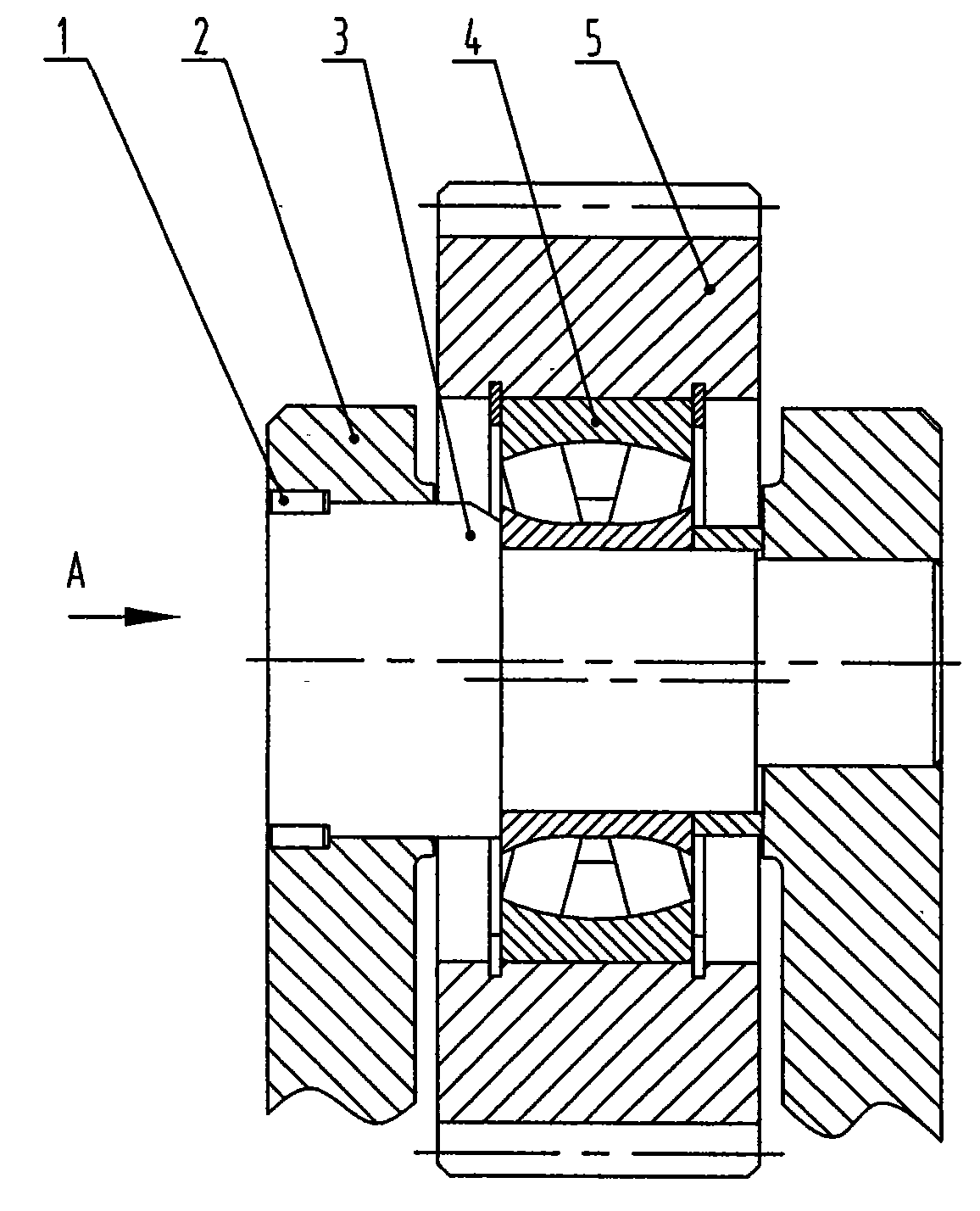

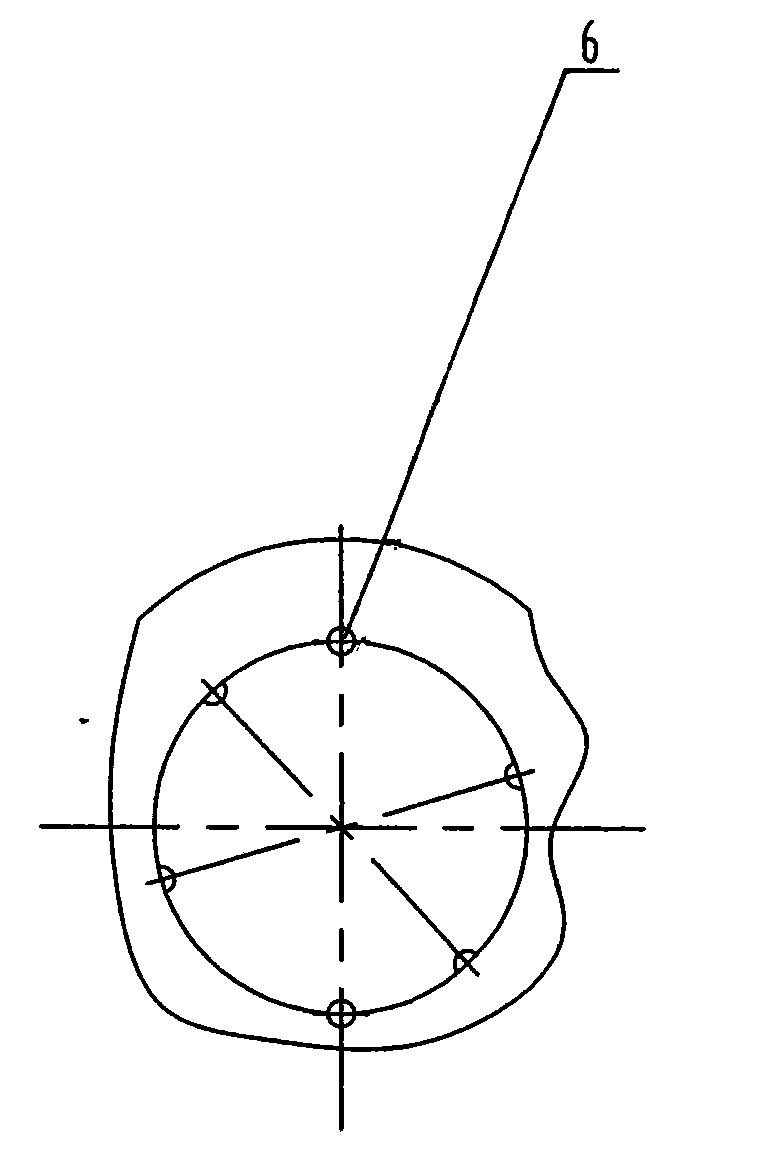

[0017] In the figure: 1, pin shaft; 2, planet carrier; 3, eccentric planet shaft; 4, bearing; 5, planetary wheel; 6, pin hole.

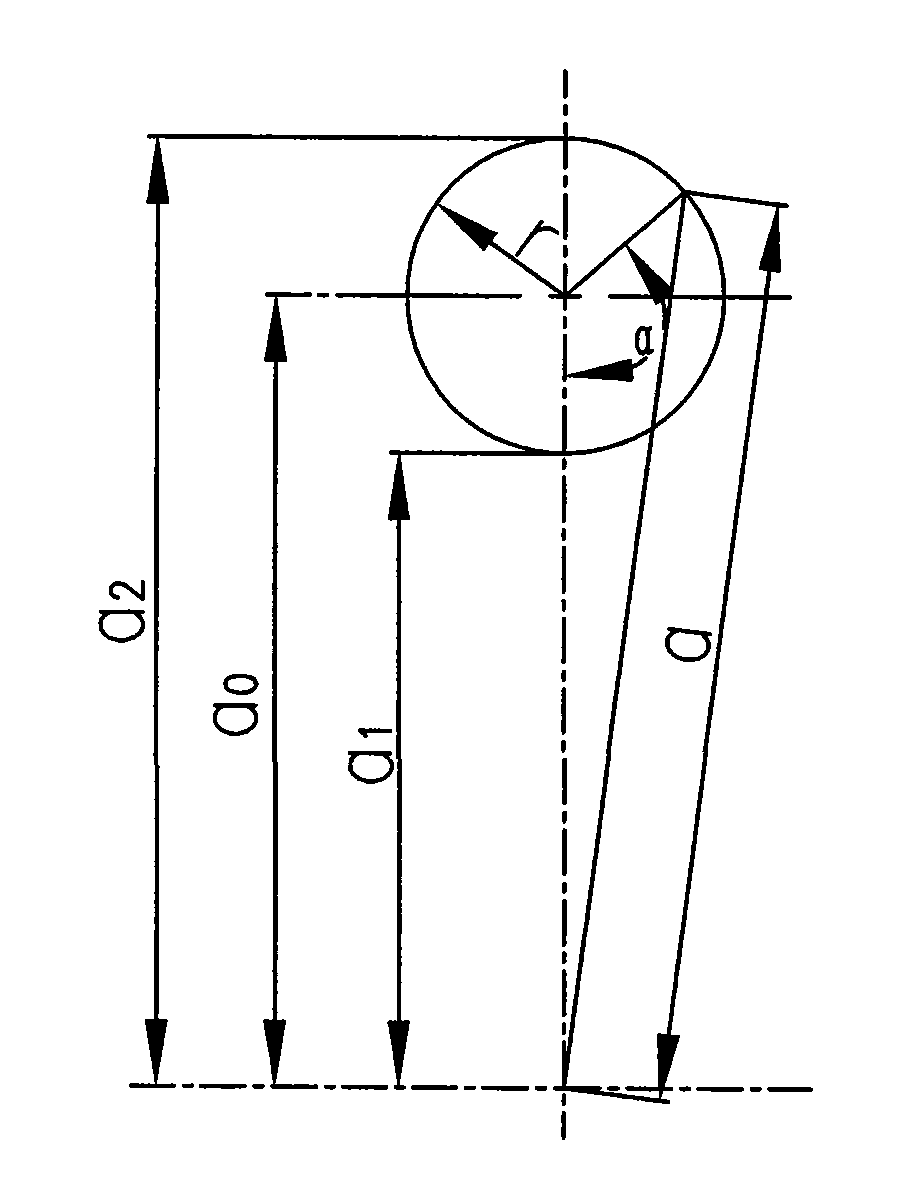

[0018] Such as Figure 1~2 As shown, an eccentric planetary shaft mechanism with adjustable center distance includes a planet carrier 2, an eccentric planetary shaft 3, a bearing 4, a planetary wheel 5 and a pin shaft 1, and the two ends of the eccentric planetary shaft 3 are concentric shafts , the middle is an eccentric shaft; the highest point and the lowest point of the inner ring at either end of the planet carrier 2 are provided with a pair of semicircular pin holes; the eccentric planet shaft 3 is correspondingly provided with at least a pair of symmetrical semicircular pin holes on the outer ring; the planet The pin hole 6 is formed after the semicircular pin hole of the frame is aligned with the semicircula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com