Construction method of formwork system for highly-deviated tower construction creeping formwork

A construction method and high-slope technology, which are applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of formwork and climbing frame deformation, construction safety and high construction cost, and reduce formwork. Damage, optimized force mode, small construction error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

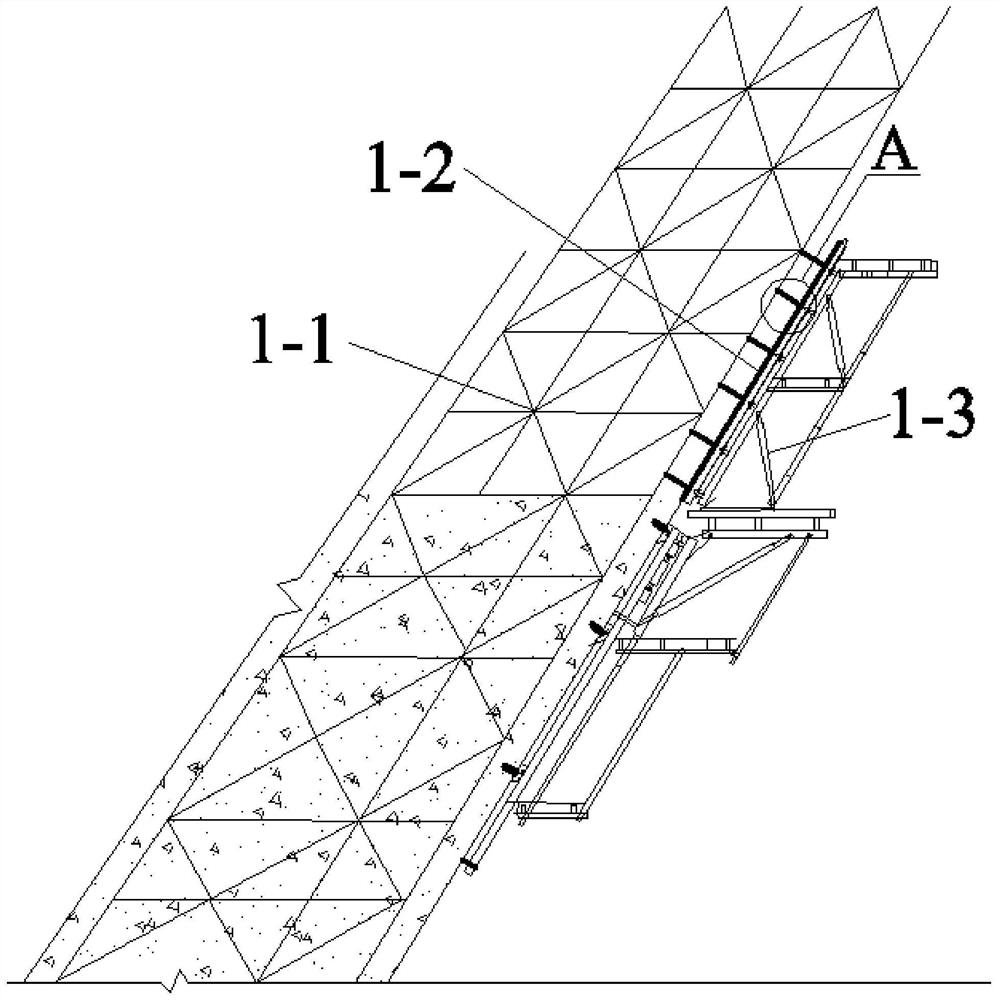

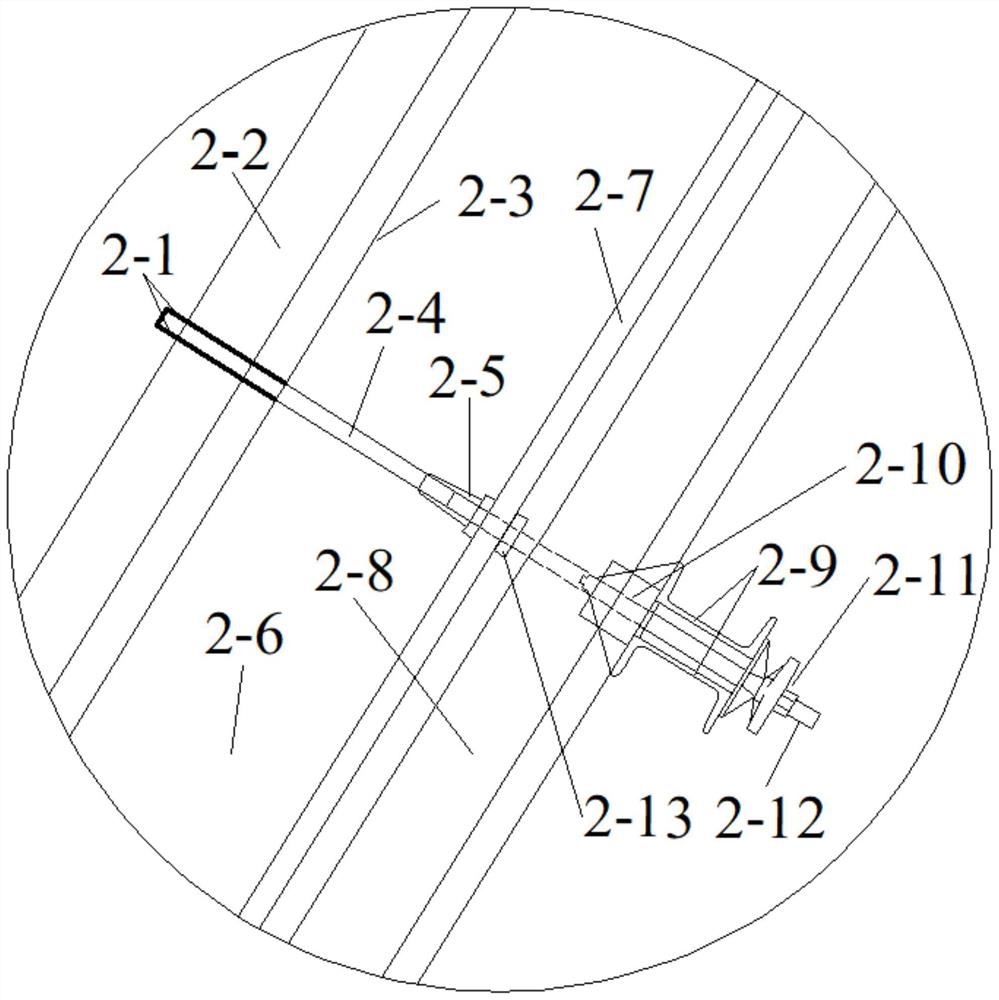

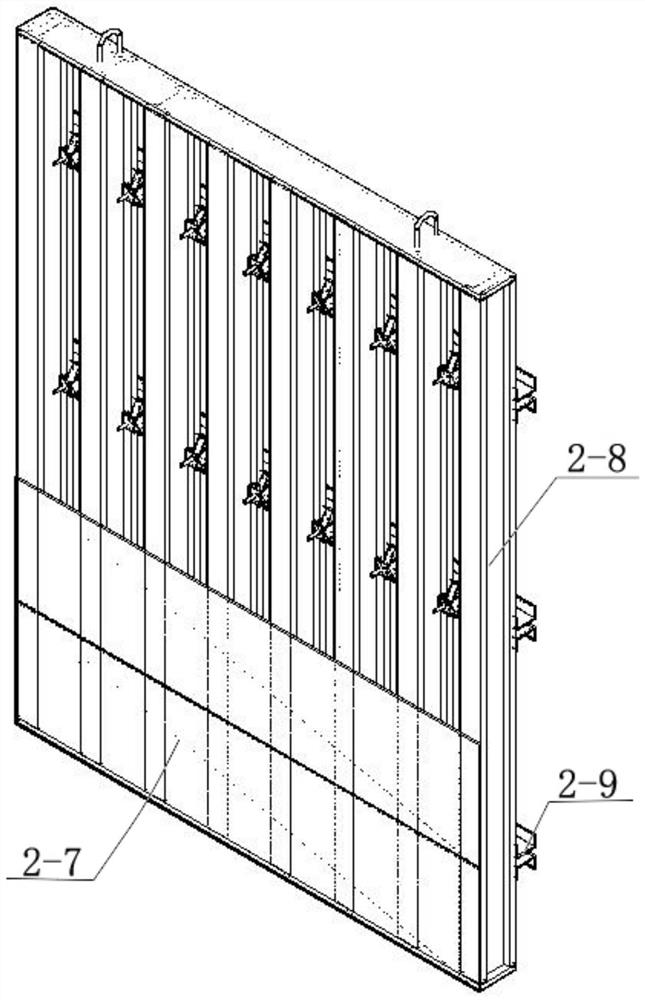

[0031] like Figure 1-2 As shown, a formwork system for climbing formwork used in the construction of steeply inclined towers is installed between the upper side of the existing climbing frame system 1-3 and the steeply inclined tower 1-1, including the climbing frame system 1 The formwork assembly 1-2 connected to the upper side of -3, the formwork assembly 1-2 is evenly inserted with a plurality of screw rods 2-12, and the end of the screw rod 2-12 facing the climbing frame system 1-3 extends out of the formwork The component 1-2 is installed through the clamping nut 2-11, and the clamping nut 2-11 is clamped on the outside of the formwork component 1-2, and the screw rod 2-12 protrudes from the formwork component at the end of the climbing frame system 1-3 The 1-2 jacket is equipped with a conical joint 2-5, and the screw 2-12 is also provided with an adjusting nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com