Permeation unit

A technology of seepage hole and pipe body, which is applied in the direction of waterway system, sewer pipe system, road bottom, etc., and can solve the problems of weakening the overall strength of seepage pipes and short seepage units that cannot be used directly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

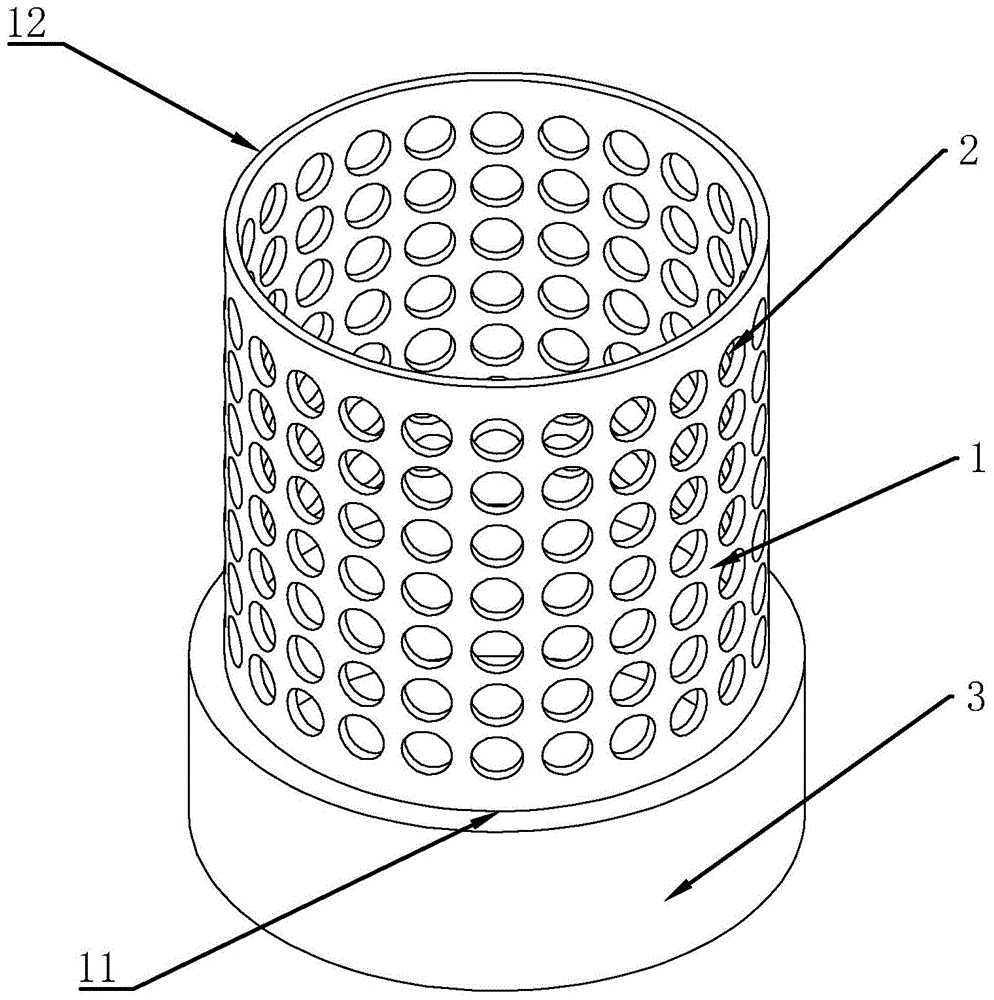

[0013] refer to figure 1 The embodiment of the seepage pipeline of the present invention will be further described.

[0014] A permeation unit includes a pipe body 1 with a number of water seepage holes 2 distributed thereon, a flaring portion 3 at the end of the pipe body 1, and all structures on the permeation unit are integrally molded by an injection molding machine.

[0015] The connection between the permeation unit and its adjacent permeation unit is described as follows: the flaring part 3 on the tube body 1 is sleeved on the tube body 1 in the adjacent permeation unit, and the transition between the flaring part 3 and the tube body 1 is The socket connection method is not only convenient for on-site pipeline installation, but also can ensure reliable pipeline connection in the actual use of seepage pipelines.

[0016] Preferably, since all structures on the permeation unit are molded by injection molding machines, the size of the permeation unit 1 is restricted by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com