Aluminum matrix composite hot-extruded tube manufacturing method capable of reducing internal surface scratches

A technology of aluminum-based composite materials and manufacturing methods, which is applied in the field of material molding, can solve problems such as internal and external surface defects and low plasticity, and achieve the effects of improving corrosion resistance, increasing service life, and avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

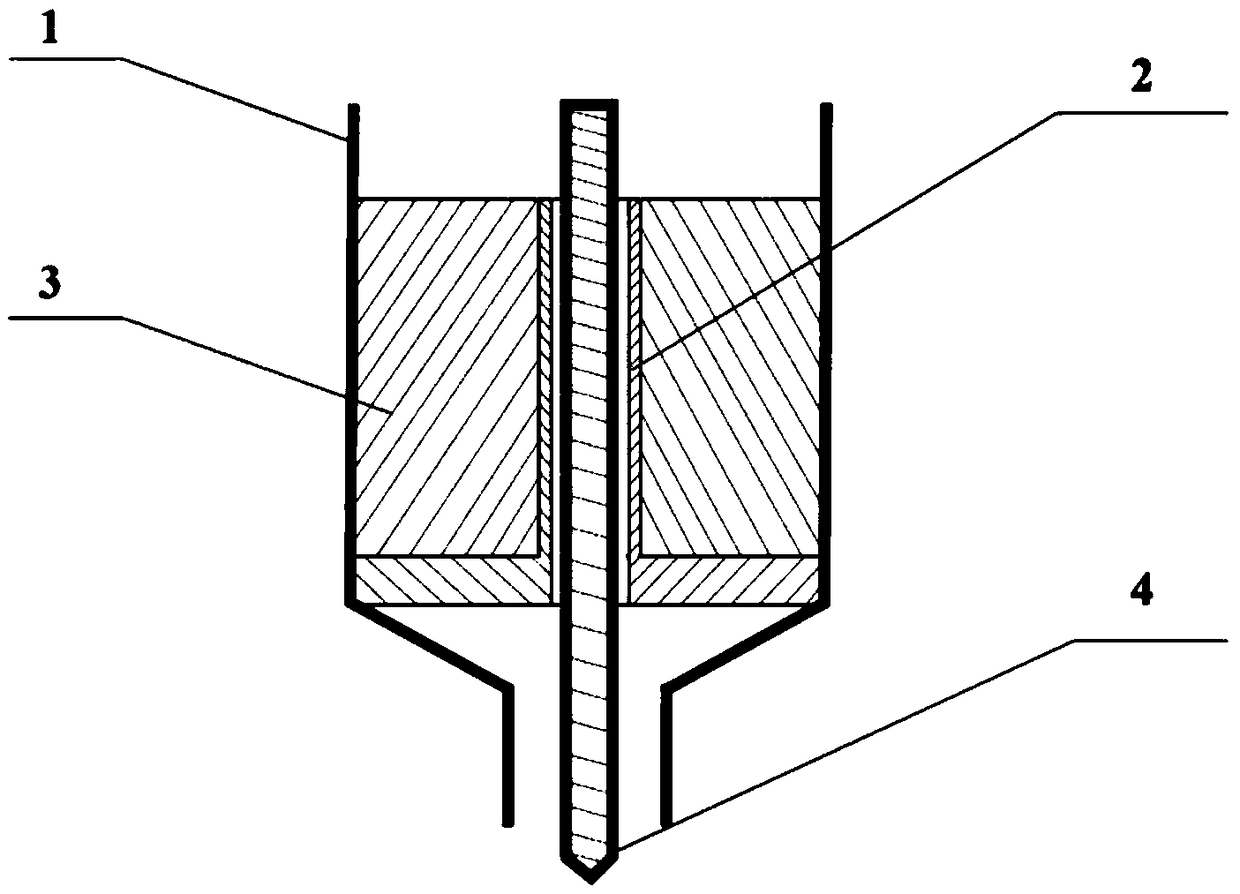

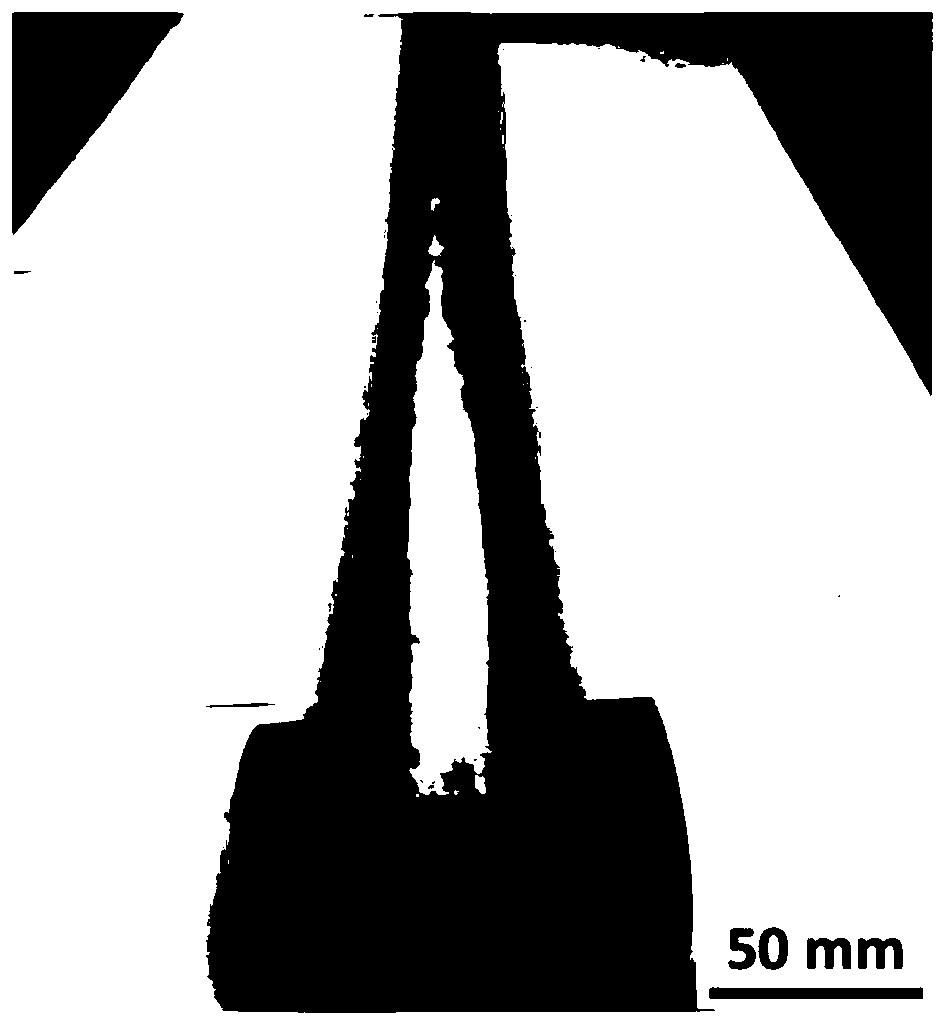

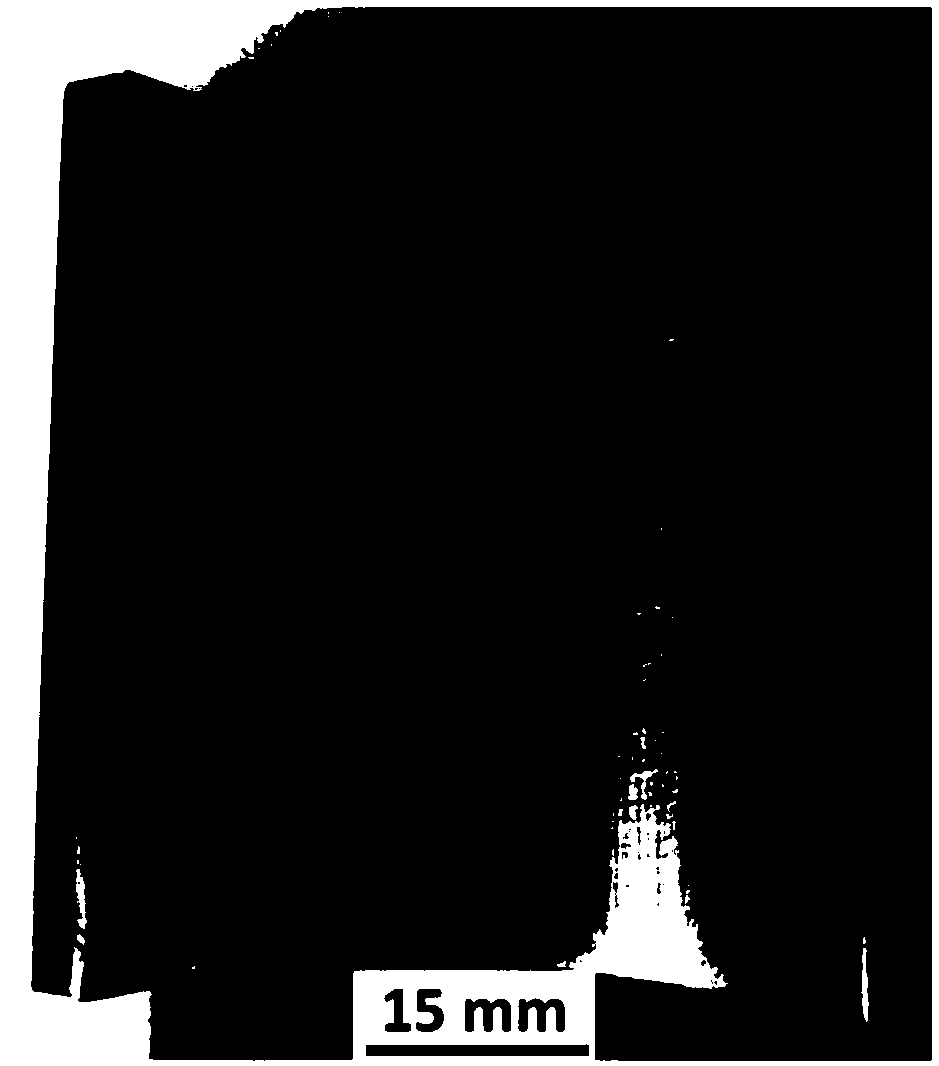

[0035] Example 1 Preparation of aluminum matrix composite material hot extrusion pipe

[0036] 1) Drilling the inner hole of the ingot: Take a cylindrical aluminum-based composite material ingot, and drill a cylindrical through hole coaxial with the ingot along the axis at the center of the ingot, which is the inner hole (such as Figure 6 (a));

[0037] 2) Treatment of the inner surface of the inner hole: pickling the inner surface of the inner hole of the ingot prepared in step 1), then washing with water, and drying;

[0038] 3) Pure aluminum casting: put the ingot obtained after step 2) into the mold, and pour molten pure aluminum liquid after preheating;

[0039] 4) Drill the pure aluminum part at the inner hole of the ingot: Drill a cylindrical through hole coaxial with the inner hole of the ingot along the axis at the center of the inner hole of the ingot, and the inner diameter of the through hole is 3.5mm smaller than the inner diameter of the inner hole of the ingot ...

Embodiment 2

[0054] 1) Drilling the inner hole of the ingot: Take a cylindrical aluminum-based composite material ingot, and drill a cylindrical through hole coaxial with the ingot along the axis at the center of the ingot, which is the inner hole (such as Figure 6 (b));

[0055] 2) inner surface treatment of the inner hole: sandblasting the inner surface of the inner hole of the ingot prepared in step 1), then washing with water and drying;

[0056] 3) Pure aluminum casting: put the ingot obtained after step 2) into the mold, and pour molten pure aluminum liquid after preheating;

[0057] 4) Drill the pure aluminum part at the inner hole of the ingot: Drill a cylindrical through hole coaxial with the inner hole of the ingot along the axis at the center of the inner hole of the ingot, and the inner diameter of the through hole is 1mm smaller than the inner diameter of the inner hole of the ingot;

[0058] 5) Extrusion: The ingot obtained in step 4) is preheated and heat-insulated, put int...

Embodiment 3

[0072] 1) Drilling the inner hole of the ingot: Take a cylindrical aluminum-based composite material ingot, and drill a cylindrical through hole coaxial with the ingot along the axis at the center of the ingot, which is the inner hole (such as Figure 6 (c));

[0073] 2) Treatment of the inner surface of the inner hole: pickling the inner surface of the inner hole of the ingot prepared in step 1), then washing with water, and drying;

[0074] 3) Pure aluminum casting: put the ingot obtained after step 2) into the mold, and pour molten pure aluminum liquid after preheating;

[0075] 4) Drill the pure aluminum part at the inner hole of the ingot: Drill a cylindrical through hole coaxial with the inner hole of the ingot along the axis at the center of the inner hole of the ingot, and the inner diameter of the through hole is 6mm smaller than the inner diameter of the inner hole of the ingot;

[0076] 5) Extrusion: The ingot obtained in step 4) is preheated and heat-insulated, put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com