Magnetic fluid device for rust prevention of steel and method

A magnetic fluid and steel technology, which is applied in the processing of building materials, building insulation materials, building maintenance, etc., can solve the problems of high cost, affecting appearance, and the length of anti-rust time, so as to prolong the service life, increase durability, and resist Effect of external loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

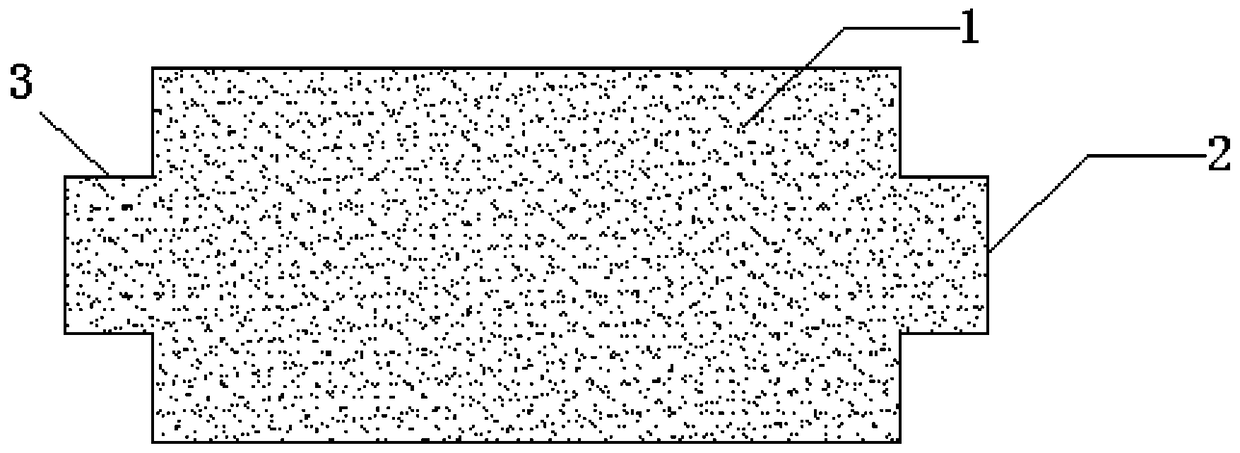

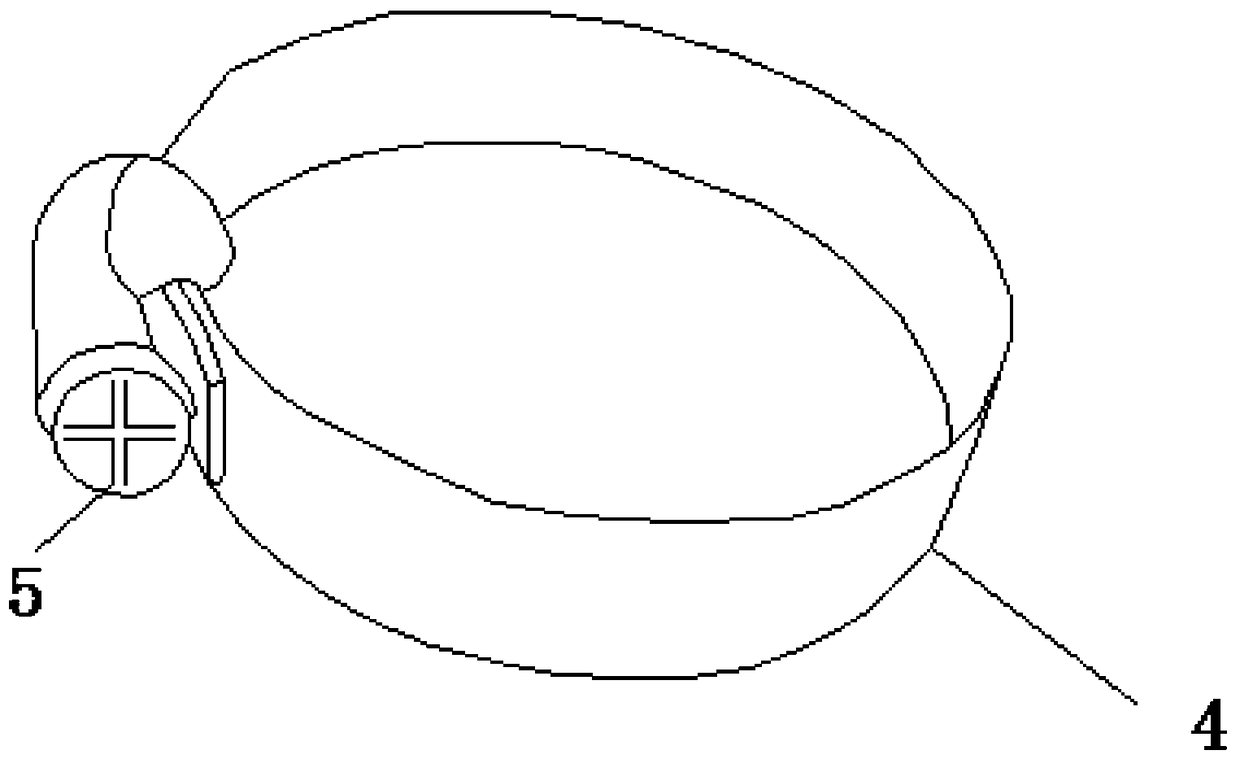

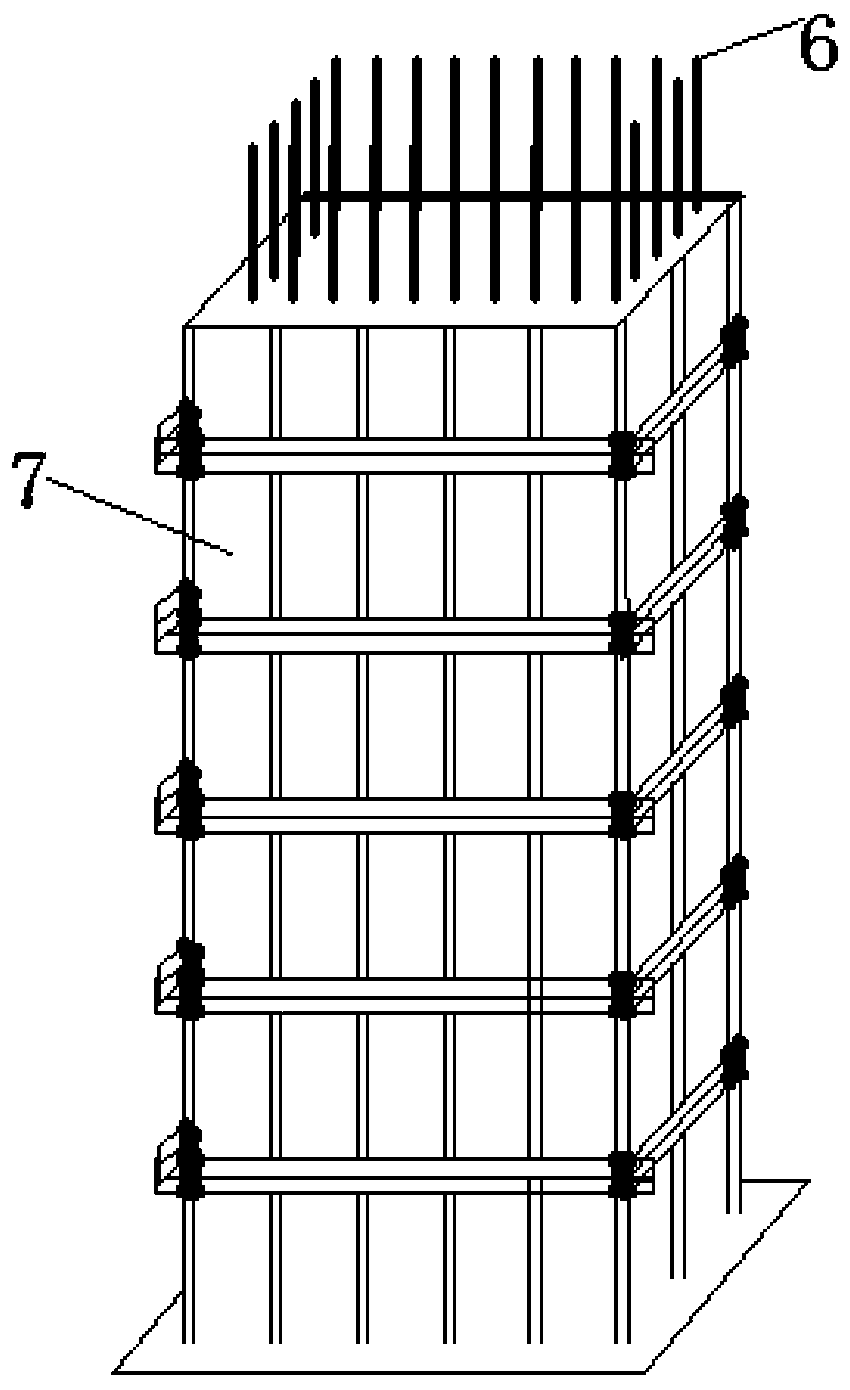

[0039] see Figure 1-5 , a magnetic fluid device for rust prevention of steel, which includes a magnetic fluid device 8, the magnetic fluid device 8 includes a flexible sleeve 2, a magnetic fluid 1 is wrapped inside the flexible sleeve 2, and the two sides of the flexible sleeve 2 The lateral symmetry is provided with a card slot 3, and the card slot 3 sets the flexible sleeve 2 on the outside of the steel bar 6 that needs to be rust-proof through the locking hoop assembly, and the steel bar 6 is poured inside the concrete, and the magnet is installed on the steel bar 6 Block 9. The magnetic fluid device with the above-mentioned structure can be used for rust prevention and repair of cracked steel components inside the concrete or steel components exposed to water, because the magnetic fluid itself can quickly absorb the cracked steel components after magnetization treatment, thereby preventing Cut off contact with water or air. This method is used in the antirust or repair ...

Embodiment 2

[0044] The method for rust-proofing the internal steel bars of the structure under construction by using any one of the magnetic fluid devices for steel anti-rust, is characterized in that it comprises the following steps:

[0045] StepA1: make flexible sleeve 2 with elastic material;

[0046] StepA2: Fill the inside of the flexible sleeve 2 with ferrofluid 1 or the mixture of ferrofluid and antirust paint. After the filling is completed, seal the interfaces at both ends with locking collar components to prevent the overflow of the ferrofluid 1, thereby forming the ferrofluid device 8;

[0047] StepA3: Place the steel bars 6 that have been treated with antirust evenly, and then place two magnet blocks 9 on both sides of the magnetic fluid device 8, so that the internal magnetic fluid or the mixture of magnetic fluid and antirust paint is adsorbed on the two sides of the inner wall of the flexible sleeve 2. side, and then unscrew the locking hoop assembly at both ends of the de...

Embodiment 3

[0052] Using any one of the magnetic fluid devices for rust prevention of steel to destroy the exposed steel reinforcement rust prevention method for internal reinforcement or components of cracked beams, plates, and column structures, it is characterized in that it includes the following steps:

[0053] StepB 1: First find the area where the component has cracks or the exposed steel bars are exposed, and then use a marker pen to mark the middle position 50cm-60cm away from the crack area;

[0054] StepB2: Use a manual drilling machine to drill a hole at the marked position, the hole diameter is 4cm-6cm, and the length of the hole is the thickness of the concrete. After the hole is completed, use the concrete perspective instrument 12 to extend the magnet block 9 along the hole into the steel bar inside the concrete. , and the small hole is blocked with a magnetic rod 10, one end of the magnetic rod 10 is connected with the magnet block 9, and finally the outer layer is painted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com