Patents

Literature

134results about How to "Reduce construction errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

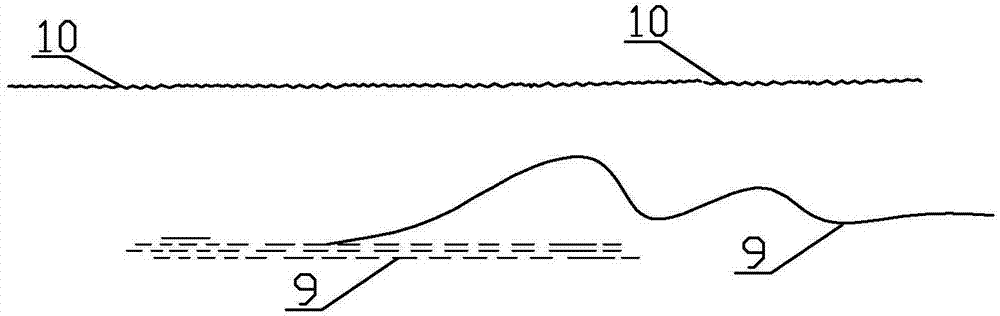

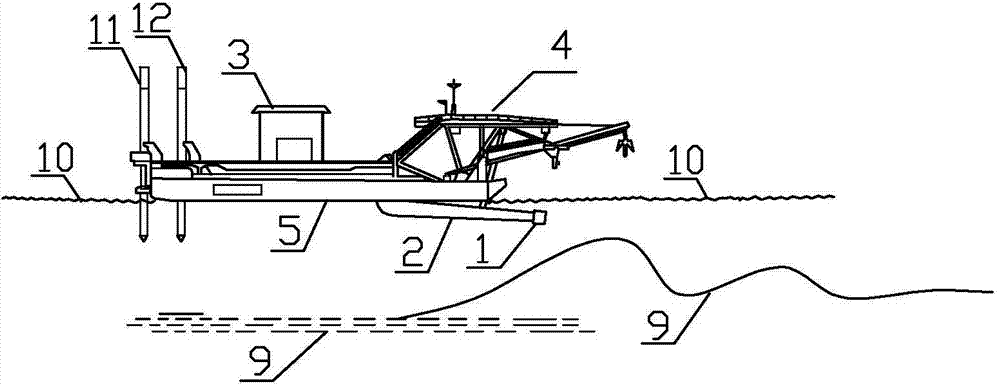

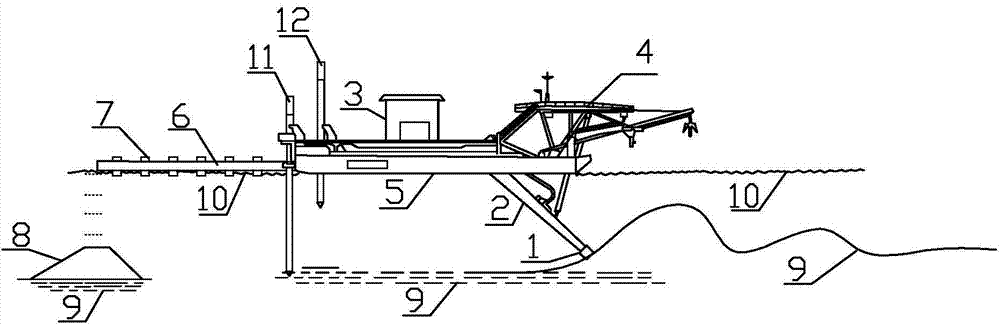

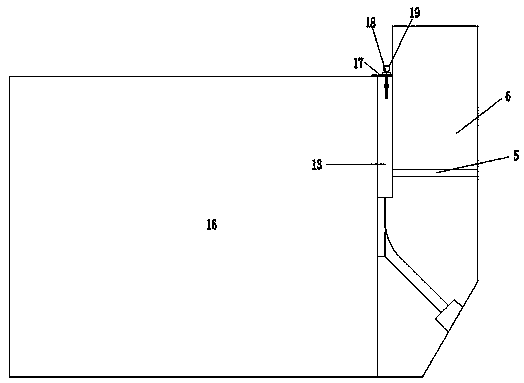

Construction method for carrying out sea reclamation with sand in shallow sea area through cutter suction dredger

ActiveCN104846787ASave resourcesAvoid damageMechanical machines/dredgersClimate change adaptationOcean bottomEcological environment

Disclosed is a construction method for carrying out sea reclamation with sand in a shallow sea area through a cutter suction dredger. The cutter suction dredger comprises a cutter suction head, a suction pipe, a power system and a ship body. The cutter suction dredger adopts a mechanical reamer of the cutter suction head to ream the underwater sand soil layer through the power system, and then mechanically excavates and sucks soil through a mud pump of the power system. The sucked sand soil is conveyed to the destination through a pipeline conveying mode, and the construction method for carrying out sea reclamation with sand in a shallow sea area is realized through water separation and sand sedimentation. The construction method includes the steps that A, machines are arranged in place; B, a sand blasting guide pipe is laid; C, soil is sucked in a cutting mode and excavated; D, soil sediments to make land. The sand sedimentting on the seafloor serves as the filling materials of a sea reclamation structure. Cutting of coastal line resources is effectively reduced. The original ecologic environment of the sea is protected to the maximum extent. The work procedures of slurry excavation, conveying, discharging, processing and the like are finished at a time, so that the construction efficiency is improved.

Owner:广西建工第五建筑工程集团有限公司

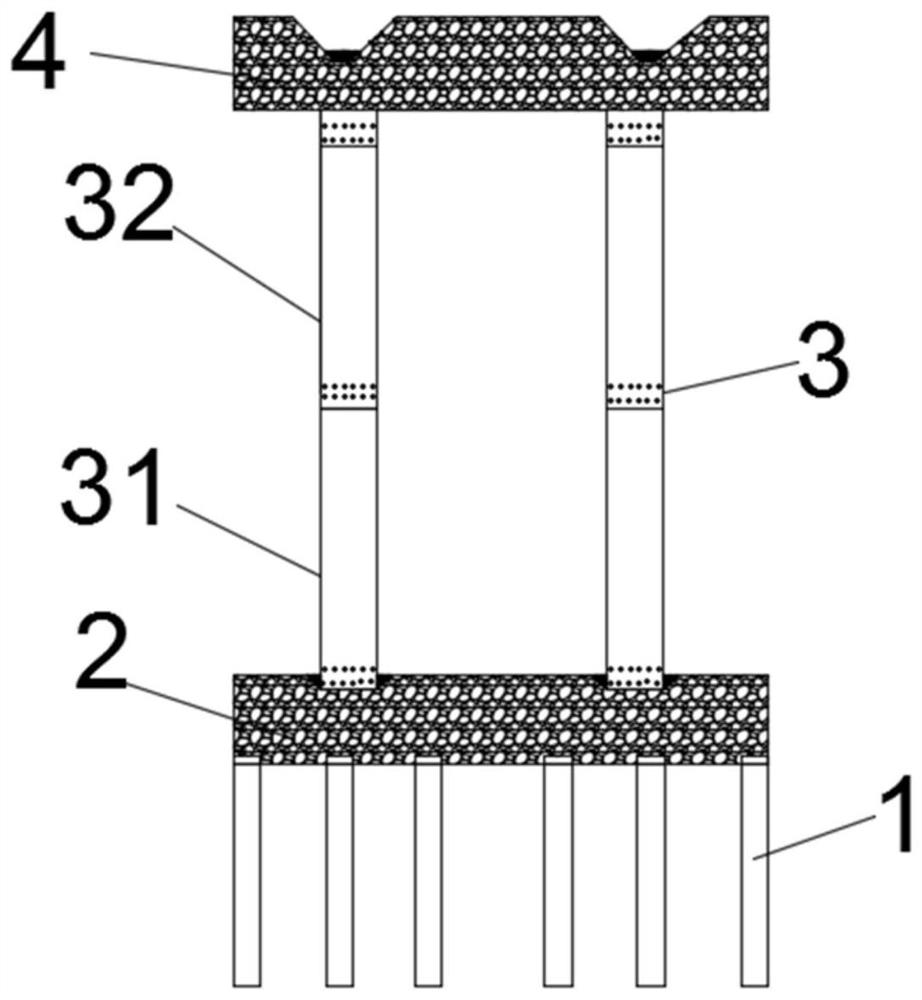

Fabricated pier and construction process thereof

PendingCN111648228AEnsure safetyEasy to assembleCeramic shaping apparatusBridge structural detailsPierConstruction engineering

The invention discloses a fabricated pier and a construction process thereof. The assembly type pier comprises a plurality of tubular piles, a bearing platform, a pier column and a cover beam. The tubular piles are arranged at the lower end of the bearing platform and connected with the bearing platform, the lower ends of the piers are mounted in pier positioning grooves in the upper end surface of the bearing platform, and the upper end and the cover beam are connected, prefabricated assembly is adopted in the construction process, all parts of the fabricated pier are prefabricated, and spliced, installed and constructed in parallel after being prefabricated, the construction period is greatly shortened, the influence of construction on the surrounding environment is improved, the appearance quality and the entity quality of engineering are improved, and the fabricated pier has the advantages of being high in standardization degree in the construction process, good in cost control effect and high in construction quality.

Owner:THE NO 1 ENG CO LTD OF THE AIRPORT GRP OF CHINA RAILWAY +1

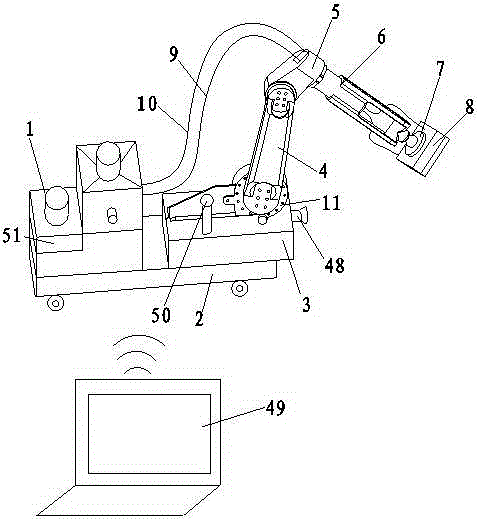

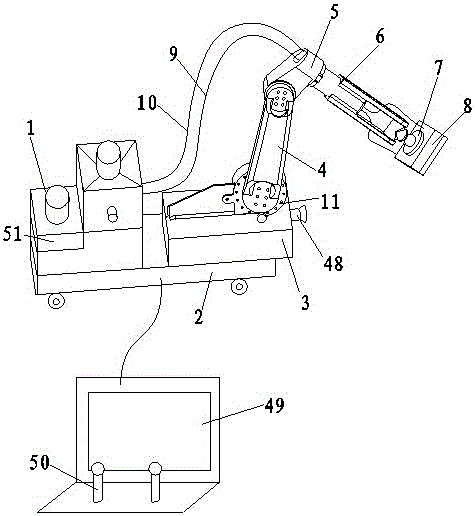

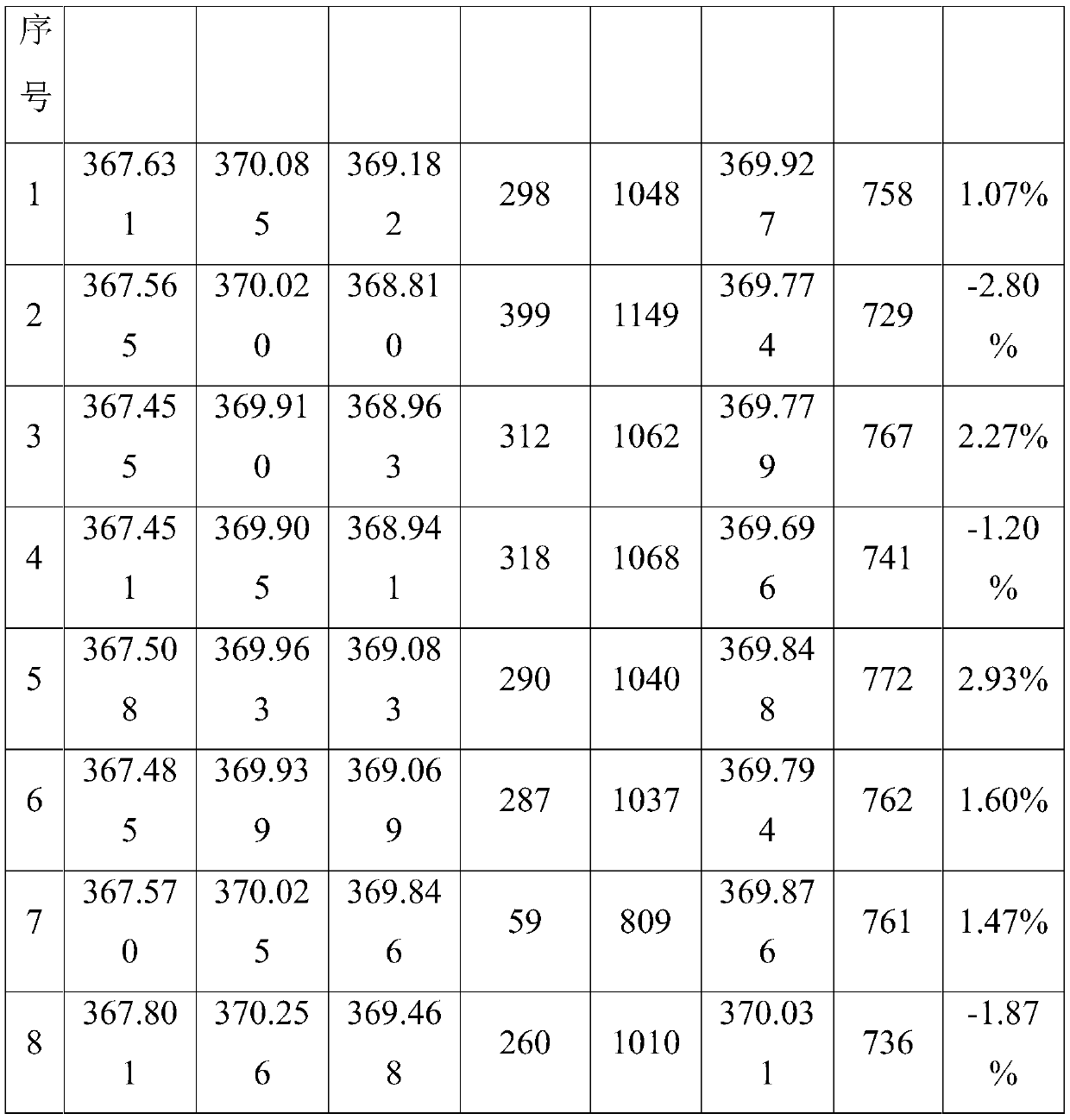

Spraying robot with automatic visual tracking function

The invention discloses a spraying robot with an automatic visual tracking function. The spraying robot comprises a conveying device, a moving device, an adjusting base, a large arm, a transition arm, a third arm, a rotary connector and a painting device. The adjusting base is mounted on the moving device, a mounting seat is mounted on the upper surface of the adjusting base and is hinged to the large arm, the large arm is hinged to the transition arm, the transition arm is hinged to the third arm, the rotary connector is arranged at the front end of the third arm, and the painting device is mounted at the front end of the rotary connector. The spraying robot has the advantages that tailing materials can be recycled, accordingly, the cost can be saved, surrounding edges can be fitted, and environmental pollution due to falling of the tailing materials in construction sites can be prevented; the spraying robot has the automatic visual tracking function, accordingly, construction personnel and equipment are separated from one another during site operation construction, and automatic construction can be implemented; fitting intensity of the painting device and walls can be adjusted at any time by the aid of load pressure sensors, and accordingly good plastering and tailing material recycling effects can be realized.

Owner:安徽东坚仓储货架制造有限公司

Suspended ceiling system and construction method thereof

ActiveCN104612307AEven by forceStable structureCeilingsBuilding material handlingEngineeringCantilever

The invention provides a suspended ceiling system which is suspended on spherical nodal points of steel structure on a roof. The suspended ceiling system is characterized by comprising a suspended system connected with the spherical nodal points; a diamond unit frame structure system arranged on the lower side of the suspended system; a ribbon board system arranged on the lower side of the diamond unit frame structure system in a lifting mode. The suspended ceiling system is characterized in that the diamond unit frame structure system comprises multiple diamond unit frames which are connected with each other in a splicing mode, the suspended system comprises multiple multi-direction movable cantilever beams which are connected with multiple spherical nodal points respectively, each multi-direction movable cantilever beam is provided with at least two extended frames, and the extended frames are connected with the diamond unit frame arranged on the lower side of the corresponding spherical nodal point in a lifting mode. The suspended ceiling system is forced uniformly in whole, and is firm in structure, good in steady performance, and excellent in displaying the suspended effect.

Owner:中建八局装饰工程有限公司

A bridge anti-collision guardrail and a construction method thereof

InactiveCN109056523AIncrease impact forcePlay a protective effectBridge structural detailsBridge erection/assemblyCushioningArchitectural engineering

The invention discloses a bridge anti-collision guardrail and a construction method thereof, Collision barriers include columns, An upper rail and a low rail are respectively sleeved with a buff cylinder and a swirling ring on that upright column, the two ends of the upright column are fix on the upper rail through a limiting seat, the lower rail is provided with a fixing ring on the upright column, the fixing ring is in contact with the limiting seat located below, an L-shaped mounting plate is provided on the upper rail, an L-shaped mounting plate is provided with an anti-collision plate, and a cushioning guardrail plate is provided on the anti-collision plate; The construction method comprises the following steps: (a) route marking; (b) Post positioning; (c) Installation of lower railings; (d) installation of an upper railing; (e) Installation of cushion shields; (f) Installation of bumper plates; (g) Installation of remaining uprights. The anti-collision guardrail of the inventionhas the advantages of high stability, convenient installation, cushioning and anti-collision, high safety, easy operation, orderly and reasonable construction, fast and convenient construction, time and labor saving, low construction intensity and convenient maintenance in the later period. The invention has the advantages of high stability, convenient installation, cushioning and anti-collision,high safety, easy operation, orderly and reasonable construction method, fast and convenient construction, and low construction intensity.

Owner:ZHEJIANG COLLEGE OF CONSTR

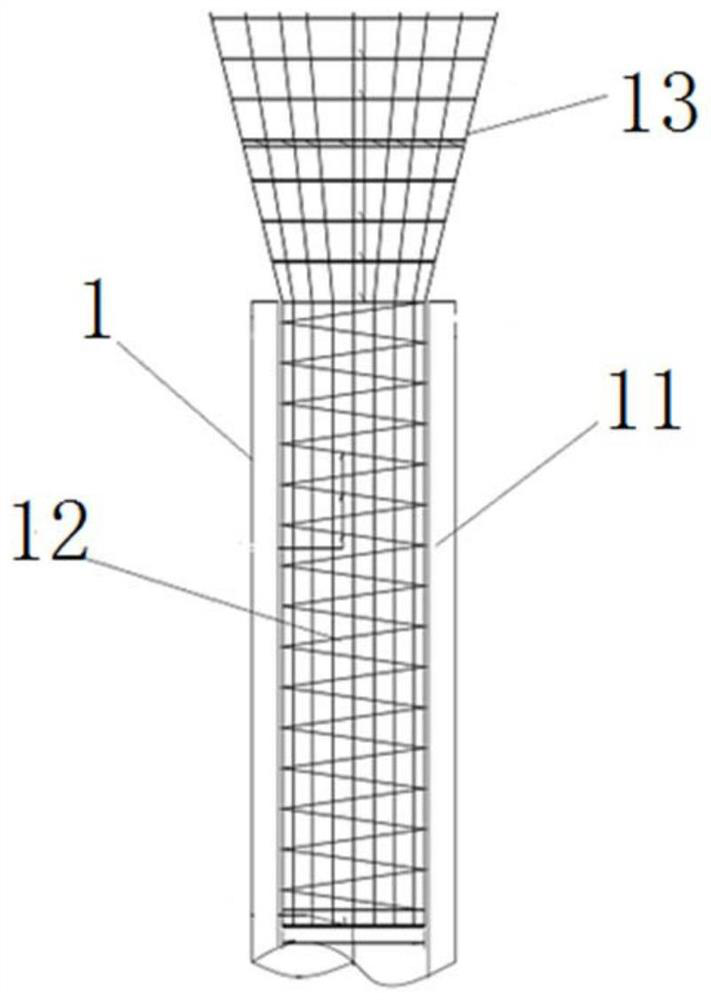

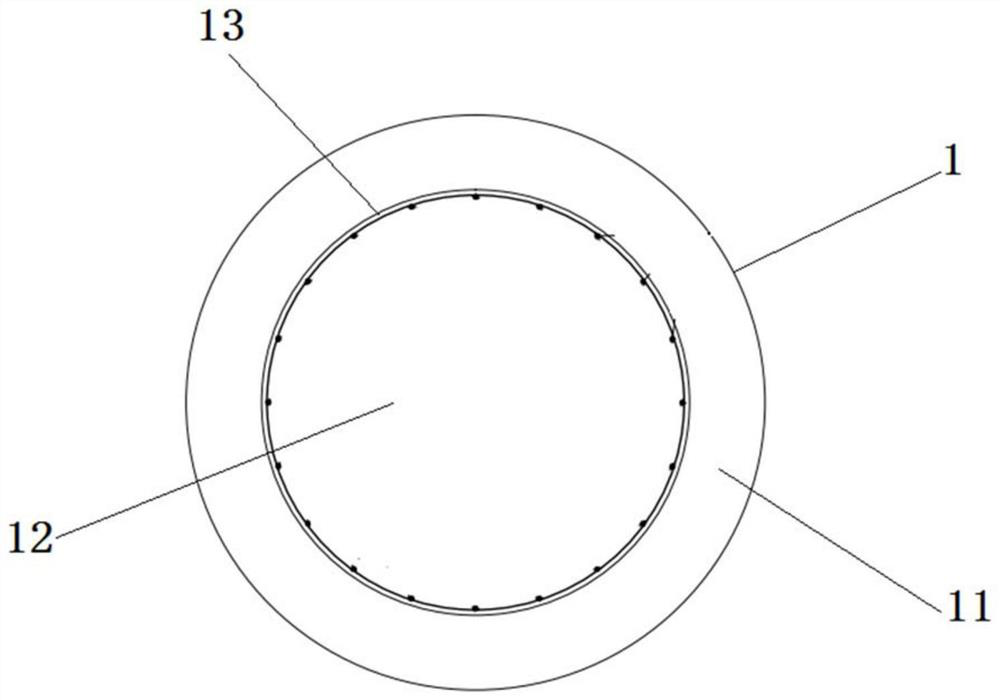

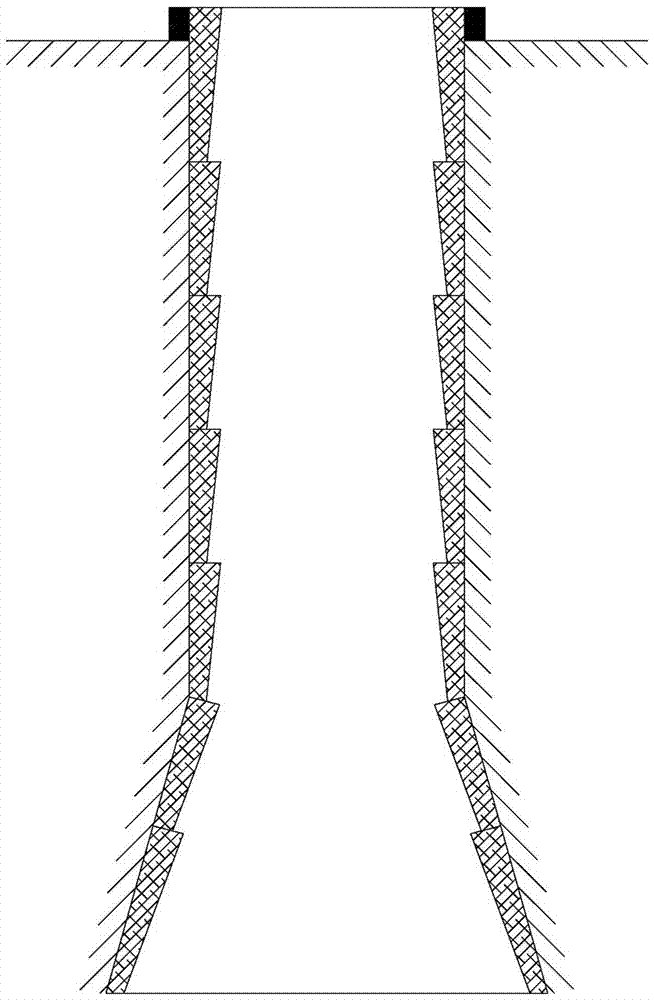

Construction method for artificial hole-digging grouting pile

ActiveCN106930277AHigh strengthImprove stress resistanceBulkheads/pilesReinforced concreteEngineering

The invention relates to the technical field of building construction, in particular to a construction method for an artificial hole-digging grouting pile. The construction method comprises the following steps that firstly, hole digging is conducted at a designed and determined artificial hole-digging grouting pile positioning point in an artificial hole digging manner, and pouring of a reinforced concrete well ring is conducted; secondly, pile hole protection wall construction is conducted, and before a protection wall template is installed, the bottom of a pile hole is downwards excavated to form a groove, and a connecting assembly connecting an upper protection wall with a lower protection wall is placed in the groove; thirdly, pile end expansion head construction is conducted; fourthly, the protection wall template is dismounted, and a reinforcement cage is hung and placed down; and fifthly, grouting pile pouring is conducted, concrete is pumped to a material barrel port through a concrete pump and pumped to the hole bottom through a material barrel via communication, and the concrete is vibrated densely through a concrete vibration machine. According to the construction method, the strength of the protection walls can be greatly improved, the anti-pressure ability that the protection walls resist a soil layer is improved, the protection walls have enough strength and stability and adapt to construction of soft soil texture, and the safety of the construction environment is improved; and the construction error between the upper protection wall and the lower protection wall can be reduced, and the precision of the pile center position and perpendicularity can be guaranteed.

Owner:HUAYU CONSTR GROUP

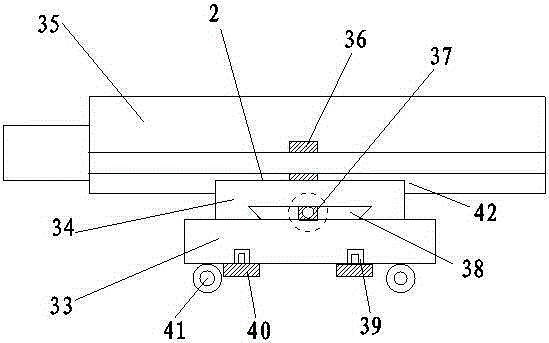

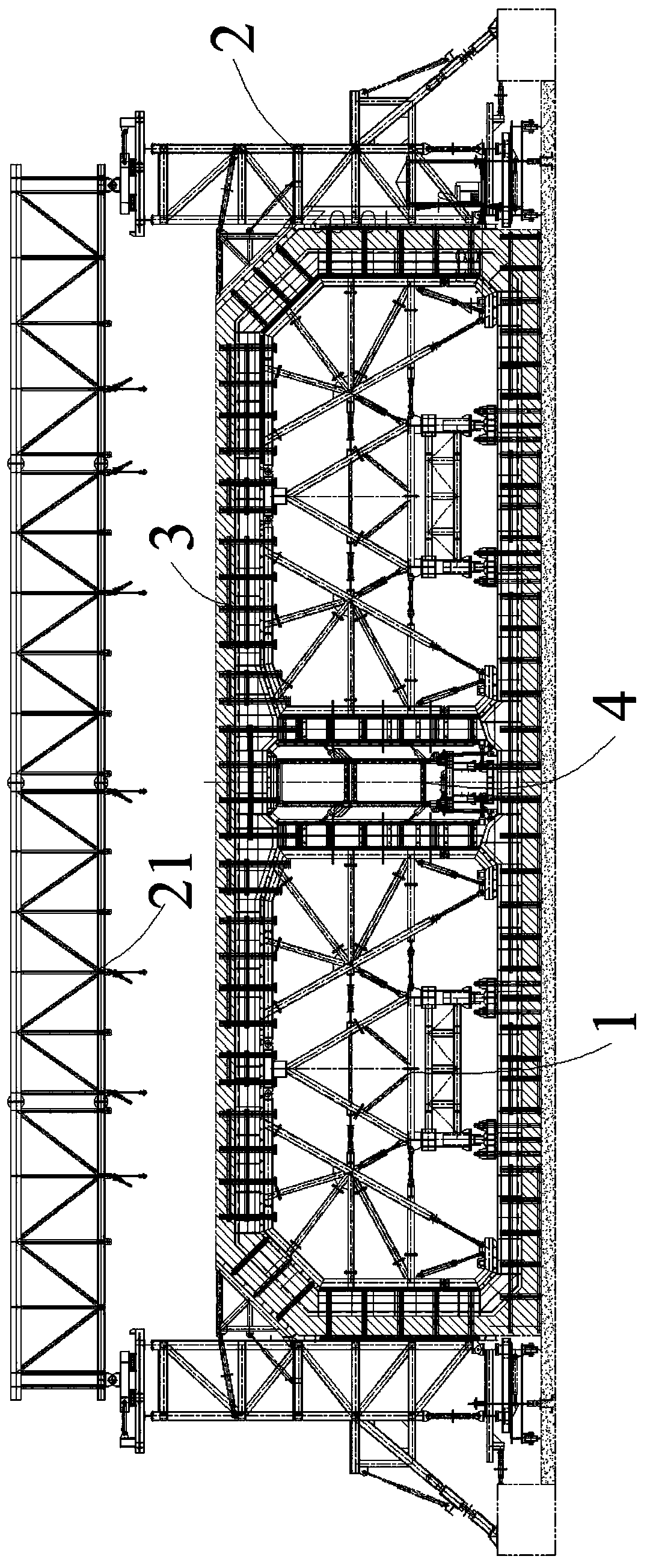

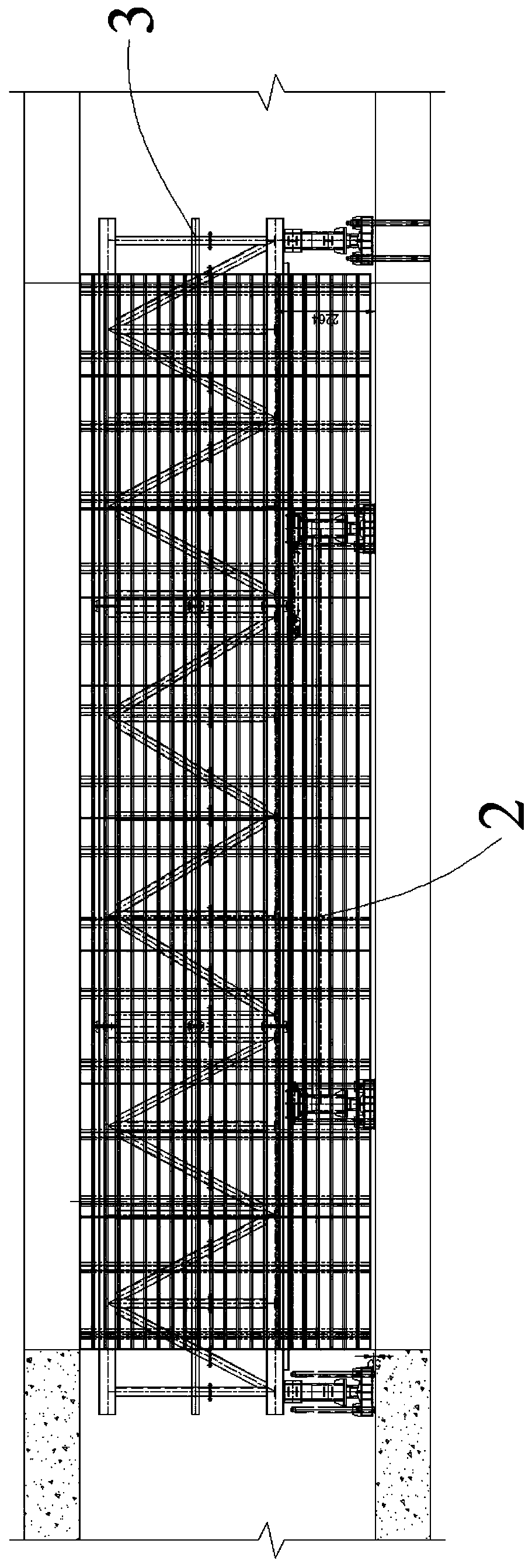

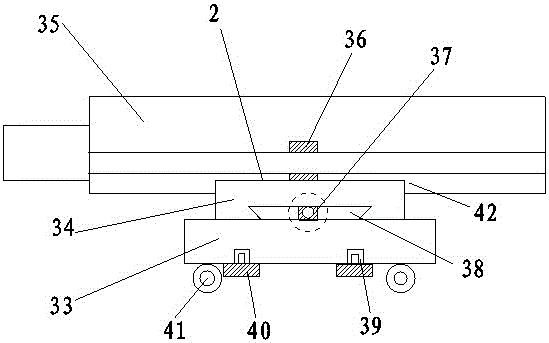

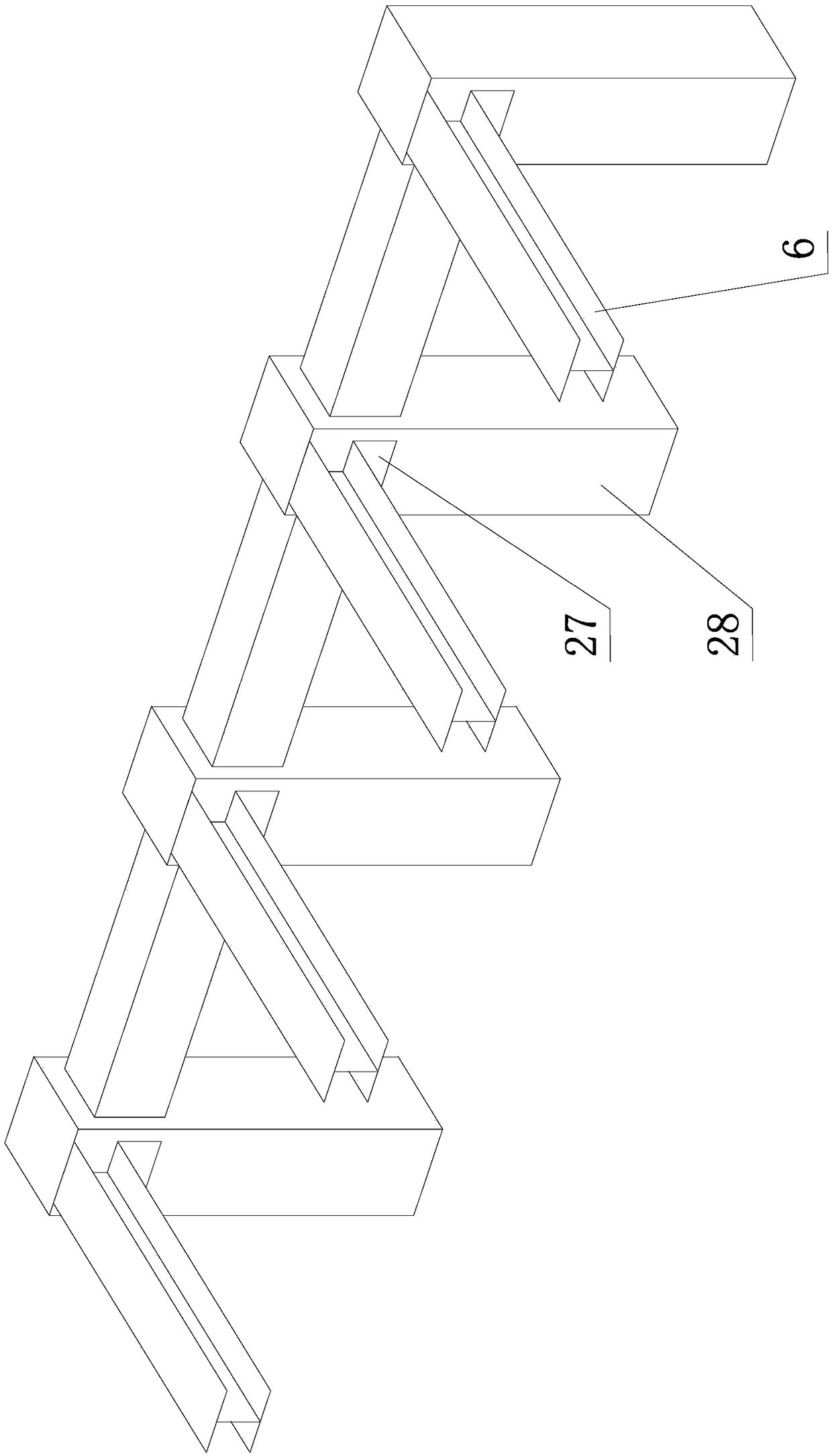

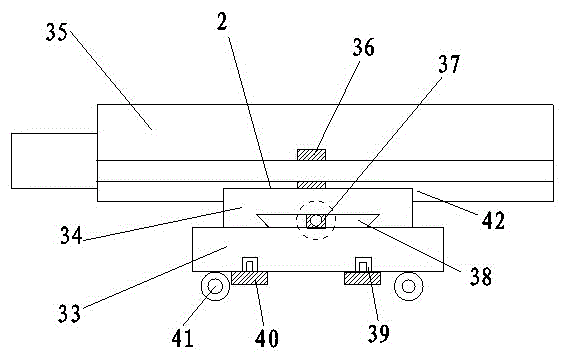

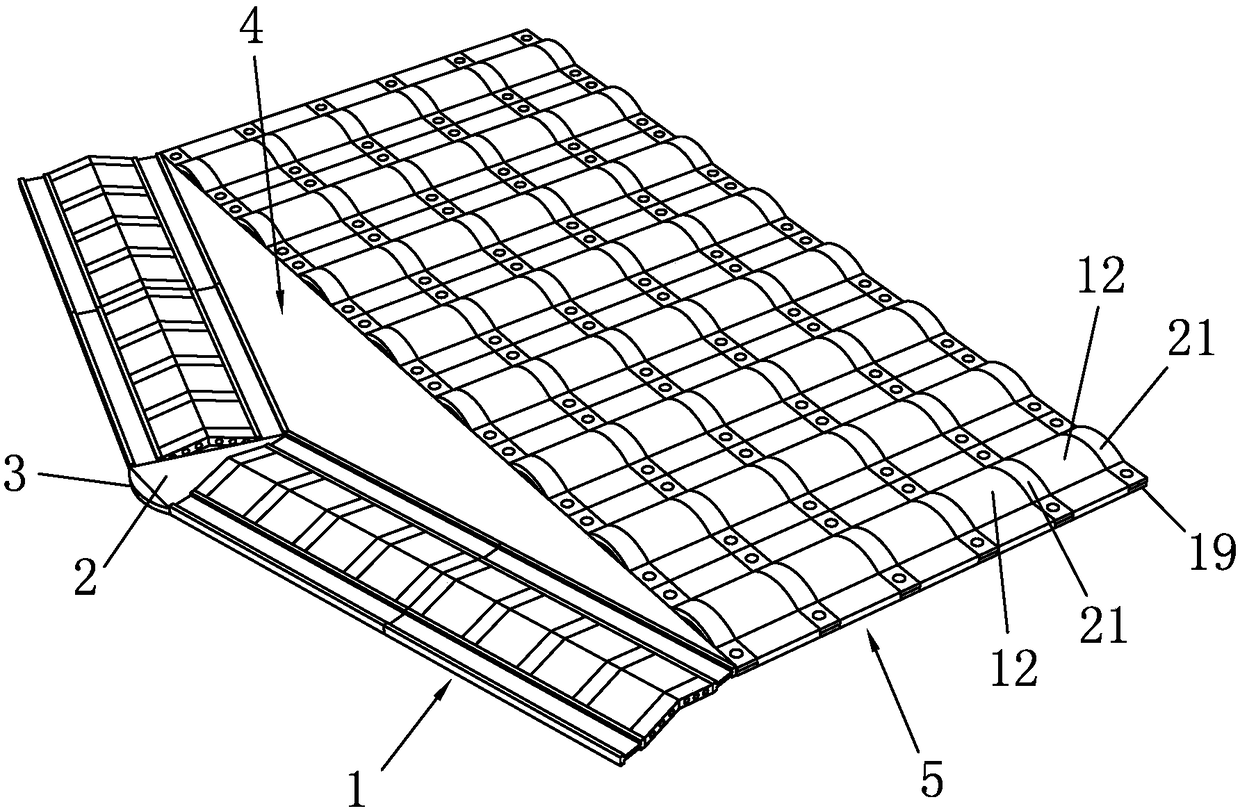

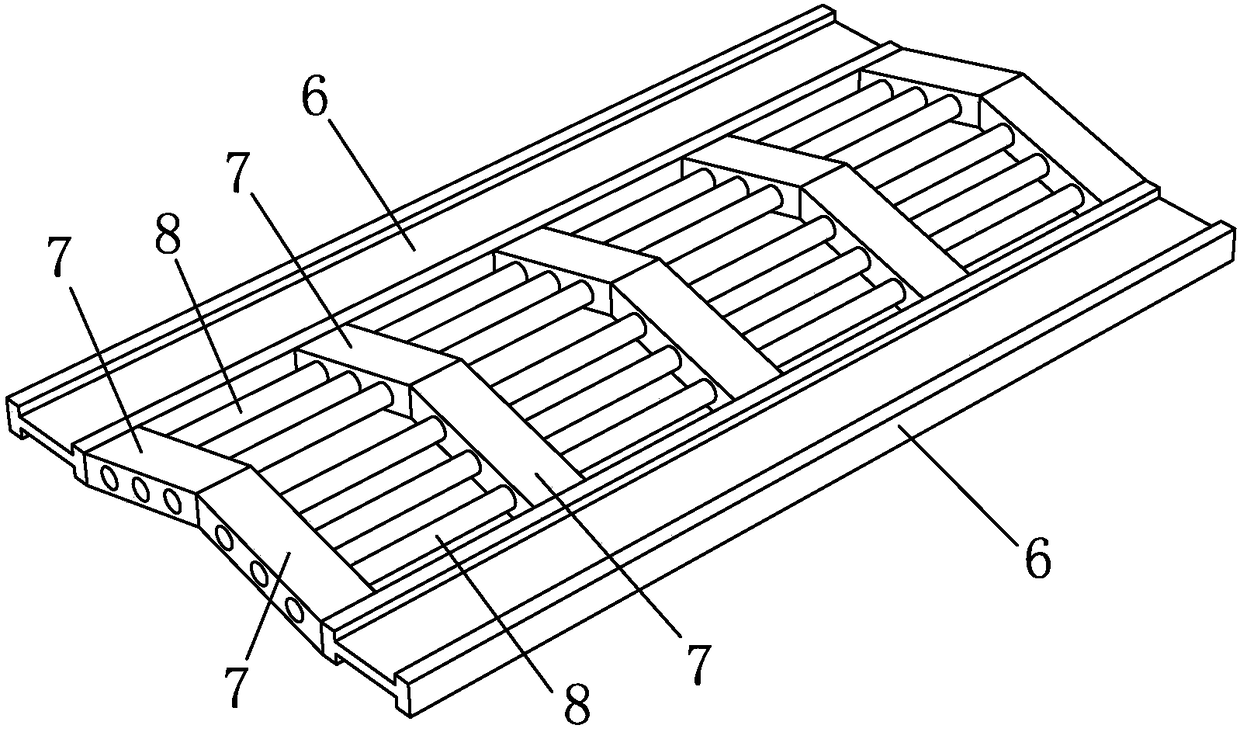

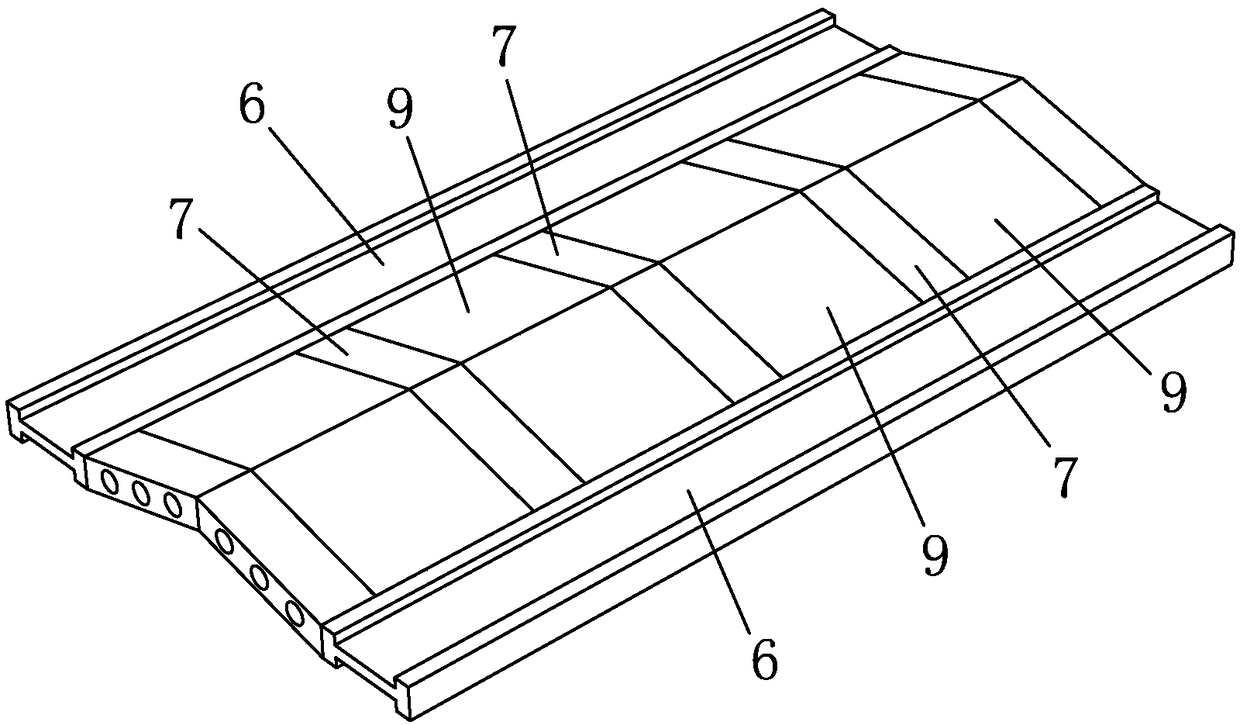

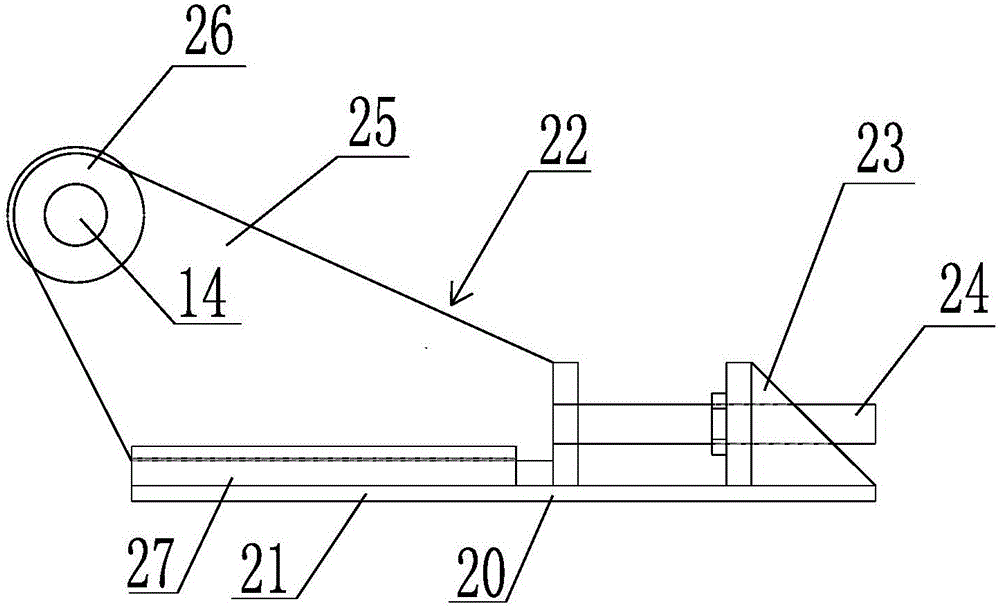

Dry dock sequential method full-section integral immersed tube prefabrication formwork system

PendingCN110076889AEasy to adjustSimple travel adjustmentDischarging arrangementMouldsSequential methodEngineering

The invention relates to the technical field of immersed tube prefabrication construction, in particular to a dry dock sequential method full-section integral immersed tube prefabrication formwork system. The system comprises an inner mold system, an outer mold system and an end mold system, wherein the inner mold system is located on the inner side of an immersed tube casting space and is connected with the outer mold system located outside the immersed tube casting space into a whole through the end mold system positioned at the longitudinal end part of the immersed tube casting space, the lower end of the inner mold system is provided with an inner mold travelling support device which is used for carrying out longitudinal, transverse and vertical position adjustment on the inner mold system, and the outer mold system is an outer side formwork structure capable of being adjusted in the longitudinal direction, the transverse direction and the vertical position. The immersed tube prefabrication method has the advantages of being accurate in position adjusting, less in main body structure damage and capable of operating all weather, so that the technical problems of sequential prefabrication, adjacent operation, compact space, longitudinal long-distance travel of an ultra-large super-heavy formwork is long, being prone to deviation and the like which occur to a sequential methodare solved.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES +1

Spraying device achieving remote video manipulation

The invention discloses a spraying device achieving remote video manipulation. A spraying robot comprises a feeding device, a moving device, an adjusting base, a big arm, a transition arm, a ternary arm, a rotating connector and a painting device. The adjusting base is installed on the moving device. An installation seat is installed on the upper surface of the adjusting base and hinged to the big arm. The big arm is hinged to the transition arm. The transition arm is hinged to the ternary arm. The front end of the ternary arm is provided with the rotating connector. The front end of the rotating connector is provided with the painting device. The spraying device achieving remote video manipulation has the advantages that tailings can be recycled, cost is saved, and an attached surrounding edge is arranged and prevents the situation that because the tailings fall off in a construction site, the environment is polluted; the spraying device can be remotely controlled, construction personnel and on-site device operation are separated, and therefore operation safety is facilitated; the attachment intensity of the painting device to a wall can be adjusted at any time through a load pressure sensor, and good plastering and tailing recovering effects are achieved.

Owner:安徽通成五金制品科技有限公司

Steady inflated steel tube concrete and construction method

InactiveCN1562860AControl clotting timeControl slump lossSolid waste managementSuperplasticizerBoric acid

The compound contains water, cement, sand material, flyash. The characteristic is that it also contains compound high-efficiency water-reducing mould-protecting agen, cement is aluminate sulfide cement 500-550, flyash 50-55, water 185-195, compound high-efficiency water-reducing mould-protecting agent 11-15, weight sand ratio of sand material is 38-42 percent. the compound high-efficiency water-reducing mould-protecting agent is composed by naphthalenes high-efficiency water-reducing agent, boric acid and xylon calcium sulphonic acid, weight percentage of each compound are azyl sulfonate high-efficiency water-reducing agent 32-38, nephthalenes high-efficiency water-reducing 37-43, boric acid 12-18, xylon calcium sylphonic acid 7-13.

Owner:WUHAN UNIV OF TECH

Method for installing incinerator

ActiveCN110440272AImprove installation efficiencyEliminate size deviationIncinerator apparatusSupporting systemSlag

The invention relates to a method for installing an incinerator. The method comprises the following steps: S1, base inspection paying-off; S2, mounting of a steel frame; S3, steel structure support installation; S4, mounting of a fire grate steel structure and a casting; S5, installing of a leachate bucket; S6, installing of a feeder; S7, mounting of a feeding hopper; S8, mounting of a furnace shell steel structure; S9, installing of a primary air chamber and a scraper ash conveyor; and S10, mounting of a slag remover. The method has the effects that the flatness, the levelness, the spacing between columns and the height difference of a whole supporting system conform to the design, the installation quality is good, and the operation quality of the incinerator is guaranteed.

Owner:HUNAN IND EQUIP INSTALLATION

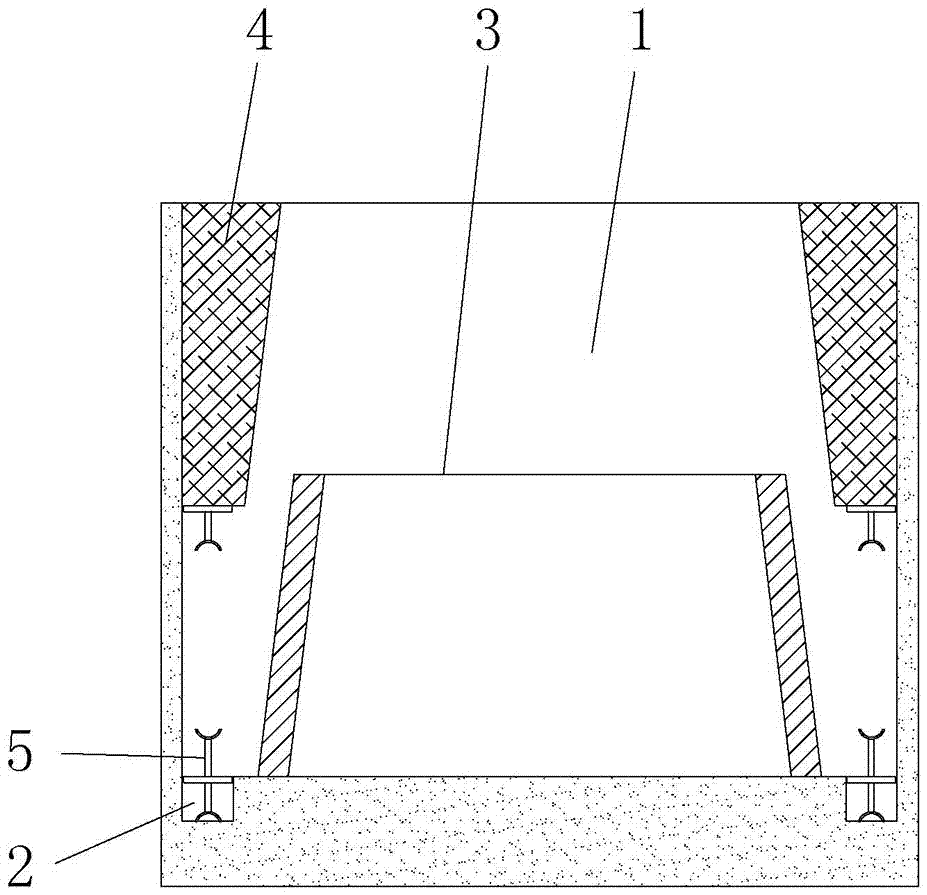

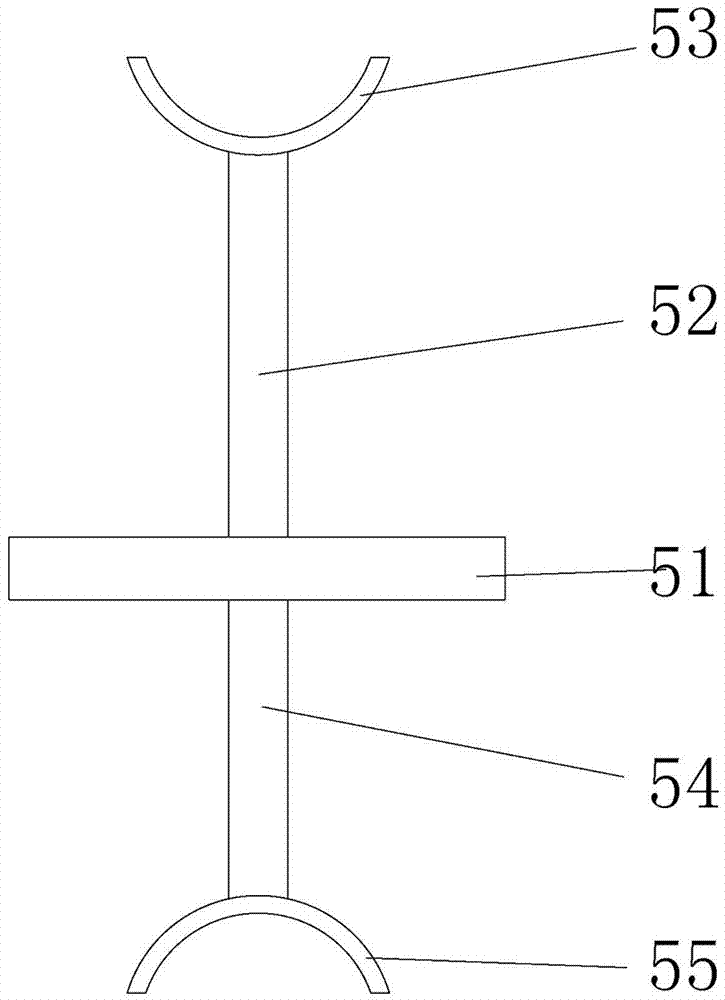

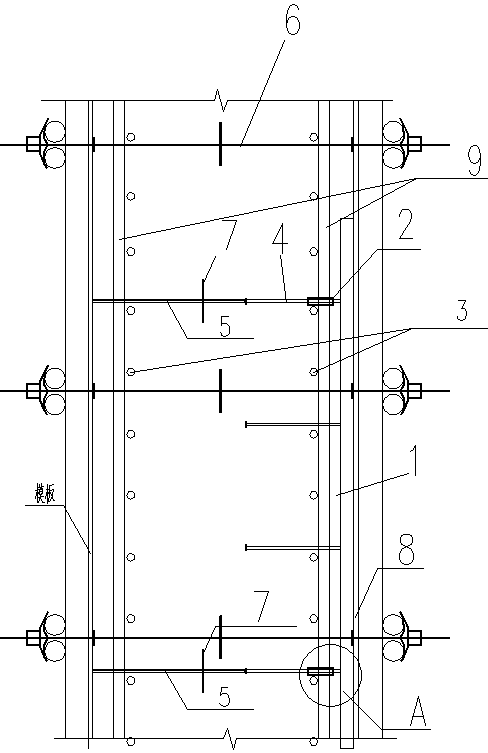

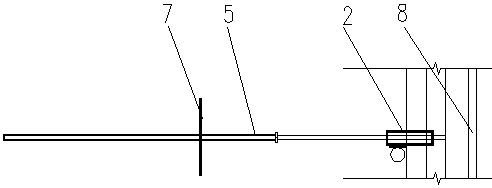

Embedded channel installation and fixation method under cast-in-place pipe gallery traditional technology

ActiveCN108086355AGuaranteed installation accuracyReduce construction errorsArtificial islandsUnderwater structuresRebarFixation method

The invention relates to an embedded channel installation and fixation method under the cast-in-place pipe gallery traditional technology. According to the embedded channel installation and fixation method, reinforcing steel bar binding is conducted first of all, and after reinforcing steel bar binding is completed, locating sleeves are welded to reinforcing steel bars, wherein the locating sleeves are perpendicular to the surface of a wall; holdfasts are connected with the embedded channel, and the holdfasts penetrate through the locating sleeves; formwork abutting rods are welded to the endsof the holdfasts; an inner formwork and an outer formwork of the wall are installed; protective layer cushion blocks are arranged on the bound wall reinforcing steel bars, split bolts penetrate through the protective layer cushion blocks, cement formwork abutting rods are installed, the interval between the inner formwork and the outer formwork is adjusted, and the channel and the formwork abutting bars are made to be in tight combination with the formworks on the two sides; the formworks are reinforced through the split bolts, the cement formwork abutting rods and primary and secondary bolts; and concrete is poured, and the embedded channel is permanently fixed. By the adoption of the embedded channel installation and fixation method under the cast-in-place pipe gallery traditional technology, the installation precision of the embedded channel is guaranteed, the construction errors are reduced, the work efficiency is improved, and the construction cost is reduced.

Owner:CHINA 22MCC GROUP CORP

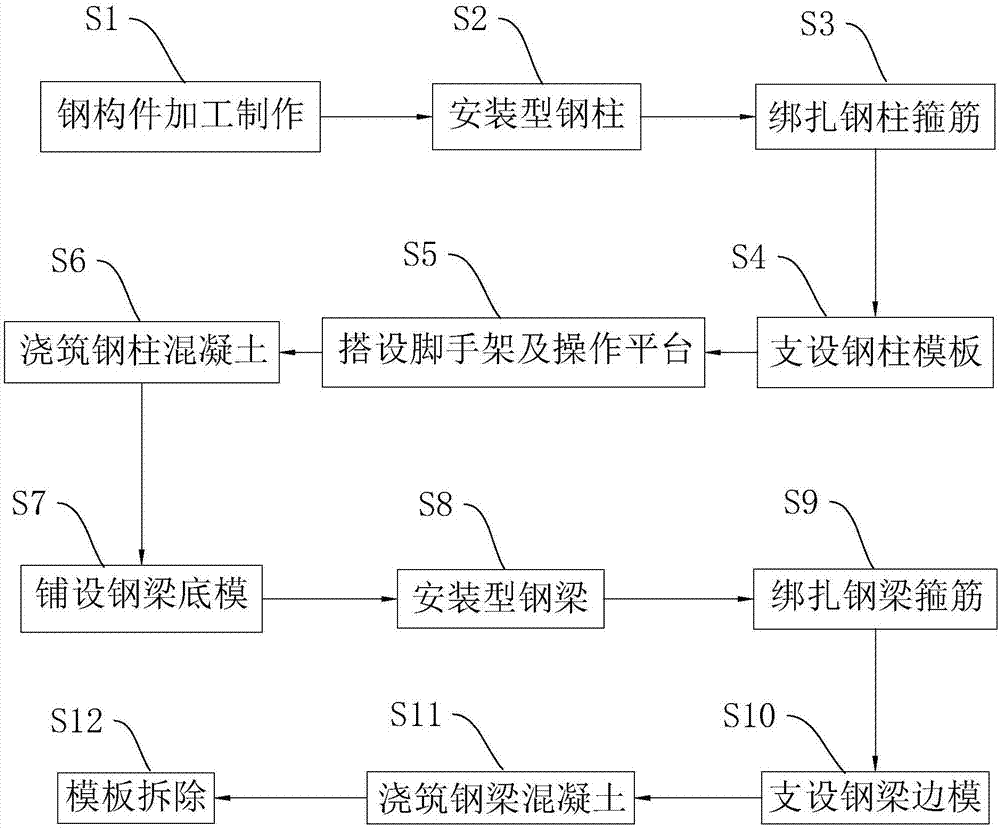

Construction method of stiffened concrete beam and column joint

InactiveCN110005075AImprove seismic performanceIncrease construction experienceGeometric CADBuilding constructionsConcrete beamsRebar

The invention belongs to the field of building construction, and particularly relates to a construction method of a stiffened concrete beam and column joint. Aiming at solving the problems that existing construction preparation is insufficient, consequently, the construction error is prone to occurring, joint optimization is insufficient, after construction is completed, the building bearing forceis not good enough, and the engineering quality is affected, the following solutions are put forward, specifically, the construction method comprises the following steps that S1, a model is established, three-dimensional setting-out of the arrayed joint is simulated through a computer BIM software, after three-dimensional setting-out of a computer, the parts which are excessively dense in array,have conflict in longitudinal steel bars and transverse steel bars, are excessively small in steel bar array pitch and cannot be welded are screened out; and S2, the steel bar array is optimized, theparts screened out in three-dimensional setting-out are subjected to steel bar replacement, and large-diameter steel bars are utilized to replace the original steel bars. According to the constructionmethod, the joint is subjected to three-dimensional simulated setting-out in advance, the steel bar array is optimized, then the construction situation is known in full angle through virtual realityequipment, the construction experience is increased, and thus the later construction error is reduced.

Owner:江苏中原建设集团有限公司

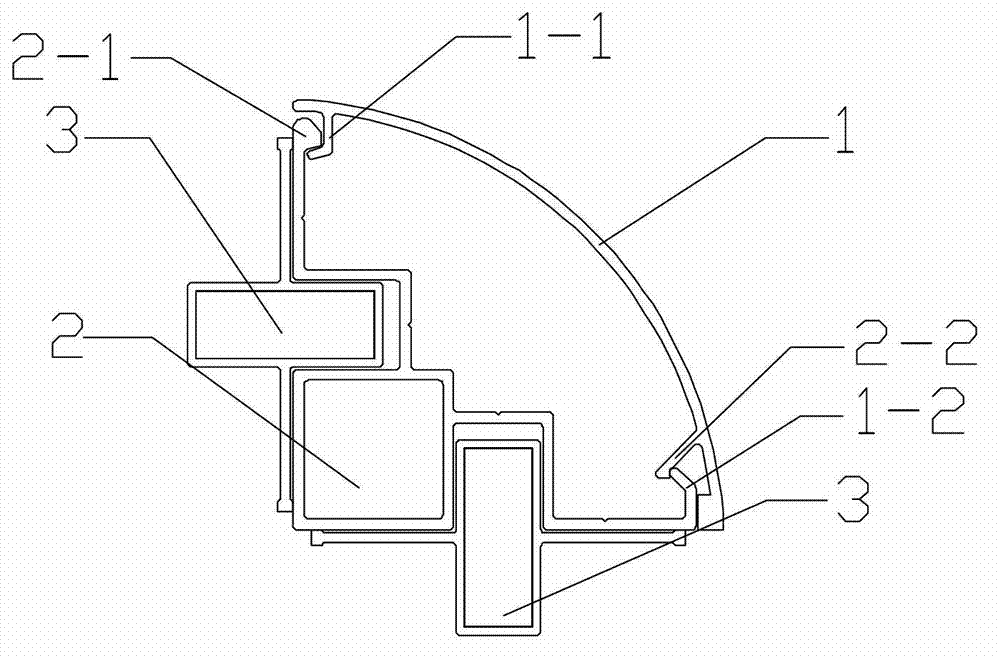

Arc corner for wallboard

The invention discloses an arc corner for a wallboard. The arc corner comprises a cylindrical arc-shaped cover plate and a base in an elongated structure. The arc corner is characterized in that an inserting fastener and a locking fastener are arranged on two sides of the cover plate respectively, an inserting block and a locking block are arranged on two sides of the base respectively, and the inserting fastener and the locking fastener are fastened with the inserting block and the locking block respectively. The arc corner for the wallboard has the advantages that the cover plate and the base are internally connected through the inserting fastener and the locking fastener and the inserting block and the locking block; and the corner position is easily damaged by bump, and the cover plate can be exchanged directly after damage, so that the dismounting and the remounting are simple.

Owner:KUNSHAN MAX METAL

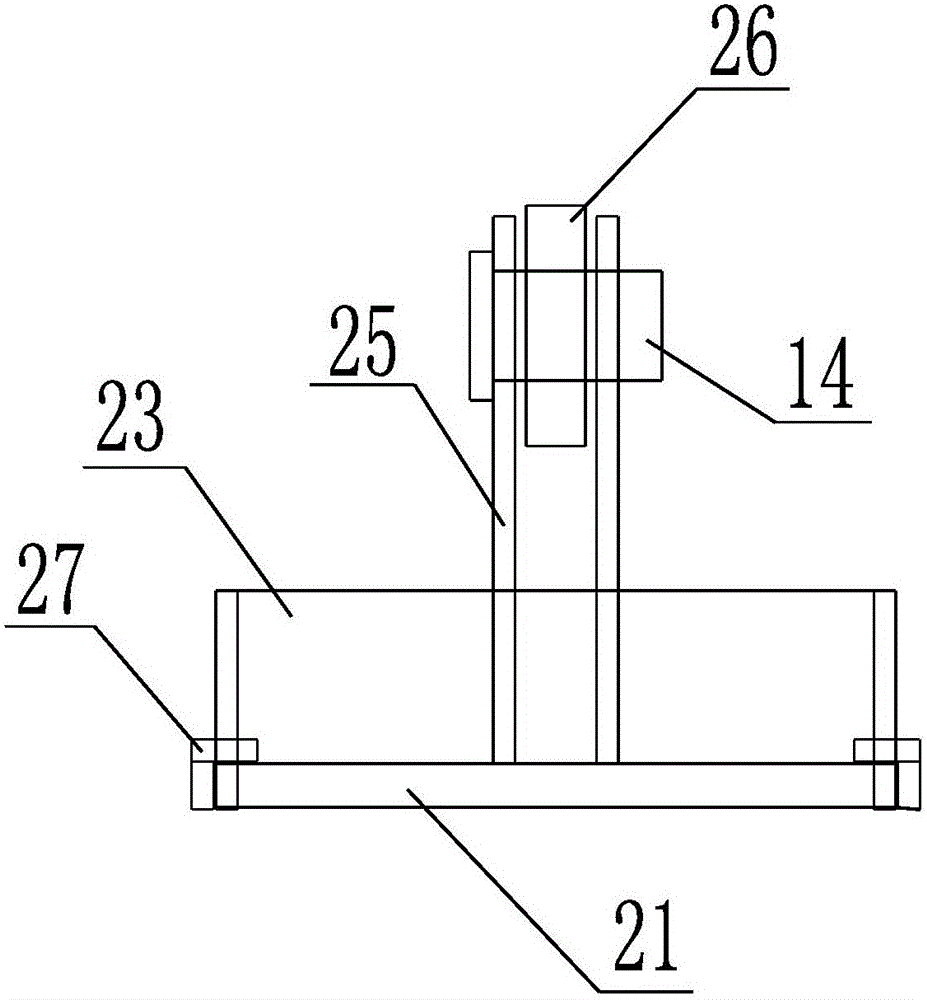

Manual correction device for cantilever steel beam and construction method thereof

The invention discloses a manual correction device for a cantilever steel beam and a construction method. The manual correction device comprises a supporting mechanism and a traction mechanism. The supporting mechanism comprises a supporting frame, a z-direction jack and a plug. The supporting frame is fixed with the plug through the z-direction jack, an x-direction jack and a y-direction jack areinstalled in the plug, x-direction idler wheels for supporting the cantilever end of the cantilever steel beam are rotatably installed on a bracket of the x-direction jack, and y-direction idler wheels for supporting the cantilever end of the cantilever steel beam are rotatably installed on a bracket of the y-direction jack. The traction mechanism comprises an x-direction traction rope and two y-direction traction ropes, and the three traction ropes are detachably connected with the outer end and the left and right sides of the cantilever steel beam through respective rope buckles of the three traction ropes. The key of the manual correction device is to use the two groups of idler wheels to alternately support and lubricate the cantilever end and use the traction ropes to pull for correction. According to the manual correction device and the construction method, the cantilever ends of the cantilever steel beams can be kept aligned in all directions of x, y, and z.

Owner:ZHEJIANG ERJIAN STEEL STRUCTURE

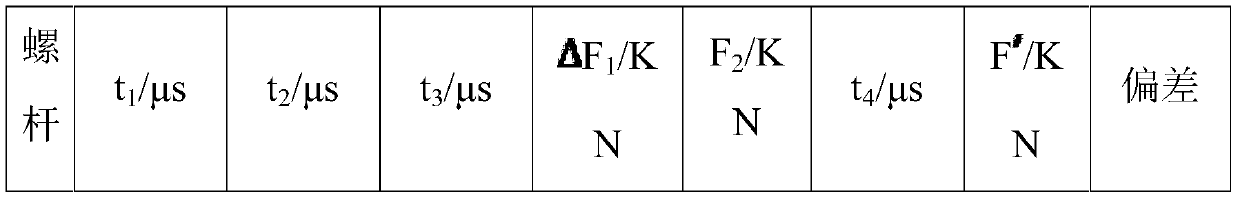

Suspension bridge cable clamp screw axial force synchronous construction system and use method thereof

ActiveCN110374003ASettle the lossSolve engineering problems with high randomnessBridge structural detailsBridge erection/assemblyBridge engineeringEngineering

The invention discloses a suspension bridge cable clamp screw axial force synchronous construction system and a use method thereof, and relates to the technical field of bridge engineering construction. The system comprises a tensioning device, an ultrasonic detection device and a control device, wherein the tensioning device is used for being connected with a to-be-tensioned screw and tensioningthe to-be-tensioned screw; the ultrasonic detection device is used for being connected with the to-be-tensioned screw, transmitting an ultrasonic signal to the to-be-tensioned screw, and detecting the transmission time of round trip of the ultrasonic signal in the to-be-tensioned screw; and the control device is connected with the tensioning device and the ultrasonic detection device and is usedfor calculating correction construction axial force F2 in the to-be-tensioned screw according to t2, t3 and a preset formula, and the tensioning device is controlled to carry out tensioning on the to-be-tensioned screw rod by adopting the correction construction axial forceF2. According to the system, a correction scheme is formulated for the retraction loss condition of single screw tensioning,and the engineering problems of large axial force loss and large randomness of the screw after a nut is screwed are well solved.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

Multifunctional environment-friendly spraying robot

The invention discloses a multifunctional environment-friendly spraying robot. The multifunctional environment-friendly spraying robot comprises a feeding device, a moving device, an adjusting base, a big arm, a transition arm, a ternary arm, a rotating connector and a painting device. The adjusting base is installed on the moving device. An installation seat is installed on the upper surface of the adjusting base and hinged to the big arm. The big arm is hinged to the transition arm. The transition arm is hinged to the ternary arm. The front end of the ternary arm is provided with the rotating connector. The front end of the rotating connector is provided with the painting device. The multifunctional environment-friendly spraying robot has the advantages that tailings can be recycled, cost is saved, and an attached surrounding edge is arranged and prevents the situation that because the tailings fall off in a construction site, the environment is polluted; the spraying robot can achieve the functions of spreading concrete, spraying emulsion paint and the like; wireless remote control operation is achieved, construction personnel and on-site device operation are separated, and therefore operation safety is facilitated; the attachment intensity of the painting device to a wall can be adjusted at any time through a load pressure sensor, and good plastering and tailing recovering effects are achieved.

Owner:MAANSHAN ZHICHENG SCI & TECH

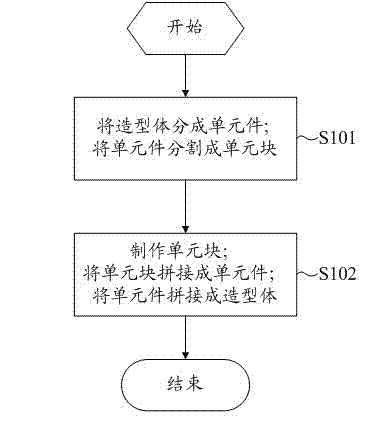

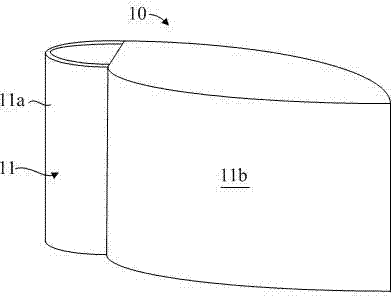

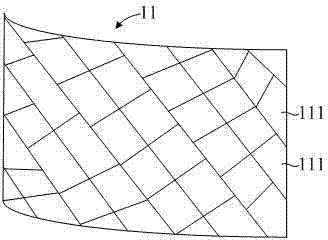

Space shaping construction method of artificial acrylic stone

The embodiment of the invention discloses a space shaping construction method of artificial acrylic stone. The space shaping construction method of the artificial acrylic stone comprises the steps that a shaping body is divided into a plurality of unit parts in a virtual space, and then each unit part is divided into a plurality of unit blocks; according to the unit blocks in the virtual space, real unit blocks are manufactured by using artificial acrylic stone, the real unit blocks are spliced to form the unit parts, and then the unit parts are spliced to form a shaping body identical with the shaping body in the virtual space. According to the space shaping construction method of the artificial acrylic stone, firstly the shaping body is divided into the unit parts and the unit blocks in the virtual space, the real unit blocks are then manufactured and assembled according to the unit blocks in the virtual space, therefore, the construction period is short, the error between the manufactured shaping body and the designed shaping body is small, the manufactured shaping body is attractive, and more complex curve surfaces can be shaped.

Owner:GUANGDONG DIANBAI CONSTR GRP

Movable formwork structure and construction method thereof

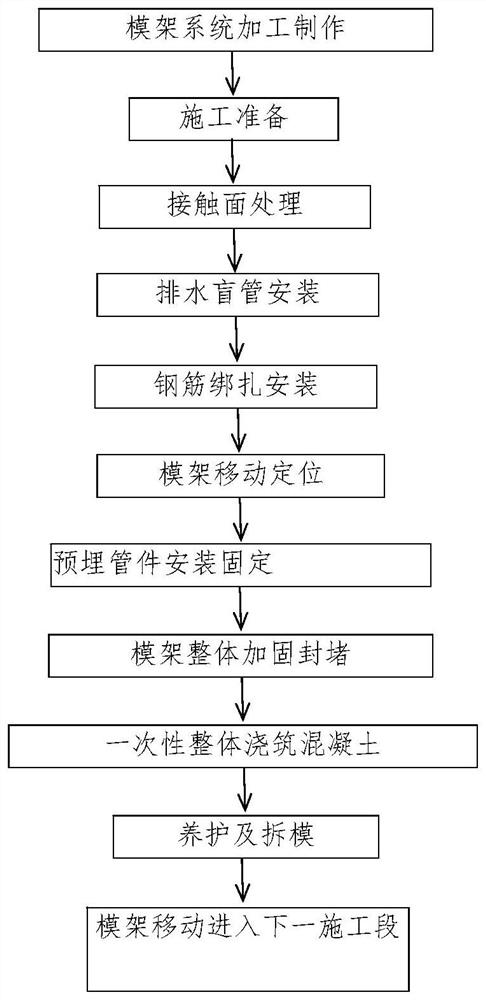

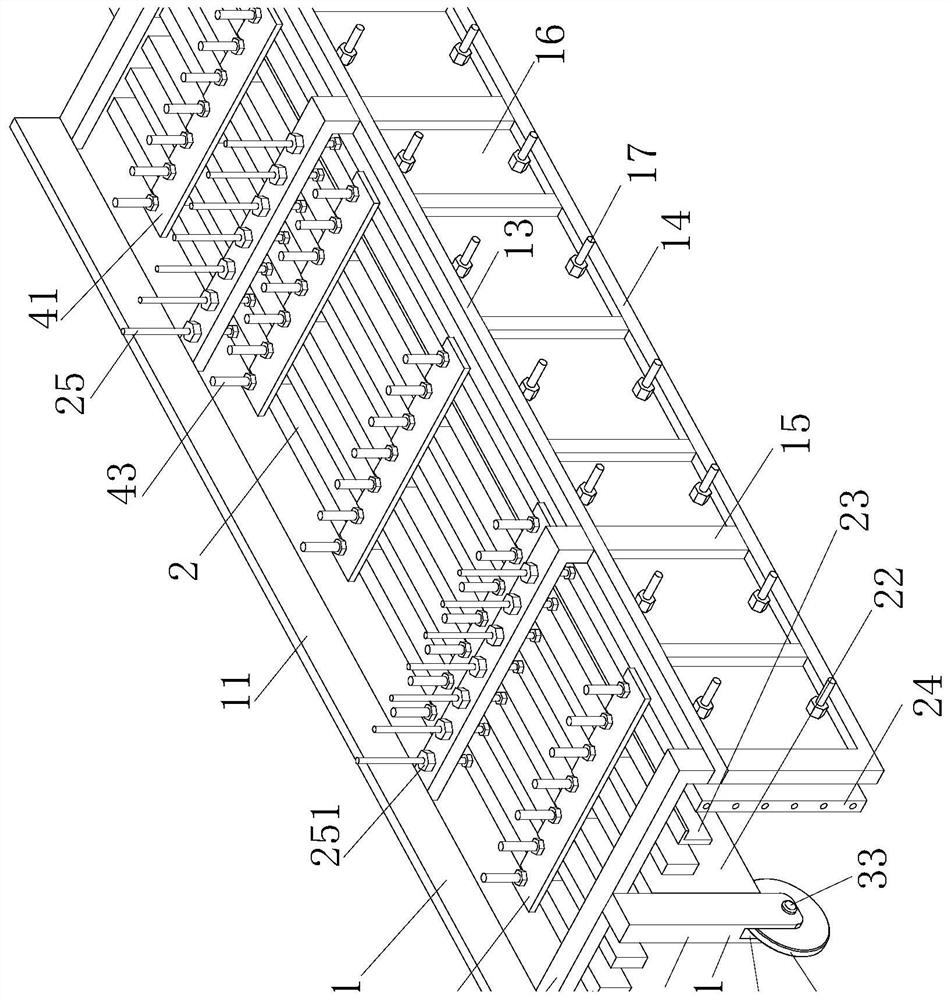

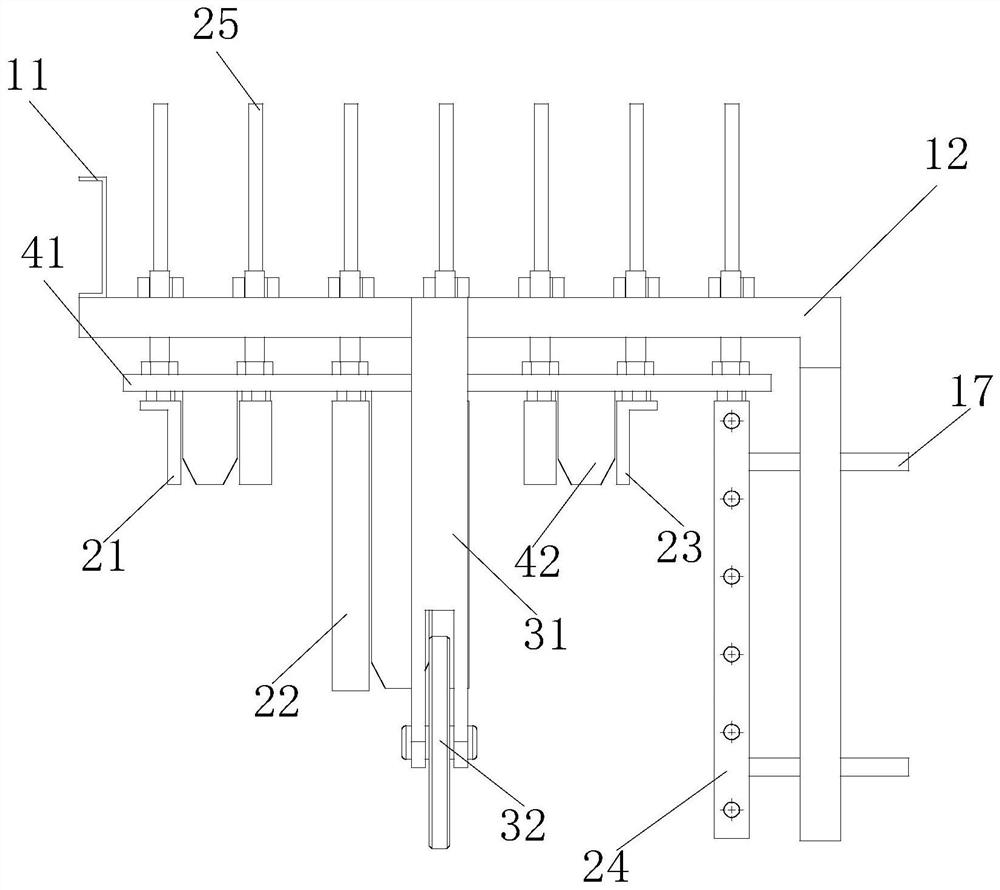

PendingCN112064676ASimple construction operationEasy to operateCable installations on groundArtificial islandsPipe fittingArchitectural engineering

The invention belongs to the technical field of cable trench construction, and particularly relates to a movable formwork structure and a construction method thereof. The construction method comprisesthe steps of formwork system machining and manufacturing, construction preparation, contact surface treatment, drainage blind pipe mounting, steel bar binding and mounting, formwork moving and positioning, pipe burying piece mounting and fixing, formwork overall reinforcing and plugging, one-time overall pouring and coagulation, maintenance and formwork dismounting and formwork moving to enter the next construction section. The construction method is simple and convenient to operate, good in quality, high in construction speed, high in efficiency, low in labor intensity, time-saving, labor-saving, low in comprehensive construction cost, good in economic benefit and suitable for construction of trench structures such as tunnel cable trenches and roadbed drainage ditches.

Owner:CHONGQING NO 3 CONSTR +1

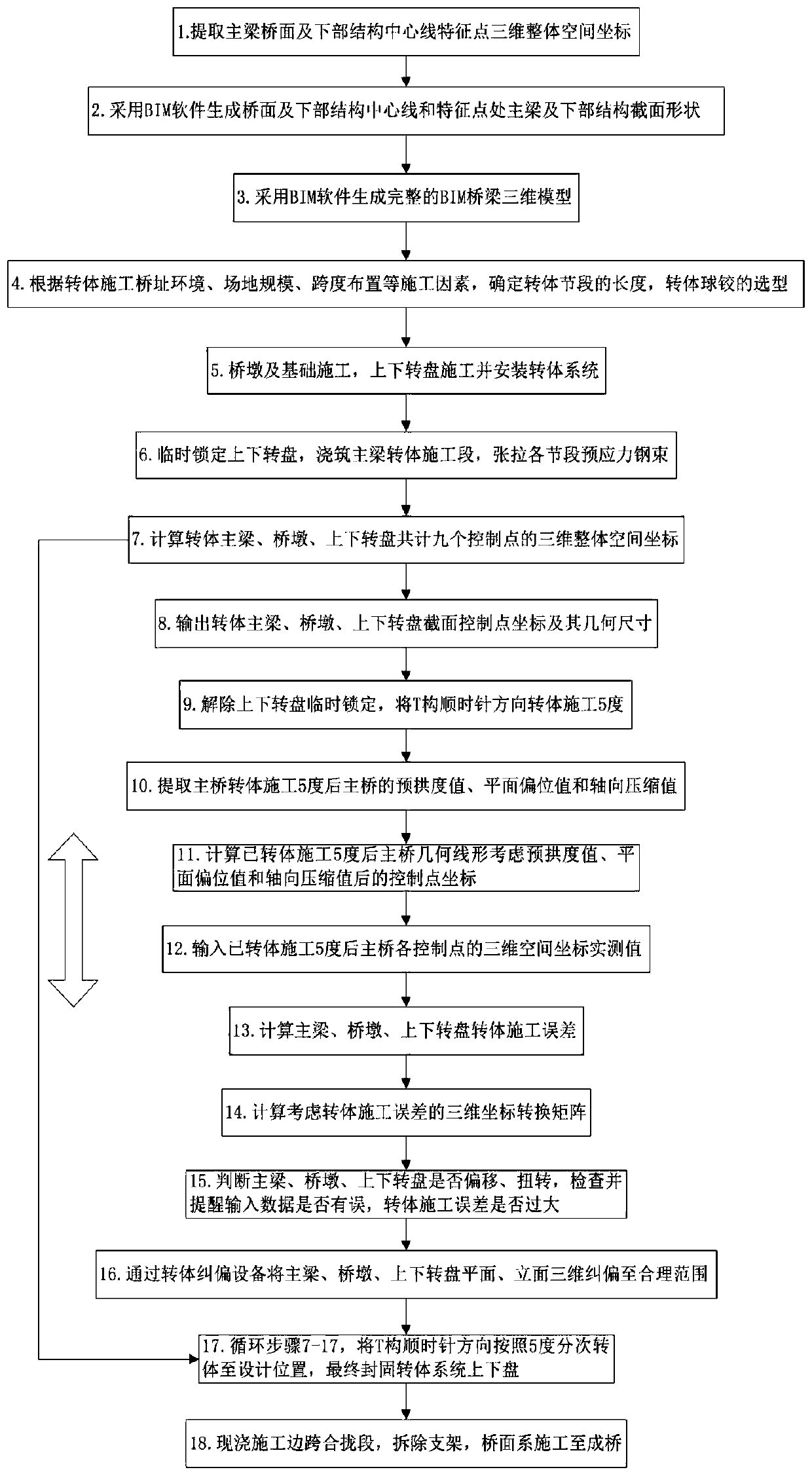

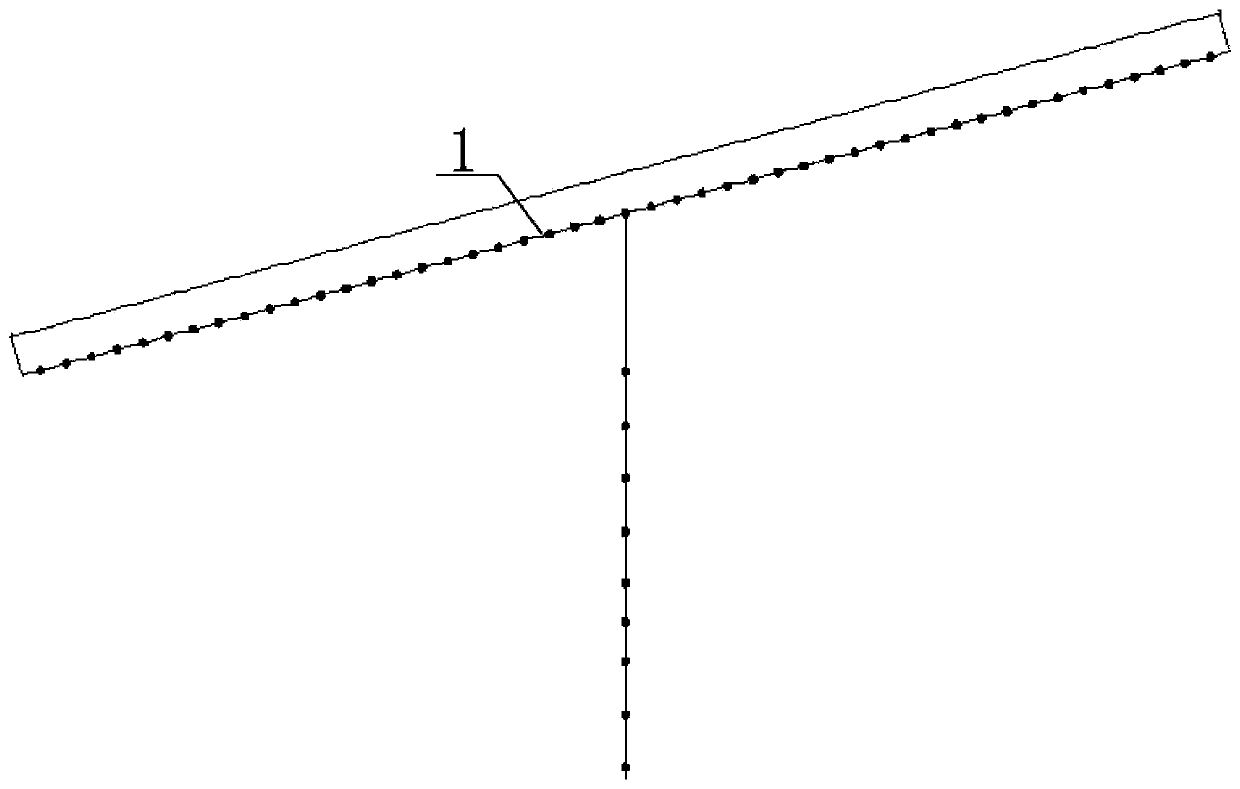

Bridge rotation construction three-dimensional linear control technology based on BIM technology

ActiveCN110820580AImprove design efficiencyReduce construction errorsGeometric CADDesign optimisation/simulationLinear controlSpace model

The invention discloses a bridge rotation construction three-dimensional linear control technology based on a BIM technology. The whole procedure comprises the steps that a bridge three-dimensional space model is built through BIM software; before rotation construction, three-dimensional space coordinates of nine control points of a main beam, a bridge pier, an upper rotary disc and a lower rotarydisc are calculated; temporary locking to the upper rotary disc and the lower is removed, and the T-shaped structure is subjected to small-angle rotation construction in the clockwise direction; thepre-camber value, the plane offset value and the axial compression value of a rotation main beam and a lower structure are extracted; the main bridge control point coordinates are calculated after small-angle rotation is in place; three-dimensional space coordinate measured values of the main bridge control points after small-angle rotation are input; a three-dimensional coordinate transformationmatrix considering rotation construction errors is calculated; and through rotation deviation rectifying equipment, the main beam, the bridge pier, the upper rotary disc and the lower rotary disc aresubjected to horizontal and vertical three-dimensional deviation rectifying to the reasonable range. According to the invention, the BIM technology is adopted to guide a three-dimensional deviation rectifying method to conduct horizontal and vertical three-dimensional deviation rectifying and twisting on the rotation main beam and the lower structure which for error adjusting, the rotation construction efficiency is improved, and the construction error is substantially decreased.

Owner:广州揽睿路桥设计有限公司

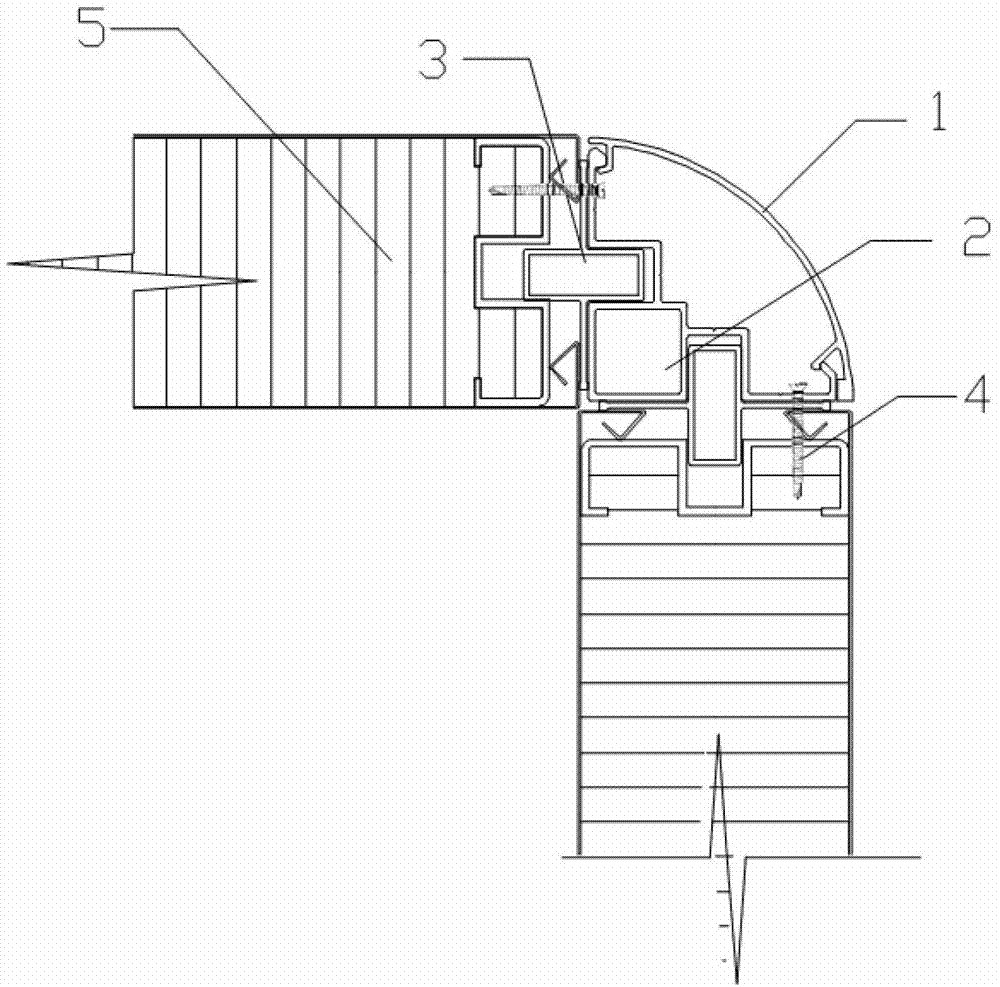

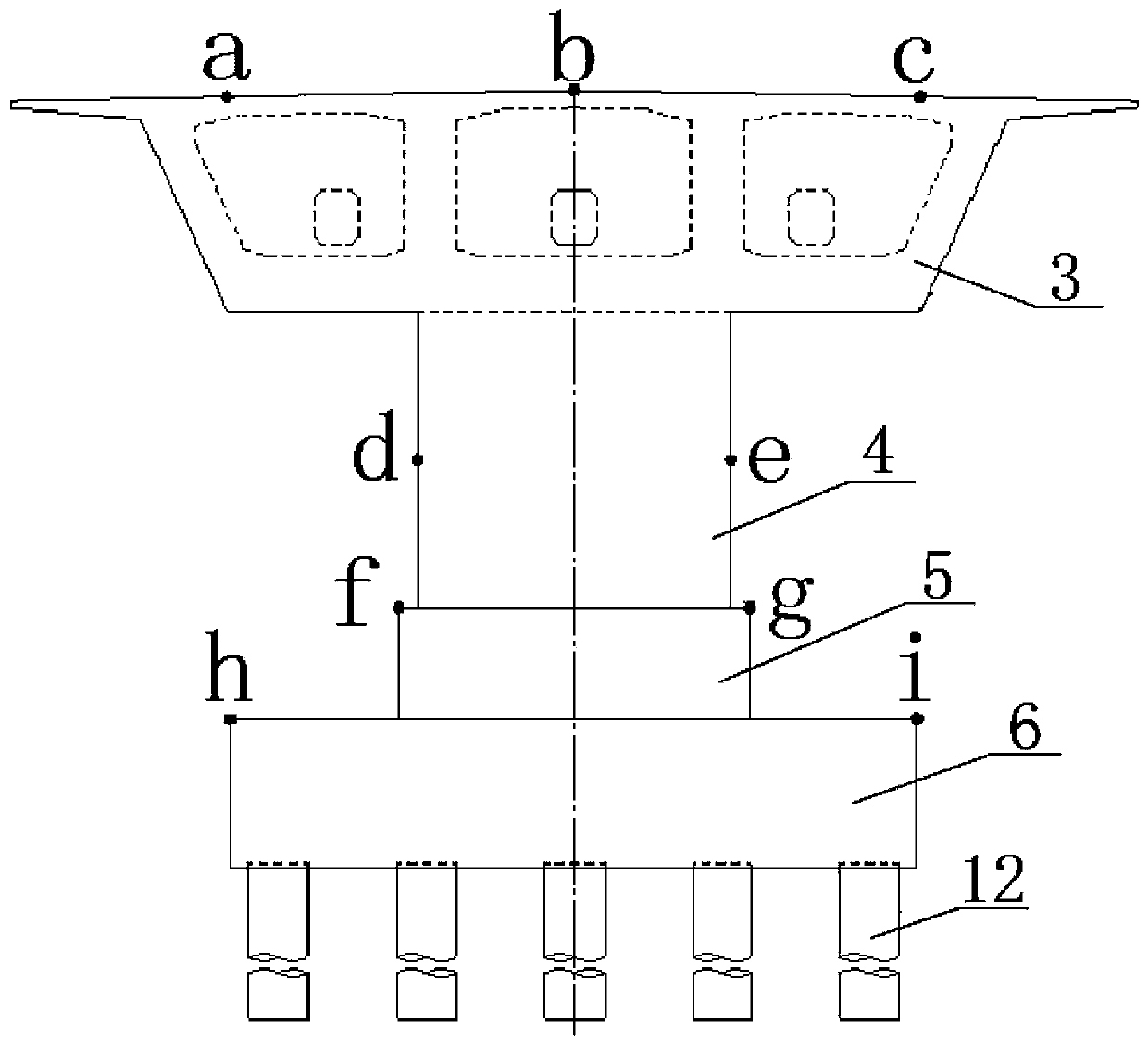

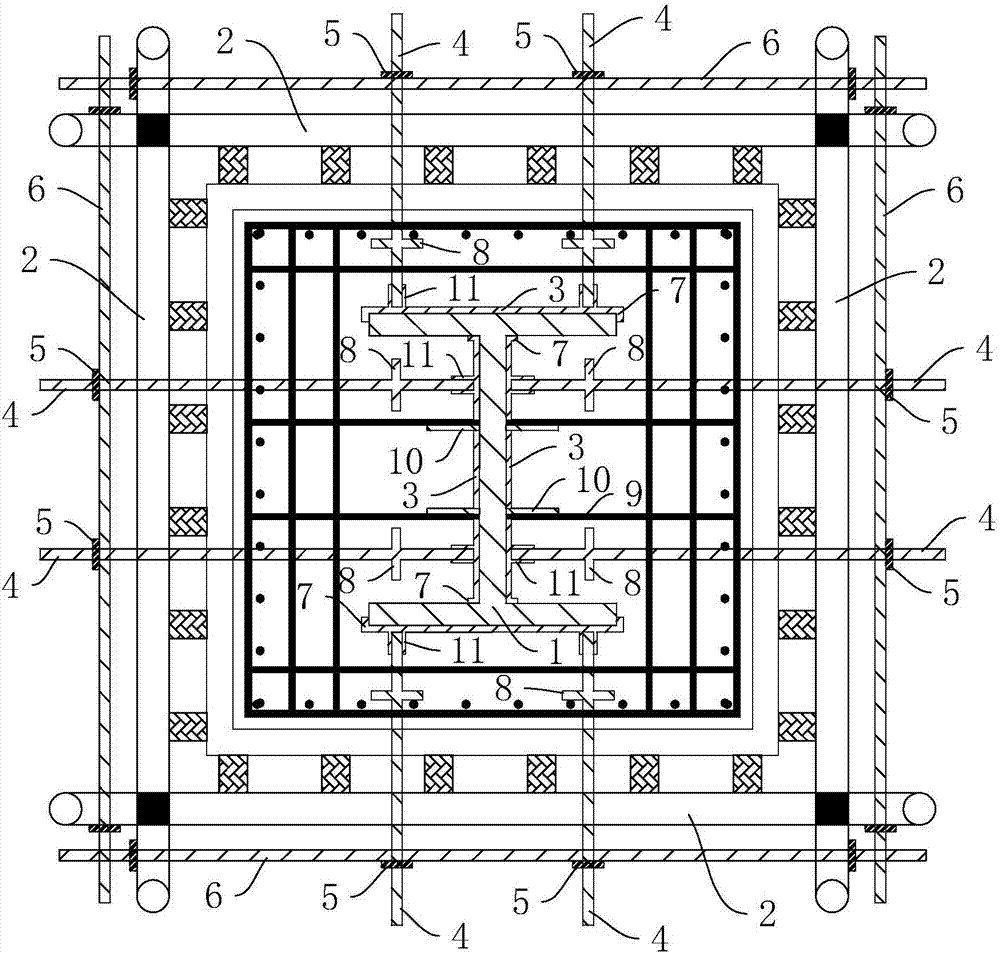

Section steel concrete formwork reinforcing structure and construction method

ActiveCN108005381AEasy to operateImprove work efficiencyForms/shuttering/falseworksEngineeringStructural engineering

Owner:广东中南建设有限公司

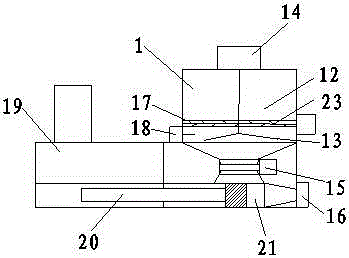

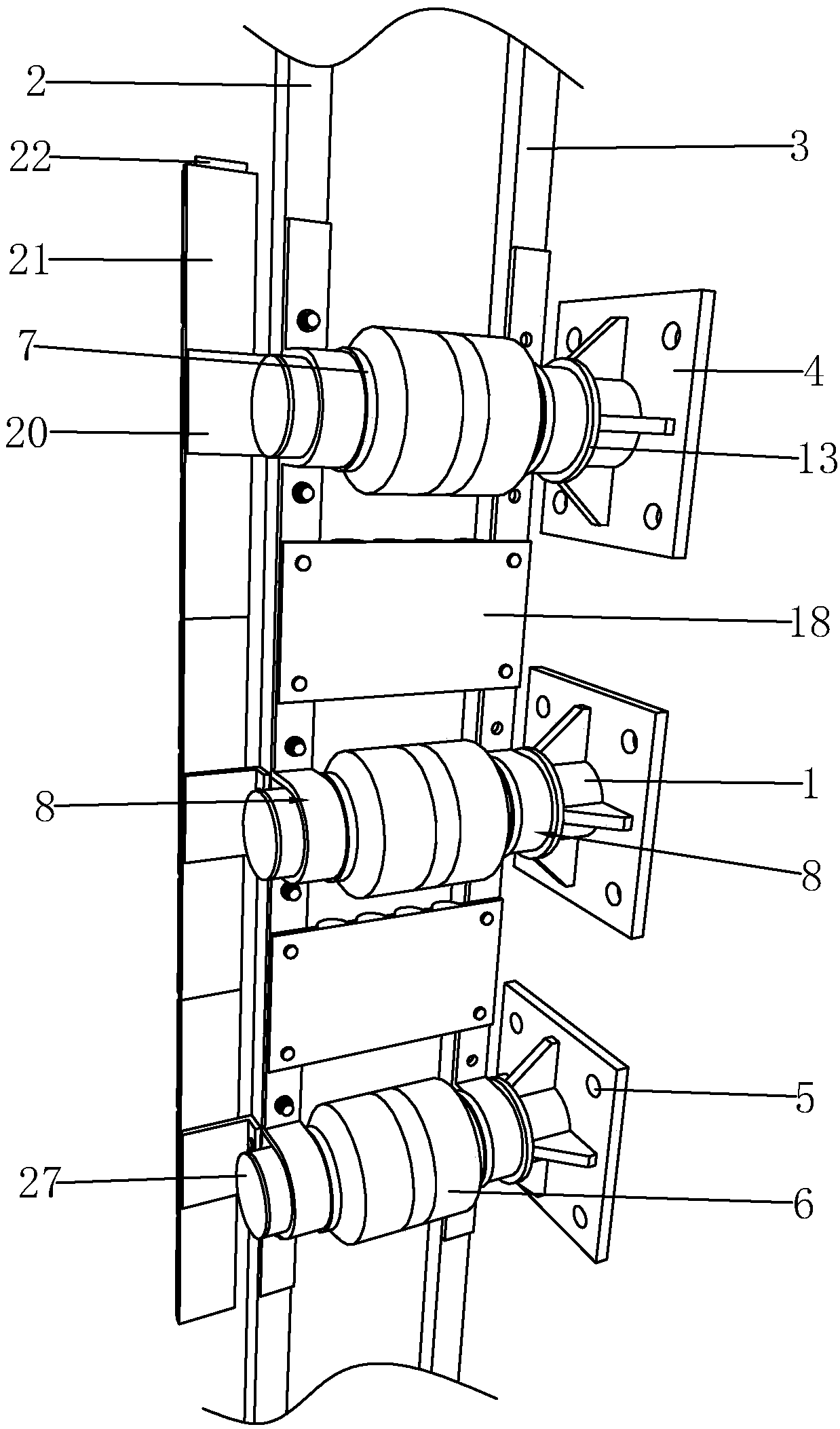

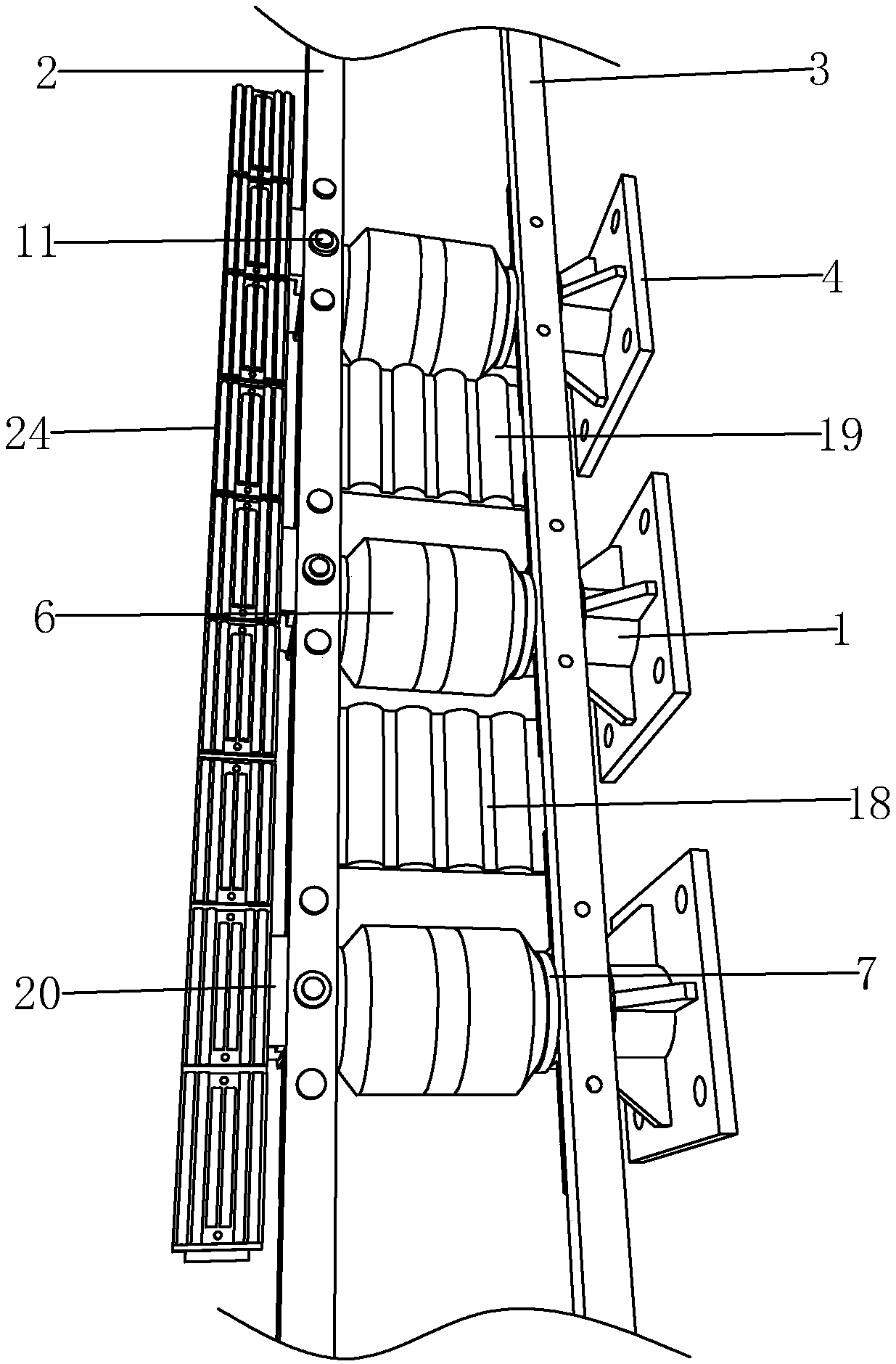

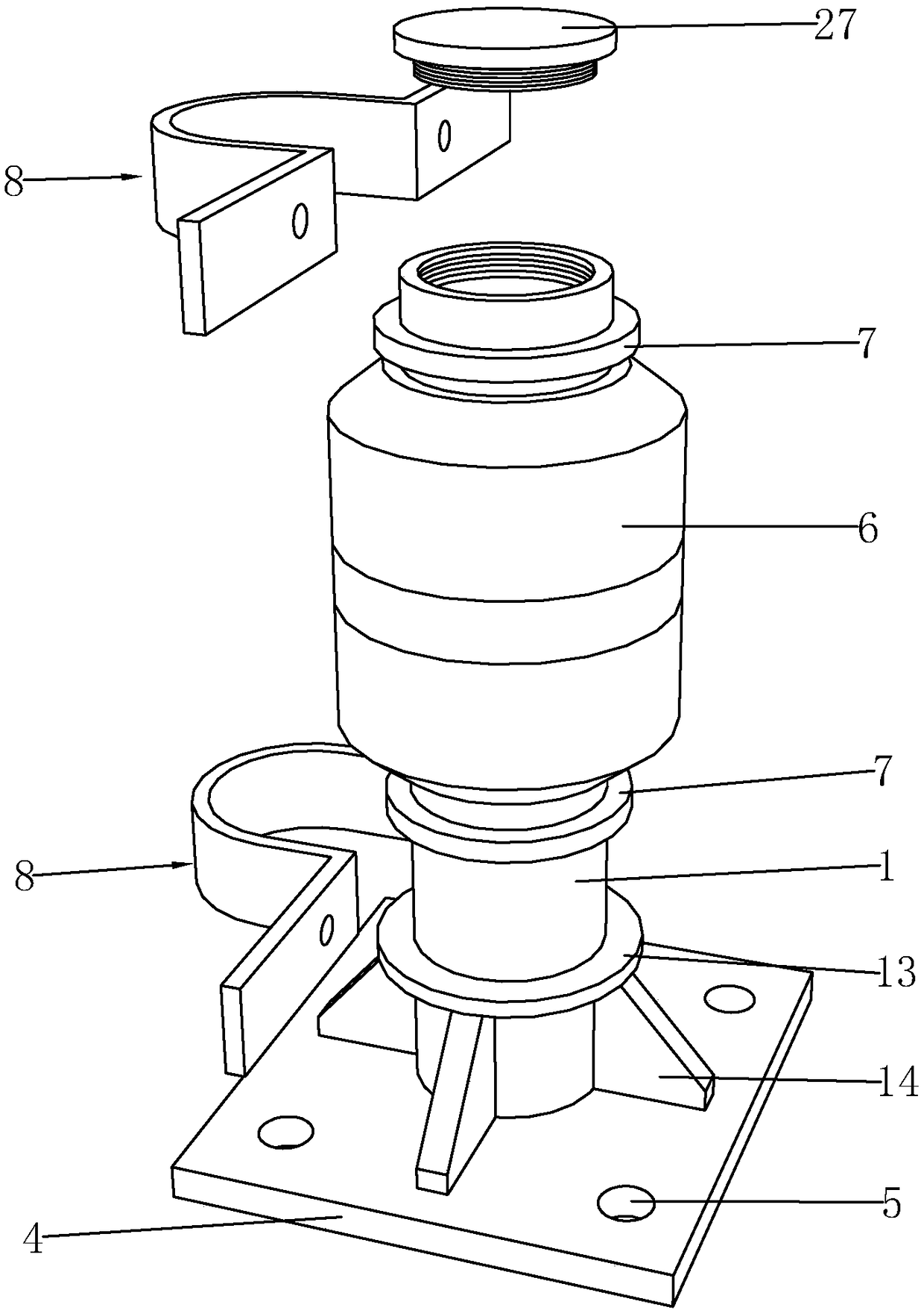

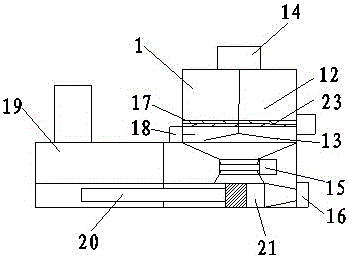

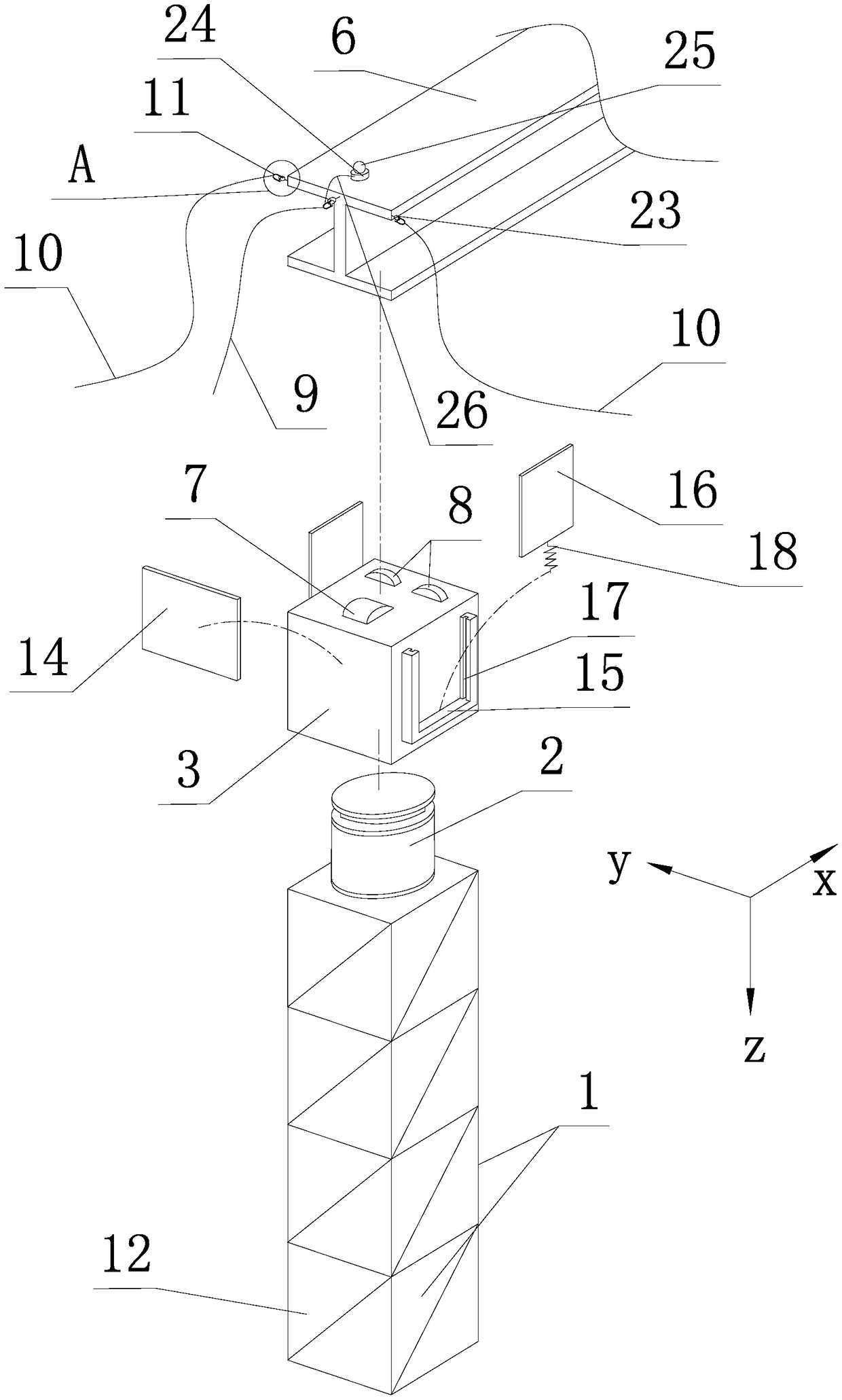

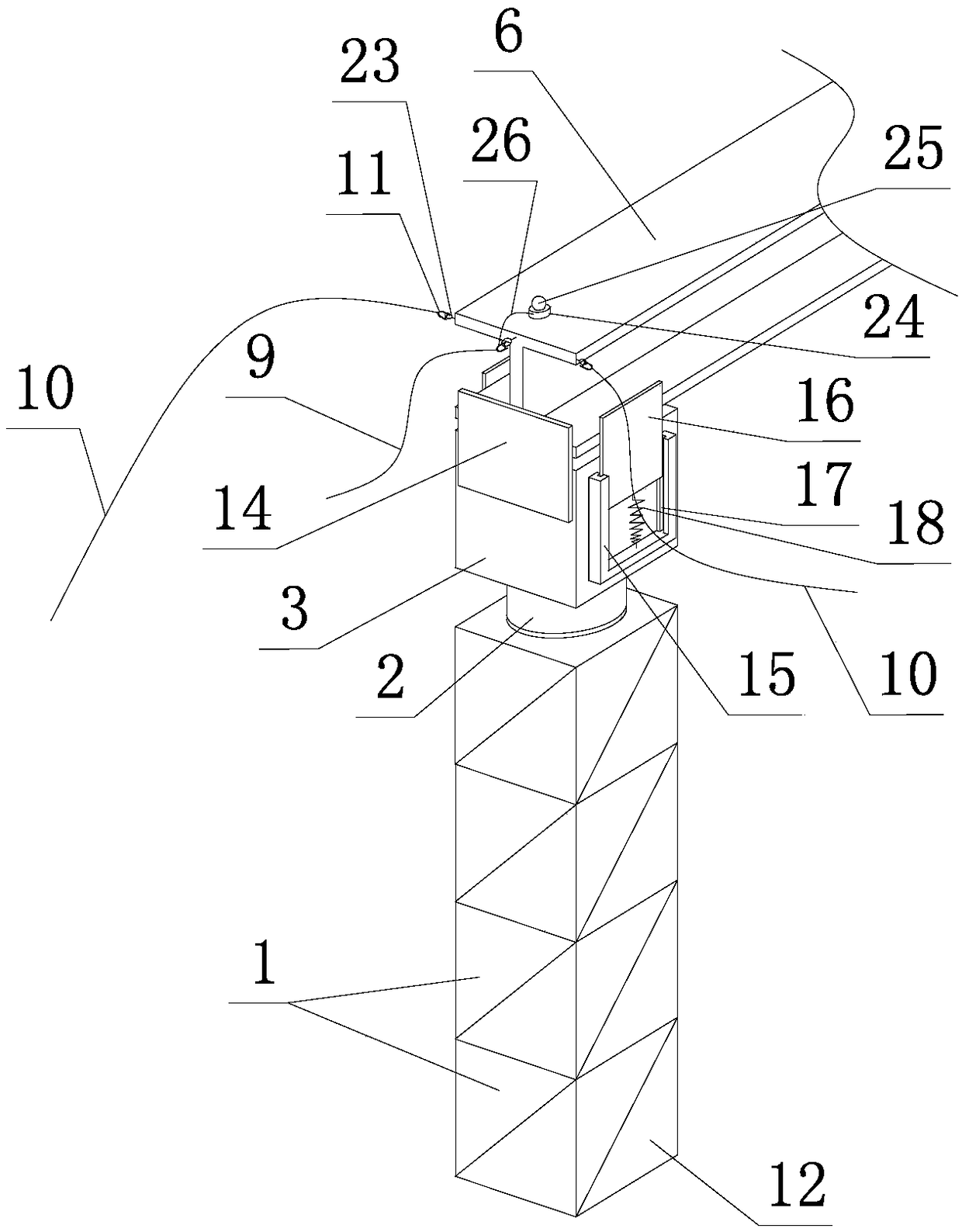

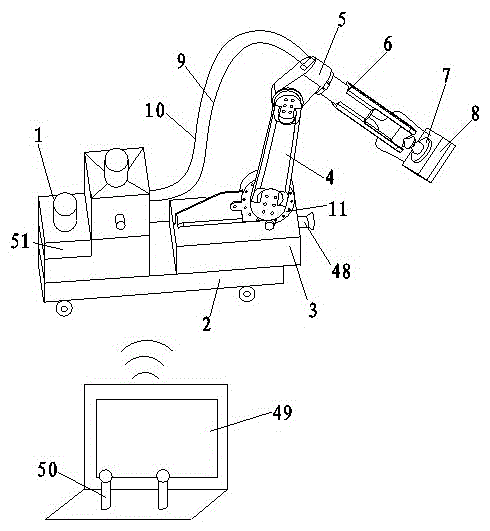

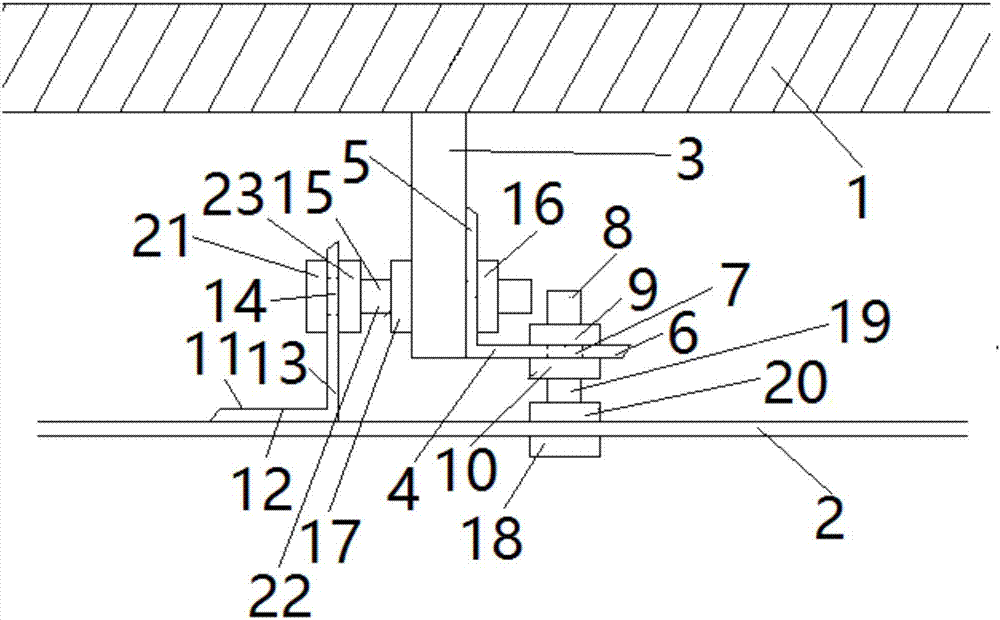

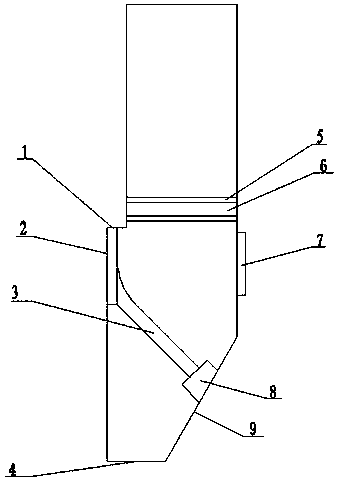

Swivel body spherical hinge position control device for bridge construction

ActiveCN107059653AHigh adjustment accuracyReduce the difficulty of adjustmentBridge erection/assemblyAssistive device/technologyEngineering

The invention provides a swivel body spherical hinge position control device for bridge construction applied to the technical field of the bridge construction auxiliary equipment. The lower end face of a spherical hinge body (1) of the swivel body spherical hinge position control device for bridge construction is provided with a spherical hinge dorsal rib (3), the welded plate piece I (5) of the connecting steel plate I (4) is connected with the spherical hinge dorsal rib (3) in a welded mode, a adjusting plate I (6) of the connecting steel plate I (4) is provided with a connecting hole I (7), the lower end of a bolt I (8) is fixedly connected with a steel angles of the top of the support (2), the bolt I (8) penetrate through connecting hole I (7), the bolt I (8) is screwed and sleeved with a clamp nut I (9) and a adjusting nut I (10). According to the swivel body spherical hinge position control device for bridge construction, the structure is simple, the height and the horizontal position of the swivel body spherical hinge can be adjusted in place fast and conveniently, the fact that the position of the spherical hinge is the regulation precision and accuracy is insured, the difficulty of adjusting the position of the spherical hinge is lower in the construction process, and the construction progress is improved effectively.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

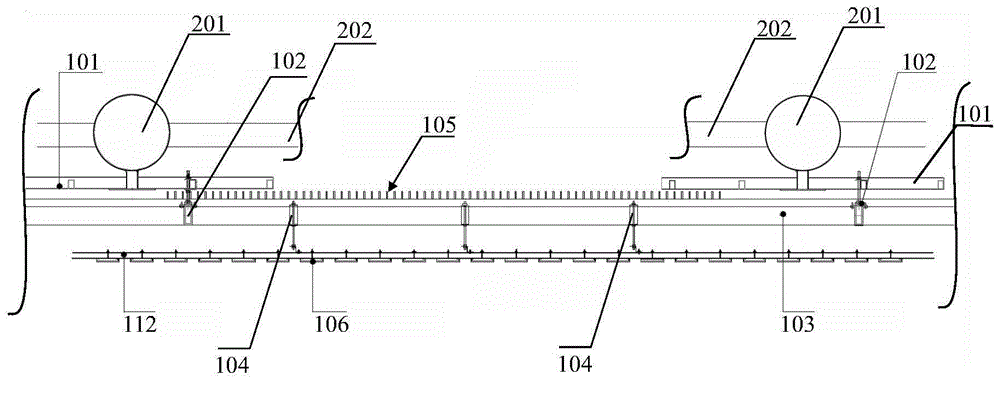

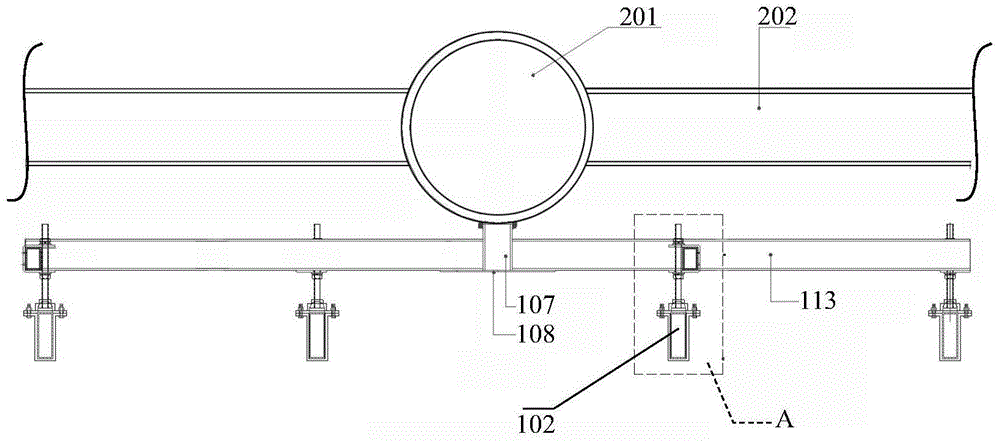

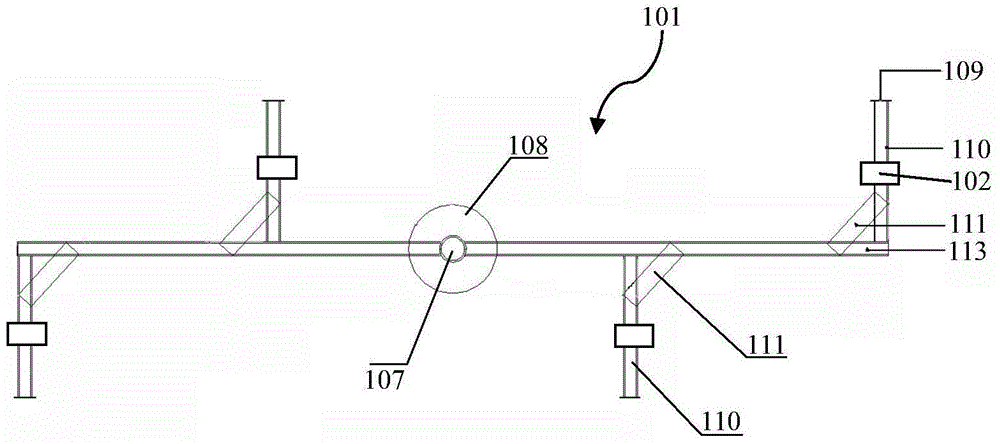

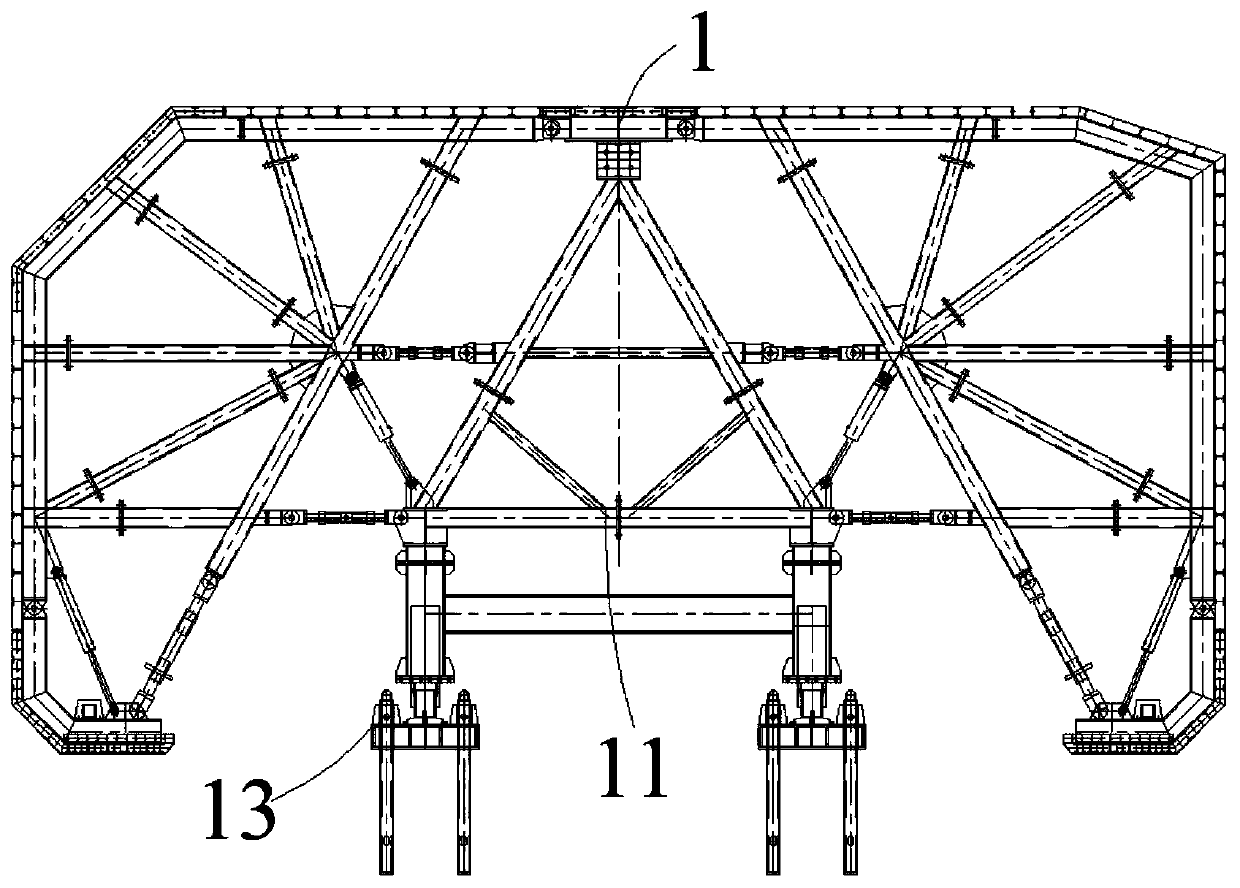

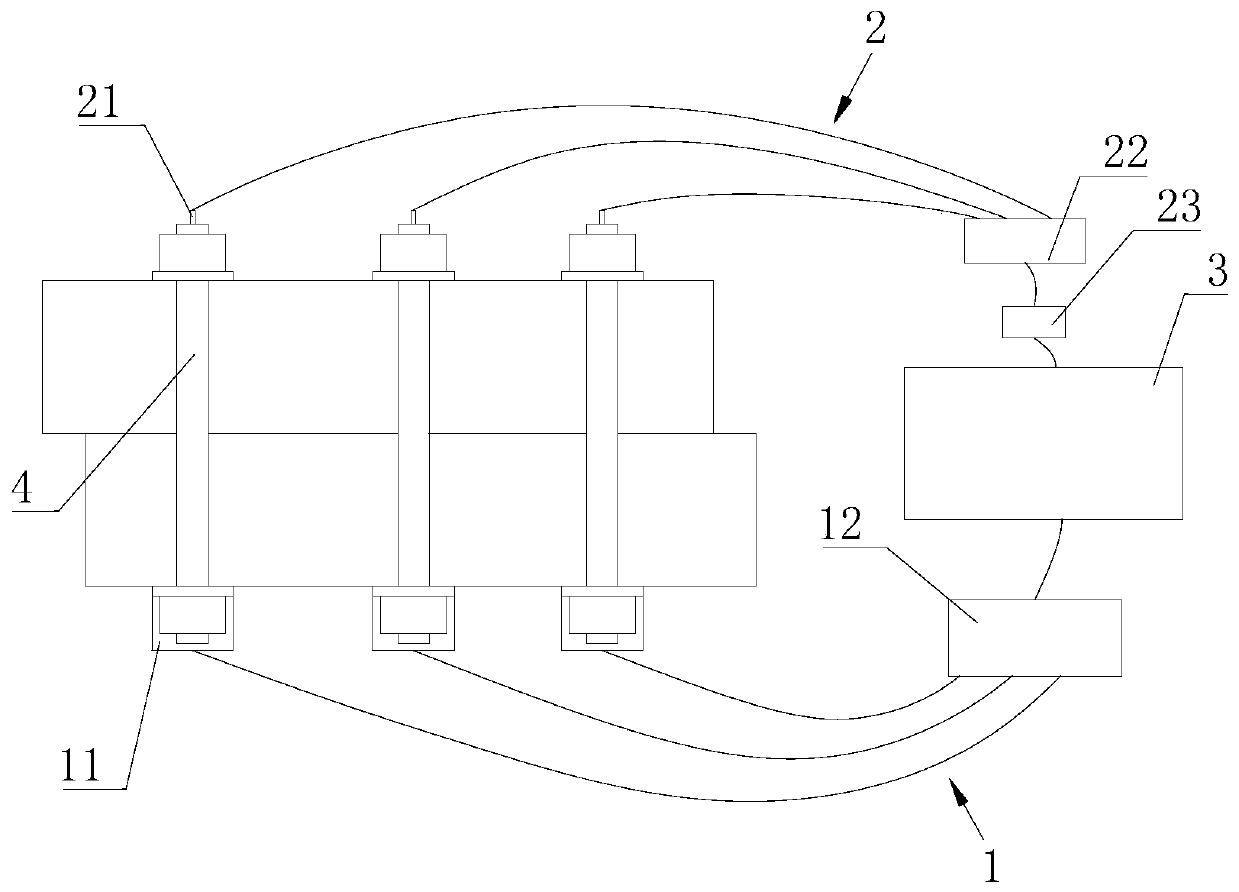

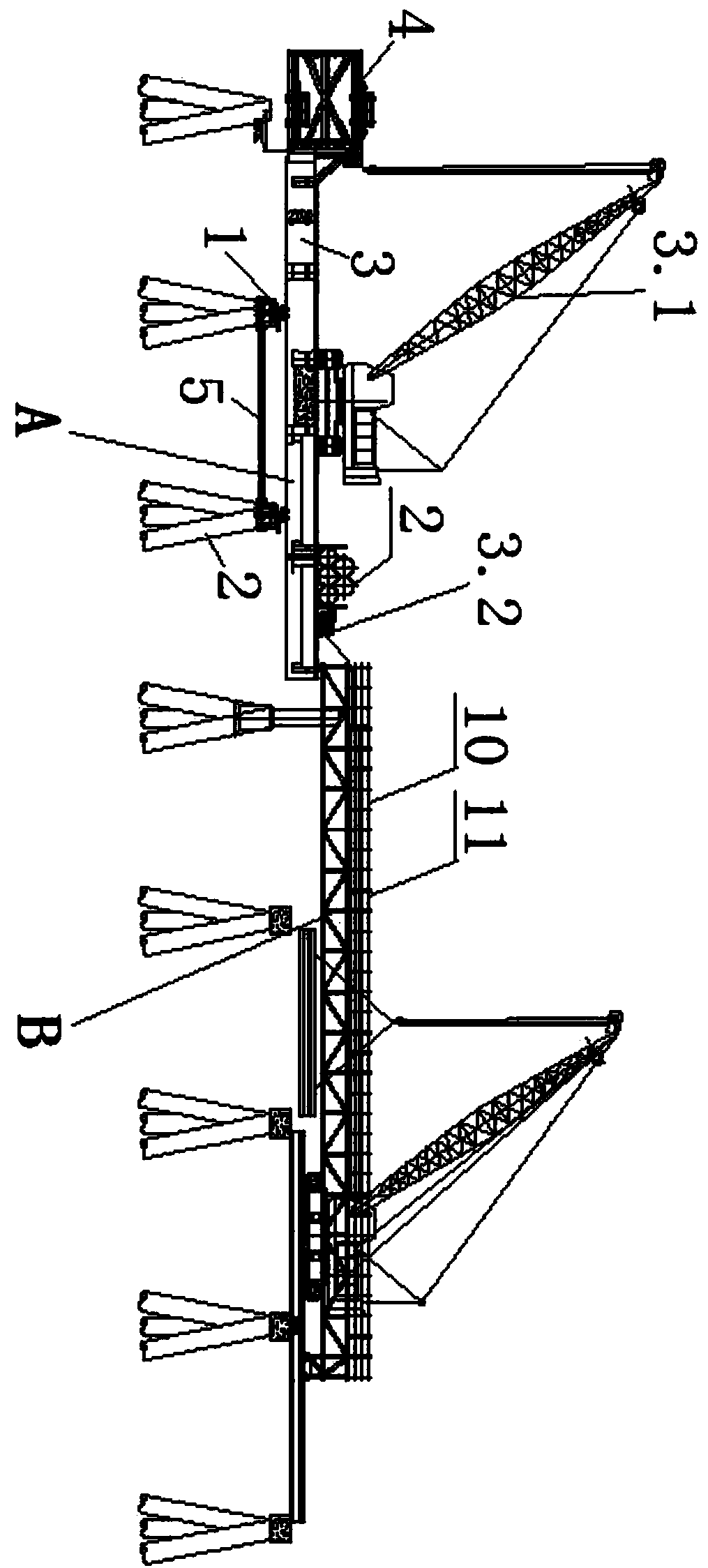

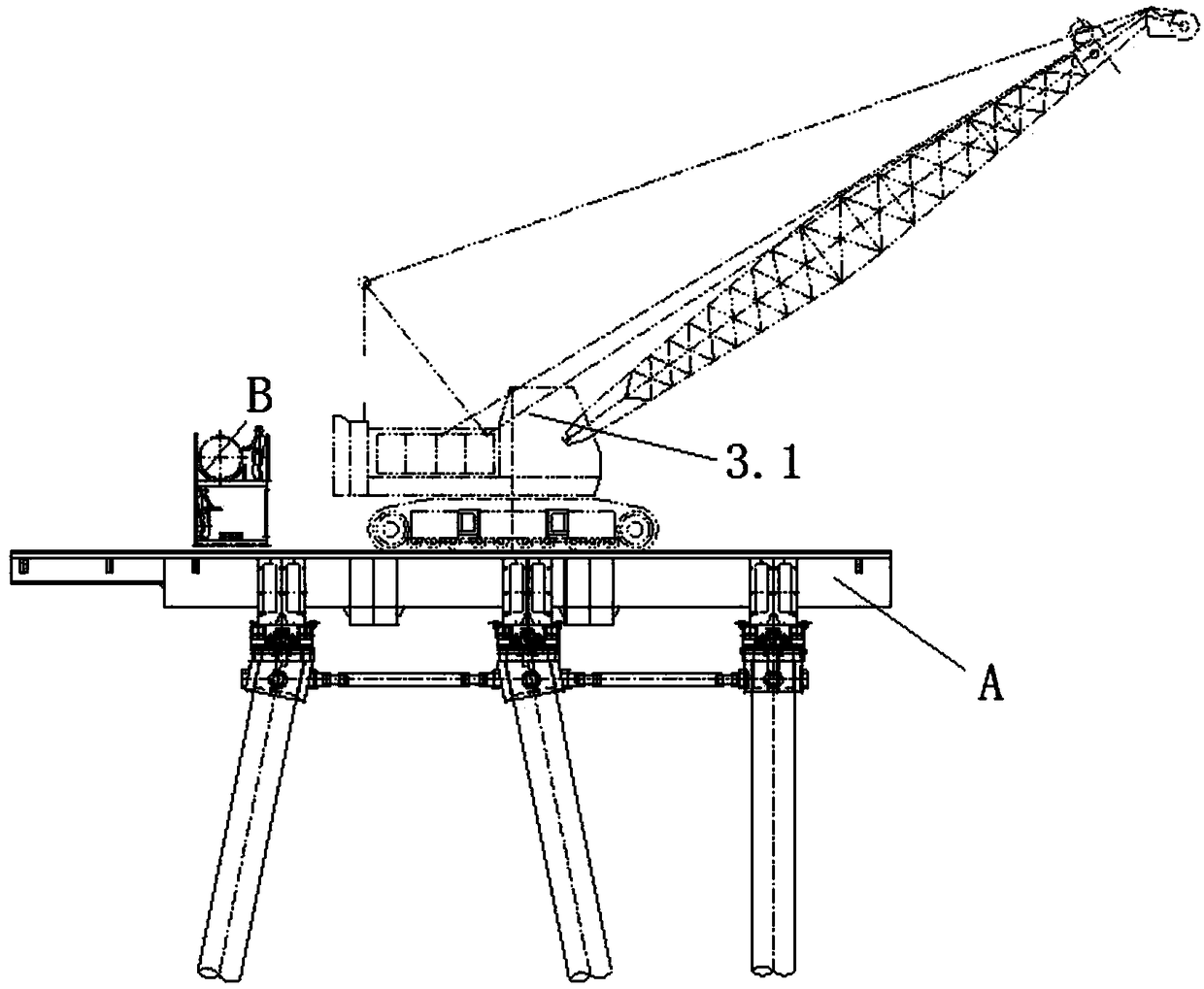

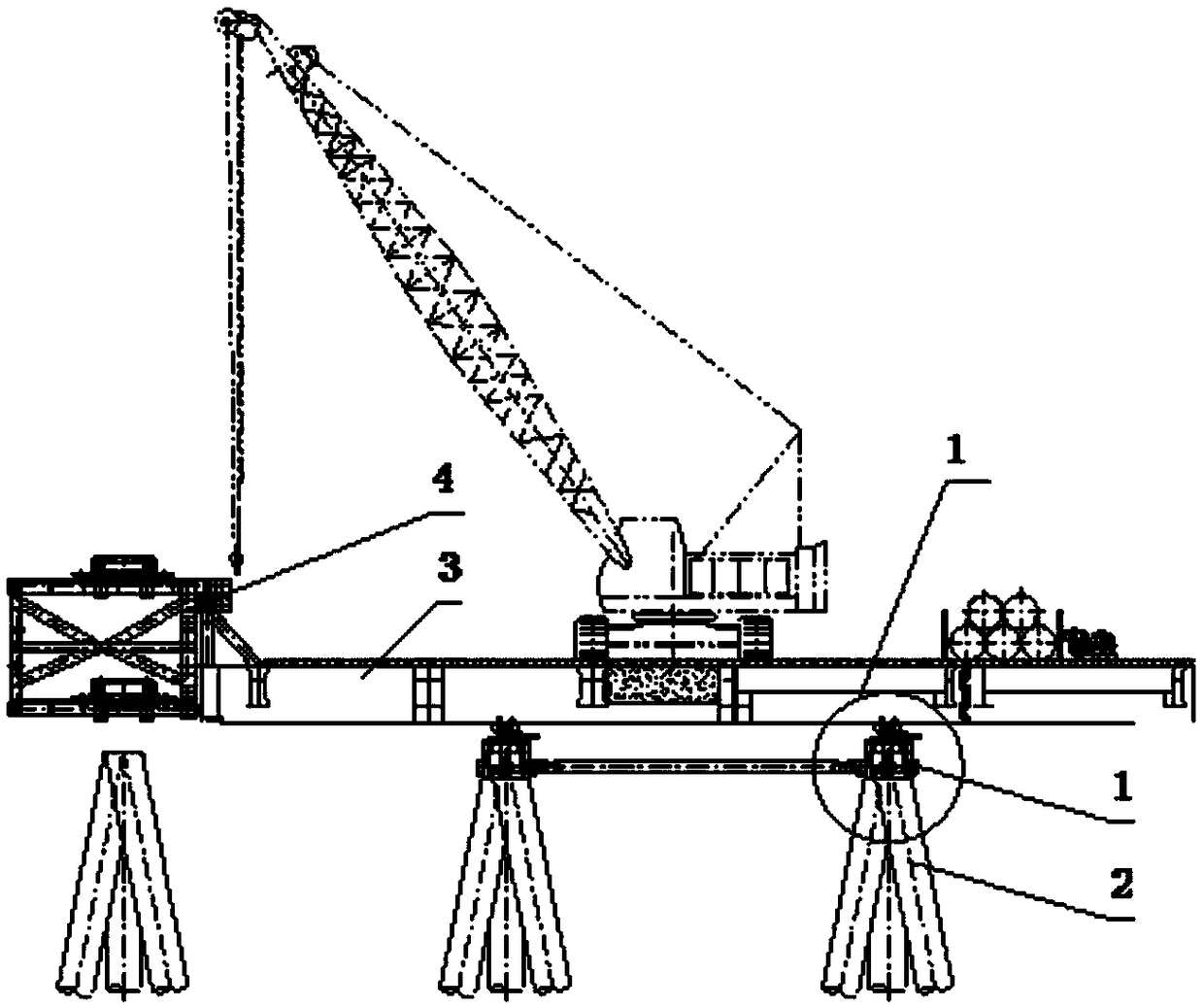

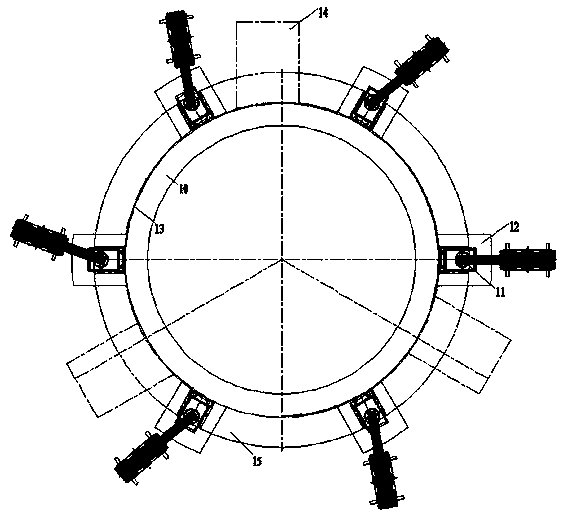

Wharf integrated construction system and method based on pile top pushing platform

The invention discloses a wharf integrated construction system and method based on a pile top pushing platform. The wharf integrated construction system based on the pile top pushing platform comprises the pile top pushing platform and a truss transportation system. The pile top pushing platform comprises a bearing operation platform, the bottom of the bearing operation platform is connected witha pile top positioning pushing device, one end of the bearing operation platform is connected with a guide frame, the other end of the bearing operation platform is connected with the truss transportation system, the truss transportation system comprises a truss, and a conveying mechanism for steel casings and a concrete pouring pipeline are arranged on the truss. The wharf integrated constructionsystem based on the pile top pushing platform is simple in structure and convenient to use; and the pile top pushing platform and the truss transportation system are integrated, the flexible movementand quick positioning of the pile top pushing platform are realized, so that the wharf integrated construction system based on the pile top pushing platform synchronously completes piling and bored pile construction flow operation, the operation period is shortened, the construction cost is reduced, and the wharf construction work efficiency is improved.

Owner:CCCC SECOND HARBOR ENG +1

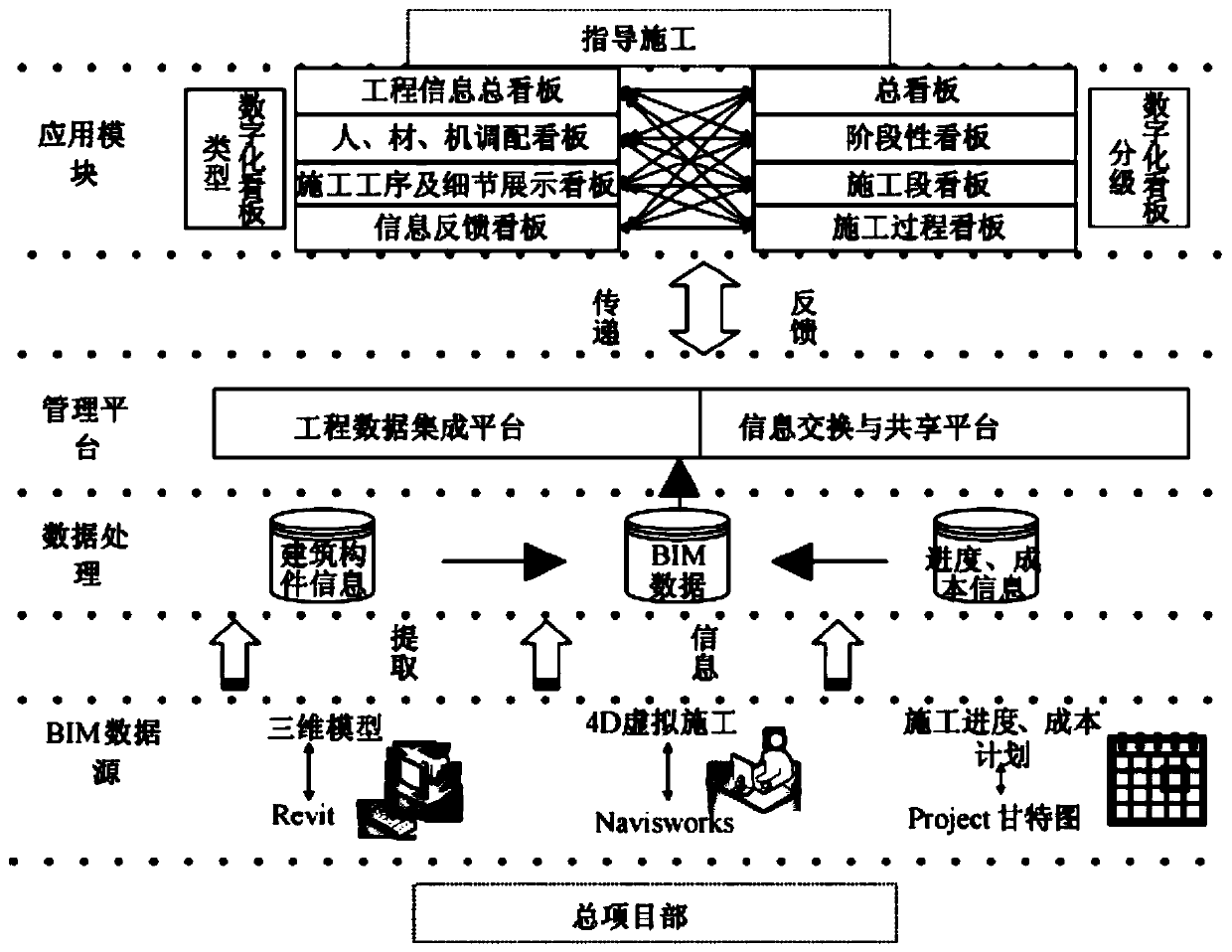

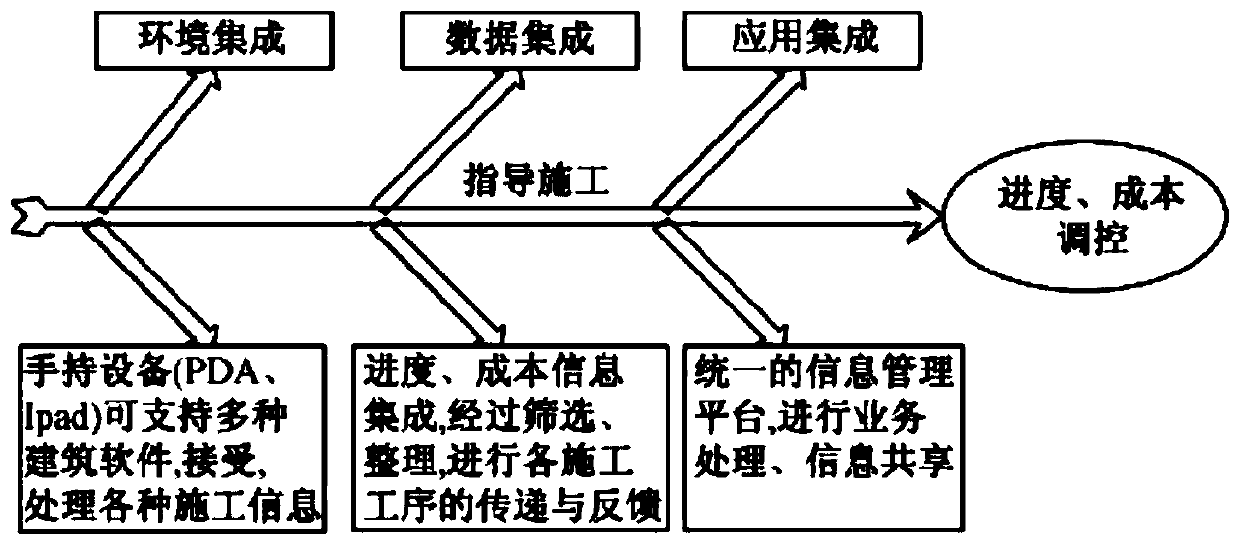

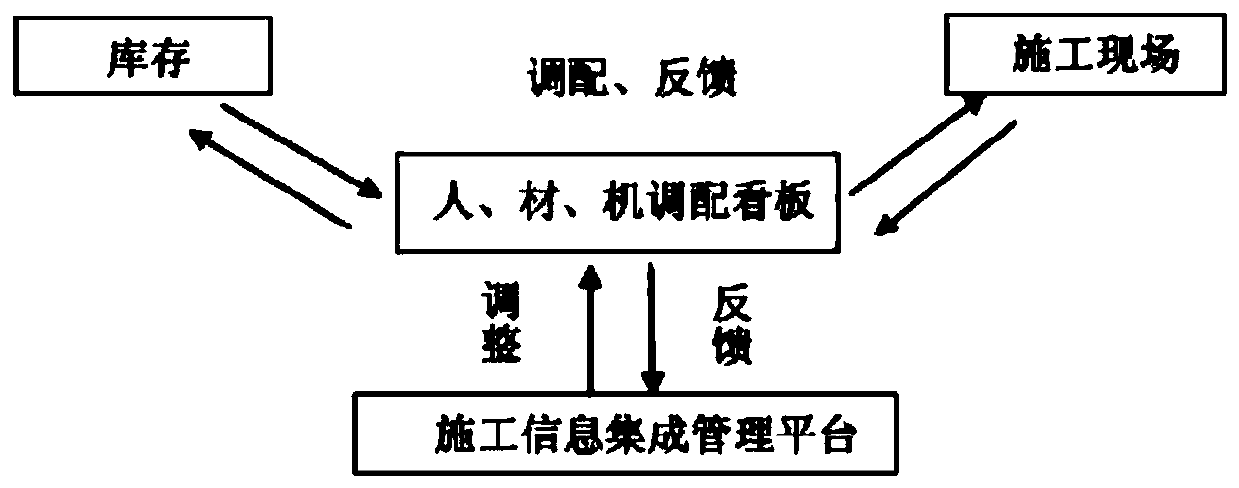

Civil engineering project on-site management BIM system

PendingCN110298584AImprove efficiencyReduce energy consumptionGeometric CADResourcesIntegrated engineeringData information

The invention provides a civil engineering project on-site management BIM system, and the system comprises a BIM data source which is used for collecting a variety of data from a civil engineering project site; a data processing module which is used for carrying out data processing and data fusion on the BIM data source; a management platform which is used for integrating engineering data and exchanging and sharing information; an application module which is used for receiving management data of the management platform to guide construction and transmitting the related data in the constructionprocess to the management platform to form shared information. The data of the BIM data source is subjected to information extraction through the data processing module to form building component information and progress and cost information; the information is stored in the data processing module and is fused to form BIM data information; the management platform is divided into an engineering data integration platform and an information exchange and sharing platform and can receive the BIM data information, and the application module adopts a BIM digital billboard and carries out type distinguishing and hierarchical processing according to a construction management WBS structure decomposition method.

Owner:裴涛

Construction method of stone pitching structure of tidal face of tidal-flat area

ActiveCN108360456AReduce impactImprove the ability to defend against water invasionCoastlines protectionTidal flatWater flow

The invention discloses a construction method of a stone pitching structure of a tidal face of a tidal-flat area. The construction method comprises the following steps: a, carrying out staking out insurvey in a construction site, then excavating a base layer, and leveling the surface of the base layer; b, structurally constructing a water retaining surface; c, constructing a first stone layer; d,constructing a second stone layer; e, constructing a pitching structure; and f, spraying and cleaning water to the pitching structure with a high pressure water gun. The construction method disclosedby the invention improves the invasion ability of a defense water flow, improves the water conveying efficiency and prevents a ponding phenomenon of the pitching structure, and meanwhile, the stone pitching structure is good in erosion resistance and durability. By carrying out structural construction of the water retaining surface, construction of the first stone layer, the second stone layer and construction of the pitching structure successively from bottom to top, the influence of water flow scouring is reduced in the construction process, and the pitching building blocks can be paved ina positioned manner, so that the construction quality of the stone pitching structure is improved.

Owner:温州市瓯飞经济开发投资有限公司

Shaft mechanical tunneling construction method

ActiveCN109736811ASolve the problem of insufficient pressure differenceSolve the problem of unable to discharge slagShaft sinkingShaft liningSlagEngineering

The invention relates to the technical field of shaft mechanical tunneling and discloses a shaft mechanical tunneling construction method. The shaft mechanical tunneling construction method comprisesthe steps of construction preparation, working pit pre-digging, open caisson blade foot ring and vertical shaft locking opening manufacturing, auxiliary equipment installation, initial lifting and tunneling machine hoisting, open caisson wall lubricant grouting, tunneling excavation, slag discharging, open caisson sinking and heightening, open caisson bottom sealing drainage and open caisson wallrear lubricant replacement. The construction safety of the underground large-diameter shaft can be improved, and the construction efficiency and the mechanization degree are improved.

Owner:CHINA CONSTR UNDERGROUND SPACE +1

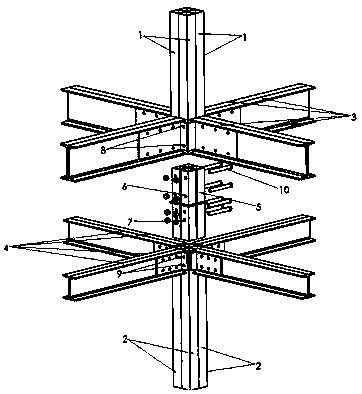

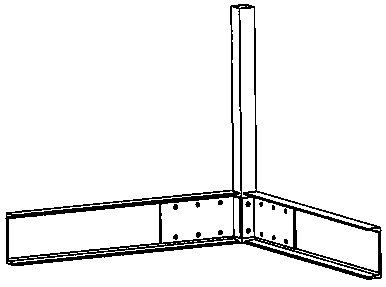

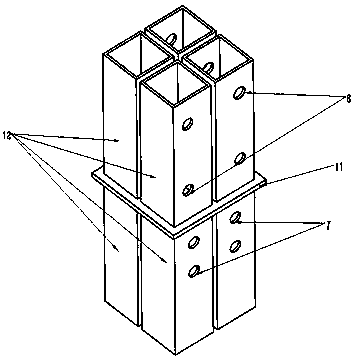

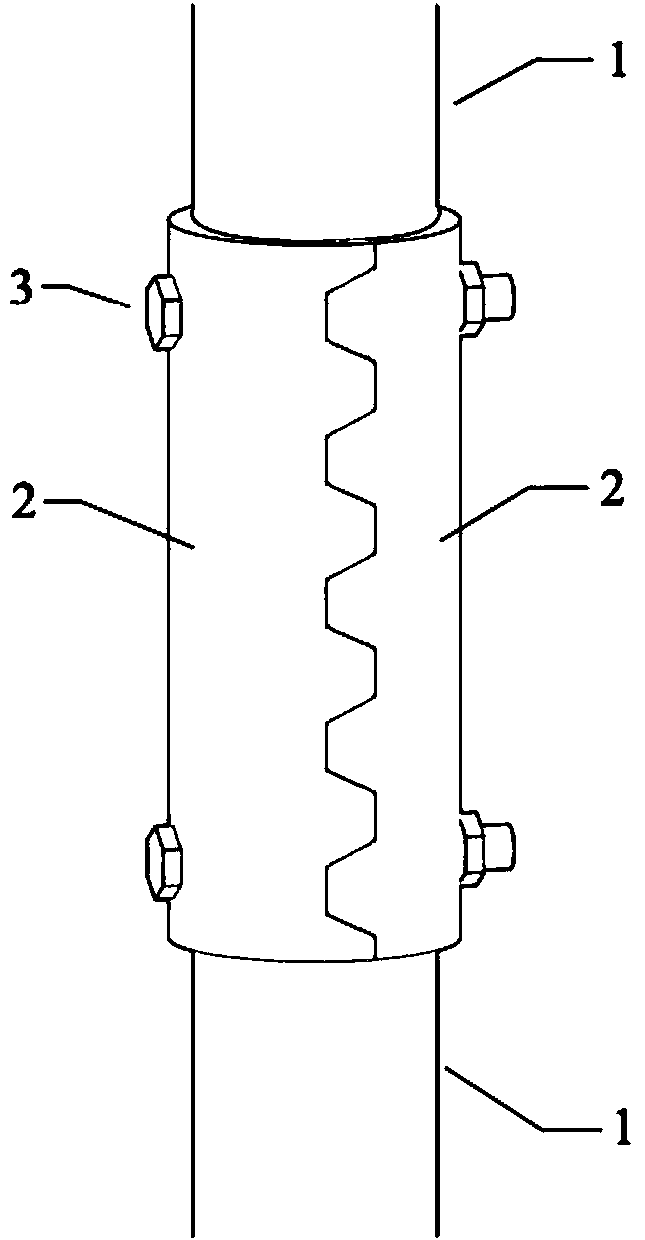

Connecting method applied to column-bearing-type modules

PendingCN108589921AAvoid unstable qualityReduce construction errorsBuilding constructionsSteel platesSteel tube

The invention relates to a connecting method applied to column-bearing-type modules. Four upper module units, four lower module units and a connecting inserting piece are included. Each module unit comprises a corner column and two plate beams; the connecting inserting piece is formed by welding a steel plate and eight hollow square steel pipe short columns in the up-down direction; the outer walls of the square steel pipe short columns are matched with the inner walls of the corner columns of upper and lower modules in size; and the connecting inserting piece is inserted into the corner columns of the upper and lower modules and fixed through split bolts. The connecting method provides the connecting scheme for the eight upper and lower module units and has the multiple advantages that the structure is concise, construction is convenient and fast, force transmitting is clear and reasonable, materials are saved, and the overall anti-lateral rigidity is high. All the construction processes are completed inside the modules, so that the safety of construction workers and the integrity of the overall building appearance are ensured.

Owner:CHINA UNIV OF MINING & TECH +1

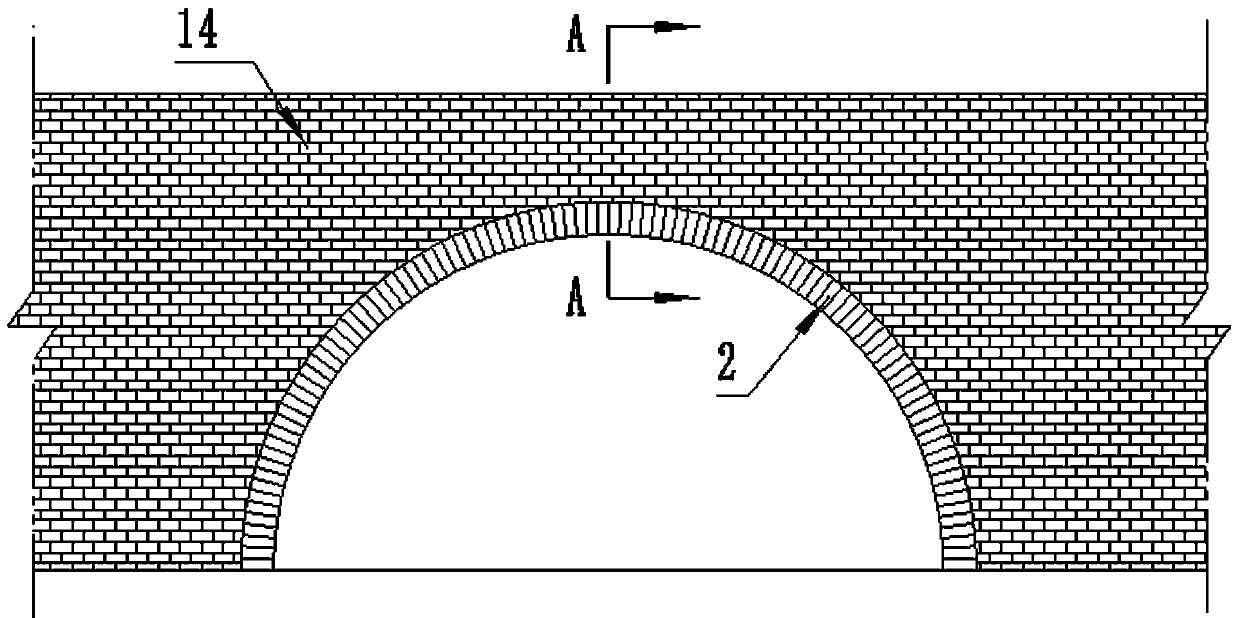

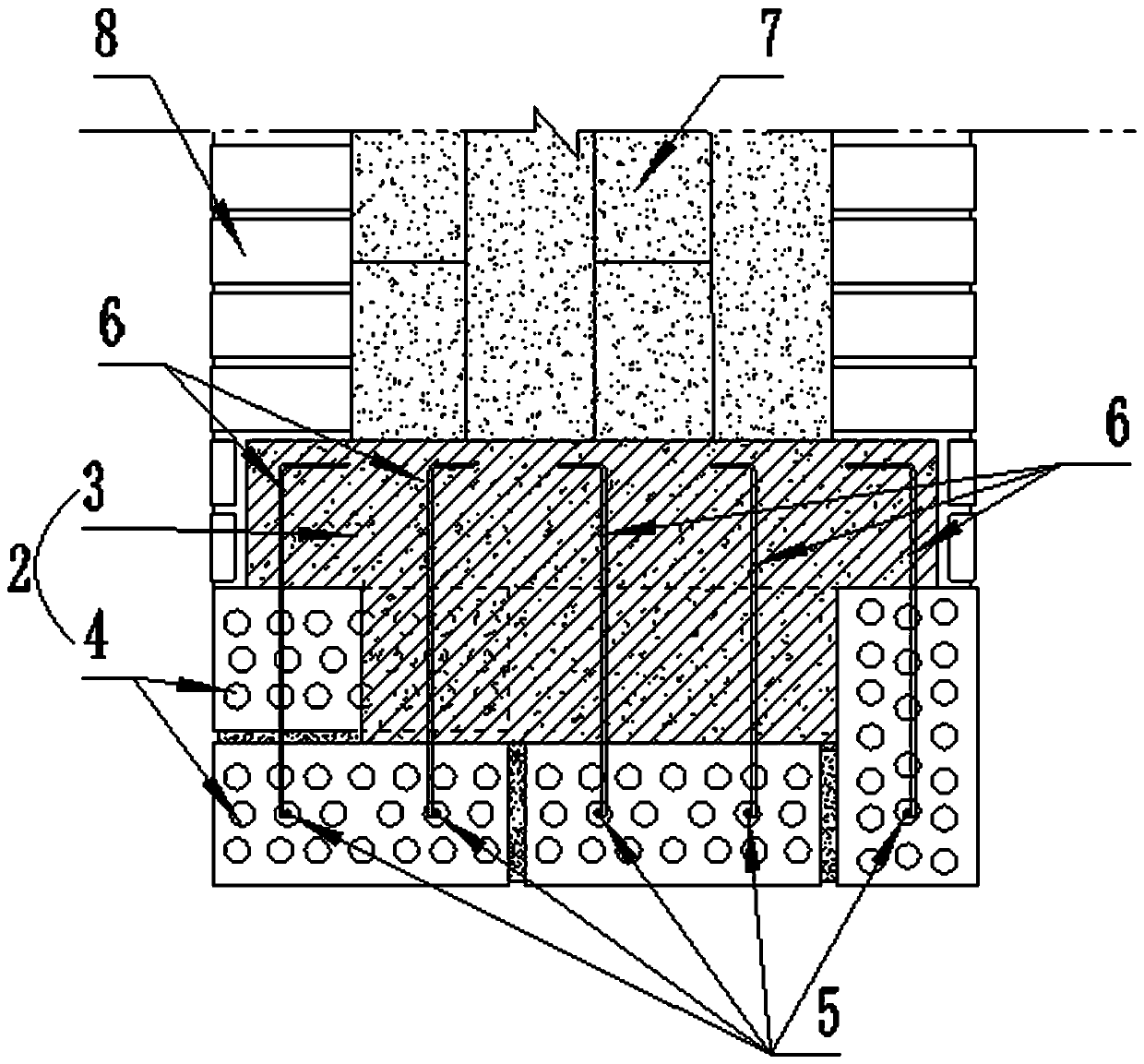

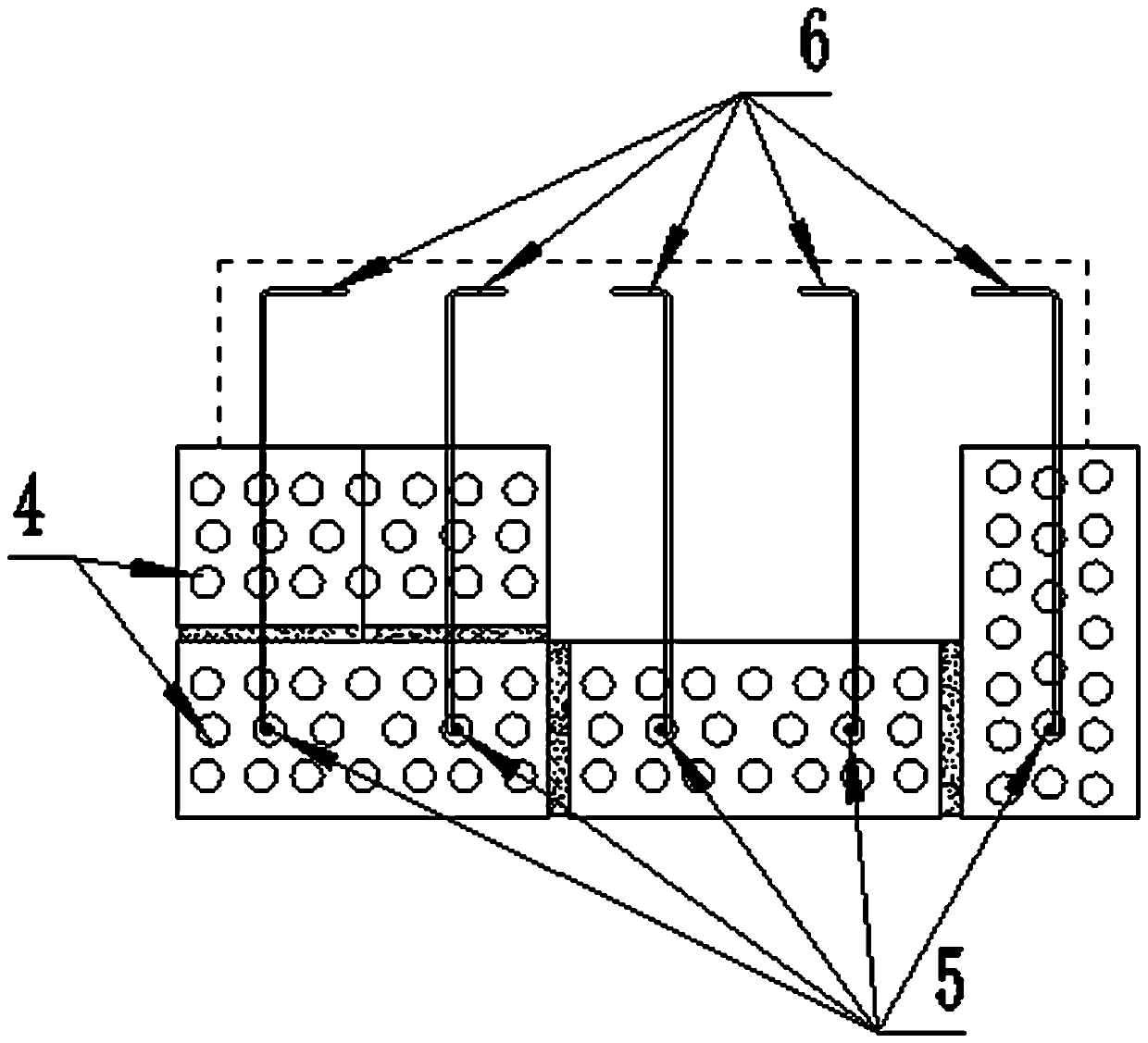

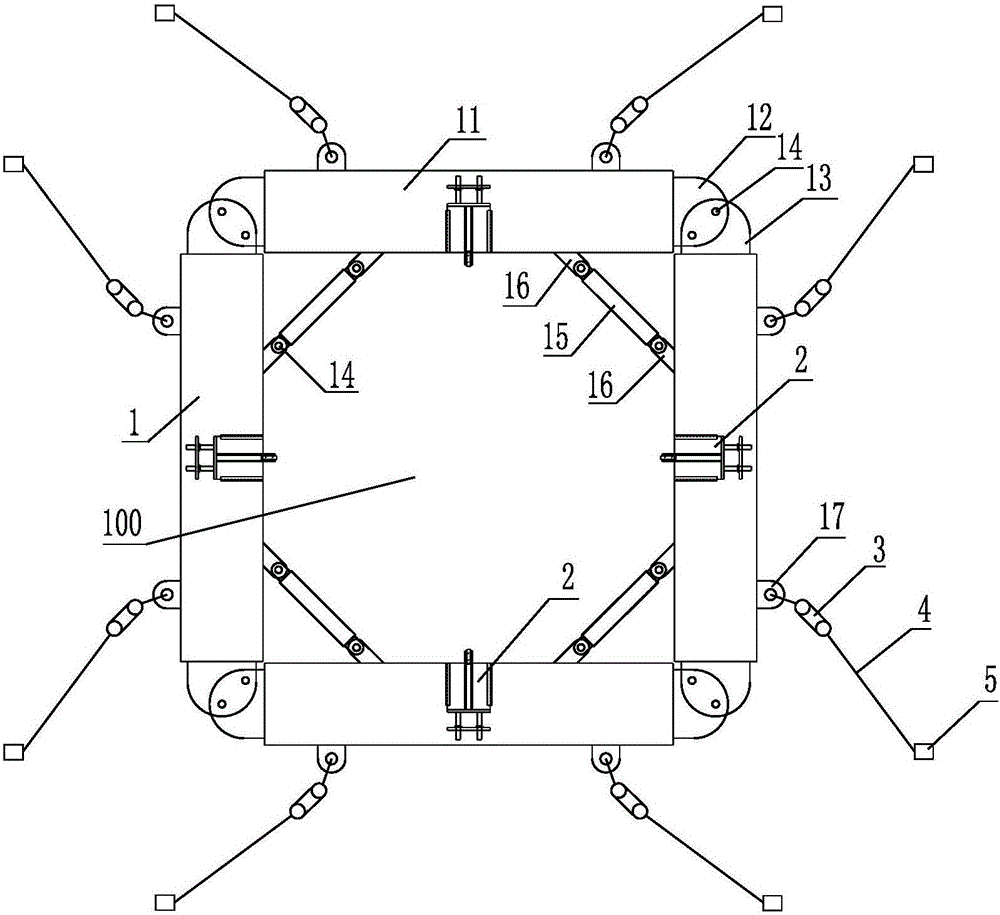

Arch construction reverse building method construction method

ActiveCN110331795AClear typographyReduce construction errorsWallsForms/shuttering/falseworksRebarSite management

The invention discloses an arch construction reverse building method construction method and belongs to the technical field of building construction. The method includes the following steps of preparing and installing an arch base membrane frame-building a double-curved face arch decoration face layer-binding and pre-burying structural rebars-constructing an arc-shaped concrete slab structure-dismantling the base membrane frame. On a transparent formwork of the base membrane frame, sintered decoration porous bricks are built to form the decoration face layer of a double-curved face arch body,layout is clear, the construction error is little, field management is facilitated, and the engineering decoration quality is guaranteed; a plurality of rows of arc-shaped rebars are pre-buried in holes of the sintered decoration porous bricks, a plurality of radial rebars are pre-buried on each row of the arc-shaped rebars at intervals, and the formed structure rebars can make the decoration facelayer and an arc-shaped concrete reinforcing plate connected and fixed together during subsequent concrete pouring. The arch construction reverse building method construction method can achieve thatthe decoration face layer of the double-curved face arch body is firstly constructed, then construction of the arc-shaped concrete reinforcing plate is performed in the reverse direction, so that thedouble-curved face arch decoration face layer and the inner structural layer are combined better, and the design effect of a clean water decoration face can be achieved.

Owner:石家庄市建筑工程有限公司

Floating guide positioning device suitable for mounting water pipe pile and application method thereof

InactiveCN105951837AEasy to moveEasy to liftWaterborne vesselsFoundation engineeringMultiple platformMarine engineering

The invention relates to the field of bridges, and discloses a floating guide positioning device suitable for mounting a water pipe pile. The device comprises a frame type floating positioning platform; the frame type floating positioning platform includes at least three frames connected end to end; the frames surround a pipe pile channel; multiple platform fixing devices are arranged around the floating positioning platform; and position adjusting devices are arranged on the frames, and are provided with extension parts for adjusting a horizontal position of the water pipe pile. The invention further discloses an application method of the floating guide positioning device suitable for mounting the water pipe pile. The floating guide positioning device is high in positioning precision of the water pipe pile and low in requirements on lifting equipment.

Owner:THE 5TH ENG MBEC +1

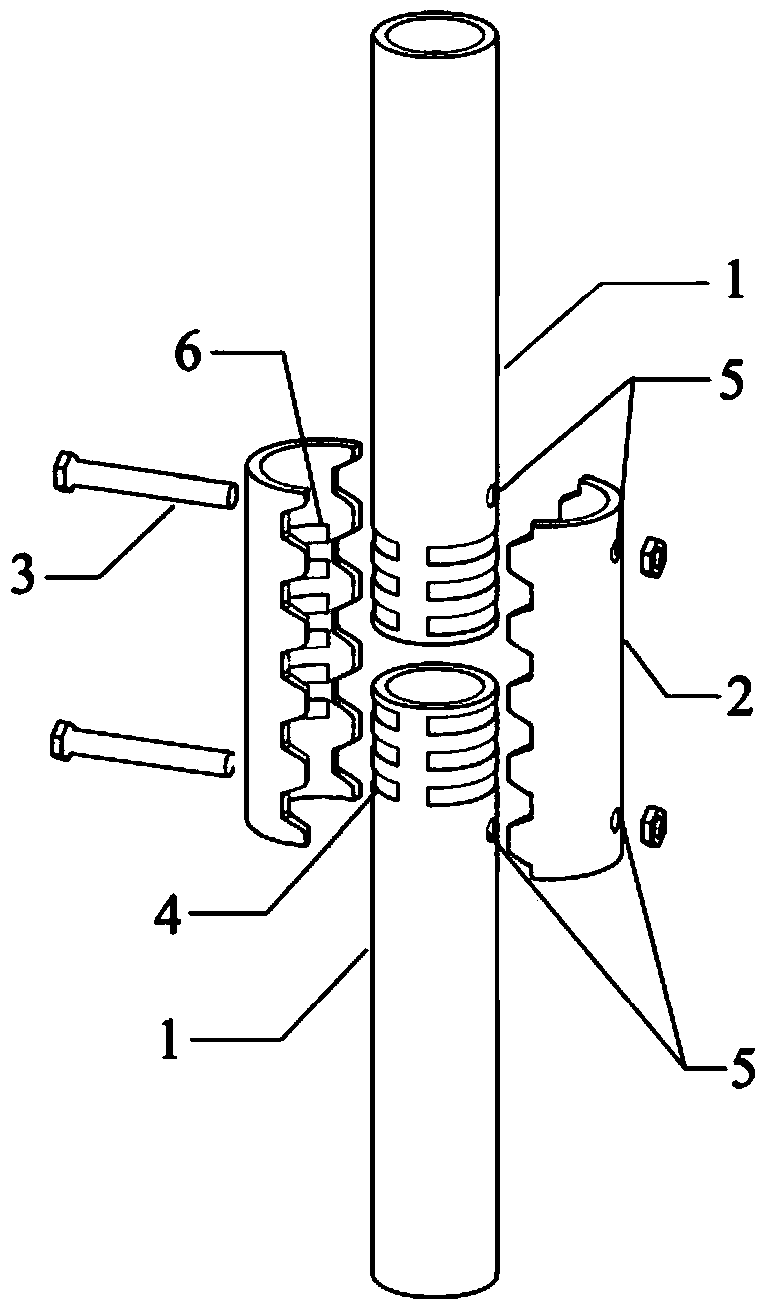

Toothed fastener node

The invention relates to a toothed fastener node. The toothed fastener node comprises two rod pieces, two semicircular pipe toothed fasteners and bolts, wherein the two rod pieces are axially and fixedly connected through the toothed fasteners which can be mutually fastened and the bolts, and the force transfer means is clear; the fasteners can be prefabricated in a factory and the node is convenient to install on the site; the installed node has certain rigidity and the safety under a normal use state can be guaranteed; the node is convenient to disassemble, the disassembled components can be repetitively used, and the node is economic and reasonable; the form of the node is simple and the attractiveness of the entire structure is not influenced.

Owner:BEIJING UNIV OF TECH

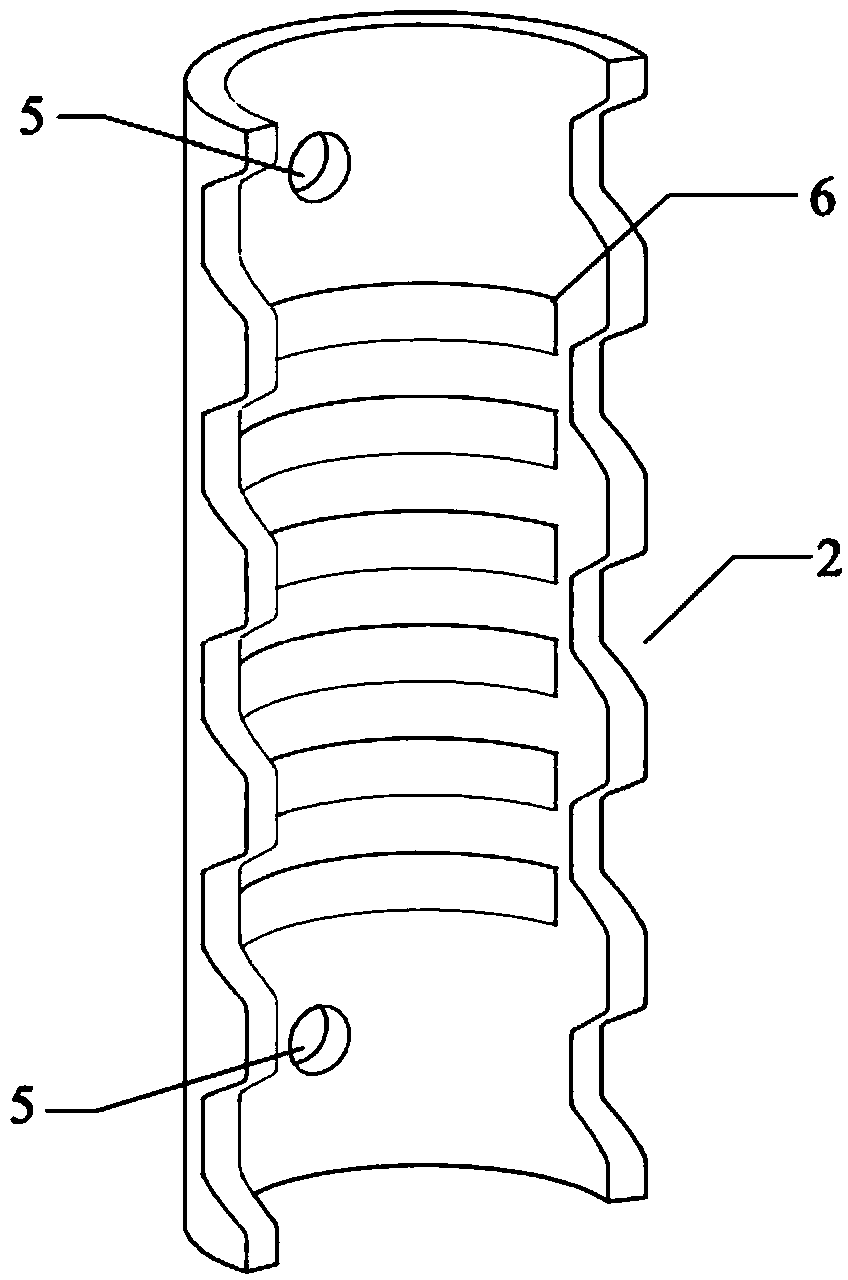

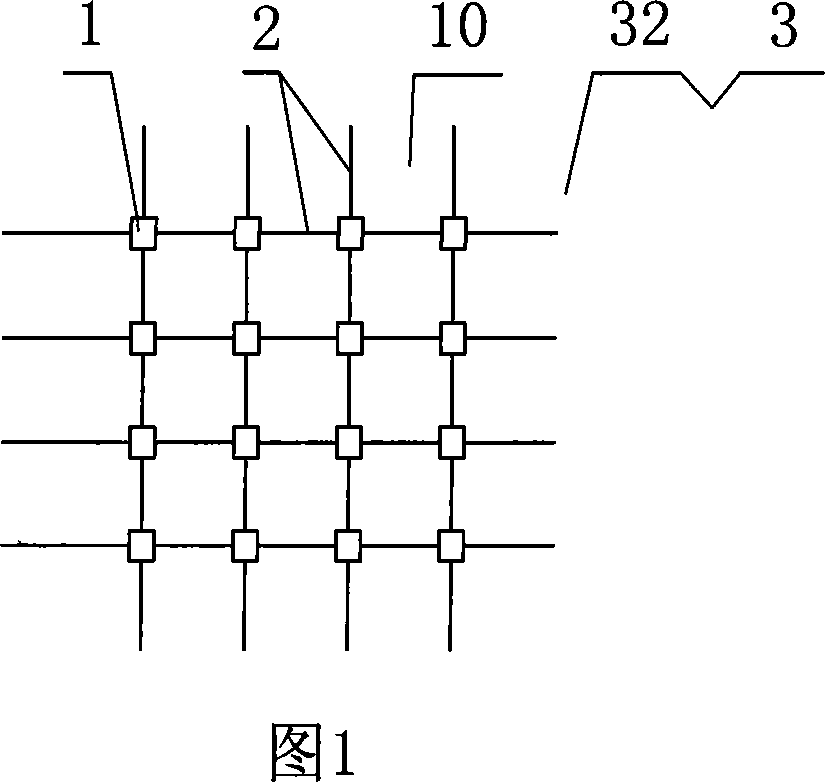

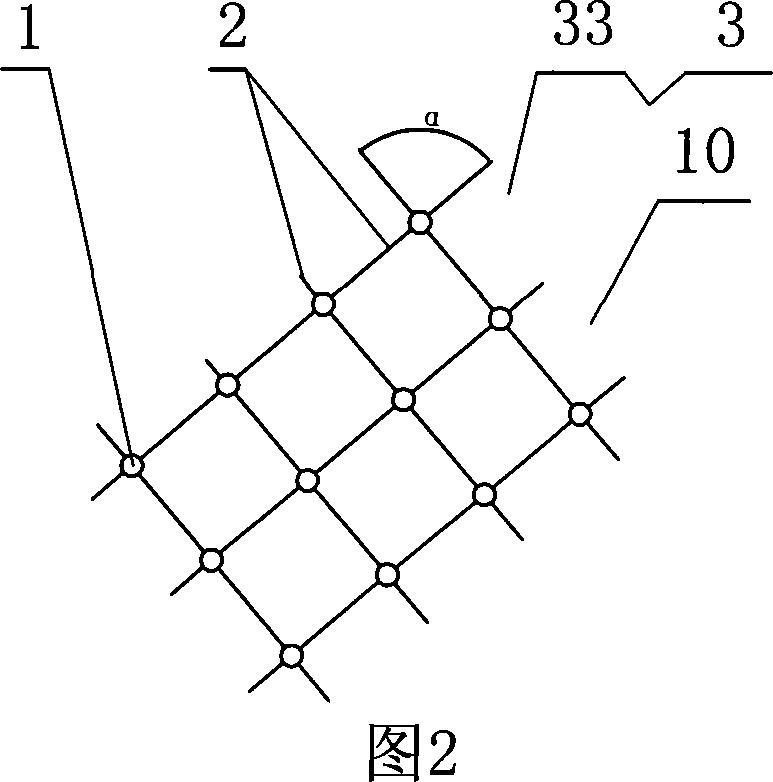

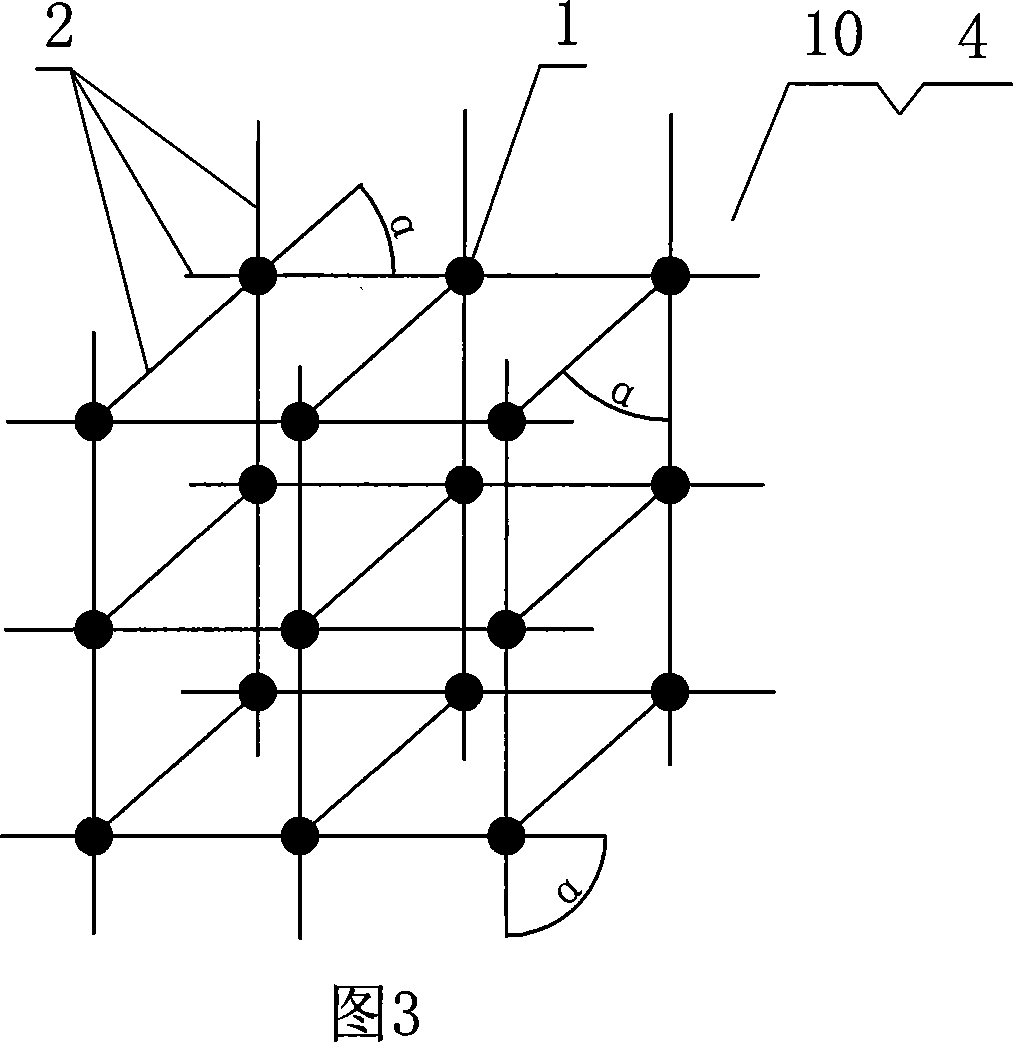

Combined inner mold and construction method thereof

A combination internal mode and its engineering method, which is a planar construction or a spatial construction formed of two or more than two modules connected by jointing components regularly. Its engineering steps contain: equip template and steel bar, pay out, set combination internal mode, colligate jointing components and locate positioning bracket. It overcomes the defects that the internal mode positioning is not accurate, the inner structure of cored slab is not uniform, the bearing capability of structure is weak and the engineering efficiency is low. It can be extensively applied in reinforced concrete of building floor and wall slabs and in reinforced concrete of bridge, dam body and underground structure.

Owner:李海深

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com