Embedded channel installation and fixation method under cast-in-place pipe gallery traditional technology

A technology of pre-embedding channels and fixing methods, applied in artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of inaccurate channel positions, difficult template installation, and different depths between channels and walls. Achieve the effect of reducing construction errors, improving work efficiency and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

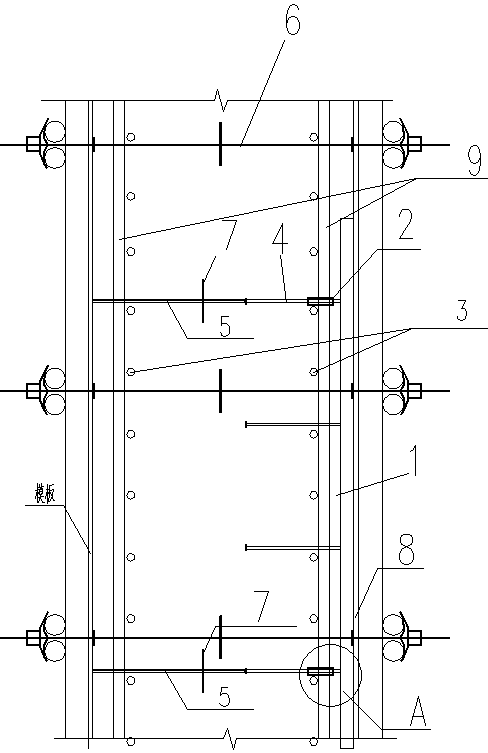

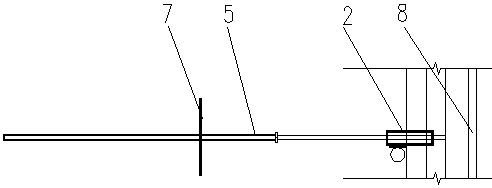

[0036] The present invention is described in detail below with reference to accompanying drawing and embodiment:

[0037] attached Figure 1-2 It can be seen that a method for installing and fixing the pre-buried channel under the traditional technology of cast-in-place pipe gallery, when constructing the wall of the pipe gallery, first carry out steel bar binding, then install the pre-embedded channel 1, install and reinforce the formwork, and finally pour concrete.

[0038] After the steel bar binding is completed, weld the positioning sleeve 2 on the steel bar; ensure that the positioning sleeve 2 is positioned accurately in the height and length direction of the wall;

[0039] The positioning sleeve 2 is perpendicular to the wall surface;

[0040] The anchor 4 is connected with the embedded channel 1;

[0041] The anchor 4 passes through the positioning sleeve 2;

[0042] Anchor 4 ends are welded to top die stick 5;

[0043] The total size of the pre-embedded channel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com