Combined inner mold and construction method thereof

A construction method and technology of internal molds, which are applied to building components, floors, buildings, etc., can solve problems such as uneven and unreliable physical properties, large changes in internal molds, and low construction efficiency, so as to improve physical and mechanical properties and improve installation efficiency , High construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

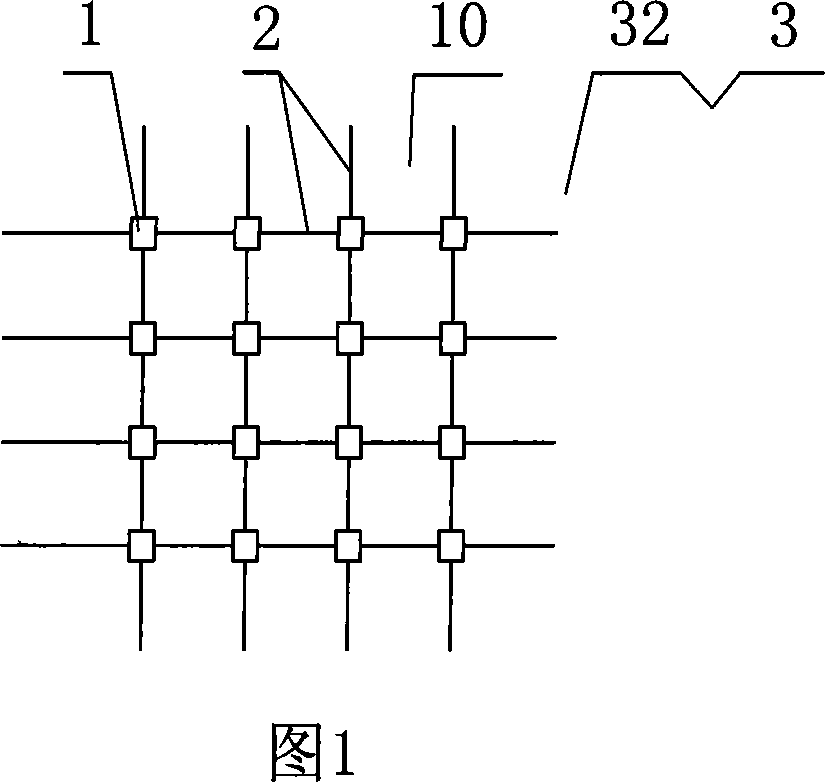

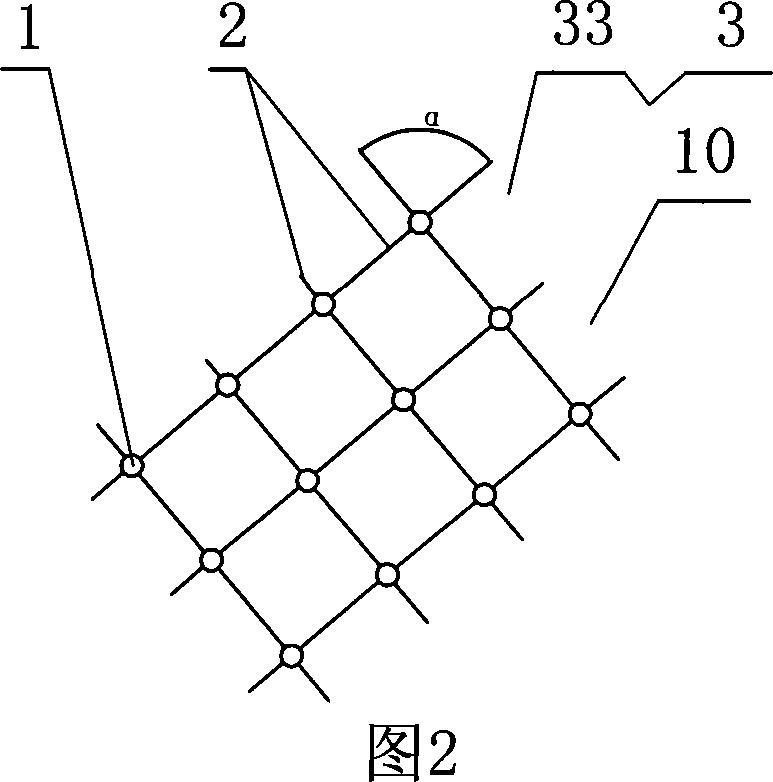

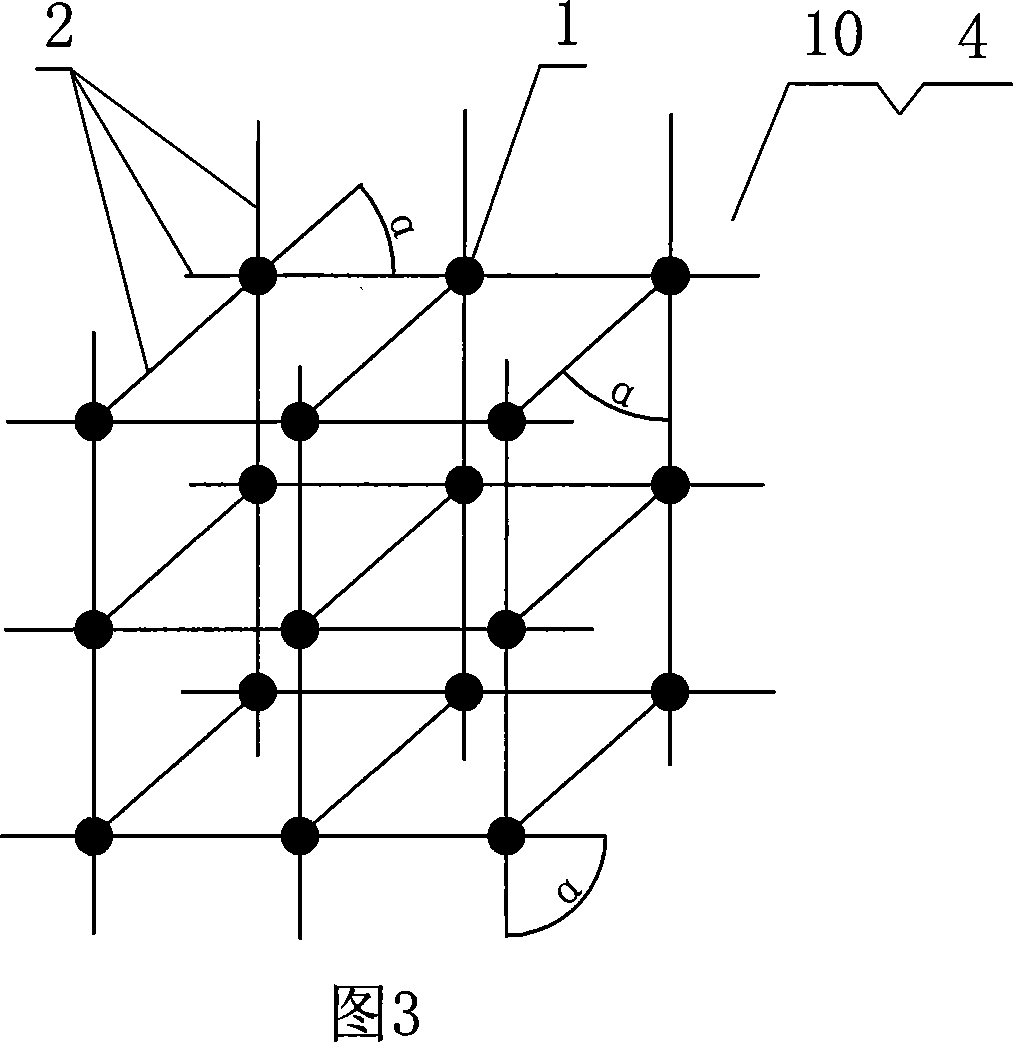

[0070] Referring to the accompanying drawings, a combined inner mold 10 of the present invention is composed of two or more modules 1 that are regularly combined and connected by connecting members 2 to form a planar structure 3 or a spatial structure 4 .

[0071] As shown in accompanying drawings 1 , 2 , 4 , and 5 , the planar structure 3 includes a single row planar structure 31 , a matrix planar structure 32 and a quincunx planar structure 33 .

[0072] As shown in Figure 2, the quincunx planar structure 33 is composed of three modules 1 or more than three modules 1 combined and connected by two groups of connecting members 2 forming an angle α, and the angle α between the two groups of connecting members 2 0-90°.

[0073] As shown in FIG. 3 , the space structure 4 is composed of three groups of connecting members 2 with an included angle α of 0-90° to connect a plurality of modules 1 into one body in the space. The arrangement of the modules 1 can be arranged regularly or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com