Connecting method applied to column-bearing-type modules

A connection method and a technology of modular units, which are applied in the direction of architecture and building construction, can solve the problems of discontinuity of upper and lower module corner columns, weaken the overall stability of the structure, and complex nodes, so as to avoid unstable quality, improve stability, The effect of reducing construction errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings, and the following embodiments are used to further illustrate the present invention, but are not used to limit the protection scope of the present invention.

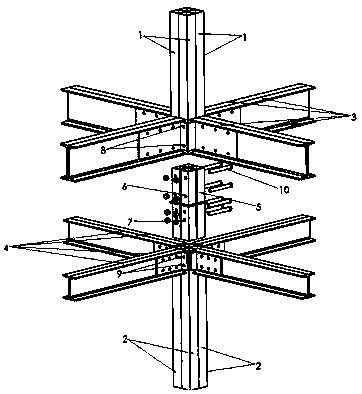

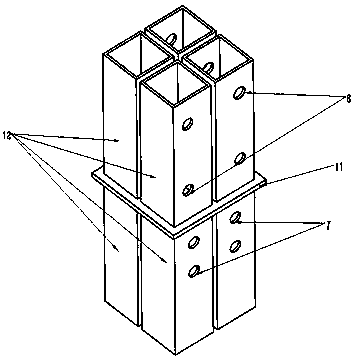

[0022] Such as figure 1 The described connection method applied between column-supported modules includes an upper module, a lower module and a connecting plug-in 5 . The upper module and the lower module each contain four modular units. The basic frame of the column-supported modular unit consists of four corner columns, four floor beams and four roof beams. All modular units are prefabricated in the factory, including the placement and decoration of internal equipment. Both the corner column 1 of the upper module and the corner column 2 of the lower module are square steel pipe columns. Both the floor beam 3 and the roof beam 4 are hot-rolled channel steel.

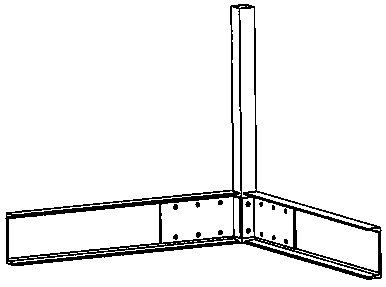

[0023] Such as figure 2 As shown, specifically, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com