Manual correction device for cantilever steel beam and construction method thereof

A manual, cantilevered technology, applied in the field of manual devices and cantilevered steel beams, can solve the problems of increased construction difficulty, lack of effective support at the cantilevered end, unacceptable and other problems, and achieve accurate and convenient z-direction correction effect Recycling and reuse, the effect of smooth and labor-saving process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

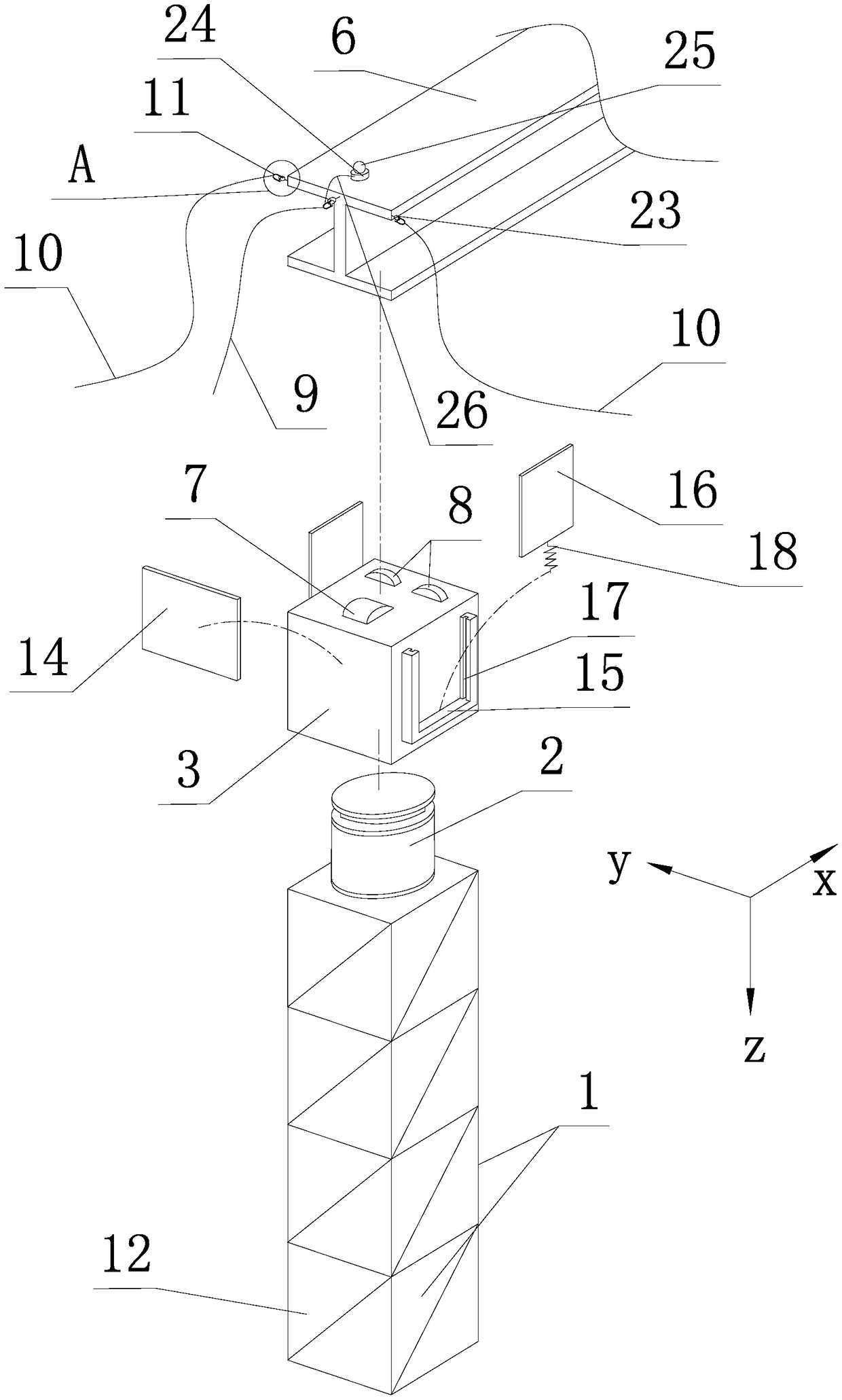

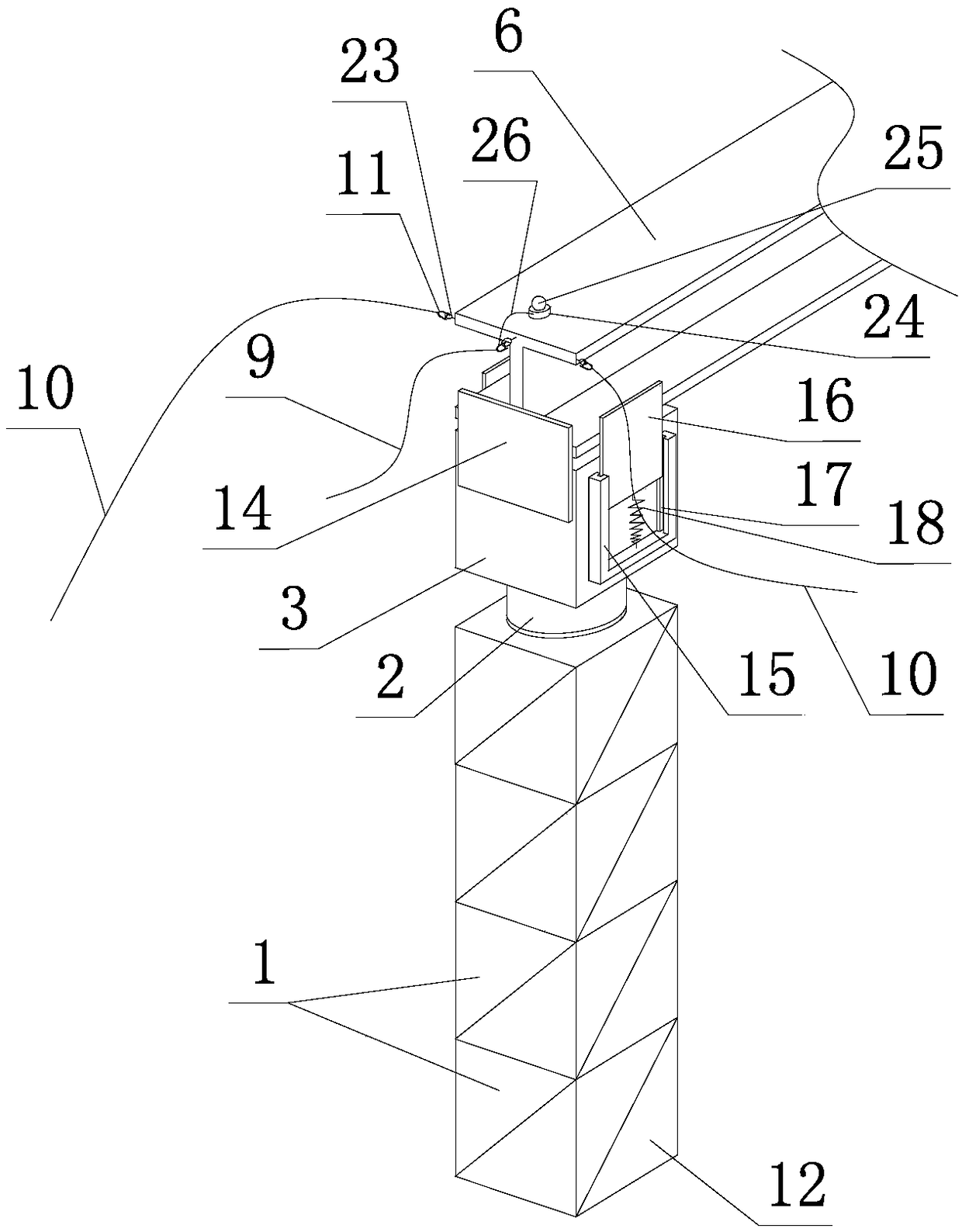

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 Shown, the manual straightening device of cantilever steel beam of the present invention, it comprises support mechanism and traction mechanism.

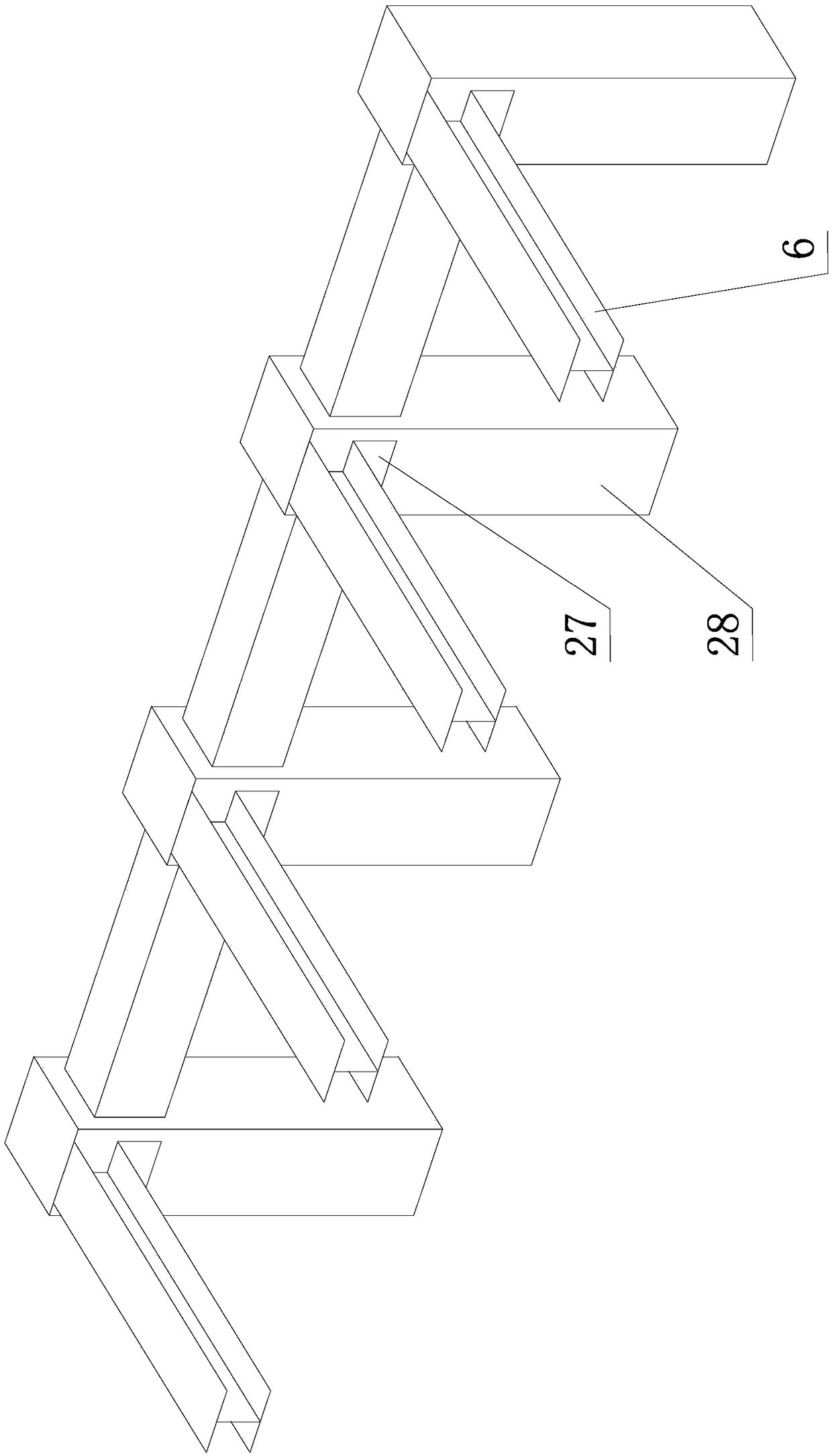

[0037] The support mechanism includes a support frame 1, a z-direction jack 2 and a jack 3; the support frame 1 is formed by a plurality of steel frame units 12 being screwed up and down. Each unit includes four vertical poles, four upper beams and four lower beams. The above-mentioned vertical poles, upper beams and lower beams are welded into a square frame structure, and six faces of the square frame are provided with a connecting slanting beam. Specifically, four upper beams form the upper frame, four lower beams form the lower frame, and four columns are located at the four corners to connect the upper and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com