Concrete gap repairing and anti-seepage treatment method

A treatment method and anti-leakage technology, which is applied in the direction of building maintenance, construction, building construction, etc., can solve problems such as construction difficulties, insufficient drilling depth, and inability to pour grout, so as to solve repair and leakage problems, reduce Drilling and grouting operations, the effect of enhancing self-healing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

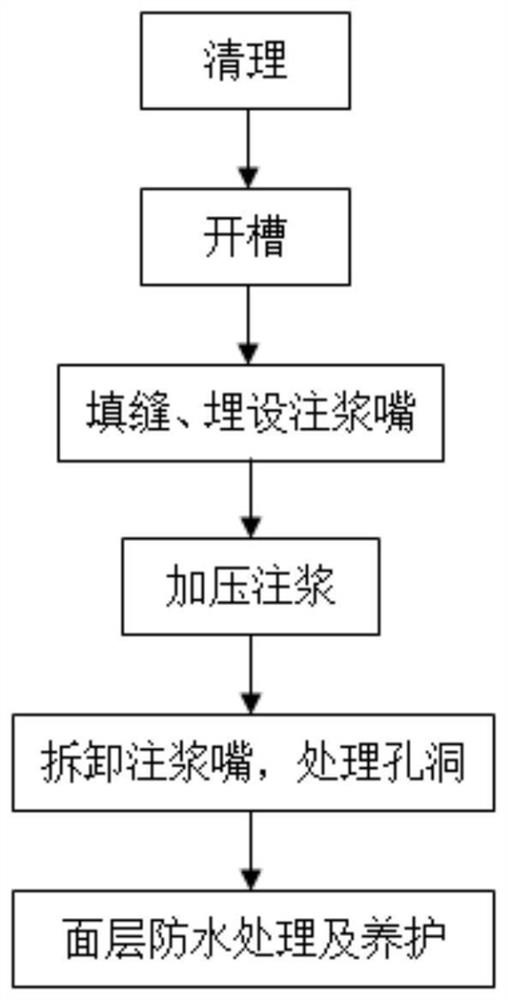

[0073] See Figure 2 to Figure 4 Shown, a kind of concrete crack repair and anti-seepage processing method, this method comprises the following steps:

[0074] (1) Clean up: use tools such as spatulas, chisels to clean up the base surface of the concrete structure 1 in the area where the crack 31 (i.e. the gap in the concrete structure) is located, find out the leaking crack 31, and check the leaking situation of the crack 31 in detail, Determine and mark the grouting location;

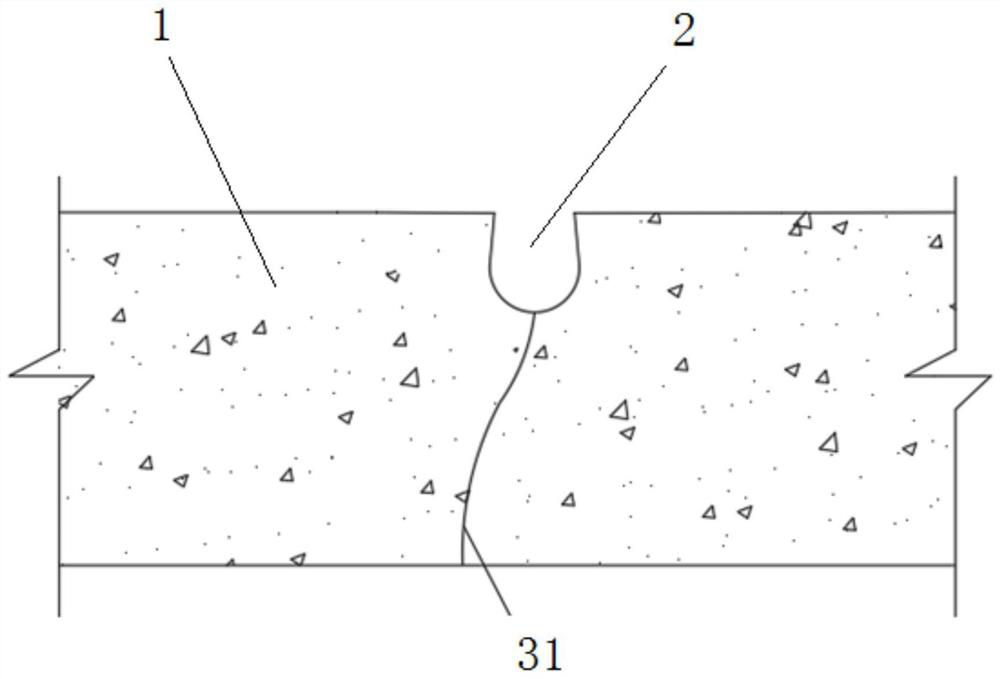

[0075] (2) Grooving: use a cutting machine to grooving with the crack 31 as the center, and drill a "U"-shaped groove (large inside and small outside) with a width of 3 cm to 4 cm and a depth of 5 cm to 6 cm at the crack 31 ;

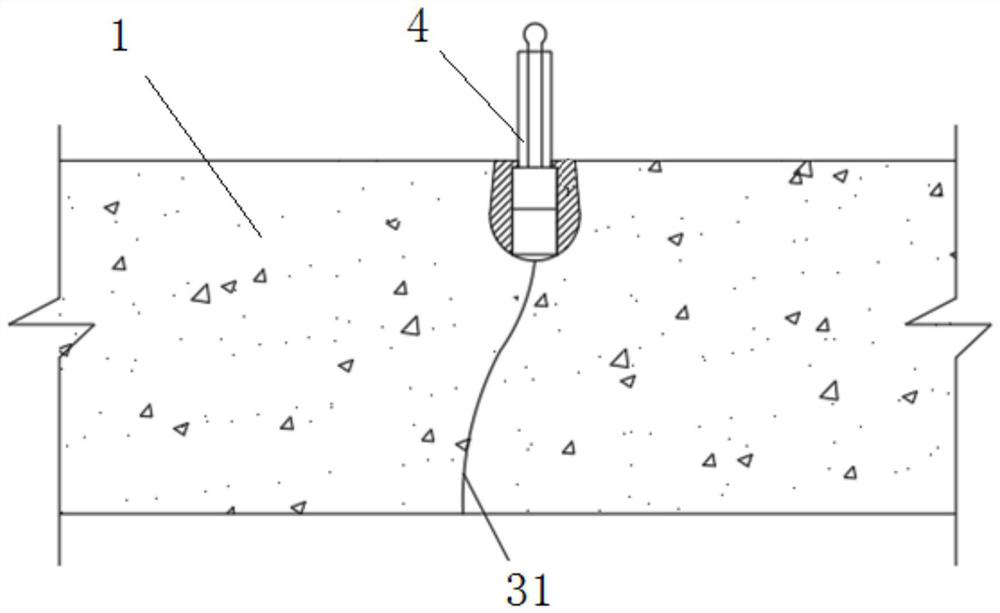

[0076] (3) Sealing the slots and burying the grouting nozzle 4: use micro-expansion quick-setting plugging material and water to mix into cement at a weight ratio of 1:0.3, and fix the grouting nozzle 4 at the preset crack 31 in the groove And seal and compact the rest of th...

Embodiment 2

[0081] See Figure 5 to Figure 7 Shown, a kind of concrete structure cold seam repair and anti-seepage treatment method, this method comprises the following steps:

[0082] (1) Cleaning: Clean up the base surface of the concrete structure 1 in the area where the structural cold joint 32 (that is, the gap in the concrete structure) is located with a spatula, chisel, etc., find out the leaking cold joint 32, and check the seepage of the cold joint 32 in detail. In case of leakage, determine and mark the grouting position;

[0083] (2) Grooving: With the cold seam 32 as the center, use a cutting machine to perform groove processing, and the cold seam 32 of the structure will be drilled into a "U"-shaped groove with a width of 3cm to 4cm and a depth of 5cm to 6cm (inner large foreign small);

[0084] (3) Sealing the slots and burying the grouting nozzle 4: use the micro-expansion quick-setting plugging material and water at a weight ratio of 1:0.3 to mix it into a cement shape, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com