Wharf integrated construction system and method based on pile top pushing platform

A pile top and platform technology, applied in water conservancy engineering, marine engineering, coastline protection and other directions, can solve the problems of steel pipe pile support, limited stabilization effect, inability to correct the construction deviation of steel pipe piles, and insufficient potential to be fully utilized. To achieve the effect of shortening the operation period, improving the construction safety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

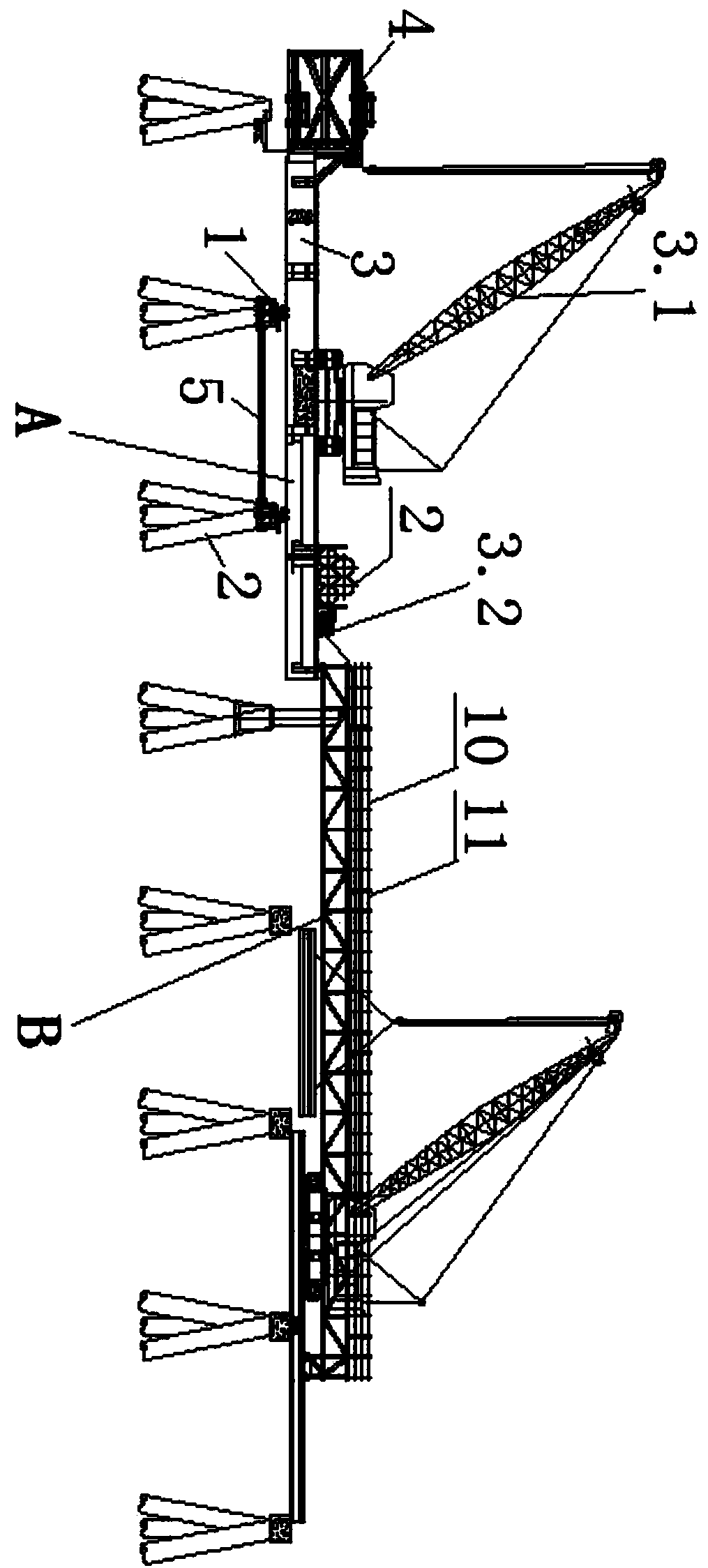

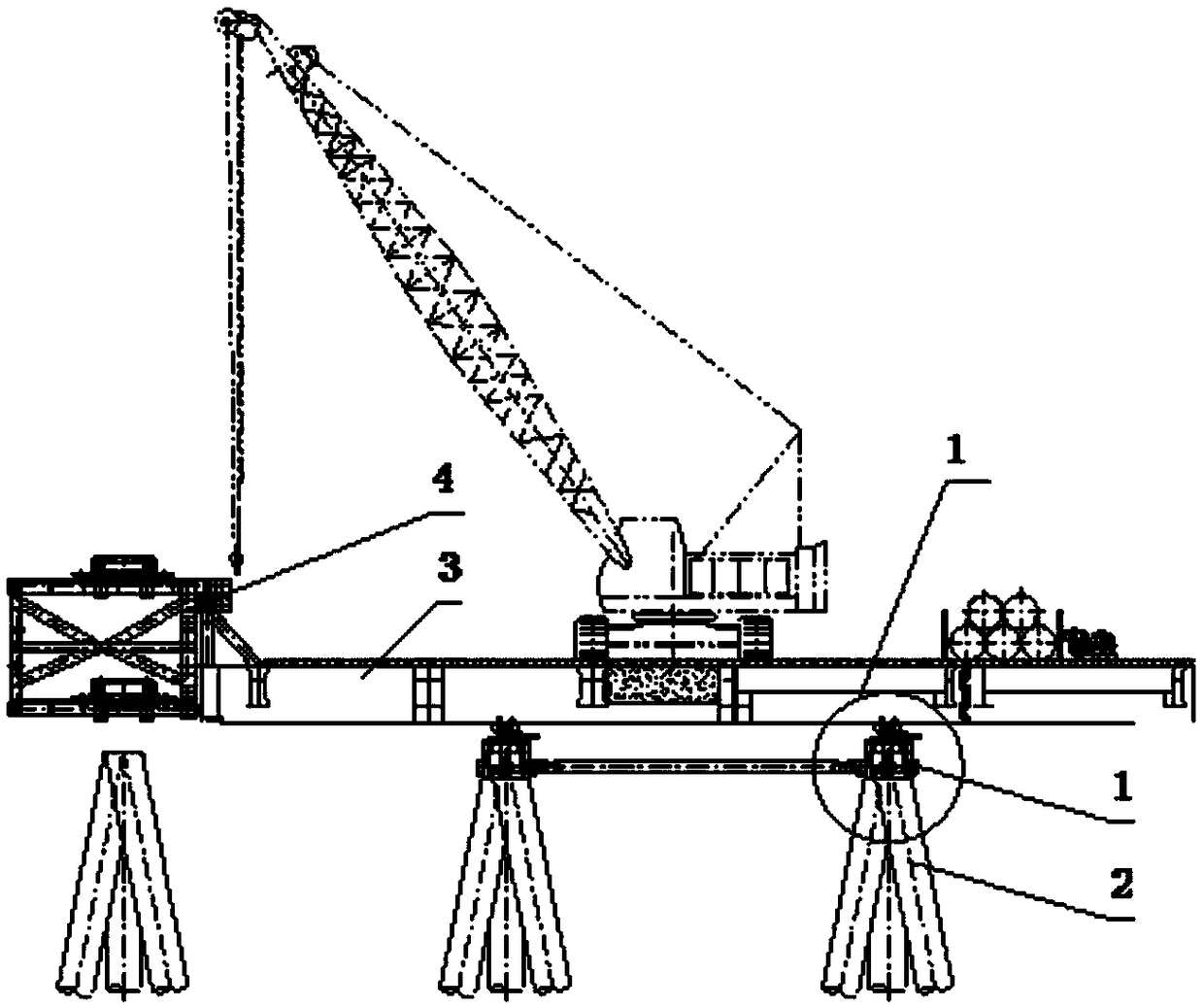

[0038] Embodiment 1: The connecting rod assembly 5 includes a first connecting rod 5.1, at least one end of the first connecting rod 5.1 is connected to the steel pipe pile 2 through a screw structure. The lead screw structure includes the second connecting rod 5.2 arranged on the steel pipe pile 2, the third connecting rod 5.3 for connecting the first connecting rod 5.1 and the second connecting rod 5.2, the internal thread at the end of the first connecting rod 5.1, The end of the second connecting rod 5.2 is provided with internal threads, and the two ends of the third connecting rod 5.3 are provided with external threads. There are also two arrangements of the second connecting rods 5.2: Arrangement 1. A plurality of second connecting rods 5.2 are arranged on the steel pipe pile 2 along its circumferential direction. Arrangement mode 2: the pile top of the steel pipe pile 2 is connected with the positioning seat of the pile top positioning and pushing device 1, and a plura...

Embodiment 2

[0040] Embodiment 2: The connecting rod assembly 5 includes a first connecting rod 5.1, at least one end of the first connecting rod 5.1 is connected to the steel pipe pile 2 through a hydraulic cylinder. The cylinder body end of the hydraulic cylinder is fixedly connected with the first connecting rod 5.1, and the piston rod end of the hydraulic cylinder is fixedly connected with the steel pipe pile 2.

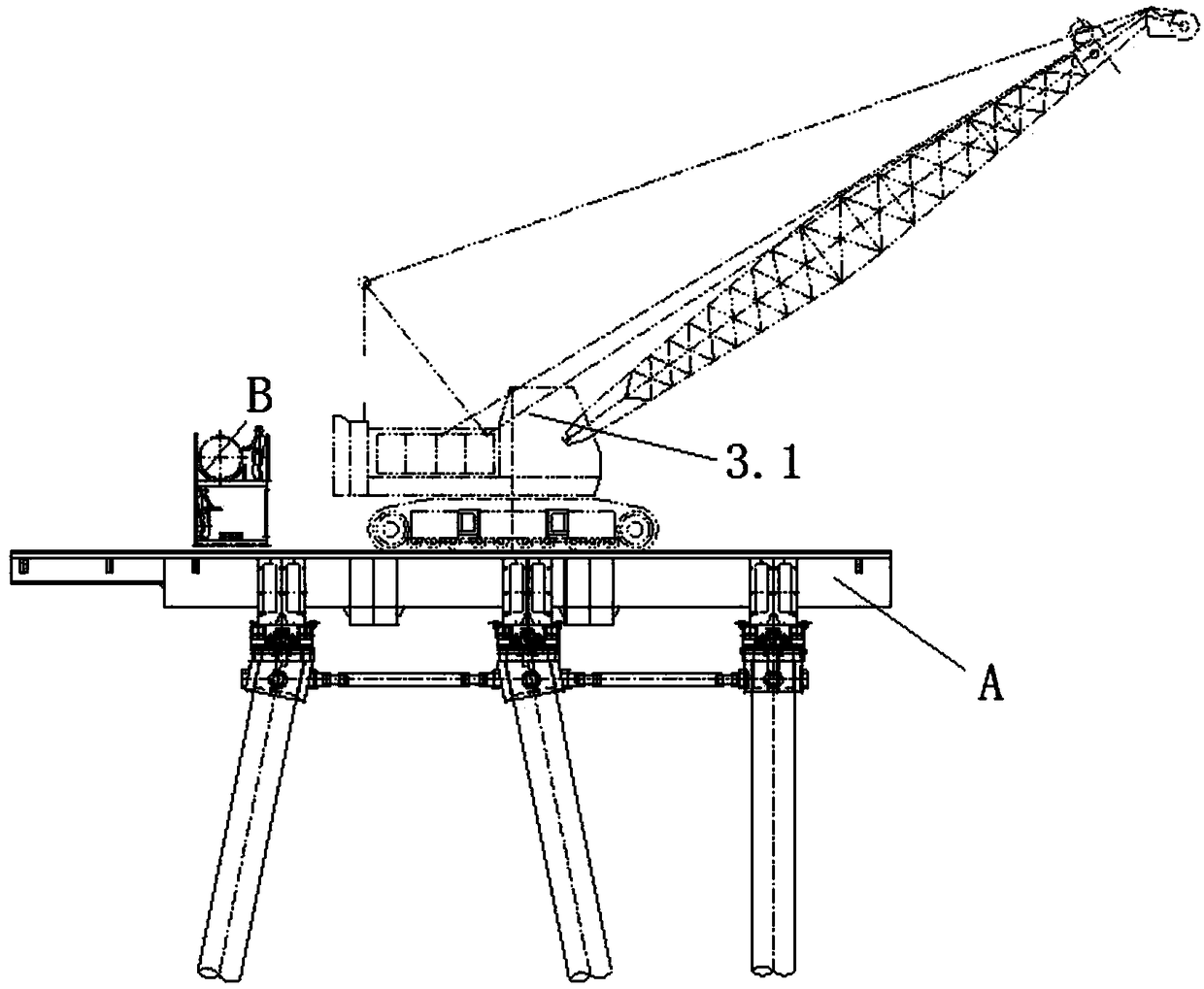

[0041] The guide frame 4 of the present invention includes a traversing track 4.1, a double-layer frame body 4.2, a sliding frame 4.3 and a pipe pile positioning claw 4.4. 4.1 Sliding fit connection, each layer of the double-layer frame body 4.2 is slidably connected with a sliding frame 4.3 arranged perpendicular to it, and the sliding frame 4.3 is slidably connected with a pipe pile positioning claw 4.4.

[0042] Preferably, the double-layer frame body 4.2 is driven by the first hydraulic cylinder 6 to move relative to the traversing rail 4.1, the sliding frame 4.3 is drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com