Movable formwork structure and construction method thereof

A technology of mobile formwork and construction methods, which is applied in the direction of infrastructure engineering, underwater structures, artificial islands, etc., and can solve the problems of high construction cost of formwork engineering, difficulty in controlling the flatness of the top surface, and poor civilized image of the working surface, etc. , to achieve the effect of ensuring the appearance quality of the structure, easy to control the flatness of the top surface, and improving civilized construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

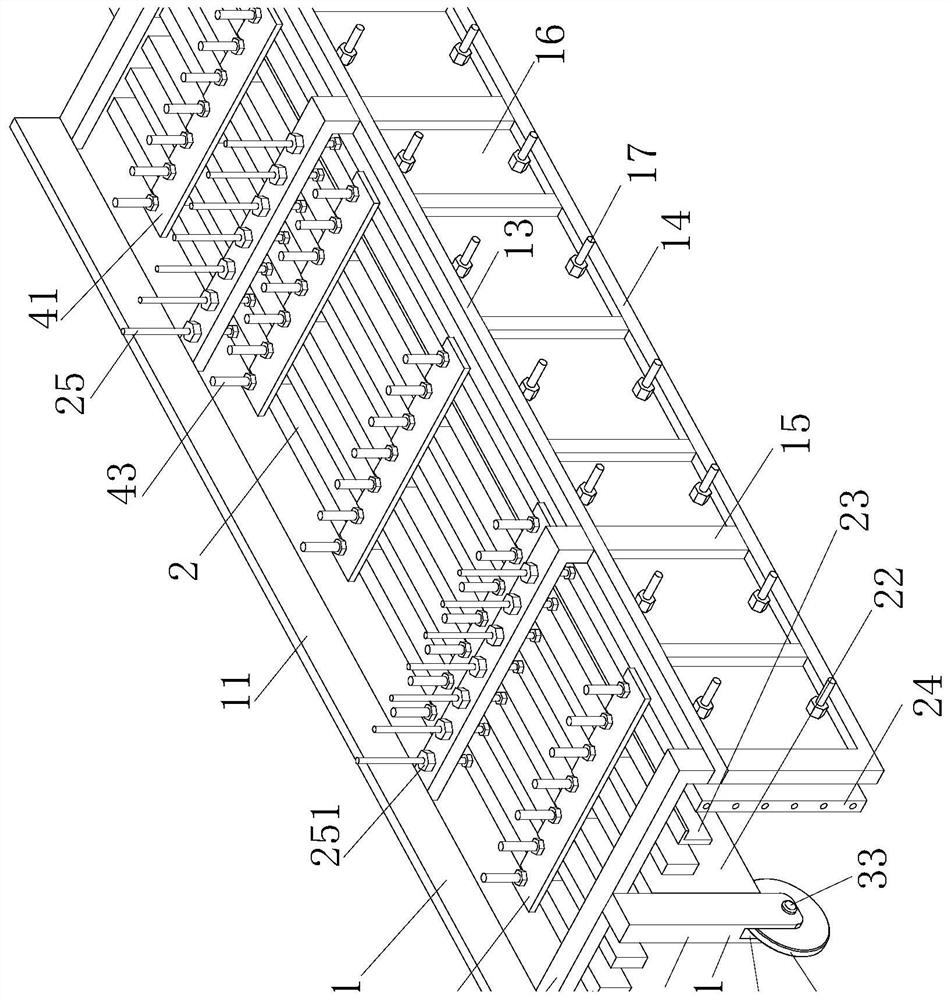

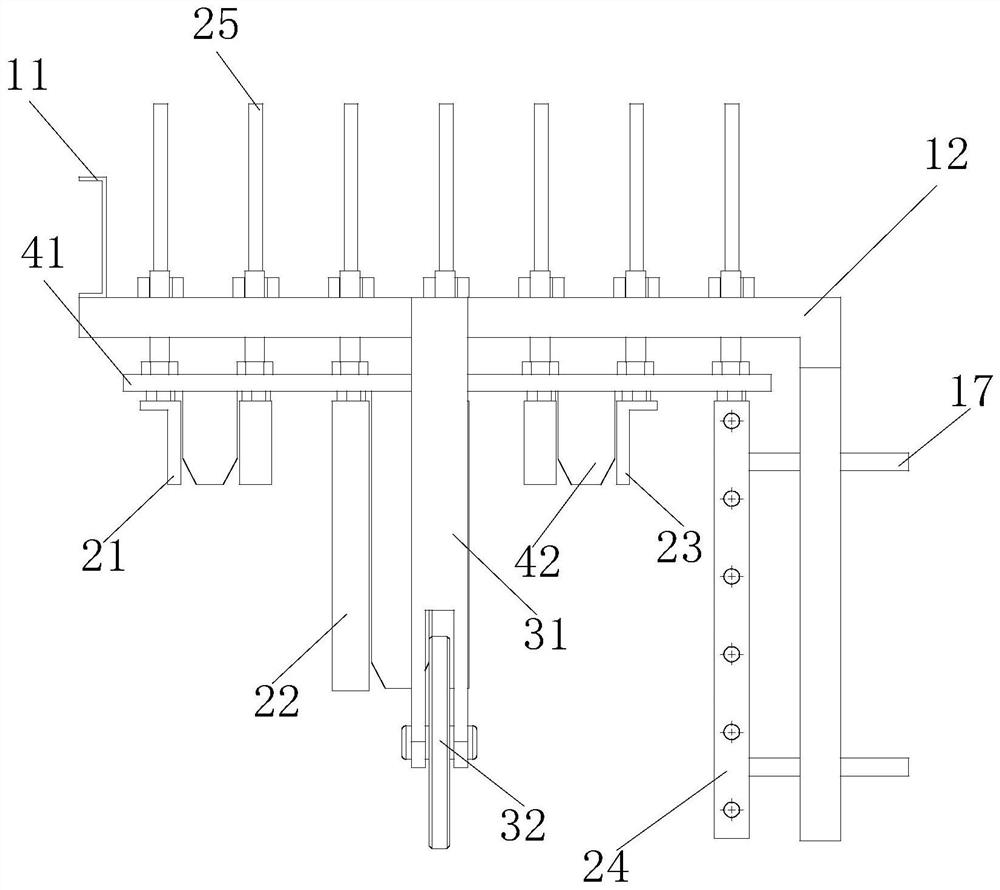

[0092] As a specific embodiment of the present invention, a positioning unit 4 is arranged between the power cable trench template 21, the drainage trench template 22, and the communication cable trench template 23; the positioning unit 4 includes a connecting plate 41, a positioning Rod 42 and fine-tuning screw rod 43; One side of described connecting plate 41 offers a plurality of draw-in slots 411, and the number of draw-in slots 411 is the same as that of power cable trench template 21, drainage trench template 22, communication cable trench template 23 and side walls The sum of the 24 numbers of the outer templates is the same, the notch of the card slot 411 is connected to the fine-tuning screw 43 through the nut 251, and one end of the fine-tuning screw 43 is fixedly connected to the power cable groove template 21, the drainage groove template 22, the communication cable groove template 23 and The upper end surface of the side wall outer formwork 24; the lower plate surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com