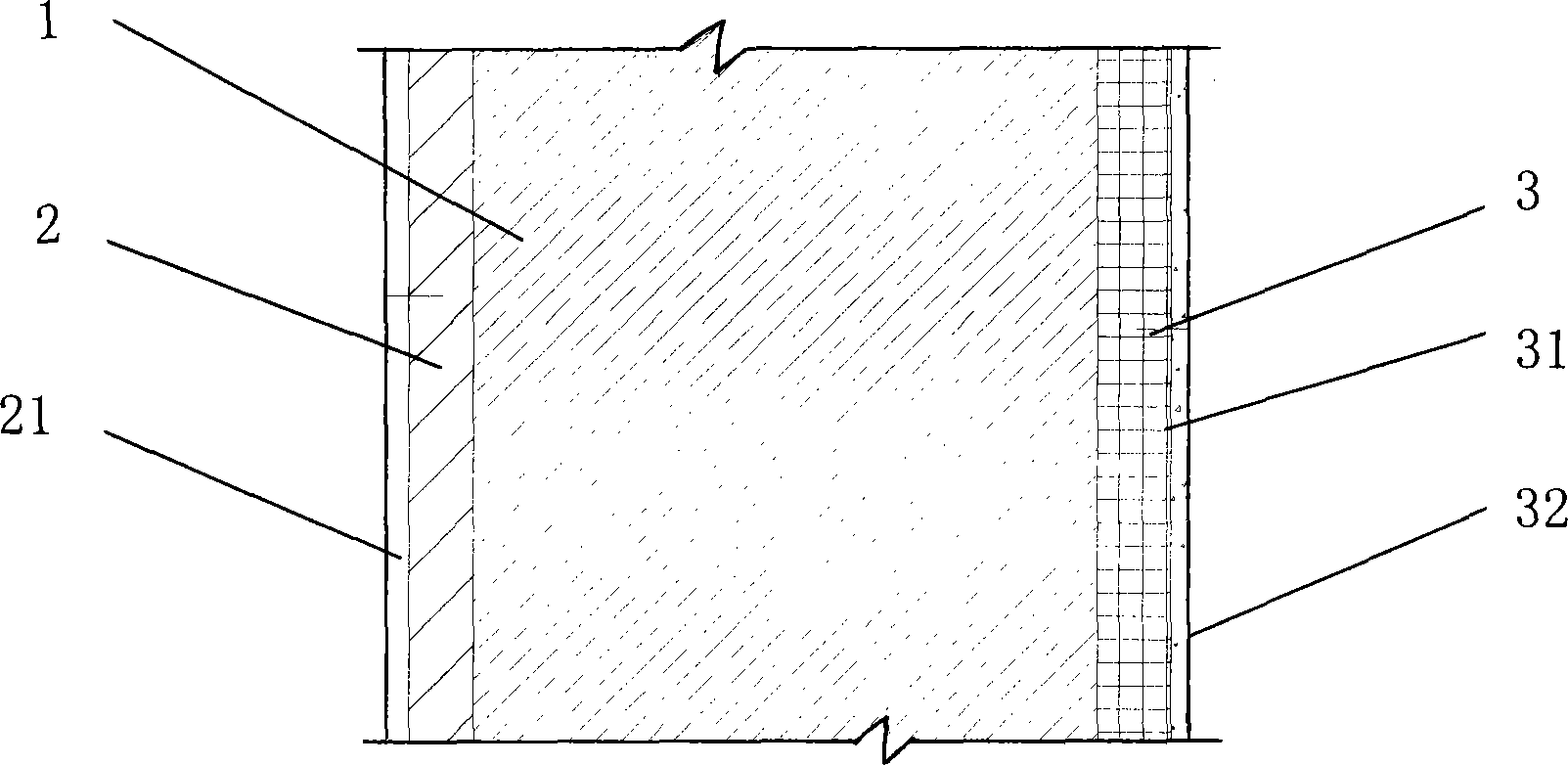

Light mortar inside and outside combined exterior wall heat-preserving system

A technology of external wall insulation and light sand, which is applied in the direction of insulation, walls, building components, etc., and can solve the problems of low density of insulation mortar, low thermal conductivity, and difficult construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] The expanded perlite is modified with organosilicon to prepare organosilicon-modified expanded perlite.

[0077] By weight percentage 55% gypsum powder, 43.65% modified expanded perlite, 0.1% cellulose ether, 0.1% lignocellulose, 0.1% retarder, 0.05% starch ether and 1% The polyvinyl alcohol is stirred evenly to make a powder.

[0078] Add appropriate amount of water to the powder to make gypsum lightweight mortar slurry to paint or plaster the exterior and interior walls of buildings.

Embodiment 2

[0080] By weight percentage, 55% gypsum powder, 43.75% modified expanded perlite, 0.15% cellulose ether, 0.1% lignocellulose, 0.15% retarder, 0.05% starch ether and 0.8% The polyvinyl alcohol is stirred evenly to make a powder.

Embodiment 3

[0082] By weight percentage, 53.5% gypsum powder, 44.77% modified expanded perlite, 0.18% cellulose ether, 0.15% lignocellulose, 0.15% retarder, 0.05% starch ether and 1.2% The polyvinyl alcohol is stirred evenly to make a powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com