Novel fabricated vehicle bearing pavement and construction method thereof

A construction method and prefabricated technology, applied in the field of prefabricated prefabricated reinforced concrete pavement systems, can solve problems such as pavement subsidence, and achieve the effects of convenient hoisting, convenient transportation and efficient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

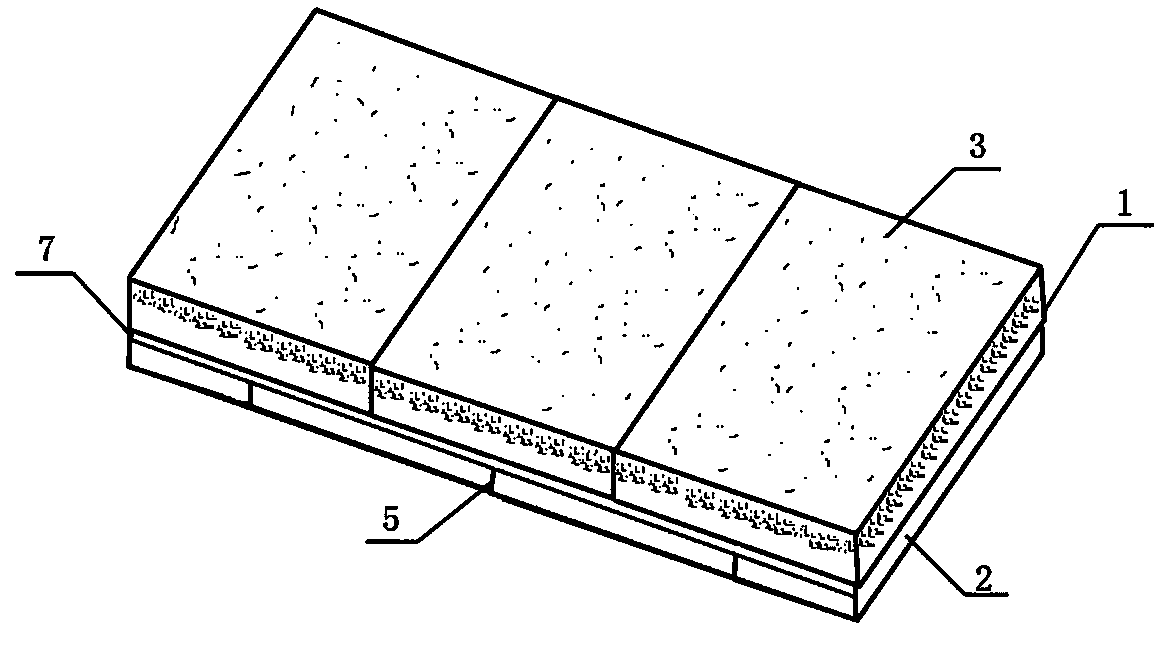

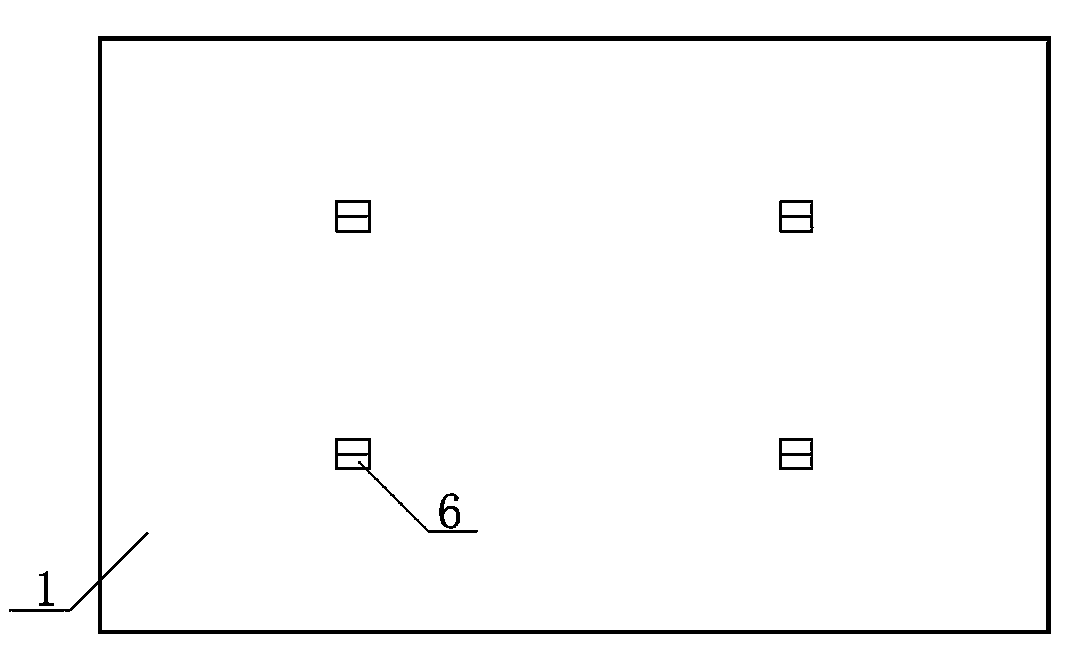

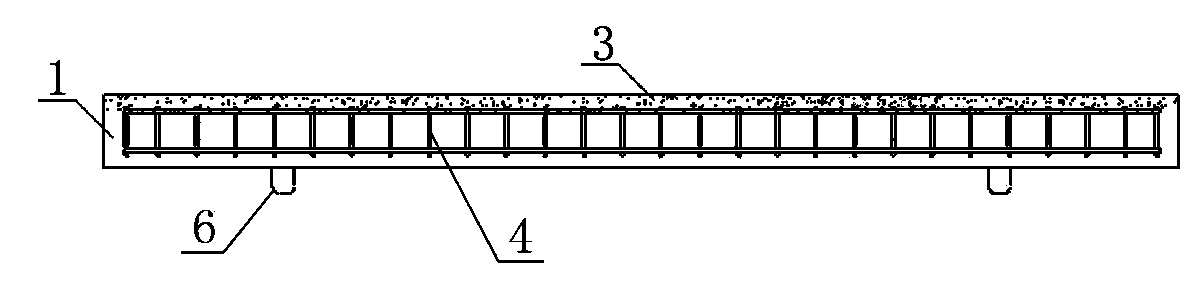

[0038] see figure 1 , image 3 , Figure 4 , this new type of prefabricated vehicle-mounted road surface is assembled and paved by prefabricated reinforced concrete plate components, and is characterized in that: the prefabricated reinforced concrete plate components are composed of upper road panels 1 and lower road panels 2 to form a double-layer laminated structure, and the upper road The inside of the panel 1 and the lower road panel 2 are evenly distributed with a double-layer two-way steel skeleton 4, and the lower part has a pre-embedded suspension ring 6; a layer of rubber film 7 with a thickness of 2mm is laid between the upper road panel 1 and the lower road panel 2, and the upper road The upper part of the panel 1 has a layer 3 of wear-resistant steel fiber concrete with a thickness of about 5 cm.

[0039] The lower panel 2 is thinner than the upper panel 1, and there is no steel fiber concrete on the surface.

[0040] The upper road panel 1 is dislocated and lai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com